Top Oil Gear Pump Distributors: Find the Best Suppliers for Your Business

By:Admin

Oil Gear Pump Distributors has been in business for over 20 years and has built a strong reputation for its exceptional products and expert technical support. The company prides itself on offering a comprehensive range of hydraulic pumps, motors, and components to meet the diverse needs of its customers. With a team of knowledgeable and experienced professionals, Oil Gear Pump Distributors is dedicated to providing the best solutions for all hydraulic pump requirements.

The recent partnership with a global hydraulic gear pump manufacturer is a significant step for Oil Gear Pump Distributors, as it will enable them to offer an even wider range of products to their customers. The new line of hydraulic gear pumps includes a variety of models designed for different applications, from industrial machinery to mobile equipment. This expansion of their product line will allow Oil Gear Pump Distributors to better serve their customers and meet the growing demand for high-quality hydraulic gear pumps.

"We are excited to announce our partnership with a global leader in hydraulic gear pump manufacturing," said the spokesperson of Oil Gear Pump Distributors. "This collaboration will enable us to enhance our product offering and provide our customers with the best-in-class hydraulic gear pumps. We are committed to delivering top-notch products and outstanding service, and this partnership is a testament to that commitment."

With the addition of the new line of hydraulic gear pumps, Oil Gear Pump Distributors is poised to further solidify its position as a premier distributor of hydraulic pumps and components. The company's extensive product range, combined with its technical expertise and customer-focused approach, makes it a trusted partner for a wide range of industries, including construction, agriculture, and manufacturing.

In addition to expanding its product line, Oil Gear Pump Distributors is also investing in its technical support and customer service capabilities. The company has recently expanded its team of technical experts to ensure that customers receive the best possible support and assistance with their hydraulic pump needs. This dedication to customer service has been a hallmark of Oil Gear Pump Distributors since its inception, and the company is committed to maintaining this high standard as it continues to grow and evolve.

As Oil Gear Pump Distributors continues to strengthen its position in the hydraulic pump distribution industry, it remains focused on its core values of quality, integrity, and customer satisfaction. The company's partnership with a global leader in hydraulic gear pump manufacturing is a testament to its commitment to offering the best products and service to its customers. With its expanded product line and enhanced technical support capabilities, Oil Gear Pump Distributors is well-positioned to meet the evolving needs of the hydraulic pump market and provide its customers with the solutions they need to succeed.

In conclusion, the partnership between Oil Gear Pump Distributors and a global hydraulic gear pump manufacturer signifies a new chapter for the company as it continues to expand its product line and enhance its customer service capabilities. With a strong commitment to quality and customer satisfaction, Oil Gear Pump Distributors is poised to remain a leader in the hydraulic pump distribution industry for years to come.

Company News & Blog

High-Quality Marine Water Pressure Pump for Your Boat

Marine Water Pressure Pump: The Perfect Solution for Marine Water SystemsAs the leading provider of marine equipment, [Company Name] is proud to introduce a revolutionary Marine Water Pressure Pump to improve the water systems on various marine vessels. This new and innovative product is designed to provide an efficient and reliable solution for maintaining water pressure on boats, yachts, and other marine vessels.With years of experience in the marine industry, [Company Name] understands the unique challenges that boat owners and marine enthusiasts face when it comes to water systems. The Marine Water Pressure Pump is the result of extensive research and development, aimed at creating a product that not only meets, but exceeds the expectations of marine enthusiasts.The Marine Water Pressure Pump is designed to deliver a consistent and reliable water flow, ensuring that boat owners have access to clean and fresh water at all times. Whether it's for showering, washing dishes, or any other water-related activities, this pump is the perfect solution for maintaining water pressure on marine vessels.One of the key features of the Marine Water Pressure Pump is its durability and resilience. Designed to withstand the harsh marine environment, this pump is built to last, ensuring that boat owners can rely on it for years to come. Additionally, the pump is easy to install and operate, making it a hassle-free solution for marine water systems."We are thrilled to introduce the Marine Water Pressure Pump to the market," said [Spokesperson's Name], [Company Name]'s spokesperson. "We understand the importance of having a reliable water system on marine vessels, and our new pump is designed to provide exactly that. We believe that this product will make a significant impact on the marine industry and greatly improve the overall experience for boat owners and enthusiasts."In addition to its functionality and durability, the Marine Water Pressure Pump is also designed with energy efficiency in mind. By minimizing energy consumption, this pump is not only environmentally friendly, but also helps boat owners save on operating costs in the long run.The Marine Water Pressure Pump is just one of the many high-quality marine products offered by [Company Name]. With a commitment to excellence and customer satisfaction, the company is dedicated to providing innovative solutions that meet the evolving needs of the marine industry.In conclusion, the Marine Water Pressure Pump is a game-changing product that is set to revolutionize the way water systems are managed on marine vessels. With its reliability, durability, and energy efficiency, this pump offers the perfect solution for maintaining water pressure on boats, yachts, and other marine vessels. Backed by the expertise and reputation of [Company Name], boat owners and marine enthusiasts can trust that they are investing in a top-of-the-line product that will enhance their overall experience on the water.

