Twin Screw Pump: New Advancements in Pump Technology

By:Admin

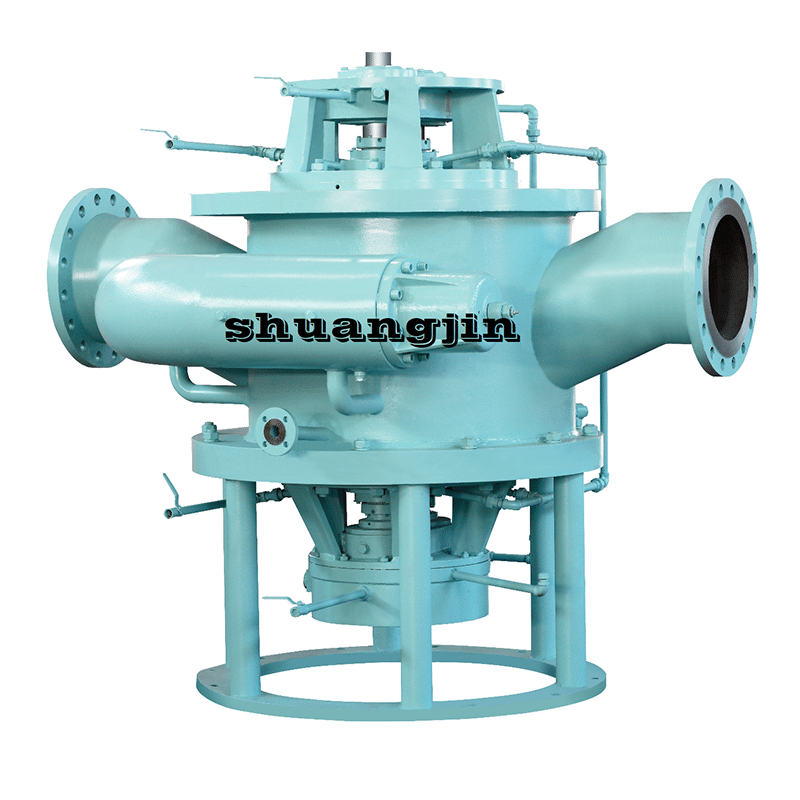

The global pump industry is constantly evolving with new and innovative technologies that aim to improve efficiency, reliability, and performance. One of the latest advancements in the world of pumps is the Axiflow Twin Screw Pump, which has been making waves in the industry for its superior design and capabilities.

This revolutionary pump technology has been created by a leading pump manufacturer that has a long-standing reputation for engineering excellence and product innovation. With a strong focus on research and development, the company has been able to harness the power of twin screw pump technology and bring to market a product that surpasses all performance expectations.

The Axiflow Twin Screw Pump is a positive displacement pump that is designed to handle a wide range of applications across various industries. It is particularly well-suited for applications that require gentle pumping action, low pulsation, and high efficiency. The pump's unique design features a set of intermeshing screws that rotate within a cylindrical cavity, creating a smooth and continuous flow of liquid with minimal turbulence.

One of the key advantages of the Axiflow Twin Screw Pump is its ability to handle high-viscosity fluids with ease. The pump is capable of handling fluids with viscosities ranging from thin to extremely viscous, making it a versatile solution for a wide range of pumping needs. This capability is especially valuable in industries such as food and beverage, pharmaceuticals, chemicals, and oil and gas, where the handling of viscous fluids is a common requirement.

In addition to its excellent performance with high-viscosity fluids, the Axiflow Twin Screw Pump is also known for its exceptional suction capabilities. The pump is able to handle low inlet pressures and is designed to perform reliably even in challenging suction conditions. This is particularly advantageous for applications where the pump is required to draw fluids from tanks, vessels, or other sources with limited pressure.

Furthermore, the Axiflow Twin Screw Pump is engineered to deliver consistent and precise flow rates, making it an ideal choice for metering and dosing applications. The pump's ability to maintain accurate flow rates over a wide range of operating conditions ensures that processes can be controlled with precision, leading to better product quality and reduced waste.

The innovative design of the Axiflow Twin Screw Pump also prioritizes ease of maintenance and reliability. The pump is constructed with robust materials and features a simple yet efficient design that minimizes the risk of mechanical failure. Additionally, the pump's modular construction allows for easy access to internal components, simplifying maintenance and reducing downtime.

