Discover the Efficiency and Versatility of Screw Pump Technology

By:Admin

Fluid transfer is a critical process in numerous industries, including chemical, pharmaceuticals, oil and gas, and food and beverage. In most cases, this process requires the use of high-quality pumps that can transport liquids and gasses from one point to another effectively.

One such pump that has gained immense popularity in recent times is the Mini Screw Pump. As the name suggests, this pump is relatively small in size but boasts unmatched performance, making it an ideal choice for a wide range of fluid transfer applications.

Designed and manufactured by one of the leading companies in the industry, the Mini Screw Pump stands out due to its unique helical rotor design. This design allows the pump to overcome various challenges posed by other popular pump types, such as centrifugal pumps.

Most centrifugal pumps have impellers that spin on a shaft to create a fluid flow. Although these pumps are highly effective, they often struggle in situations where the liquid contains entrained air or gases. The entrained air tends to accumulate in the pump casing, eventually blocking the impeller and disrupting the fluid flow.

The Mini Screw Pump, on the other hand, has a self-priming feature that eliminates the need for external priming. Additionally, the pump's helical rotor and stator design enable it to handle fluid transfer applications that contain air or gas entrainment.

One of the main advantages of the Mini Screw Pump is its ability to handle various types of fluids, including abrasive, viscous, and corrosive liquids. This feature makes it an ideal choice for industries that require the transfer of challenging fluids.

Furthermore, the pump's simple design and minimal mechanical parts make it easy to maintain and repair, reducing downtime and maintenance costs.

To ensure optimal performance, each Mini Screw Pump is rigorously tested and checked to meet the highest industry standards. The company employs advanced testing equipment and quality control measures to ensure that each pump is defect-free and can deliver unparalleled results.

The Mini Screw Pump is versatile, reliable, and efficient, making it a must-have for industries that require fluid transfer applications. Its unique design and outstanding performance make it the preferred choice for various industries, including chemical, pharmaceutical, oil and gas, and food and beverage.

In conclusion, the Mini Screw Pump is a revolutionary solution that is set to change the fluid transfer industry's landscape. Its superior design, performance, and reliability make it the go-to pump for industries that require high-quality fluid transfer applications. With its ability to handle challenging fluids, the Mini Screw Pump is a game-changer that has earned its spot as one of the most effective pumps in the market.

Company News & Blog

Critical Factors to Consider When Selecting a Top-Quality Centrifugal Pump for Oil and Gas Applications

Title: Advancement in Centrifugal Pump Technology Revolutionizes Oil and Gas IndustryIntroduction:The oil and gas industry plays a vital role in the global energy sector, and continuous innovation and improvements are essential for maximizing efficiency and productivity. Leading the way in this regard is a pioneering company dedicated to the development of advanced centrifugal pump technology for the oil and gas sector. Their cutting-edge solutions are transforming the industry, significantly enhancing operational efficiency, and ultimately contributing to sustainable energy production. In this article, we will delve into the remarkable advancements in centrifugal pump technology and explore the impact they are creating for the oil and gas sector.A Legacy of Excellence:With a long-standing commitment to excellence, the company has been a force to be reckoned with in the oil and gas industry for several decades. Their expertise lies in their innovative centrifugal pumps, which are designed to efficiently transport various fluids, including crude oil, natural gas, and their derivatives. The company has established a reputation for manufacturing durable, endurable, and reliable pumps that continually adapt to the evolving needs of the industry.Advancements in Centrifugal Pump Design:Combining their industry-leading expertise with extensive research and development, the company has made significant breakthroughs in centrifugal pump technology. One notable aspect of their innovation lies in enhanced impeller design, resulting in improved hydraulic efficiencies. By optimizing impeller geometry, the company has successfully reduced operational costs by minimizing energy consumption while maximizing fluid flow rates.Furthermore, revolutionary materials have been incorporated into the construction of these centrifugal pumps. Advanced alloys and composite materials have replaced traditional materials, enhancing durability and corrosion resistance. These innovations extend the lifespan of the pumps and reduce maintenance requirements, contributing to substantial cost savings for oil and gas companies.Smart Pumping Solutions:In line with the Industry 4.0 revolution, the company has developed smart pumping solutions that leverage cutting-edge digital technologies. By integrating sensors and data analytics, their centrifugal pumps can continuously monitor crucial parameters, such as temperature, pressure, and flow rate. Real-time data analysis enables efficient predictive maintenance, minimizing downtime and reducing the risk of unexpected breakdowns.These smart pumping solutions also facilitate remote monitoring and control of the pumps, allowing operators to adjust performance and optimize operations from anywhere in the world. Furthermore, the collected data provides valuable insights for optimizing system efficiency and identifying potential bottlenecks, thereby further increasing overall productivity.Environmental Considerations:The company recognizes the increasing need for sustainable solutions in the oil and gas industry. As a result, they have developed environmentally friendly centrifugal pumps that minimize the carbon footprint of operations. By improving energy efficiency, these pumps significantly contribute to reduced greenhouse gas emissions and promote a greener approach to energy production.Conclusion:Through constant innovation and a dedication to excellence, this pioneering company has revolutionized centrifugal pump technology for the oil and gas industry. Their advanced solutions have enhanced operational efficiency, reduced costs, and promoted environmental sustainability. As the industry continues to evolve, these cutting-edge centrifugal pumps will play a significant role in driving progress and ensuring a more efficient and sustainable oil and gas sector.