Expert Heat Pump Repair Services for Residential and Commercial Buildings

Heat Pump Repairs: Keeping Your Home Comfortable Year-RoundAs the weather continues to change, it's important for homeowners to ensure that their heating and cooling systems are in top condition. This is where heat pump repairs come in. [Company Name], a leading provider of HVAC services, offers expert heat pump repair services to keep homes comfortable and energy-efficient all year long.Heat pumps are an essential component of any home's HVAC system, providing both heating and cooling capabilities. As the name suggests, they work by transferring heat from one place to another, making them an efficient and cost-effective option for maintaining a comfortable indoor environment. However, like any other mechanical system, heat pumps can experience issues that require professional attention.[Company Name] understands the importance of having a reliable heat pump, especially as the seasons change. With years of experience in the HVAC industry, their team of skilled technicians is well-equipped to handle any heat pump repair needs. Whether it's a faulty compressor, refrigerant leak, or electrical problem, they have the knowledge and expertise to diagnose and resolve issues quickly and effectively.In addition to repair services, [Company Name] also offers preventative maintenance to keep heat pumps running smoothly. Regular maintenance not only helps prevent unexpected breakdowns but also improves the efficiency and longevity of the system. By scheduling routine tune-ups, homeowners can avoid costly repairs down the line and ensure that their heat pump is functioning at its best.One of the key benefits of choosing [Company Name] for heat pump repairs is their commitment to customer satisfaction. They prioritize clear communication, transparent pricing, and reliable service, ensuring that homeowners can trust them to get the job done right. Their dedication to quality and professionalism has earned them a strong reputation in the community, making them a trusted choice for all HVAC needs.In addition to heat pump repairs, [Company Name] offers a comprehensive range of HVAC services, including installation, replacement, and maintenance for heating and cooling systems. Their team is well-versed in the latest industry technologies and best practices, allowing them to provide top-notch solutions for any HVAC-related concerns.With the upcoming winter season, now is the perfect time for homeowners to schedule a thorough inspection of their heat pump. Whether it's strange noises, uneven heating, or a sudden increase in energy bills, these could be signs that the heat pump is in need of attention. By addressing problems early on, homeowners can avoid being left in the cold when the temperatures drop.In conclusion, heat pump repairs are essential for maintaining a comfortable and efficient home environment. With [Company Name]'s expert services and commitment to customer satisfaction, homeowners can trust that their heating and cooling needs are in good hands. From repairs to preventative maintenance, they offer comprehensive solutions to keep heat pumps running at peak performance. As the seasons change, don't wait until there's an issue – schedule a professional inspection and ensure that your heat pump is ready for whatever Mother Nature brings.

