Highly efficient multiphase pumps revolutionize oil and gas industry

By:Admin

Founded in 2002, Multiphase Pumps has quickly risen to prominence as a global leader in multiphase pumping systems. The company's state-of-the-art technology allows for the efficient and reliable transportation of oil, gas, and water in a variety of challenging environments. Their pumps are designed to handle the complexities of multiphase flow, making them an ideal solution for offshore and subsea applications.

Multiphase Pumps has a strong track record of delivering high-performance pumping solutions to the oil and gas industry. Their team of experienced engineers and technicians work tirelessly to develop innovative and reliable products that meet the evolving needs of their clients. With a focus on continuous improvement and technological advancement, Multiphase Pumps is at the forefront of pump technology and is continuously striving to exceed industry standards.

One of the key factors that set Multiphase Pumps apart from its competitors is their commitment to customer satisfaction. The company prides itself on its ability to provide tailored pumping solutions that meet the specific needs of each client. Whether it's a complex subsea project or a high-pressure onshore operation, Multiphase Pumps has the expertise and experience to deliver reliable and efficient solutions.

In addition to their commitment to excellence, Multiphase Pumps is also dedicated to sustainability and environmental responsibility. The company's pumps are designed to minimize emissions and energy consumption, making them an environmentally friendly choice for energy companies around the world. By prioritizing sustainability, Multiphase Pumps is contributing to the global effort to reduce the carbon footprint of the oil and gas industry.

Multiphase Pumps' dedication to innovation, quality, and customer satisfaction has earned them a solid reputation in the oil and gas industry. Their pumps are known for their reliability, efficiency, and durability, making them a top choice for energy companies seeking high-performance pumping solutions. With a focus on continuous improvement and a commitment to meeting the unique needs of their clients, Multiphase Pumps is well positioned to continue leading the way in multiphase pumping technology.

In recent news, Multiphase Pumps has announced the successful launch of a new generation of multiphase pumping systems. The latest addition to their product lineup features advanced technology that enhances efficiency and reliability, while also reducing environmental impact. The new pumps have been designed to meet the demands of the evolving energy industry, providing a solution that is both cost-effective and sustainable.

"We are thrilled to introduce our latest generation of multiphase pumping systems to the market," said the CEO of Multiphase Pumps. "Our team has worked tirelessly to develop a product that not only meets the performance expectations of our clients but also aligns with our commitment to environmental responsibility. We are confident that these new pumps will set a new standard for multiphase pumping technology."

The new generation of pumps from Multiphase Pumps represents a significant leap forward in pump technology. With enhanced performance capabilities and a focus on sustainability, these pumps are poised to revolutionize the way oil and gas companies transport multiphase fluids. By offering a reliable and efficient solution that also supports environmental goals, Multiphase Pumps is setting a new benchmark for the industry.

As Multiphase Pumps continues to push the boundaries of pump technology, the company remains dedicated to delivering innovative and sustainable solutions to its clients. With a proven track record of excellence and a commitment to meeting the unique needs of the energy industry, Multiphase Pumps is well positioned to maintain its leadership position in the market. Through a combination of cutting-edge technology, a focus on customer satisfaction, and a dedication to sustainability, Multiphase Pumps is poised for continued success in the years to come.