10 Essential Factors to Consider When Choosing a Pump

article.Allweiler Pump Rebrands as ACI FluidsLeading global pump manufacturer, Allweiler Pump, has officially rebranded as ACI Fluids, following the acquisition by the American industrial conglomerate, Cameron Corporation. The exciting new development will see ACI Fluids bolster their state-of-the-art product portfolio, expand their global network, and continue to offer world-class services to customers across multiple industries.ACI Fluids has a rich history of innovation, with over 150 years of experience in the pump industry. Over the years, the company has established itself as a name to be reckoned with and has become synonymous with reliability and quality. As the company takes on a new identity, it seeks to build on its legacy and scale new heights of success.ACI Fluids offers an extensive range of pumps that cater to a variety of industrial applications. Its portfolio includes centrifugal, positive displacement, and gear pumps, among others. The company has a reputation for manufacturing pumps that are durable, efficient, and operate at peak performance even under challenging conditions. ACI Fluids' product range serves industries such as oil and gas, marine, chemical, food and beverage, and water and wastewater.The acquisition of Allweiler Pump by Cameron Corporation presents numerous opportunities for ACI Fluids to expand its presence in different markets. The synergy created by the acquisition will allow the company to leverage the technological expertise and operational efficiency of both organizations. This development will translate to more significant investments in research and development, enhancing engineering capabilities, expanding product lines, and exploring new avenues of growth.ACI Fluids' mission is to be a reliable partner to its customers by offering exceptional customer service and technical support. Its team of experienced engineers and technicians work closely with customers to provide customized solutions that meet their unique requirements. The company's commitment to customer satisfaction is evident from the testimonials of its satisfied customers, who have attested to the quality of its products and services.The appointment of Kevin Snee as President of ACI Fluids marks a significant milestone in the company's growth. Kevin joins the company with a wealth of industry experience, having previously served as Senior Vice President of Global Sales and Marketing at Blackmer. In his new role, Kevin will be responsible for driving the company's strategic vision, leading its growth initiatives, and developing strong customer relationships.Kevin's appointment comes at a time when ACI Fluids is looking to strengthen its presence in emerging markets such as Asia and the Middle East. He sees these regions as critical to the company's growth and is committed to investing resources to expand the company's footprint. Kevin also plans to continue building on the company's primary focus of delivering exceptional products and services to its customers.In conclusion, the rebranding of Allweiler Pump to ACI Fluids is a significant development in the pump industry. With a history rooted in innovation and a reputation for quality, ACI Fluids is poised for growth under the leadership of Kevin Snee. As it expands its product portfolio, leverages new technologies, and explores new markets, ACI Fluids remains committed to its core values of reliability, quality, and superior customer service.