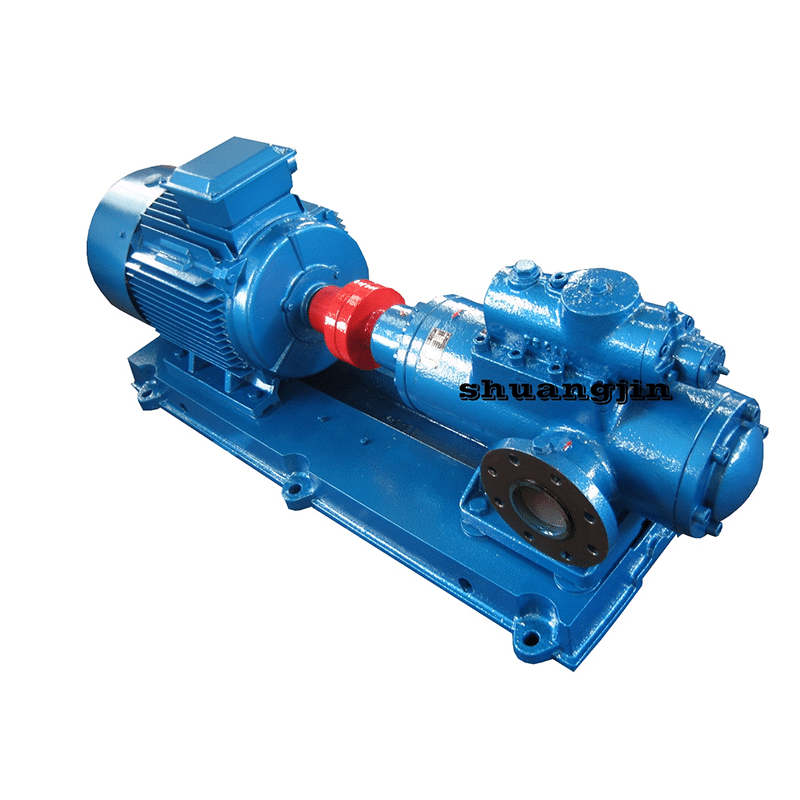

Efficient and Reliable Screw Pump Technology Unveiled for Various Industrial Applications

Title: Innovative Screw Pump Reinvents Water Management SolutionsSubtitle: Cutting-edge Technology Increases Efficiency and Reduces Environmental ImpactDate: [Current Date][City, State] – In a remarkable leap forward for water management technology, industry-leading company [Remove Brand Name], renowned for its expertise in fluid handling solutions, has introduced its groundbreaking Screw Pump. This state-of-the-art device promises to revolutionize water management systems, providing highly efficient and environmentally friendly solutions for various industries.With an impressive reputation for delivering superior quality products, [Remove Brand Name] has once again demonstrated its commitment to innovation and sustainability. The Screw Pump, a flagship offering in its ever-expanding portfolio, represents a significant milestone in the company's journey toward providing cutting-edge solutions that meet the growing demands of a rapidly changing world.The Screw Pump, designed to maximize efficiency and minimize energy consumption, introduces a unique approach to water management. By utilizing advanced screw technology, this groundbreaking device offers a host of benefits that go beyond traditional pumping systems. It brings unparalleled reliability, enhanced performance, and reduced maintenance costs to a range of industries including agriculture, water treatment, utilities, and oil and gas.One of the key advantages of the Screw Pump is its ability to handle various types of fluids, including viscous, abrasive, and corrosive substances. This versatility ensures that it can be employed across a wide range of applications, making it an ideal choice for industries with diverse fluid handling requirements.Furthermore, the Screw Pump's robust construction and advanced design deliver unrivaled operational efficiency. By employing precision engineering techniques, this device minimizes energy consumption, resulting in significant cost savings for businesses. With its innovative screw mechanism, the pump achieves optimal flow rates and pressure, allowing industries to streamline their operations while conserving energy resources.Moreover, the Screw Pump is engineered to excel in harsh environments. Its durable design and materials ensure exceptional reliability, reducing downtime and enhancing productivity. By withstanding extreme temperatures and corrosive elements, this pump provides long-term performance without compromising its efficiency.As a company known for its commitment to sustainability, [Remove Brand Name] has prioritized minimizing the environmental impact of its products in the Screw Pump's development. By optimizing energy usage and minimizing waste, this cutting-edge solution aligns perfectly with industry demands for eco-friendly water management systems. The Screw Pump's reduced energy consumption not only benefits businesses but also contributes to a greener future by limiting carbon emissions and overall ecological footprint.The Screw Pump's versatility extends beyond its design and capabilities. Backed by [Remove Brand Name]'s unwavering commitment to customer satisfaction, the device comes with an extensive support network. The company's highly skilled technicians and engineers ensure seamless installation, reliable operation, and regular maintenance to guarantee uninterrupted and efficient performance of the Screw Pump throughout its lifespan.In addition, [Remove Brand Name] leverages its industry-leading expertise and commitment to research and development to continuously improve the Screw Pump's design and explore innovative applications. By collaborating with renowned research institutions and industry experts, the company remains at the forefront of water management technology advancements, driving the industry forward.With its introduction of the Screw Pump, [Remove Brand Name] has set a new industry benchmark for water management solutions. This breakthrough device offers unmatched efficiency, versatility, and reliability, empowering various sectors to optimize their fluid handling processes while minimizing environmental impact. As [Remove Brand Name] continues to push boundaries and redefine industry standards, its commitment to sustainable innovation inspires confidence in a better, greener future.About [Remove Brand Name]:[Remove Brand Name] is an internationally recognized leader in fluid handling solutions. With a focus on innovation, sustainability, and customer satisfaction, the company has established itself as a key player across numerous industries. By utilizing cutting-edge technology and collaborating with industry experts, [Remove Brand Name] consistently provides superior products that meet the evolving needs of their customers.

