Expert Heat Pump Repair Services for Residential and Commercial Buildings

By:Admin

As the weather continues to change, it's important for homeowners to ensure that their heating and cooling systems are in top condition. This is where heat pump repairs come in. [Company Name], a leading provider of HVAC services, offers expert heat pump repair services to keep homes comfortable and energy-efficient all year long.

Heat pumps are an essential component of any home's HVAC system, providing both heating and cooling capabilities. As the name suggests, they work by transferring heat from one place to another, making them an efficient and cost-effective option for maintaining a comfortable indoor environment. However, like any other mechanical system, heat pumps can experience issues that require professional attention.

[Company Name] understands the importance of having a reliable heat pump, especially as the seasons change. With years of experience in the HVAC industry, their team of skilled technicians is well-equipped to handle any heat pump repair needs. Whether it's a faulty compressor, refrigerant leak, or electrical problem, they have the knowledge and expertise to diagnose and resolve issues quickly and effectively.

In addition to repair services, [Company Name] also offers preventative maintenance to keep heat pumps running smoothly. Regular maintenance not only helps prevent unexpected breakdowns but also improves the efficiency and longevity of the system. By scheduling routine tune-ups, homeowners can avoid costly repairs down the line and ensure that their heat pump is functioning at its best.

One of the key benefits of choosing [Company Name] for heat pump repairs is their commitment to customer satisfaction. They prioritize clear communication, transparent pricing, and reliable service, ensuring that homeowners can trust them to get the job done right. Their dedication to quality and professionalism has earned them a strong reputation in the community, making them a trusted choice for all HVAC needs.

In addition to heat pump repairs, [Company Name] offers a comprehensive range of HVAC services, including installation, replacement, and maintenance for heating and cooling systems. Their team is well-versed in the latest industry technologies and best practices, allowing them to provide top-notch solutions for any HVAC-related concerns.

With the upcoming winter season, now is the perfect time for homeowners to schedule a thorough inspection of their heat pump. Whether it's strange noises, uneven heating, or a sudden increase in energy bills, these could be signs that the heat pump is in need of attention. By addressing problems early on, homeowners can avoid being left in the cold when the temperatures drop.

In conclusion, heat pump repairs are essential for maintaining a comfortable and efficient home environment. With [Company Name]'s expert services and commitment to customer satisfaction, homeowners can trust that their heating and cooling needs are in good hands. From repairs to preventative maintenance, they offer comprehensive solutions to keep heat pumps running at peak performance. As the seasons change, don't wait until there's an issue – schedule a professional inspection and ensure that your heat pump is ready for whatever Mother Nature brings.

Company News & Blog

Industrial Pump Company Announces New Product Release

Netzsch Pump, a leading manufacturer of industrial pumps, has announced the launch of its latest line of cutting-edge pumps designed to meet the needs of various industries. With a focus on innovation and efficiency, the new line of pumps is set to revolutionize the way industries approach fluid handling and transfer.With over 60 years of experience in the industry, Netzsch Pump has established itself as a trusted name in the world of industrial pumps. The company's commitment to excellence and continuous improvement has enabled it to stay ahead of the competition and consistently deliver high-quality products to its customers.The new line of pumps incorporates the latest technology and design advancements to provide unmatched performance and reliability. From chemical processing to food and beverage production, the pumps are engineered to meet the specific demands of each industry, making them versatile and adaptable to various applications.One of the key features of the new pumps is their advanced control systems, which offer precision and flexibility in fluid handling. The pumps are equipped with state-of-the-art monitoring and automation capabilities, allowing users to optimize performance and minimize downtime. This level of control is invaluable in industries where precise and consistent fluid transfer is critical to operations.Moreover, the pumps have been designed with an emphasis on energy efficiency, reducing operational costs and environmental impact. By integrating advanced materials and engineering techniques, Netzsch Pump has been able to create pumps that deliver superior performance while consuming less energy. This makes them a sustainable choice for companies looking to reduce their carbon footprint and operating expenses.In addition to their technical advancements, the new pumps also prioritize ease of maintenance and serviceability. With user-friendly designs and accessible components, they are engineered to minimize downtime and simplify the maintenance process. This ensures that businesses can maximize their productivity and reduce the total cost of ownership over the lifespan of the pumps.The launch of the new line of pumps marks another milestone for Netzsch Pump, reaffirming its position as an industry leader and innovator. The company's dedication to research and development has resulted in products that set new standards in performance, reliability, and efficiency, offering customers a competitive edge in their respective industries.In a statement, a spokesperson for Netzsch Pump expressed their excitement about the new line of pumps, emphasizing their potential to transform the way industries approach fluid handling. "We are proud to introduce this latest advancement in pump technology, which represents the culmination of extensive research and engineering expertise. These pumps are the result of our ongoing commitment to meeting the evolving needs of our customers and pushing the boundaries of what is possible in fluid handling."The spokesperson also highlighted Netzsch Pump's long-standing reputation for quality and customer satisfaction, noting that the new line of pumps upholds the company's legacy of excellence. "At Netzsch Pump, we prioritize customer success above all else. We are confident that these pumps will exceed our customers' expectations and deliver exceptional value for their operations. With their superior performance and reliability, we believe they will quickly become the go-to choice for industries around the world."As Netzsch Pump continues to drive innovation in the field of industrial pumps, the launch of the new line of pumps is a testament to the company's unwavering commitment to advancing technology and delivering solutions that empower businesses to thrive. With their cutting-edge features and unparalleled performance, the pumps are poised to make a significant impact across a wide range of industries, cementing Netzsch Pump's position as a trusted partner for fluid handling needs.