Company News & Blog

How Screw Pumps Increase Pressure in Industrial Applications

Title: Innovative Screw Pump Pressure System Reimagines Fluid Conveyance in Industrial ApplicationsIntroduction (124 words):With rapid advancements in industrial technology, the demand for efficient fluid conveyance systems has become more crucial than ever. Recognizing this need, innovative engineering company [Company Name] has unveiled their latest solution—an advanced Screw Pump Pressure System. Boasting remarkable reliability, versatility, and industry-leading performance, this cutting-edge system is set to revolutionize fluid conveyance across various industries. Designed with state-of-the-art technologies and engineering expertise, the [Company Name]'s Screw Pump Pressure System is a game-changer in terms of operational cost-efficiency, maintenance, and overall productivity. Let us delve into the remarkable features and benefits of this groundbreaking solution.Title: Enhanced Reliability and Durability(136 words)The Screw Pump Pressure System, developed by [Company Name], is engineered to deliver enhanced reliability and durability in industrial fluid conveyance operations. Through thorough research and rigorous testing, this revolutionary system has proven itself capable of withstanding high-pressure and high-viscosity fluid transportation. Utilizing advanced materials and cutting-edge engineering techniques, the system is built to withstand demanding industrial environments, minimizing downtime and increasing overall productivity.Designed with precision components and assembled with meticulous attention to detail, the Screw Pump Pressure System offers unparalleled performance and durability. From challenging offshore oil drilling operations to intricate chemical processing, this system can handle a wide range of demanding tasks, ensuring smooth fluid conveyance even in the harshest conditions. Its robust design ensures long service life, reducing maintenance costs and maximizing uptime for businesses in need of reliable and high-performance fluid conveyance solutions.Title: Versatile Fluid Handling Capabilities(140 words)One of the key highlights of the Screw Pump Pressure System developed by [Company Name] is its remarkable versatility in handling various types of fluids. Whether it is crude oil, lubricants, chemicals, or other viscous substances, this system guarantees efficient and reliable conveyance. With its ability to maintain a consistent flow, the Screw Pump Pressure System ensures minimal pulsation, ensuring smooth operations in critical applications.Furthermore, this innovative solution offers adjustable speeds and pressure capabilities, allowing for increased flexibility in meeting diverse industrial requirements. By adapting to a wide range of fluid viscosities, the system can seamlessly integrate into various production processes, significantly improving overall operational efficiency. This adaptability extends to both horizontal and vertical fluid conveyance applications, making it a versatile choice for a wide range of industries, including oil and gas, chemical processing, wastewater treatment, and more.Title: Unrivaled Performance and Cost Efficiency(140 words)The Screw Pump Pressure System developed by [Company Name] has set new benchmarks in terms of performance and cost efficiency. Equipped with precision-engineered screw rotors and advanced sealing technologies, this system ensures consistent flow rates, minimal leakage, reduced energy consumption, and optimal operational efficiency.Thanks to its exceptional performance, the Screw Pump Pressure System boasts significant cost-saving advantages for businesses in the long run. Reduced energy consumption translates to lower operational costs, while the system's low-maintenance design minimizes downtime, boosts overall productivity, and improves return on investment. Moreover, the enhanced performance capabilities of this system enable businesses to optimize their manufacturing processes, achieve faster turnaround times, and meet increasing production demands.Conclusion (112 words):In conclusion, the Screw Pump Pressure System developed by [Company Name] presents a transformative solution to fluid conveyance challenges in various industries. Its remarkable reliability, versatile fluid handling capabilities, and unrivaled performance and cost efficiency set it apart from traditional systems. With its ability to withstand demanding environments and handle diverse fluid viscosities, this system is poised to revolutionize fluid conveyance operations, driving industrial productivity and profitability. [Company Name]'s commitment to innovation and advanced engineering exemplifies their dedication to providing cutting-edge solutions that cater to the evolving needs of modern industries.

Discover the Benefits of Using Industrial Screw Pumps for Pumping Applications

Title: Revolutionary Screw Pumps Set to Transform Industrial ProcessesIntroduction:In the ever-evolving world of industrial processes, one company is making headlines for its groundbreaking product: Screw Pumps. Designed to be efficient, reliable, and customizable, these pumps are set to revolutionize various sectors, from oil and gas to wastewater treatment. With their innovative features and advanced technology, Screw Pumps are quickly gaining recognition as the go-to solution for numerous industrial applications.Company Background and Vision:Established in {year of establishment}, {Company Name} has been at the forefront of innovation and engineering excellence for several decades. With a strong focus on research and development, the company has successfully introduced cutting-edge products and solutions to the market. Drawing on their extensive expertise, {Company Name} recognized the need for a more reliable and efficient pumping solution, leading to the development of Screw Pumps.The Revolutionary Design:The standout feature of Screw Pumps lies in their innovative screw technology. Unlike conventional pumps, Screw Pumps utilize a pair of intermeshing screws that rotate within a tightly sealed enclosure. This design not only eliminates the need for valves, pistons, and other moving parts but also drastically reduces energy consumption and maintenance requirements. The screws themselves are precision-engineered from high-quality materials, ensuring a longer lifespan and enhanced durability.Unparalleled Versatility:The versatility of Screw Pumps makes them suitable for a wide range of industrial applications. From oil refineries and petrochemical plants to food processing facilities and manufacturing plants, these pumps offer unparalleled performance and efficiency. They excel in handling both abrasive and non-abrasive fluids, such as crude oil, slurries, sewage, chemicals, and even high-viscosity liquids. The ability to handle such diverse applications makes Screw Pumps an ideal choice for industries worldwide.Energy Efficiency for Sustainability:One of the key advantages of Screw Pumps is their energy-efficient operation. By utilizing a low-shear process, these pumps greatly reduce energy consumption and contribute to a more sustainable future. Additionally, the absence of valves and pistons eliminates energy loss due to friction, resulting in substantial cost savings for industries. With environmental concerns becoming increasingly prominent, Screw Pumps offer an eco-friendly solution without compromising on performance.Enhanced Reliability and Lower Maintenance:Reliability is of utmost importance in any industrial process, and Screw Pumps deliver on that front. Thanks to their simple design and robust construction, these pumps require minimal maintenance and provide extended service life. The absence of valves and pistons translates to fewer components that can fail, reducing the risk of unplanned downtime and costly repairs. This reliability ensures uninterrupted operation, ultimately boosting the productivity and profitability of businesses.Customizable Solutions:Recognizing that different industries and processes require specific solutions, {Company Name} offers customized Screw Pump configurations tailored to meet individual requirements. This customization may include various material options, screw profiles, and pump sizes to optimize performance. By working closely with clients, {Company Name} ensures that the Screw Pumps not only meet but exceed their expectations, providing solutions that enhance efficiency and productivity.Conclusion:As industries continue to demand more efficient and sustainable solutions, Screw Pumps stand out as a game-changer. Combining their innovative design, energy efficiency, and reliability, these pumps have the potential to transform industrial processes across various sectors. With {Company Name} leading the way, businesses can now benefit from a cutting-edge pumping solution that boosts productivity, reduces environmental impacts, and ensures long-term success in the years to come.