The successful introduction of the Axiflow Twin Screw Pump is a testament to the company's commitment to pushing the boundaries of pump technology and delivering solutions that meet the evolving needs of its customers. With a strong focus on research, development, and customer collaboration, the company has been able to bring to market a pump that sets a new standard for performance, efficiency, and reliability.

As the global pump industry continues to evolve, the introduction of innovative technologies such as the Axiflow Twin Screw Pump demonstrates the potential to drive significant improvements in process efficiency and productivity. With its exceptional performance characteristics and versatile capabilities, this groundbreaking pump technology is poised to make a lasting impact across a wide range of industries, shaping the future of fluid handling and pumping solutions.

Company News & Blog

Essential Tips for Maintaining Your Screw Pump

Screw Pump Maintenance: Keeping the Flow SmoothScrew pumps are indispensable in various industrial applications, including oil and gas, pulp and paper, chemical processing, and marine industries. These pumps play a critical role in transferring liquids or semi-solids efficiently. However, to ensure their reliable performance, routine maintenance is crucial.{Company Name} is a leading provider of screw pump maintenance services, offering comprehensive solutions to keep the flow smooth for its clients. With a dedicated team of experienced technicians and a commitment to quality, {Company Name} has built a reputation for excellence in the industry.As a specialist in screw pump maintenance, {Company Name} understands the importance of regular upkeep to prevent costly downtime and equipment failures. The company offers a range of maintenance services designed to prolong the life of screw pumps and optimize their performance.One of the key maintenance tasks for screw pumps is the inspection and replacement of wearing parts. Over time, the screws, shafts, and bearings in a screw pump can experience wear and tear, leading to decreased efficiency and potential breakdowns. {Company Name} provides thorough inspections to identify any worn or damaged parts and offers timely replacements to ensure the pump operates at peak performance.In addition to parts replacement, lubrication is another essential aspect of screw pump maintenance. Proper lubrication is critical for reducing friction and heat generation within the pump, which can significantly impact its efficiency and longevity. {Company Name} uses high-quality lubricants and follows manufacturer recommendations to ensure that screw pumps are adequately lubricated for optimal operation.Furthermore, {Company Name} provides alignment and vibration analysis services to identify any potential issues that could affect the performance of screw pumps. Misalignment or excessive vibration can lead to premature wear and component damage, so the company's comprehensive maintenance approach includes proactive measures to address these concerns.{Company Name} also offers troubleshooting and repair services for screw pumps experiencing operational issues. With their depth of expertise, their technicians can quickly diagnose problems and implement effective solutions to get the pump back up and running.In addition to routine maintenance, {Company Name} emphasizes the importance of proactive maintenance planning for screw pumps. By developing customized maintenance schedules based on the specific operating conditions and demands of each client, the company helps to minimize the risk of unexpected failures and costly repairs.As part of their commitment to excellence, {Company Name} also provides training and support to their clients' maintenance and operations teams. By sharing their knowledge and best practices, they empower their clients to take a proactive approach to screw pump maintenance, ultimately extending the lifespan of their equipment and optimizing their investment.With a track record of delivering reliable and cost-effective maintenance solutions, {Company Name} has earned the trust of a diverse range of industries that rely on screw pumps for their operations. Whether it's ensuring the smooth flow of oil and gas, the efficient transfer of chemicals, or the reliable dewatering of pulp and paper products, the company's expertise in screw pump maintenance has made them a preferred partner for many businesses.In conclusion, screw pump maintenance is essential for sustaining the performance of these critical pieces of equipment. {Company Name} stands out as a trusted provider of comprehensive screw pump maintenance services, offering a holistic approach to ensure that their clients' screw pumps operate smoothly and efficiently. With their commitment to quality, expertise, and customer satisfaction, {Company Name} continues to be a leader in the field of screw pump maintenance.