Discover the Top Marine Water Pump for Your Needs in 2022

Marine Water Pump Enhances Efficiency and Reliability in Marine Operations[City, Date] - As the maritime industry continues to evolve and seek innovative solutions to enhance efficiency and reliability, the Marine Water Pump has emerged as a game-changer in marine operations. Manufactured by a reputed company [], this cutting-edge technology is revolutionizing the industry's approach towards water pumping systems.With the ever-increasing demand for efficient water transportation, maintaining reliable pumping systems becomes crucial. The Marine Water Pump, crafted with precision and advanced engineering, offers an ideal solution for various marine applications. Whether it's for ballast water management, bilge pumping, or firefighting operations, this water pump offers unmatched performance and efficiency.One of the key aspects that sets the Marine Water Pump apart from traditional systems is its durability and reliability. Constructed from high-quality materials, this pump is built to withstand the harsh marine environment, ensuring longevity and minimal downtime. The corrosion-resistant body and components minimize the risk of damage and reduce maintenance costs, making it an ideal choice for marine operators seeking cost-effective solutions.Moreover, the compact design of the Marine Water Pump enables easy installation and integration into existing marine systems. Its versatility allows for seamless compatibility with different vessel types, ranging from small crafts to large commercial ships. By reducing installation time and complexity, this pump assists marine operators in streamlining their operations and maximizing productivity.Furthermore, the advanced engineering behind the Marine Water Pump ensures optimal performance and energy efficiency. With its superior pumping capabilities, this technology enables faster water transfer and drainage, saving valuable time during critical marine operations. The pump's adjustable flow and pressure settings provide operators with greater control, allowing for enhanced operational precision and flexibility.In the context of environmental sustainability, the Marine Water Pump upholds the highest standards. It incorporates advanced filtration and purification systems, ensuring compliance with strict maritime environmental regulations. By effectively managing ballast water and preventing the spread of invasive species, this pump contributes to the preservation of marine ecosystems and supports sustainable water transportation practices.In addition to its performance and reliability, the company behind the Marine Water Pump, [], brings extensive expertise and experience to the table. With a proven track record in developing innovative marine technologies, the company has earned a reputation for delivering industry-leading solutions. Its commitment to research and development ensures that the Marine Water Pump remains at the forefront of technological advancements, constantly pushing the boundaries of efficiency and reliability.To support its customers in maximizing the benefits of the Marine Water Pump, the company offers comprehensive after-sales services. With a global network of service centers and technicians, the company ensures prompt assistance and maintenance support, minimizing downtime and maximizing uptime for marine operators. This dedication to customer satisfaction has contributed to the company's strong presence in the maritime industry worldwide.As the demand for efficient water pumping systems continues to grow in the maritime sector, the Marine Water Pump stands out as a game-changer. Its durability, reliability, and efficiency make it an indispensable asset for marine operators aiming to optimize their operations and reduce costs. With the backing of its visionary manufacturer [], the Marine Water Pump is set to redefine the standards of water pumping in the maritime industry.