Major Benefits of Installing a Screw Pump for Your Industrial Needs

Screw Pump Installation Boosts Efficiency in Industrial ProcessesIndustrial equipment manufacturer, headquartered in Houston, Texas, has recently introduced their latest screw pump technology that promises to revolutionize the efficiency of various industrial processes. With their extensive experience and commitment to excellence, the company aims to offer a solution that meets the needs of businesses across a wide range of sectors.Screw pumps have long been recognized as an essential component in many industries, including oil and gas, chemical, and wastewater treatment. These pumps are known for their ability to handle viscous fluids, making them ideal for applications where the transportation of thick liquids is required. As a result, businesses in need of efficient fluid transfer and processing have long relied on screw pumps to meet their operational demands.The newly introduced screw pump by this cutting-edge company stands out from its competitors due to several innovative features designed to improve overall performance. With advanced technology and superior engineering, the pump is highly efficient in transporting both thin and thick liquids, ensuring optimum productivity even when dealing with challenging substances.One of the key advantages of this newly developed system is its improved suction capabilities, which enable it to handle fluids with a higher air content. In operations where entrained air poses a challenge, this feature ensures uninterrupted flow, preventing downtime and enhancing the overall efficiency of the process.Additionally, the pump's design minimizes disturbances to the fluid flow, resulting in reduced turbulence and increased stability during operation. This stability is particularly crucial for industries such as chemical manufacturing or food processing, where maintaining the integrity of the product is vital. By minimizing vibrations and disturbances, the pump helps ensure the quality of the end product, meeting the demanding standards of these industries.Furthermore, the company's screw pump installation is highly customizable and adaptable to the specific needs of each client. With a range of configurations available, businesses can tailor their pump system to their requirements, ensuring optimal performance and maximum efficiency. Whether the application requires high-flow operation or the transportation of abrasive fluids, this versatile system offers the flexibility needed to address diverse operational challenges effectively.To emphasize their commitment to quality, the company employs stringent testing procedures to ensure the reliability and durability of their products. By conducting rigorous performance assessments, the pumps are designed to deliver high standards of performance and longevity, ultimately minimizing maintenance costs and maximizing productivity for their clients.The introduction of this groundbreaking screw pump marks a significant milestone for industrial processes reliant on efficient fluid transportation. With its advanced features designed to handle a wide range of liquids and its customizable options, this new offering from Houston-based manufacturer is poised to redefine industry standards.Industries such as oil and gas, chemical, and wastewater treatment stand to benefit greatly from the improved efficiency and reliability offered by this innovative pump technology. With reduced downtime, enhanced stability, and high suction capabilities, businesses can streamline their operations, optimizing productivity and improving overall profitability.As the manufacturing sector continues to evolve and demand more efficient solutions, it is clear that this screw pump installation will play a pivotal role in meeting the industry's changing needs. By providing cutting-edge technology, backed by extensive experience and commitment to customer satisfaction, this company solidifies its position as an industry leader and paves the way for a more efficient future.