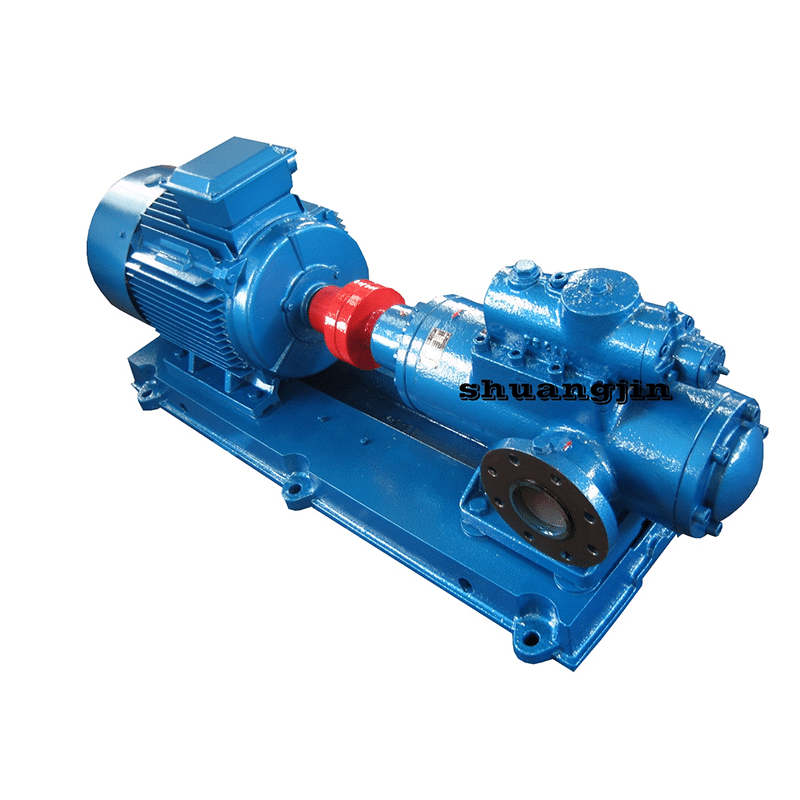

Innovative Triple Screw Pump Technology: Revolutionizing Industrial Fluid Transfer

Triple Screw Pump Offers High-Level Performance for Industrial Applications{Company Name} is proud to introduce the triple screw pump, a high-level performance solution for industrial applications. With the ability to handle viscous fluids while providing smooth and continuous flow, this reliable pump is ideal for a variety of industrial processes.One of the significant advantages of this pump is its high efficiency. It can achieve up to 90% efficiency while still being able to handle high-viscosity fluids such as crude oil, asphalt, and bitumen. This makes it an ideal solution for industries that require a high level of performance in their fluid handling processes.Another key feature of the triple screw pump is its ability to maintain consistent flow, even with varying inlet pressures. The screw design creates a clearing action within the pump, which means that there is a minimal risk of clogging or blockages, even with thicker fluids.The triple screw pump has been designed with ease of use in mind, making it an ideal choice for operators who need a low-maintenance solution. A self-priming design enables the pump to start and stop without the need for manual intervention, and it requires minimal disassembly for cleaning and servicing.Moreover, the pump has a compact footprint, which makes it easy to install and integrate into existing systems. Its low noise and vibration levels make it an ideal solution for applications where noise pollution and vibration could be an issue.It is recommended for industries that deal with liquid transfer, applications that need high pressure, high viscosity, and high temperature. Additionally, the triple screw pump is ideal for applications that involve feeding multiple points at once, as it can operate on a different number of pressures and flows.Furthermore, the triple screw pump is highly customizable, which means that it can be tailored to meet the specific needs of individual applications. Customization options include different materials of construction, various sealing systems, and different RPMs to suit the application's requirements.{Company Name} CEO, {Name}, stated "We are thrilled to offer this high-performance solution to our customers. The triple screw pump is an ideal choice for industries that require consistency and reliability in their fluid handling processes."In conclusion, the Triple Screw Pump offers high-level performance for industrial applications. With its high efficiency, consistent flow, low maintenance requirement, and customizable design, it is ideal for industries that deal with high-pressure, high-viscosity, and high-temperature applications. Operators can use it to feed multiple points at once while achieving a smooth and continuous flow.

