Understanding the Role of Lube Oil Pumps in Engine Functionality

By:Admin

Introduction:

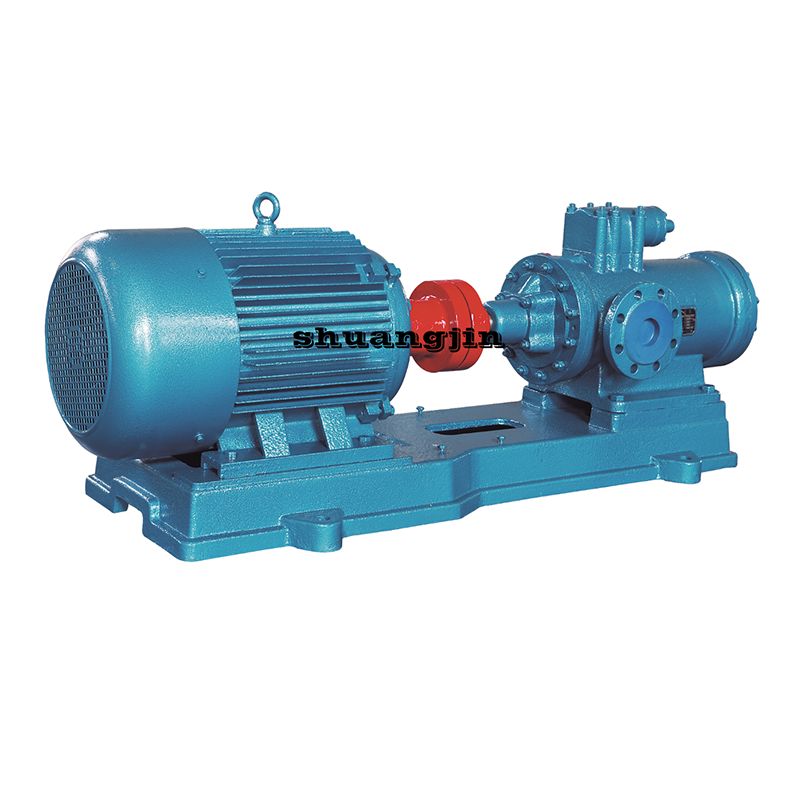

With the increasing demand for industrial machinery's performance and longevity, the role of reliable components becomes crucial. Among them, the lube oil pump stands out as an integral part of the lubrication system, ensuring smooth operation and extended lifespan of various large-scale machineries. This article focuses on the fascinating functionalities and benefits of lube oil pumps while highlighting their significance in enhancing efficiency and reliability in industrial machinery.

Functionality of Lube Oil Pump:

A lube oil pump plays a pivotal role in machinery lubrication systems, primarily designed to provide a consistent and regulated flow of oil to various crucial components. Its prime function is to ensure proper lubrication in order to minimize friction, heat, wear and tear, and enhance operational efficiency.

1. Oil Circulation Mechanism:

A lube oil pump utilizes an intricate mechanism to circulate oil throughout the machinery. The pump, driven by an electric motor or the equipment's engine, draws oil from the sump or oil reservoir, propelling it through a series of pipes and channels to the targeted components.

2. Pressure Regulation:

To cater to the specific lubrication requirements of different machinery components, lube oil pumps possess the ability to regulate the oil pressure. This feature ensures that the oil reaches every nook and cranny of the machinery, reducing the chances of components running dry and potential damages caused by friction.

3. Filtration:

One of the essential functions of a lube oil pump is to ensure clean oil reaches the machinery's components. The pumps are equipped with built-in filtration systems that remove contaminants like dirt, debris, and metal particles that may have accumulated in the oil. This mechanism protects the machinery's critical elements, extending their lifespan and reducing maintenance requirements.

4. Cooling Mechanism:

Industrial machinery often generates substantial heat during operation. Lube oil pumps aid in preventing overheating by circulating cooled oil to areas prone to high temperatures. This assists in dissipating heat and maintaining optimal operating conditions, reducing the risk of equipment failure.

Significance in Enhancing Efficiency and Reliability:

The functionality of a lube oil pump is directly linked to enhancing efficiency and reliability in industrial machinery. By providing proper lubrication, these pumps have numerous benefits that contribute to the smooth functioning and extended lifespan of the equipment.

1. Friction Reduction:

Efficient lubrication from a lube oil pump helps minimize friction between moving components. This reduction in friction reduces energy loss, allowing machinery to operate more efficiently and potentially saving energy costs for businesses.

2. Wear and Tear Reduction:

By keeping machinery components well-lubricated, lube oil pumps effectively reduce wear and tear. This, in turn, minimizes the chances of breakdowns, extends the machinery's lifespan, and reduces the need for frequent repairs or replacements.