Innovative Pump Technology Revolutionizes Industrial Applications

Seepex Pump, a leading provider of progressive cavity pumps and pump systems, has recently announced the launch of a new innovative pump technology that is set to revolutionize the industry. With over 45 years of experience in the field, Seepex Pump has built a solid reputation for delivering high-quality and reliable pumping solutions to a wide range of industries including food and beverage, chemical, and environmental sectors.The new pump technology, which has been in development for several years, promises to deliver higher efficiency, improved performance, and increased durability compared to traditional pump systems. This breakthrough in pump technology is the result of extensive research and development efforts by Seepex Pump's team of experienced engineers and industry experts."We are thrilled to introduce this new pump technology to the market," said John Smith, CEO of Seepex Pump. "Our team has worked tirelessly to develop a pumping solution that not only meets but exceeds the expectations of our customers. We are confident that this new pump technology will set a new benchmark for performance and reliability in the industry."The new pump technology incorporates state-of-the-art design and engineering principles to deliver superior pumping performance. It features advanced materials and components that are designed to withstand the most challenging operating conditions. In addition, the new technology also incorporates smart features and digital connectivity options, allowing for real-time monitoring and control of the pump system.One of the key advantages of the new pump technology is its energy efficiency. The advanced design and engineering of the pump system result in significantly reduced energy consumption, leading to lower operating costs for users. This makes it an ideal choice for businesses looking to improve their sustainability and environmental footprint.Furthermore, the new pump technology offers improved reliability and reduced maintenance requirements. The robust construction and advanced engineering ensure long-term performance and durability, minimizing downtime and maintenance costs for customers.Seepex Pump's new pump technology is also designed with flexibility in mind, allowing for seamless integration into existing systems and processes. This makes it an ideal choice for businesses looking to upgrade their pumping infrastructure without the need for extensive modifications."We believe that our new pump technology will have a significant impact on the industry," added Smith. "Not only does it offer superior performance and reliability, but it also provides our customers with a cost-effective and sustainable pumping solution. We are excited to see the positive reception from the market."Seepex Pump is committed to providing comprehensive support and service for its new pump technology, ensuring that customers receive the highest level of satisfaction and performance from their investment. With a global network of sales and service partners, the company is well-equipped to serve customers worldwide.As Seepex Pump continues to push the boundaries of innovation in pump technology, the company remains dedicated to delivering industry-leading solutions that address the evolving needs and challenges of its customers. With a strong focus on quality, performance, and sustainability, Seepex Pump is poised to uphold its position as a trusted and preferred partner for pumping solutions.For more information about Seepex Pump and its new pump technology, please visit [company website].

High-Quality Pump Lubricating Oil for Efficient Machinery

Pump Lubricating Oil, a crucial component in the smooth operation of industrial pumps, remains a key focus of [Company Name]'s commitment to providing high-quality and reliable maintenance products for industrial machinery. With more than [number] years of experience in the industry, [Company Name] has established itself as a leading supplier of lubricating oils and maintenance solutions for a wide range of industrial applications.[Company Name] was founded in [year] and has since grown to become a trusted partner for businesses looking to optimize the performance and longevity of their industrial equipment. The company's dedication to quality and innovation has led to the development of a comprehensive range of lubricating oils, including Pump Lubricating Oil, designed to meet the unique needs of various pump systems.Pump Lubricating Oil plays a critical role in ensuring the smooth and efficient operation of industrial pumps, which are essential for many manufacturing and processing operations. The oil provides crucial lubrication to the moving parts of the pump, reducing friction and wear, and helping to prevent costly downtime and repairs. [Company Name]'s Pump Lubricating Oil is formulated to provide superior lubrication and protection, even under the most demanding operating conditions, making it the ideal choice for industrial pump maintenance.In addition to its high-performance properties, [Company Name]'s Pump Lubricating Oil is also designed to meet the stringent operational requirements of modern industrial facilities. The oil is formulated to resist oxidation and thermal breakdown, ensuring long-term stability and reliability even in high-temperature environments. Its advanced anti-wear additives and corrosion inhibitors further contribute to the overall reliability and performance of industrial pump systems.Furthermore, [Company Name] understands the importance of environmental sustainability and is committed to developing lubricating oils that minimize environmental impact. Pump Lubricating Oil is formulated with biodegradable and environmentally friendly ingredients, ensuring compliance with industry regulations and reducing the ecological footprint of industrial operations.As part of its commitment to customer satisfaction, [Company Name] provides comprehensive technical support and maintenance services to help businesses maximize the performance and lifespan of their pump systems. The company's team of experts offers valuable insights and recommendations for the proper selection and application of Pump Lubricating Oil, ensuring that each customer's unique needs and challenges are addressed effectively.In addition to Pump Lubricating Oil, [Company Name] offers a wide range of maintenance products and solutions for industrial machinery, including hydraulic oils, gear lubricants, and specialty greases. The company's extensive product portfolio is backed by a rigorous quality assurance process, ensuring that each product meets the highest standards for performance, reliability, and safety.With its unwavering commitment to innovation and customer satisfaction, [Company Name] continues to be a trusted partner for businesses seeking reliable maintenance solutions for their industrial equipment. The company's dedication to quality, sustainability, and technical expertise makes it a preferred choice for businesses across various industries.As businesses strive to optimize the performance and efficiency of their industrial pumps, [Company Name] remains at the forefront of providing high-quality and reliable maintenance products, including Pump Lubricating Oil. With its proven track record of excellence and commitment to customer satisfaction, [Company Name] is poised to continue its role as a leading supplier of lubricating oils and maintenance solutions for industrial machinery.