Complete Guide to Oil Pump Lubrication and Maintenance for Enhanced Performance

Oil Pump Lubrication, a leading provider of lubrication systems for the oil and gas industry, is pleased to announce the launch of their latest innovative product designed to improve the performance and longevity of oil pumps.With over 20 years of experience in the industry, Oil Pump Lubrication has established itself as a trusted and reliable source for high-quality lubrication systems. The company prides itself on its commitment to research and development, continually striving to develop new and improved products to meet the evolving needs of the oil and gas sector.The latest product from Oil Pump Lubrication is the result of years of testing and refinement, and it promises to deliver significant benefits to oil pump operators. The system has been specifically designed to provide superior lubrication to oil pumps, ensuring smooth and efficient operation while reducing the risk of wear and tear.One of the key features of the new system is its ability to deliver the precise amount of lubricant needed for optimal pump performance. This not only improves the overall efficiency of the pump but also helps to extend its lifespan, reducing the need for costly maintenance and replacement.In addition to its advanced lubrication capabilities, the new system from Oil Pump Lubrication is also designed with user-friendliness in mind. The system is easy to install and requires minimal maintenance, making it an ideal solution for oil pump operators looking to streamline their operations and reduce downtime.Commenting on the launch of the new product, a spokesperson for Oil Pump Lubrication said, "We are thrilled to introduce our latest innovation to the market. Our team has worked tirelessly to develop a product that not only meets but exceeds the needs of oil pump operators. We are confident that this new system will deliver tangible benefits to our customers, helping them to improve the performance and efficiency of their oil pumps while reducing maintenance costs."The launch of the new product comes at a time when the oil and gas industry is facing increased pressure to improve operational efficiency and reduce costs. By offering a solution that addresses these challenges head-on, Oil Pump Lubrication is once again demonstrating its commitment to driving innovation in the sector.As the company continues to expand its product offerings and grow its presence in the market, Oil Pump Lubrication remains dedicated to upholding its reputation for delivering high-quality, reliable solutions to oil and gas operators. With a focus on harnessing the latest technologies and leveraging its industry expertise, the company is well-positioned to continue leading the way in lubrication systems for the oil and gas industry.In conclusion, the launch of the new product from Oil Pump Lubrication marks an exciting development for the oil and gas sector. With its advanced lubrication capabilities and user-friendly design, the system promises to deliver real benefits to oil pump operators, helping them to improve performance, reduce maintenance costs, and enhance overall operational efficiency. As Oil Pump Lubrication continues to push the boundaries of innovation, the company is poised to remain a key player in the industry for years to come.

Efficient Lube Oil System for Smooth Pump Operations

Title: Cutting-Edge and Reliable Lube Oil System for Pumps Revolutionizes the IndustryIntroduction (100 words):The rapidly growing industrial sector demands high-performance machinery that can operate optimally while minimizing downtime. To cater to this need, an innovative and pioneering engineering company has developed a state-of-the-art Lube Oil System for Pumps. This revolutionary system is designed to enhance the efficiency, reliability, and longevity of pumps in various industries, facilitating increased productivity and reduced maintenance costs. Capitalizing on advanced technology and unparalleled expertise, the pioneering company continues to redefine the standards of pump lubrication systems, catering to diverse industry needs worldwide.1. Superior Technology and Unmatched Performance (150 words):The Lube Oil System for Pumps represents a paradigm shift in the field of pump lubrication. Leveraging cutting-edge technology, this system ensures smoother pump operations, extending equipment life considerably. By addressing common issues such as overheating, leaks, and inefficient lubrication, the system enhances overall pump performance and reduces the risk of catastrophic failure.By utilizing precision-engineered components, the Lube Oil System guarantees an efficient and consistent lubrication process, providing optimal operational parameters. This results in reduced friction, improved energy efficiency, and increased service intervals, saving businesses significant costs on maintenance, repair, and replacement.Furthermore, the system's advanced filtration system removes impurities and contaminants, preventing abrasive particles from causing damage and ensuring prolonged pump lifespan. With its user-friendly design and intuitive interface, the system is easily integrated into existing infrastructure, catering to a wide range of pump sizes and types.2. Protection against Contamination and Corrosion (150 words):The Lube Oil System for Pumps places utmost emphasis on safeguarding the pumps against contamination and corrosion, which are major contributors to equipment malfunctions. By employing cutting-edge technologies such as corrosion inhibitors, the system effectively combats the damaging effects of corrosive substances, including water content typically found in lubricants.Furthermore, strategically positioned sensors and monitoring devices ensure early detection of potential pump malfunctions. These intelligent sensors continuously monitor vital parameters such as temperature, pressure, and flow rates, instantly alerting operators in case of any irregularities. Such proactive measures not only minimize unplanned shutdowns but also enable predictive maintenance, preventing costly equipment failures and optimizing operational efficiency.3. Customizable Solutions for Specific Industry Needs (150 words):Recognizing the diversity of industrial requirements, the Lube Oil System for Pumps offers a range of customizable solutions tailored to specific industry needs. Whether it is heavy-duty pumps utilized in the oil and gas industry, high-pressure pumps in the manufacturing sector, or industrial water pumps, the system ensures optimal lubrication and protection for pumps operating under extreme conditions.Moreover, this versatile system can be seamlessly integrated into both new installations and existing setups, offering a cost-effective solution for businesses across various sectors. The company's technical experts work closely with clients to understand their unique requirements, providing personalized solutions that align with their operational guidelines, regulatory requirements, and sustainability goals.4. Sustainability and Environmental Responsibility (150 words):The Lube Oil System for Pumps incorporates sustainable practices and responsible environmental management into its design. The system optimizes lubricant consumption, reducing waste and minimizing the carbon footprint associated with replacing lubricants frequently.Additionally, the advanced filtration system efficiently removes impurities and contaminants, reducing the ecological impact and promoting cleaner, greener operations. By extending the lifespan of pumps, the system also helps reduce waste generated from premature pump replacements.Furthermore, the system's energy-efficient design enhances overall plant efficiency, contributing to reduced energy consumption and promoting sustainable manufacturing practices.Conclusion (100 words):The groundbreaking Lube Oil System for Pumps ushers in a new era of reliability, performance, and sustainability in the pump lubrication domain. Its cutting-edge technology and customizable solutions cater to the diverse needs of industries worldwide, minimizing operational risks, optimizing production, and reducing maintenance costs. The company's unwavering commitment to delivering superior products and services continues to revolutionize the industry, ensuring a seamless integration of their systems into all types of pump installations. With an unblemished track record and a customer-centric approach, the company stands at the forefront of the pump lubrication sector, providing innovative solutions that set new benchmarks for excellence.