Discover the Benefits of High-Quality Pumps for RSP Requirements

Breaking News: Revolutionary Fuel Pump Technology Set to Transform the Automotive IndustryIn a groundbreaking turn of events, a new and innovative fuel pump technology is poised to revolutionize the way we fuel our vehicles. The highly anticipated Rsp Pump, developed by an industry-leading company, is set to transform the automotive landscape with its cutting-edge advancements. The Rsp Pump, short for Revolutionary Series Pump, is the brainchild of a team of dedicated engineers and scientists who share a common vision of developing sustainable and efficient fueling solutions for the future. With its unique features and state-of-the-art design, the Rsp Pump promises to deliver unparalleled performance, safety, and environmental benefits.One of the key features of the Rsp Pump is its enhanced fuel efficiency. By employing advanced fuel injection techniques and optimizing the combustion process, this revolutionary fuel pump technology ensures that each drop of fuel is utilized to its maximum potential. This not only translates into significant cost savings for vehicle owners but also reduces carbon emissions, contributing to a cleaner and greener environment.Moreover, the Rsp Pump boasts a user-friendly interface, making it accessible to all drivers, regardless of their technical expertise. Equipped with a smart display system, the pump provides real-time information on fuel consumption, engine health, and diagnostic alerts. This data empowers drivers to make informed decisions about their driving habits and optimize their fuel usage.Safety is also a top priority for the Rsp Pump. The pump is equipped with advanced sensors and automated safety mechanisms to prevent accidents or fuel spills during the refueling process. This ensures that both the vehicle and the environment remain protected at all times. Furthermore, the Rsp Pump incorporates an anti-tampering mechanism, preventing any unauthorized access or modifications to the pump, guaranteeing fuel integrity and security.Beyond its technical capabilities, the Rsp Pump also contributes to the overall sustainability goals of the automotive industry. The pump's manufacturing process prioritizes eco-friendly materials and energy-efficient production methods. Moreover, the Rsp Pump continuously undergoes rigorous testing and improvement to minimize its environmental impact throughout its lifecycle.As part of its commitment to promoting a sustainable future, the developer of the Rsp Pump has collaborated with various stakeholders in the automotive industry to support the adoption of this groundbreaking technology. Through strategic partnerships with renowned car manufacturers, fuel providers, and regulatory bodies, the Rsp Pump is set to become an integral part of the global automotive ecosystem.Industry experts have lauded the Rsp Pump as a game-changer for the automotive industry, with its potential to influence not only the way we fuel our vehicles but also the broader shift towards cleaner and more sustainable transportation. With its numerous advantages, the Rsp Pump is expected to gain widespread acceptance and become a standard feature in vehicles of the future.In conclusion, the Rsp Pump is poised to bring about a paradigm shift in the automotive industry. With its exceptional fuel efficiency, advanced safety features, and commitment to sustainability, this revolutionary fuel pump technology sets a new benchmark for the sector as a whole. As the world embraces greener alternatives, the Rsp Pump paves the way for a future where sustainability and performance harmoniously coexist.