Essential Guide to Different Types of Petroleum-Based Products

Title: Global Company Boosts Sustainability Efforts with Advanced Energy SolutionsIntroduction: In an endeavor to champion sustainable energy and reduce carbon emissions, {Company Name}, a leading global conglomerate, is expanding its portfolio by investing in advanced energy solutions. The company's latest move aims to strengthen its commitment to a greener future while diversifying its operations within the energy sector. By leveraging its extensive expertise in crude oil, fuel oil, cargo shipping, palm oil, pitch, asphalt, bitumen, and mineral resins, {Company Name} aims to drive significant positive change and contribute to a more sustainable world.Paragraph 1: Driving Sustainable Energy Transition{Company Name} recognizes the urgency to mitigate climate change while addressing global energy demands. As part of its sustainability strategy, the company is investing heavily in advanced energy solutions to facilitate a transition to renewable and low-carbon sources. By leveraging its vast experience in the crude oil industry, {Company Name} aims to harness the potential of emerging technologies, such as advanced biofuels and hydrogen, to promote a cleaner and more sustainable future.Paragraph 2: Clean Energy Revolution: Shifting from Fossil FuelsAcknowledging the critical need to diversify its energy sources, {Company Name} is actively exploring alternatives to conventional fossil fuels. While remaining committed to its core business of crude oil, the company is ramping up efforts to incorporate more sustainable practices and technologies. This includes researching and implementing fuel oil substitutes, such as biofuels and renewable energy sources, to reduce carbon emissions and create a more environmentally friendly energy matrix.Paragraph 3: Sustainable Cargo Shipping and Supply ChainAs a major player in the cargo shipping industry, {Company Name} is dedicated to making significant strides towards sustainability. The company's commitment extends to optimizing fuel consumption, reducing emissions, and employing eco-friendly vessels. By prioritizing the use of sustainable fuel alternatives in its shipping operations, such as biofuels, {Company Name} aims to minimize its carbon footprint and lead by example within the industry.Paragraph 4: Advancing the Biofuels IndustryRecognizing the potential of biofuels to revolutionize the energy landscape, {Company Name} is investing in research and development to enhance the efficiency and scale of biofuel production processes. Given its substantial expertise in palm oil cultivation and extraction, the company is exploring innovative ways to convert palm oil residue into biofuels, thereby reducing waste and maximizing resource utilization.Paragraph 5: Pioneering Infrastructure for Renewable Solutions{Company Name} is dedicated to accelerating the adoption of renewable energy resources and investing in the necessary infrastructure to support their integration into power grids. By expanding its involvement in the production and distribution of asphalt, bitumen, and mineral resins, the company is building a robust foundation for the implementation of renewable energy solutions, such as solar and wind farms.Conclusion: {Company Name}'s recent commitment to sustainable energy solutions signifies a pivotal moment in its history. By leveraging its extensive experience in crude oil, fuel oil, cargo shipping, palm oil, pitch, asphalt, bitumen, and mineral resins, the conglomerate is redefining its role within the energy sector. With a strong determination to drive the global shift to renewable energy, {Company Name} aims to set new industry standards and foster a sustainable future.

Innovative Centrifugal Screw Pump Technology Revolutionizing Industrial Pumping Applications