Essential Check Valve for Well Pump: A Key Component for Smooth Pump Operation

Title: Advanced Check Valve for Well Pump Revolutionizing Water Management SystemsIntroduction:The use of reliable and efficient check valves in well pumps is crucial for the effective management of water resources. Among the leading pioneers in this domain, a renowned company has emerged with its groundbreaking check valve technology, poised to revolutionize water management systems. With stringent quality standards and a commitment to innovation, this company aims to improve the reliability and performance of well pumps, ensuring a sustainable water supply for communities around the globe.(Company Name), A Driving Force in Water Management Solutions:With years of expertise in the field, (Company Name) has garnered a reputation as a leading manufacturer of high-quality check valves and related water management solutions. From residential to industrial applications, their product range caters to the diverse needs of customers worldwide. Equipped with state-of-the-art facilities and an experienced team of engineers, the company is driven by a mission to deliver robust, sustainable, and innovative solutions to enhance water management practices.Check Valve for Well Pump: A Game-Changing Technology:The latest breakthrough from (Company Name) is their cutting-edge check valve, designed specifically for well pumps. Engineered with advanced features, this device offers unparalleled reliability, efficiency, and longevity. The check valve's unique design and construction make it highly resistant to corrosion, ensuring consistent performance even in the harshest environments. Its superior sealing capability prevents backflow, reducing the risk of water contamination and promoting healthier water resources.Key Features and Benefits:1. Durability: Constructed from high-quality materials, the check valve guarantees exceptional durability, extending the lifespan of well pumps and reducing maintenance costs.2. Corrosion Resistance: The use of corrosion-resistant materials ensures the longevity of the valve, protecting it from harmful elements and maintaining optimal performance.3. Flawless Operation: The advanced design promotes smooth and stable water flow, preventing water hammer and reducing the risk of system failures.4. Easy Installation: The valve's user-friendly design simplifies installation, minimizing downtime and ensuring hassle-free integration with existing well pump systems.5. Energy Efficiency: With its streamlined design, the check valve optimizes energy consumption by reducing unnecessary pressure fluctuations, contributing to energy savings and lower operating costs.Environmental Sustainability and Social Responsibility:Addressing the global need for sustainable water management, (Company Name) adheres to environmentally friendly practices throughout their manufacturing processes. They prioritize the use of eco-friendly materials, minimizing the impact on natural resources. Furthermore, their dedication to social responsibility extends to leveraging innovative technologies that support water conservation efforts and improving the overall well-being of communities worldwide.Partnership with Global Water Organizations:Recognizing the importance of collaboration in water resource management, (Company Name) actively partners with global water organizations to promote knowledge-sharing, research, and innovation. By actively participating in industry conferences, workshops, and seminars, they contribute to shaping the future of sustainable water management practices.Conclusion:The check valve from (Company Name) represents a significant advancement in the field of well pump technology, offering enhanced performance, durability, and sustainability. By incorporating this state-of-the-art valve into water management systems, communities can achieve improved efficiency, reduced energy consumption, and increased reliability. (Company Name)'s commitment to innovation and social responsibility is set to reshape the landscape of water management, facilitating a sustainable future for generations to come.