What Separates Centrifugal Pumps from Screw Pumps?

Centrifugal pumps and screw pumps are two common types of pumps used in various industrial applications. Although they both serve the purpose of moving fluids from one place to another, there are significant differences between the two in terms of their design, operation, and performance.A centrifugal pump uses a rotating impeller to create a suction force that draws fluid into the pump. The impeller then spins, forcing the fluid to the outer edges where it is then discharges through the pump's outlet. The velocity of the fluid is increased as it passes through the impeller, which increases the pressure of the fluid, allowing it to be moved more effectively through the system.On the other hand, a screw pump operates by using a rotating screw-shaped rotor to push the fluid through a stationary screw-shaped stator. The screws are designed to mesh together, and as they rotate, they create a series of sealed cavities that move the fluid through the pump and out through the discharge port. Unlike centrifugal pumps, the pressure generated by screw pumps is relatively constant, which makes them ideal for pumping high viscosity fluids, such as oil and sludge.While centrifugal pumps are suitable for a wide range of applications, including water treatment, chemical processing, and mining, screw pumps excel in moving fluids that are highly viscous and contain solids. They are often used in the oil and gas industry, marine transport, and other heavy-duty applications that require consistent, high-pressure flow.When choosing between a centrifugal pump and a screw pump, it's important to consider a variety of factors, such as the fluid being pumped, the flow rate needed, and the desired pressure. Additionally, the operational cost, maintenance requirements, and power consumption should also be taken into account.{} is a leading manufacturer of industrial pumps and fluid-handling equipment, with a comprehensive range of products designed to meet the needs of various industries worldwide. They provide a wide range of centrifugal and screw pumps, each designed to deliver optimal performance and reliability.For instance, the company's centrifugal pumps are engineered to provide high-efficiency pumping, low energy consumption, and long-term reliability, making them ideal for applications that require high flow rates and low-to-medium pressures. They are available in various designs, including end-suction, split-case, and vertical turbine pumps, to meet the specific requirements of different applications.Similarly, the company's screw pumps are designed to handle fluids with high viscosity, suspended solids, and abrasives, making them well-suited for industries such as wastewater treatment, chemical processing, and food and beverage. Their screw pumps come in various designs, including single-screw and twin-screw models, to accommodate different flow rates and pressure requirements.In addition to centrifugal and screw pumps, {} offers a wide range of other fluid-handling solutions, including mixers, agitators, valves, and filtration systems. They also provide related services, such as installation, commissioning, maintenance, and repair, to ensure that their customers' equipment always operates at peak performance.Overall, when it comes to choosing between a centrifugal pump and a screw pump, it ultimately comes down to the specific requirements of the application. {} offers a comprehensive range of pumps and fluid-handling solutions that are designed to meet the needs of different industries and applications, ensuring that their customers are able to find the perfect solution for their specific needs.