Centrifugal Screw Pump Proves to be a Game-Changer in Industrial ApplicationsIn the world of industrial applications, finding the right kind of machinery that suits the needs of the business is essential. Centrifugal Screw Pumps, also known as twin-screw pumps, have been creating waves in various industries lately. They have gained immense popularity due to their unmatched efficiency, versatility, and durability.A centrifugal screw pump is a positive displacement pump that transfers fluid by moving it through closely-spaced screws, generating pressure and flow. This particular pump's design enables it to handle tough-to-pump fluids with high viscosity and solids content. Consequently, the centrifugal screw pump is known to reduce maintenance costs, increase the lifecycle of machines, and enhance overall operational efficiency.However, the centrifugal screw pump by a prominent brand has gained significant attention for its cutting-edge technology, exceptional performance, and outstanding customer service. This high-quality pump has been used in several industries and applications such as marine, food processing, wastewater treatment, biodiesel production, and more.One of the many advantages of the centrifugal screw pump is the considerable reduction in cavitation. When a pump experiences high-pressure changes, there could be areas of low pressure that lead to the formation of cavities or bubbles. With traditional pumps, cavitation would cause significant damage, resulting in increased maintenance costs. Installing a centrifugal screw pump substantially reduces this problem since the pump can handle a higher level of turbulence without the creation of cavities.Another crucial advantage of centrifugal screw pumps is their ability to handle fluids of varying viscosity. They operate with a wide range of viscosities, even as high as 200,000 centipoises, without the need for external pumps. This feature allows it to handle more challenging fluids such as crude oil, molasses, and syrup.This pump design also facilitates the transfer of fluids with high solid content. It is capable of transferring up to 40% blockage in its internal flow chambers without damaging the rotor or the stator. This pump design makes it ideal for transferring abrasive fluids or slurries and is a critical component in several waste treatment systems.Moreover, the centrifugal screw pump is also suitable for metering applications due to its precise flow rate. Its discharge rate is unaffected by variations in fluid viscosity, temperature, or pressure, which is uncommon in other types of pumps. This accuracy makes it an ideal solution for transferring critical fluids in the pharmaceutical and chemical industries.Overall, this high-end centrifugal screw pump equipped with state-of-the-art technology is a guaranteed game-changer in the industrial manufacturing sector. \This pump has already made a significant impact in the industry by delivering unmatched performance and efficiency. With its ability to handle complex fluids, reduce maintenance costs, increase machine longevity, and improve overall operational efficacy, it remains the top choice for many businesses.Additionally, the company that produces this innovative centrifugal screw pump takes pride in providing customers with the best service in the industry. Their team of experts makes every effort to assist and guide clients in the selection, installation, and maintenance of equipment. They also offer comprehensive training to ensure maximum productivity and efficiency from the pump.In conclusion, investing in a centrifugal screw pump from this reputable brand is the best decision any business can make. It delivers exceptional performance, reduces production costs, and adds value to the entire manufacturing process. With its unmatched versatility and durability, it is the ultimate solution to all your fluid transfer needs. Contact their team today and experience the revolution in industrial manufacturing!

Top-quality Oil & Gas Pumps: Your Guide to Efficient Industry Solutions

Oil and Gas Pumps Revolutionize the Energy IndustryIn today's rapidly evolving technological landscape, the demand for efficient and reliable equipment in the oil and gas industry is higher than ever. To meet these increasing demands, Oil and Gas Pumps (name removed) has emerged as a leading provider of cutting-edge pumping solutions. With their acclaimed company history of innovation and commitment to customer satisfaction, Oil and Gas Pumps has revolutionized the energy industry.With a diverse range of offerings, Oil and Gas Pumps provides pumping solutions that cater to various applications within the oil and gas sector. Their pumps play a crucial role in exploration, production, refining, and distribution processes, ensuring a smooth and continuous flow of oil and gas.One of the key factors that sets Oil and Gas Pumps apart from its competitors is its relentless pursuit of innovation. The company invests heavily in research and development, constantly striving to develop pumps that are more efficient, durable, and environmentally friendly. By pushing the boundaries of engineering, Oil and Gas Pumps has been able to enhance productivity while reducing the carbon footprint of its operations.Furthermore, Oil and Gas Pumps' commitment to customer satisfaction is second to none. The company takes immense pride in its ability to provide tailored solutions that meet the specific needs of its clients. By working closely with customers, Oil and Gas Pumps ensures that its pumps are perfectly suited to the varied challenges faced in the oil and gas industry, whether it be offshore drilling in extreme environments or onshore refining in remote locations.Oil and Gas Pumps owes its success, in large part, to its team of highly skilled professionals. With expertise in mechanical engineering, fluid dynamics, and industrial design, the company's engineers are at the forefront of technological advancements in pumping solutions. Through continuous training and development programs, Oil and Gas Pumps ensures that its workforce remains knowledgeable and equipped to handle even the most complex projects.Moreover, the company's dedication to quality control is unfaltering. Each pump undergoes rigorous testing and inspection to ensure it meets the highest industry standards. This commitment to quality has earned Oil and Gas Pumps a stellar reputation for reliability and durability, resulting in long-lasting relationships with customers worldwide.In addition to its technological prowess and commitment to excellence, Oil and Gas Pumps is also deeply aware of the need to minimize its environmental impact. The company strives to create sustainable solutions and reduce energy consumption in its pumps. By implementing energy-efficient designs and utilizing eco-friendly materials, Oil and Gas Pumps aims to contribute to the global effort of transitioning to a greener and more sustainable future.Through its continued investment in research and development, its customer-centric approach, and its unwavering commitment to innovation and quality, Oil and Gas Pumps has established itself as a trusted leader in the pumping solutions industry. With each new product, the company continues to drive advancements in the oil and gas sector, facilitating greater efficiency, productivity, and sustainability.As the global demand for oil and gas continues to rise, it is companies like Oil and Gas Pumps that will play a vital role in meeting these ever-increasing demands. With their state-of-the-art pumping solutions, the company is helping to shape the future of the energy industry, ensuring a smooth and reliable supply of oil and gas for years to come.