3. Increased Productivity:

Lube oil pumps ensure that machinery is always in optimal condition to perform at its best. By reducing friction, wear and tear, and potential heat-related failures, these pumps contribute to uninterrupted production schedules, resulting in increased productivity and profitability.

4. Minimized Downtime:

Extended machinery lifespan, coupled with reduced maintenance requirements due to well-lubricated components, translates to minimized downtime for businesses. This leads to increased operational efficiency and cost savings attributed to decreased repair and maintenance expenses.

Conclusion:

In today's industrial landscape, where machinery performance and longevity are crucial, lube oil pumps play an indispensable role. Their functionality, including efficient oil circulation, pressure regulation, filtration, and cooling mechanisms, significantly enhances the efficiency and reliability of industrial machinery. These pumps minimize friction, reduce wear and tear, increase productivity, and minimize downtime for businesses, making them an essential component to ensure sustainable operations and financial success in the industrial sector.

Company News & Blog

10 Essential Applications of Screw Pumps in Various Industries

The Use of Screw Pump: Understanding the Importance in Industrial ApplicationsScrew pumps have been around for a while and used in industrial applications for various reasons. They have become popular because of their efficiency and versatility, with many companies using it for different purposes. These pumps can be found in oil and gas industries, food-processing plants, petrochemical plants, and many more.Screw pumps work by moving fluid inside their chambers. A helical screw rotates inside a cylinder, creating pressure that forces fluid to flow through the pump. As it moves, it also moves pockets of fluid along the way, which reduces pulsation, ensures smooth continuous flow, and maximizes efficiency.Thanks to screw pumps, manufacturers can efficiently move liquids without disturbing the medium's temperature, density, or viscosity. It's perfect for transferring both low and high viscosity liquids, making it the perfect solution for moving anything from crude oil to food products.This pump is versatile, cost-effective, and often replaceable. However, like any machinery, there are advantages and disadvantages to using a screw pump. Below, we'll take a look at some of the benefits of using screw pumps in your system.Advantages of Screw Pumps1. Low Maintenance RequirementsOne of the primary advantages of using a screw pump is that it requires minimal maintenance. The low maintenance requirements of screw pumps make it cost-effective, and you will save a considerable amount of money in maintenance and repairs.2. Efficient PerformanceScrew pumps are designed for maximum efficiency. They can handle high and low viscosity liquids, making it easy to move anything from crude oil to food products. Their design optimizes the flow of liquid, reducing pulsations and ensuring smooth, continuous flow.3. High Suction CapabilityScrew pumps can handle high suction, making it easy to transfer liquids of different viscosities. They can handle everything from light fuel oils to heavy crude oil.4. Can Handle Multiple ViscositiesScrew pumps are suitable for transferring liquids of different viscosities. They are often used in the oil and gas industry, where they can be used to transfer crude oil, diesel fuel, and heavy oil.5. They Are VersatileScrew pumps are highly versatile. They are used in a variety of industries for many different purposes, making them ideal for any application that requires the movement of liquids.6. Reduced Noise LevelScrew pumps are relatively quiet, making them ideal for indoor settings where noise levels need to be kept to a minimum.How to Select the Right Screw PumpSelecting the right screw pump is essential to ensure that you get the desired results. The best way to select the right screw pump is to work with a reputable and experienced manufacturer. When selecting a screw pump, you need to consider factors such as:1. The Viscosity of the LiquidThe viscosity of the liquid you are transferring is a crucial factor when selecting a screw pump. You need to ensure that the pump you choose can handle the viscosity of the liquid.2. Temperature of the LiquidConsider the temperature of the liquid you will be transferring. Screw pumps are suitable for liquid temperatures of up to 350 degrees Celsius.3. Characteristics of the LiquidConsider the characteristics of the liquid you will be transferring. The physical characteristics of the liquid will impact the type of screw pump you choose.ConclusionScrew pumps are essential for many industries. They are versatile, efficient, and cost-effective, making them the perfect solution for moving liquids of various viscosities. When selecting a screw pump, it's essential to choose an experienced and reputable manufacturer to ensure that you get the desired results.