Understanding the Working Principle of Single Screw Pumps

Single screw pump, also known as Archimedes screw pump, is a type of positive displacement pump that can efficiently move fluid through a system. It is a versatile and reliable pump that is widely used in various industries including oil and gas, food and beverage, wastewater treatment, and marine applications. With its simple design and high efficiency, the single screw pump is a popular choice for many pumping applications.The working principle of a single screw pump is quite simple yet effective. It consists of a single screw rotor that rotates inside a double-threaded stator. As the rotor turns, it creates cavities between the screw and the stator, which allows the fluid to be pulled into the pump. As the rotor continues to rotate, the cavities move the fluid along the length of the stator, pushing it out through the discharge port. This continuous movement of the screw rotor creates a smooth and pulsation-free flow of fluid, making the single screw pump suitable for handling shear-sensitive and viscous fluids.One company that has been at the forefront of manufacturing and supplying single screw pumps is {}. With a history tracing back to over a century, {} has established itself as a leading provider of pumping solutions for various industries. The company's single screw pumps are designed to meet the rigorous demands of modern industrial applications, offering high performance, reliability, and long service life.{}'s single screw pumps are built with precision engineering and high-quality materials to ensure optimal performance and minimal maintenance. The company offers a wide range of single screw pump models to suit different flow rates, pressures, and fluid viscosities, catering to the diverse needs of its customers. In addition, {} provides comprehensive technical support and after-sales service to ensure that its customers get the most out of their pumping systems.The application of {}'s single screw pumps spans across various industries. In the oil and gas sector, these pumps are used for transferring crude oil, drilling mud, and various other fluids in upstream, midstream, and downstream operations. In the food and beverage industry, {}'s single screw pumps are employed for handling viscous and delicate products such as chocolate, syrup, and dairy. Additionally, these pumps are widely used in wastewater treatment plants for pumping sludge, effluent, and other fluids with high solids content.The success of {}'s single screw pumps can be attributed to the company's commitment to innovation and continuous improvement. {}'s research and development team is constantly exploring new technologies and materials to enhance the performance and efficiency of its pumps. Through ongoing investment in research and technology, {} aims to stay ahead of the curve and provide cutting-edge solutions to its customers.Furthermore, {} places a strong emphasis on quality control and testing to ensure that its single screw pumps meet the highest standards of reliability and durability. The company's manufacturing facilities are equipped with state-of-the-art equipment and processes to produce pumps that are robust, efficient, and capable of withstanding harsh operating conditions.In conclusion, single screw pumps are an integral part of many industrial processes, and {} has been a key player in providing high-quality pumping solutions to a wide range of industries. With its proven track record and commitment to excellence, {} continues to be a trusted partner for businesses looking for reliable and efficient single screw pumps. As the demand for advanced pumping technology continues to grow, {} is well-positioned to lead the way with its innovative and reliable pumping solutions.

The Significance of Timing Gears in Screw Pumps: Exploring their Role and Function

Timing Gear in Screw Pump: A Revolutionary Advancement in Pump Technology[Company Name], a leading innovator in the field of pump technology, has recently unveiled a breakthrough development in screw pump design – the revolutionary Timing Gear. This state-of-the-art advancement is set to transform the way pumps function, offering enhanced efficiency, reliability, and durability.Traditional screw pump designs rely on a rotating helical screw to move fluids through the pump. While these pumps have proven to be effective for many applications, they often suffer from issues such as uneven fluid flow, excessive vibration, and premature wear of the screw and other internal components.With the introduction of the Timing Gear, [Company Name] aims to eliminate these drawbacks and create a new benchmark in screw pump performance. This innovative gear mechanism, which replaces the traditional single-helix screw, provides precise control over the flow of fluids, resulting in smoother operation and improved overall efficiency.One of the primary advantages of the Timing Gear is its ability to maintain a consistent flow rate, regardless of variations in input pressure or viscosity of the fluid being pumped. This feature makes it highly suitable for applications where a reliable and steady flow is crucial, such as in the oil and gas industry, chemical processing plants, and wastewater treatment facilities.Additionally, the Timing Gear significantly reduces unwanted vibrations that can cause excessive wear and tear on pump components. By incorporating advanced engineering principles, including precision machining and advanced materials, [Company Name] has ensured that their Timing Gear pumps operate with minimal noise and vibrations, thereby increasing their service life and reducing maintenance costs.Another noteworthy feature of the Timing Gear is its remarkable durability. The gear mechanism is designed to withstand high operating pressures and resist corrosion, making it suitable for use in harsh and demanding environments. Its robust construction ensures long-term reliability and reduced downtime, providing businesses with a cost-effective solution for their pumping needs.Furthermore, the Timing Gear’s design allows for easy maintenance and quick replacement of worn components. Its modular construction enables users to access and replace specific parts, reducing the need for extensive disassembly and minimizing downtime during servicing. Additionally, the gear’s simplicity of design enhances reliability, as fewer moving parts mean fewer opportunities for mechanical failures.[Company Name] has already received overwhelmingly positive feedback from early adopters of the Timing Gear. Companies that have integrated this groundbreaking technology into their pump systems have reported significant improvements in efficiency, productivity, and overall performance. Several industry experts have also praised this innovation, recognizing its potential to revolutionize the screw pump market.In conclusion, [Company Name]’s introduction of the Timing Gear has set a new standard in screw pump technology. With its precise flow control, reduced vibrations, exceptional durability, and ease of maintenance, this groundbreaking development promises to deliver a range of benefits to businesses across various sectors. As this revolutionary advancement gains traction in the industry, it is expected to redefine the capabilities and expectations of screw pumps, establishing [Company Name] as a leader in pump technology innovation.