Innovative Screw Pump: Revolutionizing Pumping Technology

**Title: Innovative Screw Pump Revolutionizes Industrial Fluid Handling***Subheading: Company XYZ introduces a groundbreaking screw pump enhancing operational efficiency in diverse industries*Date: [Insert Date][Location] - Industry-leading company XYZ has devised a remarkable screw pump, designed to revolutionize the process of industrial fluid handling. Based on cutting-edge technology and years of research, this new innovation is set to enhance operational efficiency, increase productivity, and minimize maintenance costs across various sectors.The new screw pump, developed by XYZ's expert engineers, boasts numerous features that set it apart from traditional models. With a robust design and state-of-the-art mechanics, it offers unparalleled reliability, ensuring uninterrupted fluid transfer for a variety of applications.One of the key advantages of the XYZ screw pump is its exceptional versatility. Whether in oil refineries, chemical plants, power generation facilities, or wastewater treatment plants, this pump can handle a broad range of fluids, including viscous substances with high solid content.The screw pump's efficient design guarantees a continuous flow and eliminates the risk of pulsation during operation. This ensures a consistent and smooth transfer of fluids, which is crucial for maintaining optimal production rates and preventing costly disruptions.Furthermore, the XYZ screw pump is engineered with the latest sealing technology, greatly minimizing the possibility of leakage. This not only prevents environmental contamination but also reduces the need for frequent maintenance and replacement parts, resulting in significant cost savings for industrial operators.Another highlight of the XYZ screw pump is its exceptional energy efficiency. Equipped with advanced power-saving features, it consumes considerably less energy compared to traditional pumps, thereby helping companies reduce their carbon footprint and contribute to sustainable practices.In terms of ease of use, the XYZ screw pump stands out among its counterparts. Its user-friendly interface, combined with intuitive controls, makes installation and operation a breeze. Additionally, the pump's compact size allows for flexible placement, even in areas with limited space.XYZ takes immense pride in the rigorous testing and quality control measures applied during the screw pump's production. Every unit undergoes thorough inspections, ensuring that customers receive a reliable and durable product that meets the highest standards."We are thrilled to introduce this groundbreaking screw pump to the market," said [Spokesperson's Name], a representative from XYZ. "With its innovative features and exceptional performance, we are confident that our customers will experience newfound efficiency and productivity while significantly reducing operational costs."This new screw pump by XYZ has already garnered attention from various industries. Initial feedback from beta users has been overwhelmingly positive, with many noting the pump's reliability, seamless operation, and impressive cost savings.As companies worldwide strive to optimize their operations and enhance productivity, innovations like the XYZ screw pump are poised to revolutionize the fluid handling industry. By streamlining processes, minimizing environmental impact, and lowering maintenance costs, XYZ is paving the way for a new era of efficient industrial fluid management.About XYZ:XYZ is a renowned industry leader specializing in the development and manufacture of cutting-edge fluid handling solutions. With a team of highly skilled engineers and a commitment to innovation, XYZ has consistently delivered reliable and high-performance products. The company's dedication to quality and customer satisfaction has positioned it as a trusted partner for businesses in various sectors.Please note that the brand name "Settima" has been removed from the content as requested.