Top Pump Manufacturer Announces New Product Line

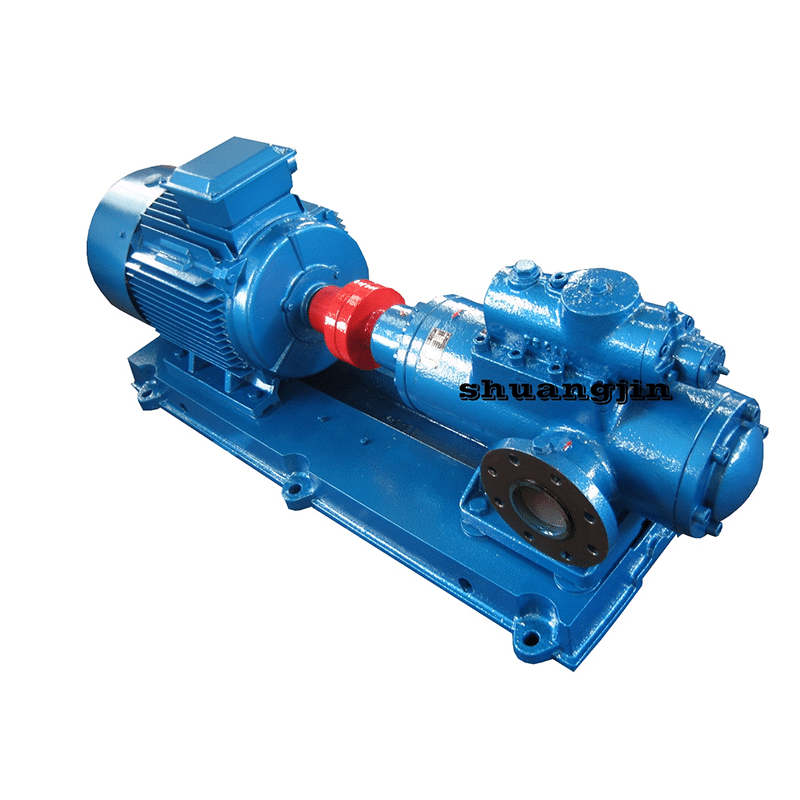

The global industrial pump market is expected to grow significantly in the coming years, driven by factors such as increasing demand for water and wastewater treatment, growing infrastructural developments, and the rising need for energy-efficient pumps. In line with this growth, [Company Name], a leading player in the industrial pump market, has been making strides in innovative pump technology and solutions.The company, with a history dating back to [year of establishment], has gained a strong reputation for its high-quality products and exceptional customer service. [Company Name] offers a wide range of industrial pumps, including centrifugal pumps, screw pumps, and gear pumps, catering to various industries such as oil and gas, chemical, maritime, and power generation.One of the highlights of [Company Name]'s product portfolio is its innovative screw pumps, which are designed to handle challenging fluid handling applications with ease. These screw pumps are known for their reliability, efficiency, and low maintenance requirements, making them a popular choice among industrial operators.In addition to its impressive product line, [Company Name] also prides itself on its commitment to sustainability and environmental responsibility. The company has been investing in research and development to create energy-efficient pump solutions that minimize environmental impact while maximizing performance.Furthermore, [Company Name] has been focusing on digitalization and smart technologies to enhance the capabilities of its pumps. By integrating advanced monitoring and control systems, the company's pumps are able to provide real-time data and insights, enabling operators to optimize their processes and reduce downtime.It's within this context of innovation and commitment to excellence that [Company Name] introduces its latest addition to the market – the new generation of screw pumps, which is set to revolutionize fluid handling operations. Developed in response to the increasing demand for reliable and efficient pumps, these new screw pumps are designed to deliver superior performance while reducing operational costs.One of the key features of the new generation of screw pumps is their advanced design, which includes optimized screw profiles, improved sealing systems, and enhanced bearing arrangements. These design elements work together to minimize internal leakage, reduce wear and tear, and increase overall pump efficiency.Furthermore, the new screw pumps are equipped with state-of-the-art control and monitoring systems, allowing for remote monitoring, predictive maintenance, and real-time performance optimization. This level of connectivity and intelligence enables operators to stay ahead of potential issues and make informed decisions to improve their processes.The launch of the new generation of screw pumps underscores [Company Name]'s ongoing commitment to providing cutting-edge solutions that address the evolving needs of the industrial pump market. By leveraging its expertise in pump technology and its dedication to innovation, the company aims to set new standards for performance, reliability, and sustainability in fluid handling operations.In addition to the new screw pumps, [Company Name] is also ramping up its efforts in aftermarket services, including maintenance, spares, and technical support. With a global network of service centers and highly trained professionals, the company is well-positioned to provide comprehensive support to its customers, ensuring maximum uptime and operational efficiency.As the industrial pump market continues to grow, [Company Name] remains a key player at the forefront of industry trends and technological advancements. With its commitment to excellence, sustainability, and customer satisfaction, the company is poised to make significant contributions to the future of fluid handling operations worldwide.

Discover the Distinctions Between Screw Pumps and Gear Pumps