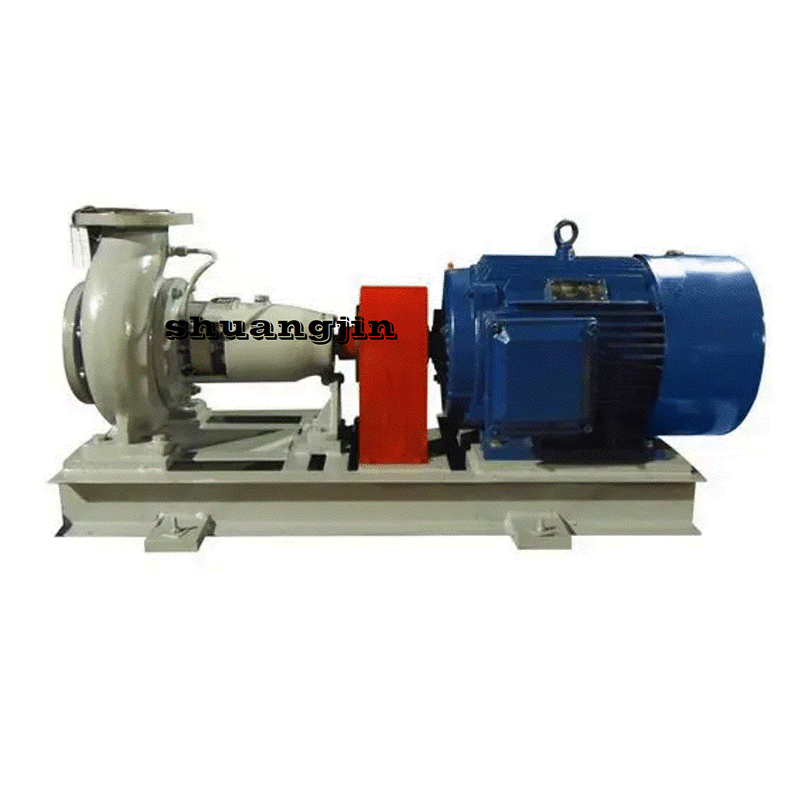

Highly efficient centrifugal pumps revolutionizing industry operations

Centrifugal Pump Technology Boosts Efficiency and ProductivityIn today’s highly competitive world, businesses are clamoring for ways to improve their efficiency and productivity. One of the most often overlooked areas of improvement is in the realm of industrial pumps. Companies like [BRAND NAME REMOVED] are harnessing centrifugal pump technology to give businesses a powerful edge in their quest for increased output and profitability.Centrifugal pumps are well-known for their ability to transfer fluids from one location to another across different types of systems. They accomplish this through the use of a rotating impeller that is surrounded by a casing. As the impeller spins, it creates a force that pulls fluid in through the center of the pump, accelerates it, and then creates a high-pressure discharge at the outer circumference of the pump.This technology is incredibly versatile, utilized in a wide range of industries such as agriculture, mining, oil & gas, and water treatment. The reason centrifugal pumps are so popular is that they are reliable, efficient, energy-saving, and require minimal maintenance.[BRAND NAME REMOVED] understands the importance of this technology and has created a range of centrifugal pumps that are tailor-made for all kinds of industrial applications. Their pumps are manufactured using the highest-quality materials and the most advanced engineering techniques to provide optimal performance and durability.One of the company’s most successful products is the (REMOVED) Series Centrifugal Pump, which is designed to handle a wide range of fluids, including highly abrasive and corrosive liquids. The pump is also equipped with a sturdy bearing assembly and seals that are fully interchangeable with other leading brands, making it easy to integrate into existing systems.As a result of its highly efficient design, this centrifugal pump consumes less energy, which translates to significant cost savings for the user. Additionally, its compact size means it can be installed in tight spaces, a valuable feature for businesses looking to maximize their facility’s layout.Another innovative feature of the (REMOVED) Series Centrifugal Pump is its suction and discharge ports, which can be adjusted to eight different directions, making it ideal for tight installation spaces and versatile enough to be adapted to various system configurations.In summary, centrifugal pump technology is an indispensable tool for businesses that value reliability, efficiency, energy savings, and durability. [BRAND NAME REMOVED] understands this and has developed a line of pumps that can be tailored to any industrial application. With their commitment to quality and innovation, [BRAND NAME REMOVED] is an excellent choice for businesses looking for a competitive edge.