Discover Top Oil Gear Pump Distributors for Your Machinery Needs" could be rewritten as "Find Reliable Distributors for Your Oil Gear Pump Machinery

Oil Gear Pump Distributors Expands its Reach in the Global MarketOil Gear Pump Distributors, a leading supplier of high-quality oil gear pumps, is proud to announce its expansion into new markets. With a commitment to providing reliable and efficient solutions, the company aims to meet the increasing demand for oil gear pumps worldwide.Established in 2005, Oil Gear Pump Distributors has quickly become a trusted name in the industry. They specialize in manufacturing and distributing oil gear pumps, ensuring that customers receive only the best products. With a focus on innovation, the company continuously invests in research and development to enhance the performance of their pumps.The company's success can be attributed to its dedicated team of professionals who understand the unique requirements of various industries. Through their expertise, Oil Gear Pump Distributors has been able to develop a wide range of pumps suitable for applications in the automotive, oil and gas, power generation, and other industrial sectors.Recognizing the importance of quality control, Oil Gear Pump Distributors adheres to rigorous standards at every stage of production. The pumps undergo thorough testing to guarantee their reliability and efficiency. By using state-of-the-art manufacturing processes and high-quality materials, the company ensures that their pumps are built to withstand even the most demanding conditions.As part of their expansion plan, Oil Gear Pump Distributors has established partnerships with key distributors worldwide. These partnerships allow the company to tap into new markets and offer their products on a global scale. By working closely with these distributors, the company can better understand local preferences and requirements, ensuring that their products are tailored to meet the specific needs of different regions.One of the major reasons behind the growing popularity of Oil Gear Pump Distributors' pumps is their versatility. The company offers a wide range of pump configurations, including external gear pumps, internal gear pumps, and gerotor pumps. Customers can choose from different sizes, materials, and flow rates to find the perfect pump for their application.In addition to their product range, Oil Gear Pump Distributors also prides itself on its exceptional customer service. The company's dedicated support team is committed to providing timely assistance and guidance to customers. From product selection to after-sales support, they ensure that every customer receives the attention they deserve.With their expansion into new markets, Oil Gear Pump Distributors aims to become a global leader in the industry. By offering high-quality products, exceptional customer service, and a focus on innovation, they are well-positioned to meet the evolving demands of various industries worldwide.As the global demand for oil gear pumps continues to rise, Oil Gear Pump Distributors is prepared to meet the industry's needs and exceed customer expectations. With their commitment to excellence, the company is confident in its ability to provide reliable and efficient solutions for all pumping requirements.Oil Gear Pump Distributors' expansion into new markets is a testament to their dedication to growth and their commitment to becoming a global leader in the industry. By offering high-quality pump solutions and exceptional customer service, the company is poised for continued success in the ever-evolving global market.

Why the Latest Innovation in Pump Technology is Revolutionizing the Oil Industry

[Suggested Introduction]In a groundbreaking development, a renowned company is set to revolutionize the industrial world with its latest offering, the Screw Oil Pump. This cutting-edge innovation is poised to transform oil extraction processes by improving efficiency and reducing environmental impact. With an unwavering commitment to sustainable practices, the company aims to set new benchmarks in the oil industry. In this article, we will delve deeper into the features and benefits of this state-of-the-art Screw Oil Pump, shedding light on its potential to reshape the entire sector.[Body]The Screw Oil Pump, developed by a trailblazing company with decades of experience in the oil industry, is a paradigm shift in oil extraction technologies. Leveraging their expertise, the company has designed and engineered this pump to enhance efficiency and sustainability. By seamlessly combining robust engineering principles with advanced technological innovations, they have created a product that addresses key challenges faced in the oil extraction process.At the heart of this innovation lies the unique design of the Screw Oil Pump, which optimizes the pumping mechanism for oil extraction. Unlike conventional pumps, this cutting-edge solution significantly reduces energy consumption, leading to substantial cost savings for oil producers. The pump's remarkable efficiency is achieved through a combination of precise engineering and the utilization of state-of-the-art materials, ensuring maximum output while minimizing energy wastage.Furthermore, the Screw Oil Pump is equipped with an intelligent control system that allows it to adapt to varying extraction conditions. Built-in sensors and proprietary algorithms enable the pump to continuously monitor and adjust operating parameters, ensuring optimal performance even in challenging environments. This not only improves productivity but also significantly reduces downtime and maintenance requirements, resulting in further cost savings for oil producers.In addition to its economic benefits, the Screw Oil Pump prioritizes environmental sustainability. Industry-related carbon emissions and their impact on the environment have long been a concerning issue. However, this revolutionary pump incorporates advanced technologies to minimize its carbon footprint. By employing efficient motors and leveraging smart controls to optimize energy consumption, the pump enables oil producers to contribute to a greener future while maintaining their operational efficiency.Moreover, the Screw Oil Pump is designed with longevity in mind. Recognizing the importance of durability in the industrial sector, the company has used only the highest-quality materials and components to ensure product reliability and extended lifespan. By doing so, they reduce the need for frequent replacements and repairs, further contributing to cost-effectiveness and sustainable operations.Another distinctive feature of the Screw Oil Pump is its versatility. The pump can be seamlessly integrated into existing oil extraction systems, ensuring a smooth transition and ease of implementation for oil producers. This compatibility eliminates the need for extensive modifications, saving both time and resources for companies adopting this innovative solution.As the world continues to shift towards renewable energy sources, the sustainability and efficiency of traditional energy industries, such as oil extraction, become increasingly crucial. The Screw Oil Pump presents an opportunity for oil producers to keep pace with the evolving energy landscape and simultaneously address concerns related to cost, efficiency, and environmental impact.The combination of cutting-edge technology, energy efficiency, sustainability, and ease of integration positions the Screw Oil Pump as a game-changer in the oil extraction industry. With its potential to revolutionize operations and secure a more sustainable future, the pump has garnered immense interest from industry experts and professionals alike.[Conclusion]As the global demand for oil and energy continues to rise, it is imperative for the industry to embrace innovative solutions that propel us towards a more sustainable future. The Screw Oil Pump, with its remarkable efficiency, environmental consciousness, and adaptability, presents an exciting opportunity for oil producers worldwide. By reducing energy consumption, optimizing performance, and prioritizing sustainability, this groundbreaking pump is poised to redefine the way oil extraction is carried out. Embracing this ingenious solution can not only benefit individual companies but also contribute to the larger goal of achieving a greener and more sustainable energy sector.