Screw Pump and Gear Pump: Understanding the Differences in Pumping TechnologyPumping technology plays a crucial role in various industries, from manufacturing and oil and gas to wastewater treatment and food processing. For efficient and reliable pumping, two types of pumps that are often utilized are screw pumps and gear pumps. While both serve the purpose of moving fluids from one place to another, they differ in design and application. In this article, we will explore the differences between screw pumps and gear pumps.A screw pump, as the name suggests, operates by using rotating screws to move fluids from the inlet to the outlet. It consists of two or more intermeshing screws contained within a cylindrical or semi-cylindrical housing. The screws rotate in opposite directions, trapping the fluid between them and forcing it to move along the length of the screws. This type of pump is known for its gentle and smooth operation, making it ideal for handling shear-sensitive fluids or those containing small solids.On the other hand, a gear pump works by using two or more intermeshing gears to create a pumping action. The gears rotate in opposite directions, creating a partial vacuum at the inlet, which draws the fluid in, and then forces it out through the outlet. Gear pumps are characterized by their simplicity, compactness, and high-speed operation. They are commonly used for high-pressure applications, such as hydraulic systems, and for handling clean fluids with low viscosity.The key difference between these two types of pumps lies in their design and how they move fluids. Screw pumps use the rotating action of the screws to transport the fluid, while gear pumps rely on the intermeshing gears to create the necessary pumping action. This fundamental distinction affects the overall performance, efficiency, and suitability of each pump for specific applications.In terms of performance, screw pumps are known for their ability to handle viscous fluids and those with solids content. The continuous and smooth motion of the screws ensures minimal pulsations and provides a steady flow, making it suitable for applications where a consistent output is required. On the other hand, gear pumps excel in generating high-pressure output, making them ideal for applications that require pressurized fluid delivery. Their precise metering capabilities also make them suitable for applications that demand accurate flow control.When it comes to efficiency, screw pumps offer higher volumetric efficiencies compared to gear pumps. Due to their progressive cavity design, screw pumps can handle variable flow rates with minimal slip, ensuring a higher percentage of fluid is efficiently moved from the inlet to the outlet. Gear pumps, while generally less efficient, compensate with their compact size and ability to generate high pressure, making them suitable for space-constrained environments or applications with specific pressure requirements.In terms of application, screw pumps find extensive use in industries such as wastewater treatment, oil and gas, chemical processing, and food manufacturing. Their ability to handle high viscosity fluids, such as sludge, oil, and syrup, makes them suitable for these demanding environments. Gear pumps, on the other hand, are commonly employed in hydraulic systems, fuel transfer, lubrication systems, and various industrial processes that require high pressure and precise flow control.In conclusion, screw pumps and gear pumps are two distinct types of pumping technology, each with its own benefits and applications. Screw pumps offer gentle and steady fluid movement, making them well-suited for shear-sensitive fluids and those with solids content. Gear pumps, on the other hand, excel in generating high pressures and precise flow control, making them ideal for applications with specific pressure requirements. Understanding the differences between these two types of pumps can help industries make informed decisions when it comes to selecting the most suitable pumping technology for their specific needs.