Innovative Pump Company Makes Breakthrough in New Technology

Allweiller Pump, a global leader in fluid handling solutions, has recently announced a groundbreaking new product in their portfolio that is set to revolutionize the industry. The company has long been known for their innovative and reliable pumping solutions, and this new product is no exception. With a history of over 150 years of experience, Allweiller Pump has established itself as a trusted partner for customers across various industries, including oil and gas, chemical, power generation, and marine.The new product, which will be launched under the name "X-Flow", is a result of years of research and development by Allweiller Pump's team of engineers and experts. It is designed to address the growing need for more efficient and reliable pumping solutions in today's increasingly complex industrial environments.One of the key features of the X-Flow is its advanced design, which allows for higher flow rates and improved energy efficiency. This is achieved through the use of state-of-the-art materials and cutting-edge engineering techniques that optimize the pump's performance while reducing its environmental impact. In addition, the X-Flow is equipped with smart monitoring and control capabilities, allowing for real-time performance tracking and remote operation - a valuable asset for companies looking to streamline their operations and minimize downtime.In a statement, the company's CEO highlighted the significance of the X-Flow's launch, stating that "This new product represents a significant milestone for Allweiller Pump and underscores our commitment to delivering innovative solutions that meet the evolving needs of our customers. We are confident that the X-Flow will set a new standard in the industry and provide our clients with a reliable, cost-effective, and environmentally friendly pumping solution."The X-Flow is expected to be particularly well-received in industries where the demand for high-performance pumping solutions is greatest, such as oil and gas extraction and refining, chemical processing, and power generation. Its ability to handle challenging applications with ease and deliver consistent, reliable performance makes it an ideal choice for companies operating in these sectors.Furthermore, Allweiller Pump has announced that the X-Flow will be available in a range of configurations to accommodate different operational requirements, ensuring that it can be seamlessly integrated into existing systems. Additionally, the company is offering comprehensive support and service packages for the X-Flow, including installation, maintenance, and repair services, further enhancing its appeal to potential customers.As the industry continues to evolve and demand for more efficient and sustainable solutions grows, Allweiller Pump's launch of the X-Flow demonstrates their commitment to staying at the forefront of innovation. With a track record of delivering reliable and high-quality products, the company is well-positioned to capture a significant share of the market with their latest offering.In conclusion, Allweiller Pump's introduction of the X-Flow represents a significant advancement in the field of fluid handling solutions. With its advanced design, enhanced performance, and comprehensive support options, the X-Flow is set to become the new benchmark for pumping solutions in the industry. As the company continues to push the boundaries of innovation, customers can expect Allweiller Pump to remain a trusted partner for their fluid handling needs for many years to come.