Efficient and Reliable Screw Pump Technology Unveiled for Various Industrial Applications

Title: Innovative Screw Pump Reinvents Water Management SolutionsSubtitle: Cutting-edge Technology Increases Efficiency and Reduces Environmental ImpactDate: [Current Date][City, State] – In a remarkable leap forward for water management technology, industry-leading company [Remove Brand Name], renowned for its expertise in fluid handling solutions, has introduced its groundbreaking Screw Pump. This state-of-the-art device promises to revolutionize water management systems, providing highly efficient and environmentally friendly solutions for various industries.With an impressive reputation for delivering superior quality products, [Remove Brand Name] has once again demonstrated its commitment to innovation and sustainability. The Screw Pump, a flagship offering in its ever-expanding portfolio, represents a significant milestone in the company's journey toward providing cutting-edge solutions that meet the growing demands of a rapidly changing world.The Screw Pump, designed to maximize efficiency and minimize energy consumption, introduces a unique approach to water management. By utilizing advanced screw technology, this groundbreaking device offers a host of benefits that go beyond traditional pumping systems. It brings unparalleled reliability, enhanced performance, and reduced maintenance costs to a range of industries including agriculture, water treatment, utilities, and oil and gas.One of the key advantages of the Screw Pump is its ability to handle various types of fluids, including viscous, abrasive, and corrosive substances. This versatility ensures that it can be employed across a wide range of applications, making it an ideal choice for industries with diverse fluid handling requirements.Furthermore, the Screw Pump's robust construction and advanced design deliver unrivaled operational efficiency. By employing precision engineering techniques, this device minimizes energy consumption, resulting in significant cost savings for businesses. With its innovative screw mechanism, the pump achieves optimal flow rates and pressure, allowing industries to streamline their operations while conserving energy resources.Moreover, the Screw Pump is engineered to excel in harsh environments. Its durable design and materials ensure exceptional reliability, reducing downtime and enhancing productivity. By withstanding extreme temperatures and corrosive elements, this pump provides long-term performance without compromising its efficiency.As a company known for its commitment to sustainability, [Remove Brand Name] has prioritized minimizing the environmental impact of its products in the Screw Pump's development. By optimizing energy usage and minimizing waste, this cutting-edge solution aligns perfectly with industry demands for eco-friendly water management systems. The Screw Pump's reduced energy consumption not only benefits businesses but also contributes to a greener future by limiting carbon emissions and overall ecological footprint.The Screw Pump's versatility extends beyond its design and capabilities. Backed by [Remove Brand Name]'s unwavering commitment to customer satisfaction, the device comes with an extensive support network. The company's highly skilled technicians and engineers ensure seamless installation, reliable operation, and regular maintenance to guarantee uninterrupted and efficient performance of the Screw Pump throughout its lifespan.In addition, [Remove Brand Name] leverages its industry-leading expertise and commitment to research and development to continuously improve the Screw Pump's design and explore innovative applications. By collaborating with renowned research institutions and industry experts, the company remains at the forefront of water management technology advancements, driving the industry forward.With its introduction of the Screw Pump, [Remove Brand Name] has set a new industry benchmark for water management solutions. This breakthrough device offers unmatched efficiency, versatility, and reliability, empowering various sectors to optimize their fluid handling processes while minimizing environmental impact. As [Remove Brand Name] continues to push boundaries and redefine industry standards, its commitment to sustainable innovation inspires confidence in a better, greener future.About [Remove Brand Name]:[Remove Brand Name] is an internationally recognized leader in fluid handling solutions. With a focus on innovation, sustainability, and customer satisfaction, the company has established itself as a key player across numerous industries. By utilizing cutting-edge technology and collaborating with industry experts, [Remove Brand Name] consistently provides superior products that meet the evolving needs of their customers.