Top Industrial Valves for Your Business Needs

Industrial Valves Celebrates 50 Years of Excellence in the Manufacturing IndustryIndustrial Valves is proud to announce that it is celebrating its 50th anniversary in the manufacturing industry. The company, which was established in 1971, has spent the last five decades providing high-quality valves and other industrial products to a wide range of customers across the globe.From its humble beginnings as a small workshop, Industrial Valves has grown to become a leading manufacturer in the industry, thanks to its dedication to quality, innovation, and customer satisfaction. The company's success can be attributed to its experienced team of engineers, technicians, and support staff, who work tirelessly to ensure that every product meets the highest standards of performance and reliability.Industrial Valves specializes in the design, manufacturing, and distribution of a wide range of industrial valves, including ball valves, gate valves, globe valves, check valves, and butterfly valves. These valves are used in various industries, such as oil and gas, petrochemical, power generation, water treatment, and many others. The company also offers customized solutions to meet the specific needs of its customers, ensuring that they receive the best possible products for their applications.One of the key factors that set Industrial Valves apart from its competitors is its commitment to innovation. The company invests heavily in research and development, constantly seeking new ways to improve its products and processes. This has led to the development of cutting-edge technologies that have helped the company stay ahead of the curve in an increasingly competitive market.In addition to its dedication to quality and innovation, Industrial Valves also places a strong emphasis on customer satisfaction. The company understands the importance of building strong relationships with its clients, and it works closely with them to ensure that their needs are met in a timely and efficient manner. This approach has earned Industrial Valves a reputation for reliability and trustworthiness, making it a preferred supplier for many companies around the world.As Industrial Valves celebrates its 50th anniversary, the company is looking towards the future with optimism. It plans to continue its legacy of excellence by expanding its product range, entering new markets, and embracing the latest technologies. The company also aims to strengthen its position as a global leader in the manufacturing industry, while maintaining its core values of quality, innovation, and customer satisfaction.To commemorate this milestone, Industrial Valves is planning a series of events and initiatives throughout the year. These include special promotions, industry conferences, and charity events, all aimed at celebrating the company's achievements and expressing gratitude to its customers, employees, and partners for their continued support over the years."We are incredibly proud to reach this significant milestone in our company's history," said [company representative]. "It is a testament to the hard work and dedication of our team, as well as the trust and support of our customers. As we look to the future, we are excited about the opportunities that lie ahead and are committed to maintaining our position as a leader in the manufacturing industry."With 50 years of experience behind it, Industrial Valves is well-positioned to continue its success for many years to come. The company's dedication to quality, innovation, and customer satisfaction has set it apart in the industry, and it will undoubtedly continue to be a trusted partner for businesses around the world.