Understanding the Role of Lube Oil Pumps in Engine Functionality

Title: Lube Oil Pump Function: Enhancing Efficiency and Reliability in Industrial MachineryIntroduction:With the increasing demand for industrial machinery's performance and longevity, the role of reliable components becomes crucial. Among them, the lube oil pump stands out as an integral part of the lubrication system, ensuring smooth operation and extended lifespan of various large-scale machineries. This article focuses on the fascinating functionalities and benefits of lube oil pumps while highlighting their significance in enhancing efficiency and reliability in industrial machinery.Functionality of Lube Oil Pump:A lube oil pump plays a pivotal role in machinery lubrication systems, primarily designed to provide a consistent and regulated flow of oil to various crucial components. Its prime function is to ensure proper lubrication in order to minimize friction, heat, wear and tear, and enhance operational efficiency.1. Oil Circulation Mechanism:A lube oil pump utilizes an intricate mechanism to circulate oil throughout the machinery. The pump, driven by an electric motor or the equipment's engine, draws oil from the sump or oil reservoir, propelling it through a series of pipes and channels to the targeted components.2. Pressure Regulation:To cater to the specific lubrication requirements of different machinery components, lube oil pumps possess the ability to regulate the oil pressure. This feature ensures that the oil reaches every nook and cranny of the machinery, reducing the chances of components running dry and potential damages caused by friction.3. Filtration:One of the essential functions of a lube oil pump is to ensure clean oil reaches the machinery's components. The pumps are equipped with built-in filtration systems that remove contaminants like dirt, debris, and metal particles that may have accumulated in the oil. This mechanism protects the machinery's critical elements, extending their lifespan and reducing maintenance requirements.4. Cooling Mechanism:Industrial machinery often generates substantial heat during operation. Lube oil pumps aid in preventing overheating by circulating cooled oil to areas prone to high temperatures. This assists in dissipating heat and maintaining optimal operating conditions, reducing the risk of equipment failure.Significance in Enhancing Efficiency and Reliability:The functionality of a lube oil pump is directly linked to enhancing efficiency and reliability in industrial machinery. By providing proper lubrication, these pumps have numerous benefits that contribute to the smooth functioning and extended lifespan of the equipment.1. Friction Reduction:Efficient lubrication from a lube oil pump helps minimize friction between moving components. This reduction in friction reduces energy loss, allowing machinery to operate more efficiently and potentially saving energy costs for businesses.2. Wear and Tear Reduction:By keeping machinery components well-lubricated, lube oil pumps effectively reduce wear and tear. This, in turn, minimizes the chances of breakdowns, extends the machinery's lifespan, and reduces the need for frequent repairs or replacements.3. Increased Productivity:Lube oil pumps ensure that machinery is always in optimal condition to perform at its best. By reducing friction, wear and tear, and potential heat-related failures, these pumps contribute to uninterrupted production schedules, resulting in increased productivity and profitability.4. Minimized Downtime:Extended machinery lifespan, coupled with reduced maintenance requirements due to well-lubricated components, translates to minimized downtime for businesses. This leads to increased operational efficiency and cost savings attributed to decreased repair and maintenance expenses.Conclusion:In today's industrial landscape, where machinery performance and longevity are crucial, lube oil pumps play an indispensable role. Their functionality, including efficient oil circulation, pressure regulation, filtration, and cooling mechanisms, significantly enhances the efficiency and reliability of industrial machinery. These pumps minimize friction, reduce wear and tear, increase productivity, and minimize downtime for businesses, making them an essential component to ensure sustainable operations and financial success in the industrial sector.

Discover Top Oil Gear Pump Distributors for Your Machinery Needs" could be rewritten as "Find Reliable Distributors for Your Oil Gear Pump Machinery