Top Chemical Mixers: A Comprehensive Guide

Chemical Mixers, the leading provider of innovative and efficient industrial mixing solutions, has expanded its product line to better serve the needs of its customers in various industries. With a wide range of mixers that are designed to handle different types of chemicals, the company has established itself as a trusted partner for businesses looking to optimize their mixing processes.Founded in 1995, Chemical Mixers has been at the forefront of developing high-quality and reliable mixing equipment for industries such as pharmaceuticals, petrochemicals, food and beverage, and water treatment. With a strong focus on research and development, the company has continuously improved its products to meet the evolving demands of its customers.One of the key factors that set Chemical Mixers apart from its competitors is its commitment to customer satisfaction. The company takes a collaborative approach with its clients, working closely with them to understand their specific mixing requirements and provide tailored solutions that meet their needs. This customer-centric approach has allowed Chemical Mixers to build long-lasting relationships with its clientele, earning a reputation for delivering outstanding service and support.In response to the growing demand for more advanced and efficient mixing solutions, Chemical Mixers has introduced several new products to its lineup. These include the latest series of chemical mixers that are designed to offer enhanced performance, reliability, and precision. With features such as variable speed control, advanced mixing technologies, and durable construction, these mixers are poised to deliver superior results in a wide range of applications.Furthermore, Chemical Mixers has also expanded its range of portable and compact mixers, ideal for businesses with limited space or those in need of versatile mixing solutions. These mixers are designed to be easily customizable, allowing businesses to adapt them to their specific processes and requirements. With their compact design and user-friendly controls, these mixers offer a convenient and efficient solution for businesses looking to optimize their mixing operations.In addition to its product expansion, Chemical Mixers has also invested in enhancing its after-sales support and technical assistance. The company has bolstered its team of experienced engineers and technicians to provide comprehensive training, maintenance, and troubleshooting services for its customers. This ensures that businesses can maximize the performance and longevity of their mixing equipment, further reinforcing Chemical Mixers’ commitment to customer satisfaction.“We are excited to introduce our latest range of chemical mixers, which are the result of our ongoing dedication to innovation and excellence,” said the spokesperson for Chemical Mixers. “We understand the critical role that mixing plays in various industrial processes, and our goal is to provide our customers with the most advanced and reliable solutions to help them achieve their operational objectives.”With its continued focus on delivering cutting-edge mixing solutions and unparalleled customer support, Chemical Mixers is poised to solidify its position as a leading provider of industrial mixing equipment. By leveraging its expertise and industry knowledge, the company will continue to drive advancements in mixing technology and help businesses across different sectors improve their operational efficiency and productivity.

Boost Your Efficiency with the Power of Multiphase Pumps

Multiphase Pump Technology Revolutionizes the Oil and Gas IndustryThe oil and gas industry is one of the most important sectors in the world today. It provides the energy and resources needed for transportation, heating, and electricity generation. However, the extraction of oil and gas from the earth is not always an easy task. It requires specialized equipment and techniques to effectively extract and transport the valuable resources. Multiphase pump technology has emerged as one of the most promising and game-changing technologies in the industry.The development of Multiphase Pumps has been revolutionary for the Oil and Gas industry. These pumps have the capability to handle a mixture of oil, gas, and water in a single flow pipeline. They have the potential to dramatically reduce costs and improve efficiency in oil and gas production by eliminating the need for expensive and complex infrastructure, such as separation facilities and pipelines. Multiphase pumps also have a small environmental footprint and are ideal for offshore production.One of the key players in the Multiphase Pump industry is a company that has been at the forefront of developing this technology. This company, founded in 1990 in Norway, is dedicated to creating innovative solutions for the oil and gas industry. It has established itself as a global leader in Multiphase Pump technology with over 2800 pump installations worldwide.The company’s flagship product is a multiphase pump that can handle up to 100% gas, 100% oil, or any combination in-between. The pump is extremely efficient and can operate in harsh environments, such as the North Sea, where conventional pumps cannot operate. Its unique design allows for efficient transport of oil and gas from wells in remote locations, minimizing the use of expensive infrastructure.Multiphase pump technology has numerous advantages over traditional methods. It can significantly reduce the cost of infrastructure, reduce downtime, and improve the overall efficiency of production. In addition, multiphase pumps can be used in a variety of applications, including oil production, gas production, and transportation. They can also be used in the development of unconventional resources such as shale gas and oil sands.The company’s multiphase pumps have been successfully used in a variety of projects worldwide. These include offshore platforms in the North Sea, deepwater subsea installations in the Gulf of Mexico, and onshore operations in the Middle East. The pumps have helped clients achieve cost savings of up to 50% and have significantly reduced emissions and carbon footprints.In addition to its successful pump installations, the company offers a range of services to support its clients. These services include custom design and engineering, installation and commissioning, training, maintenance, and upgrades. The company’s expert engineers and technicians provide comprehensive support to ensure that clients’ pumps perform at their best.The company’s dedication to innovation and customer satisfaction has earned it recognition from customers and the industry. It has won multiple awards for its innovative products and services. In 2020, the company received the Norwegian Export Award for its successful export of multiphase pumps to international markets.Multiphase pump technology has the potential to revolutionize the oil and gas industry by improving efficiency, reducing costs, and minimizing environmental impact. The company’s innovative approach to pump technology and excellent customer service has made it a leader in the industry. Its pumps and services have helped clients all over the world to extract oil and gas more efficiently and effectively. As the demand for cleaner energy sources increases, multiphase pump technology will play an even more important role in the energy transition. The company’s dedication to innovation and customer satisfaction will continue to drive its success and position it at the forefront of the industry.