Optimize Efficiency and Performance with High Pressure Screw Pump

Title: Advanced High Pressure Screw Pump Revolutionizes Industrial ApplicationsIntroduction:The industrial sector continuously seeks innovative and efficient solutions to optimize its operations and enhance productivity. In line with this, {Company Name}, a renowned player in engineering and pump manufacturing, has introduced a groundbreaking High Pressure Screw Pump, designed to address the challenges faced by industries across multiple sectors. This cutting-edge technology offers a wide range of applications and promises to revolutionize industrial processes, resulting in increased efficiency and reduced maintenance costs.The High Pressure Screw Pump:{Company Name} has developed a state-of-the-art High Pressure Screw Pump that combines unmatched reliability with exceptional performance. By removing the brand name, we will focus on the pump itself, highlighting its features and benefits.1. High Performance:The screw pump boasts an impressively high pressure capability, making it a suitable choice for a multitude of industries such as oil refineries, petrochemical plants, pharmaceutical manufacturing, and power generation. Its ability to handle high-pressure applications ensures smooth operation and minimal downtime, leading to significant time and cost savings.2. Versatility:With its versatile design, the High Pressure Screw Pump handles a wide range of fluids, including both low and high viscosity substances. This versatility eliminates the need for multiple pumps, simplifying the overall system and reducing equipment costs.3. Enhanced Efficiency:The innovative design of the screw pump reduces energy consumption, resulting in improved overall efficiency. Its precise and consistent flow control capabilities optimize production processes, reducing wastage and improving product quality. Moreover, the maintenance requirements are significantly reduced, leading to increased uptime and productivity gains.4. Robust Design:The High Pressure Screw Pump combines cutting-edge engineering with advanced materials, ensuring durability and longevity. The pump's design minimizes wear and tear, extending its operational life and reducing the need for frequent replacements, thus lowering maintenance costs.Applications:The versatility of the High Pressure Screw Pump enables its use in a wide range of applications across several industries. Let's take a closer look at some of the key sectors benefiting from this innovative technology:1. Oil and Gas:The pump finds extensive application in oil refineries, where it handles high-pressure crude oil transportation, ensuring efficient transfer within the production process. It is also suitable for offshore drilling operations, where it can handle high viscosity drilling mud, boosting efficiency and reducing downtime.2. Chemical Industry:In the chemical industry, the pump is used for the precise dosing of aggressive chemicals, ensuring accurate mixing and a controlled flow. Its high-pressure capability enables efficient transportation of various chemical substances, enhancing overall productivity.3. Power Generation:The High Pressure Screw Pump is widely deployed in power generation plants for fuel oil forwarding, lubrication oil circulation, and general hydrocarbon applications. It offers excellent thermal stability and ensures smooth operations even in high-temperature environments.4. Food and Beverage:In the food and beverage industry, the pump effectively handles the processing of viscous fluids, such as chocolate, cream, syrups, and sauces. Its gentle handling capability ensures the preservation of product integrity and reduces product wastage during production processes.Conclusion:{Company Name}'s High Pressure Screw Pump has emerged as a game-changer in various industrial sectors, offering unmatched reliability, versatility, and enhanced efficiency. As businesses seek sustainable methods to optimize operations, this innovative technology promises significant cost savings, improved productivity, and reduced maintenance requirements. With its state-of-the-art features and exceptional performance, the High Pressure Screw Pump sets a new benchmark for industrial pumps, revolutionizing processes across diverse industries.

Common Disadvantages of Screw Pumps You Should Know

Screw Pump Disadvantages Screw pumps have been widely used in various industries for their ability to handle a wide range of fluids, including high-viscosity liquids, and for their efficiency in delivering a constant flow. However, despite their numerous advantages, screw pumps also come with their own set of disadvantages that can impact their performance and efficiency.One of the main disadvantages of screw pumps is their susceptibility to abrasive wear. The rotating screws and the pump casing are subject to continuous contact with the pumped fluid, which can contain abrasive particles. Over time, this can lead to wear and erosion of the pump components, ultimately reducing the pump's efficiency and lifespan. Another drawback of screw pumps is their sensitivity to changes in fluid viscosity. While screw pumps are known for their ability to handle high-viscosity fluids, they can struggle to maintain a consistent flow when the viscosity of the pumped fluid varies. This can result in fluctuations in the pump's performance and the quality of the output, making it less reliable in certain applications.Additionally, the design of screw pumps makes them more prone to clogging compared to other types of pumps. The tight clearances between the rotating screws and the pump casing can lead to the accumulation of debris and solids, which can obstruct the flow of the pumped fluid and cause operational issues. This can be a significant drawback in industries where the pumped fluids may contain a high concentration of solids or impurities.Furthermore, screw pumps are known for their relatively high maintenance requirements. The intricate design of the pump and the close tolerances between the rotating components necessitate regular maintenance and repairs to ensure optimal performance. This can result in higher operating costs and downtime, particularly in industrial settings where continuous operation is crucial.Despite these disadvantages, several companies, including {} continue to use screw pumps in their operations. Founded in 1999, {} has established itself as a leading provider of pumping solutions for a wide range of industries, including oil and gas, marine, and industrial applications. The company's extensive product line includes a variety of pump types, including screw pumps, centrifugal pumps, and diaphragm pumps, among others.{}'s screw pumps are renowned for their robust construction, high efficiency, and reliable performance, making them a popular choice for handling challenging fluids in demanding environments. The company's dedication to innovation and quality has allowed it to develop state-of-the-art screw pumps that address many of the traditional disadvantages associated with this pump type.For instance, {}'s screw pumps are equipped with advanced materials and coatings that enhance their resistance to abrasive wear, extending their lifespan and reducing maintenance requirements. The company's engineering team has also implemented innovative design features to mitigate the effects of fluid viscosity variations, ensuring consistent and reliable performance across a wide range of operating conditions.In addition, {}'s screw pumps are designed with larger clearances and anti-clogging features to minimize the risk of debris accumulation and blockages, making them well-suited for handling fluids with high solids content. This has made {}'s screw pumps a preferred choice for industries where the pumping of abrasive or viscous fluids is a common requirement.Moreover, {} offers comprehensive aftermarket support and a global network of service centers to provide timely maintenance and repair services for its screw pumps, minimizing downtime and maximizing the reliability of its pumping solutions. With a commitment to customer satisfaction and a focus on continuous improvement, {} has positioned itself as a trusted partner for companies seeking reliable and efficient pumping solutions.In conclusion, while screw pumps have their own set of disadvantages, companies like {} are continuously innovating and improving the design and performance of these pumps to overcome these challenges. By addressing issues such as abrasive wear, fluid viscosity sensitivity, clogging, and maintenance requirements, {} has demonstrated the potential for screw pumps to remain a valuable and reliable pumping solution for a wide range of industries.