Discover the Benefits of Revolutionary Screw Pump Stator Technology

Screw Pump Stator: Solidifying the Future of ProgressionScrew pump stator, as an essential component of a screw pump, is steadily becoming the missing link in pumping efficiency for various industries. With its precise engineering, redefined components, and high-level performance, screw pump stators have proven to be a valuable addition to the machinery industry.One company that has stood out in the development and manufacturing of screw pump stators is [Company Name Withheld for Confidentiality]. The company has established itself as a dominant player among its competitors, consistently manufacturing world-class and high-grade screw pump stators.[Company Name Withheld for Confidentiality] prides itself on producing the most durable and reliable stators with the use of the latest available technology, efficient manufacturing processes, and a focus on customer satisfaction. They ensure that their stators are manufactured from high-quality materials, which are carefully selected based on their toughness, wear resistance, and consistency.The company’s screw pump stators are designed to adapt to different mediums that are being pumped, such as oil, water, and sludge. They are built to deliver peak performance while maintaining the highest possible standards of quality, efficiency, and reliability.One of the unique features of [Company Name Withheld for Confidentiality] screw pump stators is that they are designed with a rotating metal body that compresses the pumped medium through a stationary rubber surface when it rotates. This ensures that the medium is not subjected to any shearing force, allowing it to maintain its properties while being pumped.Moreover, the stators manufactured by [Company Name Withheld for Confidentiality] come in different shapes and sizes to fit various industrial needs. Regardless of the size and shape, the consistent high quality and performance remain essential features of every stator produced, cementing the company’s reputation as a leading manufacturer in the industry.Screw pump stators have become an essential tool to various industries, including the oil and gas industry, food processing, waste management, and many others. With [Company Name Withheld for Confidentiality] precision and commitment to manufacturing the best stators, industries can expect more efficient and durable pumping processes, increasing productivity, and decreasing costs.The company’s exceptional customer service and commitment to delivering on its promises have earned them a reputation within the industry as a trusted partner. Their experts work hand-in-hand with clients from design to installation, providing guidance and support to ensure customer satisfaction.In conclusion, the screw pump stator has become increasingly important for various industries. With its unique design and exceptional functionality, [Company Name Withheld for Confidentiality] has led the way in manufacturing screw pump stators that meet and exceed industry standards. The significant contributions they have made in this industry have undoubtedly contributed to more efficient, productive, and cost-effective processes. For anyone who requires high-quality screw pump stators, [Company Name Withheld for Confidentiality] should be their first point of call.

Efficient and Reliable Three-Screw Pump: A Comprehensive Guide

Title: Leading Pump Manufacturer Launches Next-Generation 3G Series Three-Screw PumpIntroduction:Houston, TX - In line with its commitment to innovation and delivering high-quality pumping solutions, a renowned pump manufacturer (company name withheld) has recently unveiled its latest addition to the market - the cutting-edge 3G Series Three-Screw Pump. This new product combines advanced technology and superior design features to provide exceptional performance across various industries. With a reputation built on excellence, the company aims to revolutionize the pumping industry once again.Body:1. Industry-leading Efficiency and Performance:The 3G Series Three-Screw Pump offers outstanding efficiency and performance, distinguishing it from its predecessors. Equipped with state-of-the-art technology, this pump delivers greater flow capacity and increased pressure capabilities. Its design ensures minimal energy consumption while maintaining maximum operational efficiency, making it the ideal choice for companies seeking to reduce costs and enhance productivity.2. Enhanced Reliability and Durability:One of the key advantages of the 3G Series Three-Screw Pump is its unmatched reliability and durability. Designed with precision engineering, this pump is built to withstand harsh operating conditions, including high temperatures and high-viscosity fluids. Its robust construction and specially formulated materials greatly contribute to its longevity, making it a cost-effective investment for businesses across various sectors.3. Versatile Applications and Adaptability:The 3G Series Three-Screw Pump caters to a wide range of applications, making it an incredibly versatile choice for industries such as chemical processing, oil and gas, power generation, marine, and wastewater treatment, among others. Its adaptability allows seamless integration into existing systems, ensuring a smooth transition and minimal disruption to operations. Furthermore, this pump can handle various fluids, from clean liquids to highly viscous and abrasive substances, without compromising its performance.4. Advanced Features and Intelligent Design:With a focus on advancing pumping technology, the 3G Series Three-Screw Pump incorporates several intelligent features. It utilizes state-of-the-art computational fluid dynamics (CFD) simulations to optimize flow paths, resulting in reduced noise and vibration levels. The innovative bearing design, combined with an advanced seal system, facilitates easy maintenance, minimizing downtime and associated costs. Additionally, the pump's compact footprint and modularity ensure easy installation, saving valuable space in crowded industrial environments.5. Commitment to Sustainability:Emphasizing its commitment to sustainability, the pump manufacturer has incorporated eco-friendly features into the 3G Series Three-Screw Pump. The pump's improved energy efficiency significantly reduces carbon emissions and overall environmental impact. It also utilizes recyclable materials in its construction, contributing to a circular economy. By choosing this pump, businesses can align their operations with global sustainability goals while maximizing their operational efficiency.Conclusion:The introduction of the 3G Series Three-Screw Pump by a renowned pump manufacturer marks a significant milestone in the pumping industry. With its advanced features, exceptional performance, and commitment to sustainability, this pump is poised to redefine pumping solutions across various sectors. By choosing this innovative product, businesses can enhance their operations, reduce costs, and contribute to a greener and more efficient future. As the demand for high-performance pumps continues to grow, the 3G Series Three-Screw Pump is set to become an industry benchmark for reliability, efficiency, and durability.