Oil Gear Pump Distributors Expands its Reach in the Global MarketOil Gear Pump Distributors, a leading supplier of high-quality oil gear pumps, is proud to announce its expansion into new markets. With a commitment to providing reliable and efficient solutions, the company aims to meet the increasing demand for oil gear pumps worldwide.Established in 2005, Oil Gear Pump Distributors has quickly become a trusted name in the industry. They specialize in manufacturing and distributing oil gear pumps, ensuring that customers receive only the best products. With a focus on innovation, the company continuously invests in research and development to enhance the performance of their pumps.The company's success can be attributed to its dedicated team of professionals who understand the unique requirements of various industries. Through their expertise, Oil Gear Pump Distributors has been able to develop a wide range of pumps suitable for applications in the automotive, oil and gas, power generation, and other industrial sectors.Recognizing the importance of quality control, Oil Gear Pump Distributors adheres to rigorous standards at every stage of production. The pumps undergo thorough testing to guarantee their reliability and efficiency. By using state-of-the-art manufacturing processes and high-quality materials, the company ensures that their pumps are built to withstand even the most demanding conditions.As part of their expansion plan, Oil Gear Pump Distributors has established partnerships with key distributors worldwide. These partnerships allow the company to tap into new markets and offer their products on a global scale. By working closely with these distributors, the company can better understand local preferences and requirements, ensuring that their products are tailored to meet the specific needs of different regions.One of the major reasons behind the growing popularity of Oil Gear Pump Distributors' pumps is their versatility. The company offers a wide range of pump configurations, including external gear pumps, internal gear pumps, and gerotor pumps. Customers can choose from different sizes, materials, and flow rates to find the perfect pump for their application.In addition to their product range, Oil Gear Pump Distributors also prides itself on its exceptional customer service. The company's dedicated support team is committed to providing timely assistance and guidance to customers. From product selection to after-sales support, they ensure that every customer receives the attention they deserve.With their expansion into new markets, Oil Gear Pump Distributors aims to become a global leader in the industry. By offering high-quality products, exceptional customer service, and a focus on innovation, they are well-positioned to meet the evolving demands of various industries worldwide.As the global demand for oil gear pumps continues to rise, Oil Gear Pump Distributors is prepared to meet the industry's needs and exceed customer expectations. With their commitment to excellence, the company is confident in its ability to provide reliable and efficient solutions for all pumping requirements.Oil Gear Pump Distributors' expansion into new markets is a testament to their dedication to growth and their commitment to becoming a global leader in the industry. By offering high-quality pump solutions and exceptional customer service, the company is poised for continued success in the ever-evolving global market.

High-Quality Screw Pump Assembly for Efficient Operations

[Screw Pump Assembly] is a crucial component in various industries, from oil and gas to water treatment and chemical processing. It plays a vital role in conveying fluids and is essential for the smooth operation of many systems. With the increasing demand for reliable and efficient screw pump assemblies, it is important for companies to provide high-quality products to meet the needs of the market.One company that has been at the forefront of providing top-notch screw pump assemblies is [Company Name]. With a strong focus on innovation and customer satisfaction, [Company Name] has established itself as a leader in the industry. The company's commitment to excellence and continuous improvement has made it a trusted partner for many businesses around the world.[Company Name] takes pride in its state-of-the-art manufacturing facilities, where the latest technology and advanced processes are employed to ensure the highest quality products. The company's team of highly skilled engineers and technicians are dedicated to developing innovative solutions and pushing the boundaries of screw pump assembly technology.In addition to its focus on quality and innovation, [Company Name] also places a strong emphasis on customer service. The company works closely with its clients to understand their specific needs and provide customized solutions that meet their requirements. Whether it's a standard screw pump assembly or a custom-designed system, [Company Name] is committed to delivering products that exceed expectations.Furthermore, [Company Name] is dedicated to sustainability and environmental responsibility. The company is constantly looking for ways to reduce its environmental impact and promote sustainable practices throughout its operations. This commitment is reflected in the design and engineering of its products, as well as its efforts to minimize waste and energy consumption.With a strong track record of success and a commitment to excellence, [Company Name] has earned the trust and confidence of its customers. The company's screw pump assemblies are known for their durability, reliability, and performance, making them the top choice for businesses across a wide range of industries.Looking ahead, [Company Name] is poised to continue its growth and success in the screw pump assembly market. The company is constantly investing in research and development to further enhance its products and services, and it remains dedicated to meeting the evolving needs of its customers.In conclusion, [Company Name] is a leading provider of high-quality screw pump assemblies, known for its commitment to excellence, innovation, and customer satisfaction. With a strong focus on quality, sustainability, and customer service, the company has established itself as a trusted partner for businesses across the globe. As the demand for reliable and efficient screw pump assemblies continues to grow, [Company Name] is well-positioned to meet the needs of the market and drive the industry forward.