Highly efficient centrifugal pumps revolutionizing industry operations

Centrifugal Pump Technology Boosts Efficiency and ProductivityIn today’s highly competitive world, businesses are clamoring for ways to improve their efficiency and productivity. One of the most often overlooked areas of improvement is in the realm of industrial pumps. Companies like [BRAND NAME REMOVED] are harnessing centrifugal pump technology to give businesses a powerful edge in their quest for increased output and profitability.Centrifugal pumps are well-known for their ability to transfer fluids from one location to another across different types of systems. They accomplish this through the use of a rotating impeller that is surrounded by a casing. As the impeller spins, it creates a force that pulls fluid in through the center of the pump, accelerates it, and then creates a high-pressure discharge at the outer circumference of the pump.This technology is incredibly versatile, utilized in a wide range of industries such as agriculture, mining, oil & gas, and water treatment. The reason centrifugal pumps are so popular is that they are reliable, efficient, energy-saving, and require minimal maintenance.[BRAND NAME REMOVED] understands the importance of this technology and has created a range of centrifugal pumps that are tailor-made for all kinds of industrial applications. Their pumps are manufactured using the highest-quality materials and the most advanced engineering techniques to provide optimal performance and durability.One of the company’s most successful products is the (REMOVED) Series Centrifugal Pump, which is designed to handle a wide range of fluids, including highly abrasive and corrosive liquids. The pump is also equipped with a sturdy bearing assembly and seals that are fully interchangeable with other leading brands, making it easy to integrate into existing systems.As a result of its highly efficient design, this centrifugal pump consumes less energy, which translates to significant cost savings for the user. Additionally, its compact size means it can be installed in tight spaces, a valuable feature for businesses looking to maximize their facility’s layout.Another innovative feature of the (REMOVED) Series Centrifugal Pump is its suction and discharge ports, which can be adjusted to eight different directions, making it ideal for tight installation spaces and versatile enough to be adapted to various system configurations.In summary, centrifugal pump technology is an indispensable tool for businesses that value reliability, efficiency, energy savings, and durability. [BRAND NAME REMOVED] understands this and has developed a line of pumps that can be tailored to any industrial application. With their commitment to quality and innovation, [BRAND NAME REMOVED] is an excellent choice for businesses looking for a competitive edge.