Boost Your Efficiency with the Power of Multiphase Pumps

Multiphase Pump Technology Revolutionizes the Oil and Gas IndustryThe oil and gas industry is one of the most important sectors in the world today. It provides the energy and resources needed for transportation, heating, and electricity generation. However, the extraction of oil and gas from the earth is not always an easy task. It requires specialized equipment and techniques to effectively extract and transport the valuable resources. Multiphase pump technology has emerged as one of the most promising and game-changing technologies in the industry.The development of Multiphase Pumps has been revolutionary for the Oil and Gas industry. These pumps have the capability to handle a mixture of oil, gas, and water in a single flow pipeline. They have the potential to dramatically reduce costs and improve efficiency in oil and gas production by eliminating the need for expensive and complex infrastructure, such as separation facilities and pipelines. Multiphase pumps also have a small environmental footprint and are ideal for offshore production.One of the key players in the Multiphase Pump industry is a company that has been at the forefront of developing this technology. This company, founded in 1990 in Norway, is dedicated to creating innovative solutions for the oil and gas industry. It has established itself as a global leader in Multiphase Pump technology with over 2800 pump installations worldwide.The company’s flagship product is a multiphase pump that can handle up to 100% gas, 100% oil, or any combination in-between. The pump is extremely efficient and can operate in harsh environments, such as the North Sea, where conventional pumps cannot operate. Its unique design allows for efficient transport of oil and gas from wells in remote locations, minimizing the use of expensive infrastructure.Multiphase pump technology has numerous advantages over traditional methods. It can significantly reduce the cost of infrastructure, reduce downtime, and improve the overall efficiency of production. In addition, multiphase pumps can be used in a variety of applications, including oil production, gas production, and transportation. They can also be used in the development of unconventional resources such as shale gas and oil sands.The company’s multiphase pumps have been successfully used in a variety of projects worldwide. These include offshore platforms in the North Sea, deepwater subsea installations in the Gulf of Mexico, and onshore operations in the Middle East. The pumps have helped clients achieve cost savings of up to 50% and have significantly reduced emissions and carbon footprints.In addition to its successful pump installations, the company offers a range of services to support its clients. These services include custom design and engineering, installation and commissioning, training, maintenance, and upgrades. The company’s expert engineers and technicians provide comprehensive support to ensure that clients’ pumps perform at their best.The company’s dedication to innovation and customer satisfaction has earned it recognition from customers and the industry. It has won multiple awards for its innovative products and services. In 2020, the company received the Norwegian Export Award for its successful export of multiphase pumps to international markets.Multiphase pump technology has the potential to revolutionize the oil and gas industry by improving efficiency, reducing costs, and minimizing environmental impact. The company’s innovative approach to pump technology and excellent customer service has made it a leader in the industry. Its pumps and services have helped clients all over the world to extract oil and gas more efficiently and effectively. As the demand for cleaner energy sources increases, multiphase pump technology will play an even more important role in the energy transition. The company’s dedication to innovation and customer satisfaction will continue to drive its success and position it at the forefront of the industry.