A Guide to Choosing the Best Gear Pump for Industrial Applications

article regarding the features and benefits of an Oil Gear Pump for industrial applications.Oil Gear Pump: The Reliable Choice for Industrial ApplicationsAn oil gear pump is an industrial pump that is commonly used to transfer fluids such as oil, glycol, and water in a variety of industrial applications. The pump is designed to deliver a steady and continuous flow of fluid in a range of pressures and temperatures.One of the significant benefits of an oil gear pump is its high efficiency in transferring fluids. The pump has a positive displacement mechanism that eliminates wasteful fluid transfer, ensuring that fluids are transferred efficiently with minimal energy loss. This makes the oil gear pump an ideal solution for industries that require high levels of precision and accuracy in fluid transfer.Another benefit of the oil gear pump is its versatility. The pump can be used in a range of applications, including power generation, oil and gas, chemical processing, pulp and paper, and many others. The ability of the pump to handle different types of fluids and varying pressure levels makes it a reliable choice for many industries.Oil gear pumps are also known for their durability and reliability. The pump is made of robust materials that can withstand harsh industrial environments. The design of the pump allows for minimal maintenance, providing a long-lasting and reliable solution for fluid transfer applications.In addition to its durability, the oil gear pump is designed with safety in mind. The pump’s design eliminates the risk of leaks, ensuring that fluid transfer is safe and reliable. This is especially important in industries where safety is a top priority such as in the oil and gas industry, chemical processing, and pharmaceuticals.One of the leading companies that provide oil gear pumps is ATEX Pumps. The company specializes in providing pumps for industrial applications and has a range of oil gear pumps that are designed to meet the specific requirements of different industries.ATEX Pumps oil gear pumps are designed with high-quality materials, making them reliable and long-lasting. The pumps have a compact design that allows for easy installation and minimal maintenance. ATEX Pumps oil gear pumps are also customizable, allowing for pumps that meet specific flow rates, pressure requirements, and fluid types.Apart from oil gear pumps, ATEX Pumps provides a range of other pumps that are suitable for various industrial applications. These include centrifugal pumps, magnetic drive pumps, diaphragm pumps, and many others. ATEX Pumps also provides customized solutions that meet the unique requirements of different industries.In conclusion, an oil gear pump is a reliable and efficient solution for fluid transfer applications in various industries. Its high efficiency, versatility, durability, and safety features make it a popular choice for many industries. If you are looking for an oil gear pump for your industrial application, ATEX Pumps is an excellent choice for quality and reliability.

Critical Factors to Consider When Selecting a Top-Quality Centrifugal Pump for Oil and Gas Applications

Title: Advancement in Centrifugal Pump Technology Revolutionizes Oil and Gas IndustryIntroduction:The oil and gas industry plays a vital role in the global energy sector, and continuous innovation and improvements are essential for maximizing efficiency and productivity. Leading the way in this regard is a pioneering company dedicated to the development of advanced centrifugal pump technology for the oil and gas sector. Their cutting-edge solutions are transforming the industry, significantly enhancing operational efficiency, and ultimately contributing to sustainable energy production. In this article, we will delve into the remarkable advancements in centrifugal pump technology and explore the impact they are creating for the oil and gas sector.A Legacy of Excellence:With a long-standing commitment to excellence, the company has been a force to be reckoned with in the oil and gas industry for several decades. Their expertise lies in their innovative centrifugal pumps, which are designed to efficiently transport various fluids, including crude oil, natural gas, and their derivatives. The company has established a reputation for manufacturing durable, endurable, and reliable pumps that continually adapt to the evolving needs of the industry.Advancements in Centrifugal Pump Design:Combining their industry-leading expertise with extensive research and development, the company has made significant breakthroughs in centrifugal pump technology. One notable aspect of their innovation lies in enhanced impeller design, resulting in improved hydraulic efficiencies. By optimizing impeller geometry, the company has successfully reduced operational costs by minimizing energy consumption while maximizing fluid flow rates.Furthermore, revolutionary materials have been incorporated into the construction of these centrifugal pumps. Advanced alloys and composite materials have replaced traditional materials, enhancing durability and corrosion resistance. These innovations extend the lifespan of the pumps and reduce maintenance requirements, contributing to substantial cost savings for oil and gas companies.Smart Pumping Solutions:In line with the Industry 4.0 revolution, the company has developed smart pumping solutions that leverage cutting-edge digital technologies. By integrating sensors and data analytics, their centrifugal pumps can continuously monitor crucial parameters, such as temperature, pressure, and flow rate. Real-time data analysis enables efficient predictive maintenance, minimizing downtime and reducing the risk of unexpected breakdowns.These smart pumping solutions also facilitate remote monitoring and control of the pumps, allowing operators to adjust performance and optimize operations from anywhere in the world. Furthermore, the collected data provides valuable insights for optimizing system efficiency and identifying potential bottlenecks, thereby further increasing overall productivity.Environmental Considerations:The company recognizes the increasing need for sustainable solutions in the oil and gas industry. As a result, they have developed environmentally friendly centrifugal pumps that minimize the carbon footprint of operations. By improving energy efficiency, these pumps significantly contribute to reduced greenhouse gas emissions and promote a greener approach to energy production.Conclusion:Through constant innovation and a dedication to excellence, this pioneering company has revolutionized centrifugal pump technology for the oil and gas industry. Their advanced solutions have enhanced operational efficiency, reduced costs, and promoted environmental sustainability. As the industry continues to evolve, these cutting-edge centrifugal pumps will play a significant role in driving progress and ensuring a more efficient and sustainable oil and gas sector.