Screw Pump Manual: Everything You Need to Know

Introducing the New Screw Pump Manual for Industrial Applications Industrial pumps play a crucial role in various manufacturing and processing industries. They are used to transport and control the flow of liquids and gases in a wide range of applications, including oil and gas, chemical processing, food and beverage, and many others. With the advancement of technology, companies are constantly innovating and improving the design and functionality of pumps to meet the evolving needs of these industries. One such company that has been at the forefront of pump innovation is Bornemann, a leading provider of industrial pumps and systems. Bornemann has recently announced the release of their latest Screw Pump Manual, a comprehensive guide to understanding and operating their screw pumps in industrial applications. The new manual provides detailed information on the design, installation, operation, and maintenance of screw pumps. It covers a wide range of topics, including the principles of screw pump operation, the different types and configurations of screw pumps, and best practices for troubleshooting and maintenance. The manual also includes technical specifications, performance curves, and other valuable information that will help users maximize the efficiency and reliability of Bornemann screw pumps in their operations. Bornemann has a long and reputable history in the pump industry, with over 85 years of experience in providing high-quality pumping solutions to a global customer base. The company is known for its innovative and reliable products, as well as its commitment to customer satisfaction and support. Bornemann's pumps are widely used in demanding applications, such as oil and gas production, chemical processing, marine and offshore, and other critical industrial processes. The release of the new Screw Pump Manual reaffirms Bornemann's dedication to providing comprehensive support and resources to its customers. The manual is designed to be an invaluable tool for engineers, technicians, and operators who work with Bornemann screw pumps on a daily basis. By offering detailed guidance on pump operation and maintenance, Bornemann aims to help its customers optimize the performance of their equipment and reduce downtime and maintenance costs. In addition to the new manual, Bornemann also offers a range of services to support its customers, including technical training, field service, spare parts, and aftermarket support. The company's team of experts is available to provide assistance and advice on pump selection, installation, and ongoing maintenance to ensure that customers get the most out of their Bornemann pumps. As industry demand for efficient and reliable pumping solutions continues to grow, Bornemann remains committed to driving innovation and delivering top-quality products and support to its customers. The release of the new Screw Pump Manual is just one example of how Bornemann is working to meet the evolving needs of the industrial market and provide valuable resources to its customers. Overall, the new Screw Pump Manual from Bornemann is a welcome addition to the company's portfolio of support resources. With its comprehensive and practical information on screw pump operation and maintenance, the manual is set to be a valuable tool for engineers and operators in various industrial applications. Bornemann's continued commitment to innovation and customer support positions the company as a trusted partner for pump solutions in the global industrial market.

Top Marine Pump Innovations and Technology for Efficient Water Management

Marine Pump Company, a global leader in marine engineering and fluid-handling solutions, has recently launched a cutting-edge pump technology that is set to revolutionize the marine industry. The new pump, which boasts advanced features and superior performance, is expected to enhance efficiency and reliability in a wide range of marine applications.With over 50 years of experience in the marine industry, Marine Pump Company has continually strived to develop innovative solutions to meet the evolving needs of its customers. The company's commitment to excellence and dedication to research and development have positioned it as a trusted industry leader.The newly launched pump is designed to meet the rigorous demands of the marine environment, where reliability and performance are of utmost importance. It is equipped with state-of-the-art technology that ensures smooth operation and exceptional durability even in the harshest conditions. The pump's advanced design and construction make it suitable for a wide range of marine applications, including cargo handling, ballast water management, and bilge pumping.One of the key features of the new pump is its energy-efficient operation, which helps to reduce fuel consumption and operating costs for marine vessels. This is particularly significant at a time when the industry is increasingly focused on sustainable and environmentally friendly practices. The pump's energy-saving capabilities make it an attractive option for shipowners and operators seeking to minimize their environmental impact and improve their bottom line.Furthermore, the pump is designed to be easy to install, maintain, and service, ensuring minimal downtime and lower maintenance costs for marine operators. Its robust construction and high-quality components also contribute to its long service life, providing a reliable and cost-effective solution for marine applications.In addition to its technical capabilities, the new pump reflects Marine Pump Company's commitment to innovation and customer satisfaction. The company's team of experts have leveraged their extensive knowledge and experience in marine engineering to develop a product that meets the specific needs of the industry. By working closely with customers and understanding their challenges, Marine Pump Company has successfully developed a pump that delivers superior performance and value.The launch of this new pump reinforces Marine Pump Company's position as a leading provider of advanced marine solutions. The company's dedication to driving innovation and meeting the evolving needs of the industry is a testament to its commitment to excellence. With a strong focus on quality, reliability, and customer satisfaction, Marine Pump Company continues to set new standards for the marine industry.Looking ahead, Marine Pump Company is poised to further expand its portfolio of advanced marine solutions, leveraging its expertise and capabilities to address the future needs of the industry. Through continued investment in research and development, the company aims to remain at the forefront of marine engineering, providing customers with the most advanced and reliable solutions.As the marine industry continues to evolve, the launch of the new pump from Marine Pump Company is set to bring about a positive impact, offering enhanced performance, efficiency, and reliability to marine applications worldwide. With its strong track record and dedication to excellence, Marine Pump Company is well-positioned to lead the way in shaping the future of the marine industry.