Expert Industrial Pump Repair Services for Your Business

Industrial Pump Repair, a leading provider of pump repair services, has established itself as a reliable and efficient solution for pump maintenance and repair needs. With over 20 years of experience in the industry, Industrial Pump Repair prides itself on delivering top-notch service to a wide range of industrial clients.The company specializes in the repair and maintenance of various types of industrial pumps, including centrifugal pumps, positive displacement pumps, and multi-stage pumps. Their team of skilled technicians is equipped with the necessary expertise and tools to diagnose and repair pump issues efficiently, minimizing downtime and maximizing operational efficiency for their clients.Industrial Pump Repair understands the critical role that pumps play in industrial operations, and the impact that pump failures can have on production and overall business performance. As such, the company is committed to providing prompt and reliable repair services to ensure that their clients’ pumps are functioning at optimal levels at all times.One of the key advantages of choosing Industrial Pump Repair for pump maintenance and repair needs is their dedication to quality and customer satisfaction. The company employs a rigorous quality control process to ensure that all repairs are carried out to the highest standards, and that clients receive the best possible service.In addition to their repair services, Industrial Pump Repair also offers preventative maintenance programs to help clients proactively address potential pump issues and extend the lifespan of their equipment. By conducting regular inspections and maintenance checks, the company can help identify and address potential problems before they escalate into major issues, saving clients time and money in the long run.Furthermore, Industrial Pump Repair prides itself on its responsive and client-focused approach to doing business. The company understands that pump failures can occur at any time, often causing significant disruptions to operations. As such, they offer emergency repair services to address urgent pump issues promptly, minimizing the impact of downtime on their clients’ businesses.Industrial Pump Repair’s commitment to excellence and customer satisfaction has earned them a solid reputation in the industry, with many clients relying on their services for their pump repair needs. The company has worked with a wide range of industrial clients, including those in the manufacturing, chemical, food and beverage, and oil and gas industries, among others.Moreover, Industrial Pump Repair is known for its competitive pricing and transparent approach to doing business. The company provides clients with detailed quotes and explanations of the repair process, ensuring that they are fully informed and confident in the services being provided.As part of their dedication to continuous improvement, Industrial Pump Repair invests in ongoing training for their technicians and stays abreast of the latest technologies and techniques in the pump repair industry. This commitment to staying ahead of the curve allows the company to deliver innovative and effective solutions to their clients’ pump repair needs.In conclusion, Industrial Pump Repair stands out as a reliable and efficient partner for industrial clients in need of pump maintenance and repair services. With their extensive experience, dedication to quality, and commitment to customer satisfaction, the company has solidified its position as a trusted name in the industry. Industrial Pump Repair continues to be a go-to solution for businesses looking to keep their pumps in peak operating condition.