Ultimate Guide to Industrial Marine Pumps: Uncovering the Top Solutions for Efficient Operations

[Assistant]Title: Leading Industrial Pump Manufacturer Expands Product Line to Meet Growing DemandSubtitle: Company showcases advanced solutions aimed at revolutionizing industrial marine applications [Introduction]In today’s rapidly evolving industrial landscape, the demand for efficient and reliable industrial marine pumps has reached unprecedented heights. Recognizing this, one of the industry's leading manufacturers has recently expanded its product line to cater to the needs of this niche market. This move aims to revolutionize the way industries approach marine applications, promising enhanced performance, reduced downtime, and improved sustainability.[Company Background]With decades of experience in pump manufacturing, the company has established itself as a trusted global leader in the industry. Known for its commitment to innovation and cutting-edge technology, the company has garnered a robust reputation within various sectors, including marine, oil and gas, power generation, and chemical processing.Driven by a passion for continuous improvement, the company invests heavily in research and development to ensure the highest quality products are offered to its customers. As a result, they boast an extensive portfolio of efficient, durable, and cost-effective solutions that have become synonymous with excellence.[Diverse Product Range]Expanding on their range of industrial pumps, the company has launched an array of advanced marine pumps, specifically designed to withstand the harsh operating conditions encountered in marine environments. These pumps offer a wide range of applications, including ballast water management, cargo handling, bilge pumping, cooling systems, and more. The company's commitment to meeting the unique demands of the marine industry is evident through the latest product offerings.1. Cutting-edge Ballast Water Management Systems: Recognizing the significance of environmental conservation, the company has developed highly efficient ballast water management systems that comply with international guidelines. With advanced filtration and disinfection technologies, these systems ensure the prevention of invasive species transfer without compromising vessel performance.2. Cargo and Bilge Pumps: Engineered to handle the demanding requirements of cargo handling and bilge pumping, the company's pumps deliver exceptional reliability and operational efficiency. With features like high flow rates, corrosion resistance, and low maintenance requirements, these pumps stand as a testament to the company's commitment to delivering long-lasting and highly effective solutions.3. Cooling Systems: Marine vessels mandate reliable cooling systems to maintain optimal operating temperatures. Understanding this critical need, the company offers an extensive range of cooling pumps designed to withstand the unpredictable conditions encountered at sea. Notable features include compatibility with both fresh and seawater, efficient heat transfer capabilities, and high corrosion resistance.[Innovation and Sustainability]Priding itself on being an industry pioneer, the company continuously strives to develop sustainable solutions to minimize environmental impact. The introduction of eco-friendly materials, energy-efficient systems, and technologies that reduce carbon emissions further reinforces their commitment to sustainability.To enhance operational efficiency, the company has incorporated smart monitoring technologies into their marine pumps. Real-time data monitoring and predictive maintenance capabilities ensure optimal performance, reduced downtime, and cost-effective operations.[Future Prospects]With their expanded marine pumps portfolio, the company is well-positioned to cater to the rapidly growing industrial marine sector. As the demand for efficient water management, cargo handling, and cooling systems continue to rise, the company's advanced solutions are set to play a pivotal role in transforming the industry.To further support their customers, the company has bolstered its after-sales services, ensuring timely maintenance, spare parts availability, and a dedicated support team to cater to any queries or concerns. These customer-centric initiatives reinforce the company's commitment to delivering holistic and reliable solutions to clients worldwide.In conclusion, the recent expansion of industrial marine pumps by the leading pump manufacturer demonstrates their dedication to meeting the requirements of this rapidly expanding market. With innovative technologies, sustainable practices, and a commitment to customer satisfaction, the company aims to revolutionize the industrial marine industry, setting new benchmarks for efficiency, reliability, and environmental responsibility.