Innovative Triple Screw Pump Technology: Revolutionizing Industrial Fluid Transfer

Triple Screw Pump Offers High-Level Performance for Industrial Applications{Company Name} is proud to introduce the triple screw pump, a high-level performance solution for industrial applications. With the ability to handle viscous fluids while providing smooth and continuous flow, this reliable pump is ideal for a variety of industrial processes.One of the significant advantages of this pump is its high efficiency. It can achieve up to 90% efficiency while still being able to handle high-viscosity fluids such as crude oil, asphalt, and bitumen. This makes it an ideal solution for industries that require a high level of performance in their fluid handling processes.Another key feature of the triple screw pump is its ability to maintain consistent flow, even with varying inlet pressures. The screw design creates a clearing action within the pump, which means that there is a minimal risk of clogging or blockages, even with thicker fluids.The triple screw pump has been designed with ease of use in mind, making it an ideal choice for operators who need a low-maintenance solution. A self-priming design enables the pump to start and stop without the need for manual intervention, and it requires minimal disassembly for cleaning and servicing.Moreover, the pump has a compact footprint, which makes it easy to install and integrate into existing systems. Its low noise and vibration levels make it an ideal solution for applications where noise pollution and vibration could be an issue.It is recommended for industries that deal with liquid transfer, applications that need high pressure, high viscosity, and high temperature. Additionally, the triple screw pump is ideal for applications that involve feeding multiple points at once, as it can operate on a different number of pressures and flows.Furthermore, the triple screw pump is highly customizable, which means that it can be tailored to meet the specific needs of individual applications. Customization options include different materials of construction, various sealing systems, and different RPMs to suit the application's requirements.{Company Name} CEO, {Name}, stated "We are thrilled to offer this high-performance solution to our customers. The triple screw pump is an ideal choice for industries that require consistency and reliability in their fluid handling processes."In conclusion, the Triple Screw Pump offers high-level performance for industrial applications. With its high efficiency, consistent flow, low maintenance requirement, and customizable design, it is ideal for industries that deal with high-pressure, high-viscosity, and high-temperature applications. Operators can use it to feed multiple points at once while achieving a smooth and continuous flow.