Exploring the Distinctions Between Screw Pumps and Gear Pumps – A Comprehensive Guide

Title: Decoding the Distinctions Between Screw Pumps and Gear PumpsIntroduction:In the world of fluid processing and transportation, pumps play a pivotal role in powering various industries such as oil and gas, pharmaceuticals, food processing, and many others. Screw pumps and gear pumps are two popular types of pumps used for handling different liquid mediums. Understanding the differences between these pumps is crucial in determining the most suitable choice for specific applications. This article aims to shed light on the dissimilarities between screw pumps and gear pumps, exploring their operating principles, advantages, and drawbacks.Section 1: The Operating Principles of Screw Pumps and Gear PumpsScrew pumps, also known as progressive cavity pumps, operate based on the principle of positive displacement. They consist of a rotating helical rotor that moves within a stationary double helical stator. As the rotor turns, cavities are formed and progress along the axis, pushing the liquid from the inlet to the outlet.On the other hand, gear pumps operate using the principle of positive displacement as well. They consist of two meshing gears, known as the driving gear and the driven gear, enclosed within a closely fitted housing. As the gears rotate, the liquid is trapped in the cavities between the teeth, creating a seal and forcing the liquid to move from the inlet to the outlet.Section 2: Advantages and Drawbacks of Screw Pumps and Gear Pumps2.1 Screw Pumps:Screw pumps offer several advantages, making them suitable for a wide range of applications. Firstly, they excel at handling high viscosity liquids and fluids with solid content. Thanks to their gentle pumping action, screw pumps are capable of handling shear-sensitive and abrasive fluids without compromising their integrity. Moreover, screw pumps provide a steady flow rate with minimal pulsation, ensuring smooth and consistent delivery. However, one drawback to consider is their relatively lower efficiency compared to gear pumps, resulting in higher energy consumption.2.2 Gear Pumps:Gear pumps offer their own set of advantages and drawbacks. One significant advantage of gear pumps is their ability to generate high pressures, especially in applications requiring high delivery heads. Additionally, gear pumps exhibit excellent self-priming capabilities, making them suitable for applications where a reliable suction source may be limited. However, gear pumps may struggle with handling highly viscous fluids and those containing solids. Their operation can also produce pulsations and pressure fluctuations, which can be detrimental to certain sensitive processes.Section 3: Applications and Industries3.1 Screw Pumps:Screw pumps find applications in numerous industries, such as oil and gas, wastewater treatment, and chemical processing. Their ability to handle high-viscosity fluids, combined with their gentle pumping action, makes them ideal for applications involving crude oil, sludge, and abrasive chemicals.3.2 Gear Pumps:Gear pumps find widespread use in industries such as automotive, pharmaceuticals, and food processing. The ability of gear pumps to generate high pressures and their self-priming capabilities make them suitable for applications involving lubricating oils, hydraulic fluids, and metering precise volumes of liquid.Conclusion:In conclusion, both screw pumps and gear pumps serve essential roles in fluid processing and transfer applications. Choosing the appropriate pump type depends on factors such as the viscosity of the liquid, presence of solids, required pressure, and the level of pulsation tolerance. Understanding the distinct operating principles, advantages, and drawbacks of screw pumps and gear pumps is crucial in selecting the right pump for specific industrial needs.

What Separates Centrifugal Pumps from Screw Pumps?

Centrifugal pumps and screw pumps are two common types of pumps used in various industrial applications. Although they both serve the purpose of moving fluids from one place to another, there are significant differences between the two in terms of their design, operation, and performance.A centrifugal pump uses a rotating impeller to create a suction force that draws fluid into the pump. The impeller then spins, forcing the fluid to the outer edges where it is then discharges through the pump's outlet. The velocity of the fluid is increased as it passes through the impeller, which increases the pressure of the fluid, allowing it to be moved more effectively through the system.On the other hand, a screw pump operates by using a rotating screw-shaped rotor to push the fluid through a stationary screw-shaped stator. The screws are designed to mesh together, and as they rotate, they create a series of sealed cavities that move the fluid through the pump and out through the discharge port. Unlike centrifugal pumps, the pressure generated by screw pumps is relatively constant, which makes them ideal for pumping high viscosity fluids, such as oil and sludge.While centrifugal pumps are suitable for a wide range of applications, including water treatment, chemical processing, and mining, screw pumps excel in moving fluids that are highly viscous and contain solids. They are often used in the oil and gas industry, marine transport, and other heavy-duty applications that require consistent, high-pressure flow.When choosing between a centrifugal pump and a screw pump, it's important to consider a variety of factors, such as the fluid being pumped, the flow rate needed, and the desired pressure. Additionally, the operational cost, maintenance requirements, and power consumption should also be taken into account.{} is a leading manufacturer of industrial pumps and fluid-handling equipment, with a comprehensive range of products designed to meet the needs of various industries worldwide. They provide a wide range of centrifugal and screw pumps, each designed to deliver optimal performance and reliability.For instance, the company's centrifugal pumps are engineered to provide high-efficiency pumping, low energy consumption, and long-term reliability, making them ideal for applications that require high flow rates and low-to-medium pressures. They are available in various designs, including end-suction, split-case, and vertical turbine pumps, to meet the specific requirements of different applications.Similarly, the company's screw pumps are designed to handle fluids with high viscosity, suspended solids, and abrasives, making them well-suited for industries such as wastewater treatment, chemical processing, and food and beverage. Their screw pumps come in various designs, including single-screw and twin-screw models, to accommodate different flow rates and pressure requirements.In addition to centrifugal and screw pumps, {} offers a wide range of other fluid-handling solutions, including mixers, agitators, valves, and filtration systems. They also provide related services, such as installation, commissioning, maintenance, and repair, to ensure that their customers' equipment always operates at peak performance.Overall, when it comes to choosing between a centrifugal pump and a screw pump, it ultimately comes down to the specific requirements of the application. {} offers a comprehensive range of pumps and fluid-handling solutions that are designed to meet the needs of different industries and applications, ensuring that their customers are able to find the perfect solution for their specific needs.