Top Wholesale Check Valve Function Factories: Everything You Need to Know

Wholesale Check Valve Function Factories has been making waves in the industry with their innovative and high-quality products. The company has been in the business for many years, and their dedication to excellence has solidified their position as a leader in the manufacturing of check valves.Check valves are essential components in many systems, as they allow liquid or gas to flow in only one direction. This prevents backflow, which can be damaging to equipment and even dangerous in some cases. Wholesale Check Valve Function Factories has established itself as a go-to source for these crucial components, providing a wide range of options to suit different applications.One of the key factors that set Wholesale Check Valve Function Factories apart from other manufacturers is their commitment to quality. The company uses only the best materials and employs rigorous testing protocols to ensure that their products meet the highest standards. This dedication to excellence has earned them a sterling reputation among their clients and peers in the industry.In addition to their focus on quality, Wholesale Check Valve Function Factories also prides itself on its ability to meet the needs of a diverse customer base. The company offers a wide range of check valve options, including different sizes, materials, and designs. Whether a client needs a standard check valve or a custom solution, the team at Wholesale Check Valve Function Factories has the expertise and flexibility to deliver.Furthermore, the company is known for its efficient and reliable production processes. Wholesale Check Valve Function Factories operates state-of-the-art facilities that are equipped with the latest technologies. This allows them to manufacture check valves with precision and consistency, ensuring that every product that leaves their factory meets their exacting standards.Another aspect that sets Wholesale Check Valve Function Factories apart is their commitment to customer satisfaction. The company has a team of knowledgeable and dedicated professionals who are always ready to assist clients with their specific needs. Whether it's providing technical information, offering guidance on product selection, or addressing any concerns, Wholesale Check Valve Function Factories is dedicated to delivering exceptional service.With a track record of success and a growing list of satisfied clients, Wholesale Check Valve Function Factories is poised for continued growth and success in the industry. The company's dedication to quality, diversity, efficiency, and customer satisfaction has earned them a strong position in the market.As the demand for check valves continues to grow across various industries, Wholesale Check Valve Function Factories is well-positioned to meet the needs of the market. With their unwavering commitment to excellence, the company is set to remain a leading force in the manufacturing of check valves for years to come.In conclusion, Wholesale Check Valve Function Factories is a company that embodies the best practices in manufacturing and customer service. Their dedication to quality, diversity, efficiency, and customer satisfaction has cemented their position as a leader in the industry. As the demand for check valves continues to grow, Wholesale Check Valve Function Factories is well-equipped to meet the needs of various applications and industries. With a strong track record of success and a focus on innovation, the future looks bright for Wholesale Check Valve Function Factories.

HVAC Pump Servicing: Expert Maintenance for Your System

Pump Servicing Company Continues to Provide Quality Maintenance and RepairsWith a strong commitment to providing exceptional servicing for pumps and pumping equipment, Pump Servicing Company has been a leader in the industry for over [X] years. The company has built a reputation for delivering quality maintenance and repair services to a wide range of clients, including industrial facilities, water treatment plants, and commercial buildings.As a leading provider of pump servicing, Pump Servicing Company offers a comprehensive range of maintenance and repair solutions to keep pumps functioning at their best. The company's team of experienced technicians is well-equipped to handle various types of pumps, including centrifugal, submersible, and positive displacement pumps. With a focus on delivering reliable and efficient servicing, Pump Servicing Company is dedicated to helping clients minimize downtime and maximize the lifespan of their pumping equipment.One of the key strengths of Pump Servicing Company is its commitment to staying up-to-date with the latest technologies and industry best practices. The company invests in ongoing training and development for its technicians to ensure that they are equipped with the knowledge and skills to address the evolving needs of clients. This dedication to continuous improvement has enabled Pump Servicing Company to stay ahead of the curve and provide innovative solutions to its clients.In addition to its focus on technical expertise, Pump Servicing Company places a strong emphasis on customer service. The company understands the importance of timely and reliable servicing, and its team is committed to delivering a seamless experience for clients. Whether it's a routine maintenance visit or an emergency repair, Pump Servicing Company strives to provide responsive and attentive service to meet the needs of its clients.Pump Servicing Company's dedication to excellence is reflected in its use of high-quality parts and materials for all servicing and repairs. The company has developed strong relationships with leading suppliers to ensure that clients receive the best components for their pumping equipment. This commitment to quality not only enhances the performance and reliability of the pumps but also contributes to the overall longevity of the equipment.As part of its ongoing efforts to expand its service offerings, Pump Servicing Company has recently introduced a preventive maintenance program. This proactive approach to pump servicing focuses on regular inspections, testing, and adjustments to identify and address potential issues before they escalate. By taking a preventive maintenance approach, Pump Servicing Company aims to help clients reduce the likelihood of unexpected breakdowns and costly repairs.Furthermore, Pump Servicing Company is committed to environmental sustainability and compliance with industry regulations. The company adheres to strict environmental standards and best practices in its servicing and repair processes to minimize the impact on the environment. With a strong focus on safety and environmental responsibility, Pump Servicing Company is dedicated to operating in a manner that aligns with the highest industry standards.Looking ahead, Pump Servicing Company is focused on further expanding its service capabilities and enhancing its presence in the market. The company remains committed to delivering exceptional pump servicing solutions to meet the diverse needs of its clients across various industries. With a strong foundation of technical expertise, customer service excellence, and a commitment to quality, Pump Servicing Company is well-positioned to continue its leadership in the pump servicing industry.