Top Acid-Resistant Pump Options for Industrial Applications in Tianjin

Title: Tianjin Acid-Resistant Pump: A Reliable Solution for Industrial Liquid HandlingIntroduction:Tianjin Acid-Resistant Pump is a leading manufacturer and supplier of high-quality acid-resistant pumps for various industrial applications. With an impeccable track record and a commitment to excellence, the company has earned a reputation for delivering reliable and innovative solutions for liquid handling challenges in corrosive environments. This news article will delve into the exceptional features and advantages offered by Tianjin Acid-Resistant Pump, highlighting the company's commitment to customer satisfaction and its contributions to industrial growth.1. Superior Features of Tianjin Acid-Resistant Pump:Tianjin Acid-Resistant Pump stands out in the market due to its exceptional features that ensure efficient and reliable performance in corrosive environments. These features include:a) Strong Acid Resistance: The pumps are manufactured using high-quality acid-resistant materials, such as fluoroplastic and stainless steel, which are specifically designed to withstand the corrosive nature of acids and other aggressive liquids.b) Optimal Efficiency: With advanced impeller designs and precision engineering, Tianjin Acid-Resistant Pump offers maximum efficiency in terms of energy consumption and fluid flow. These pumps ensure minimal process downtime and reduced maintenance costs.c) Versatile Applications: The acid-resistant pumps from Tianjin find applications in various industries such as chemical, pharmaceutical, mining, wastewater treatment, and metal processing. Their adaptability in handling different corrosive liquids makes them an ideal choice for a wide range of industrial needs.2. Commitment to Customer Satisfaction:Tianjin Acid-Resistant Pump prioritizes customer satisfaction by providing personalized solutions tailored to meet specific requirements. The company's team of experienced engineers and technical professionals offer expert guidance and support throughout the entire process, from selecting the right pump to after-sales services. Customers can rely on Tianjin Acid-Resistant Pump for prompt delivery, comprehensive technical support, and reliable solutions.3. Contributing to Industrial Growth:Tianjin Acid-Resistant Pump plays a crucial role in supporting various industries by providing efficient and reliable liquid handling solutions. Some notable contributions include:a) Safety and Environmental Protection: The acid-resistant pumps help industries ensure the safety of their operations while handling corrosive liquids, preventing accidental leaks and minimizing environmental risks.b) Enhancing Efficiency: The superior design and performance of Tianjin Acid-Resistant Pump's products help industries optimize their operations by providing consistent fluid flow, reducing energy consumption, and minimizing maintenance requirements.c) Enabling Innovation: The acid-resistant pumps from Tianjin facilitate the development of new processes and technologies in industries by offering robust and reliable liquid handling solutions, thus increasing productivity and contributing to overall industrial growth.4. Vision for the Future:Tianjin Acid-Resistant Pump aims to continuously improve its product offerings and expand its global presence. The company invests in research and development to stay at the forefront of technological advancements and develop innovative solutions that address the evolving needs of industries. By building strong partnerships with clients and fostering a culture of excellence, Tianjin Acid-Resistant Pump strives to become the preferred choice for acid-resistant pumps worldwide.Conclusion:Tianjin Acid-Resistant Pump's commitment to providing high-quality acid-resistant pumps and exceptional customer service has positioned the company as a reliable solution for industrial liquid handling needs. With their superior features and versatile applications, these pumps ensure efficient and safe operations in corrosive environments. As industries continue to evolve and demand more reliable liquid handling solutions, Tianjin Acid-Resistant Pump is poised to meet these challenges and contribute to the growth and progress of industries worldwide.