Exploring the Versatility of Screw Pumps - Unraveling the Inner Workings of Centrifugal Designs

Centrifugal Screw Pump Revolutionizes Fluid Transfer: Introducing a Game-Changing Device by Leading Pump Manufacturer[Company Name], a renowned manufacturer in the fluid transfer industry, has recently unveiled their latest innovation – the Centrifugal Screw Pump. This groundbreaking device promises to revolutionize fluid transfer processes across various sectors, offering improved efficiency, reliability, and ease of use.The Centrifugal Screw Pump is a result of meticulous research and development by [Company Name], a company with a longstanding reputation for delivering high-quality fluid transfer solutions. With a rich history spanning several decades, [Company Name] has continuously strived to push the boundaries of innovation in the pump manufacturing field.The Centrifugal Screw Pump is designed to address the challenges faced by industries dependent on smooth fluid transfer operations. Its cutting-edge technology combines the benefits of centrifugal force and screw pumping mechanisms, resulting in a device that boasts excellence in both performance and versatility.One of the key features of the Centrifugal Screw Pump is its ability to handle a wide range of fluids, including those with high viscosity and entrained solids. This adaptability makes it ideal for applications across a multitude of industries, such as oil and gas, chemical processing, power generation, and wastewater treatment.The unique design of the Centrifugal Screw Pump allows for enhanced operational efficiency. Its innovative screw impeller ensures a smooth and consistent flow rate, minimizing the risk of pulsation and cavitation. This feature not only increases productivity but also prolongs the lifespan of the pump, reducing maintenance costs for businesses.Moreover, the Centrifugal Screw Pump offers significant energy savings compared to traditional fluid transfer devices. Its advanced motor design, combined with a robust impeller structure, reduces power consumption while delivering optimal performance. This translates into reduced operational costs and a smaller environmental footprint, aligning with the global push towards sustainability.Furthermore, the Centrifugal Screw Pump is engineered for easy installation and maintenance. Its compact and modular design simplifies on-site assembly, minimizing downtime during installation. Additionally, the pump's user-friendly interface provides operators with real-time performance metrics and alerts, facilitating proactive troubleshooting and ensuring consistent operation.Safety is also prioritized with the Centrifugal Screw Pump, as it incorporates various features to mitigate risks. Equipped with advanced sensors, the pump actively monitors temperature, pressure, and other parameters, automatically shutting down in case of system anomalies. This proactive approach not only protects valuable assets but also prevents accidents and ensures operator well-being.The Centrifugal Screw Pump comes backed by [Company Name]'s extensive customer support and service network. With a global footprint and a commitment to customer satisfaction, the company offers comprehensive technical assistance, spare parts availability, and prompt maintenance services. This ensures that businesses using the Centrifugal Screw Pump can rely on uninterrupted operations and optimal performance.As [Company Name] continues to advance the boundaries of pump manufacturing and revolutionize the fluid transfer industry, they solidify their position as a pioneer in the field. The Centrifugal Screw Pump stands as a testament to their dedication to innovation, efficiency, and customer-centricity, offering businesses a game-changing solution for their fluid transfer needs.In conclusion, the introduction of the Centrifugal Screw Pump by [Company Name] is set to transform fluid transfer processes across industries. With its exceptional performance, versatility, energy efficiency, and user-friendly features, this revolutionary pump device promises to enhance productivity, reduce operational costs, and contribute to a more sustainable future.

10 Essential Applications of Screw Pumps in Various Industries

The Use of Screw Pump: Understanding the Importance in Industrial ApplicationsScrew pumps have been around for a while and used in industrial applications for various reasons. They have become popular because of their efficiency and versatility, with many companies using it for different purposes. These pumps can be found in oil and gas industries, food-processing plants, petrochemical plants, and many more.Screw pumps work by moving fluid inside their chambers. A helical screw rotates inside a cylinder, creating pressure that forces fluid to flow through the pump. As it moves, it also moves pockets of fluid along the way, which reduces pulsation, ensures smooth continuous flow, and maximizes efficiency.Thanks to screw pumps, manufacturers can efficiently move liquids without disturbing the medium's temperature, density, or viscosity. It's perfect for transferring both low and high viscosity liquids, making it the perfect solution for moving anything from crude oil to food products.This pump is versatile, cost-effective, and often replaceable. However, like any machinery, there are advantages and disadvantages to using a screw pump. Below, we'll take a look at some of the benefits of using screw pumps in your system.Advantages of Screw Pumps1. Low Maintenance RequirementsOne of the primary advantages of using a screw pump is that it requires minimal maintenance. The low maintenance requirements of screw pumps make it cost-effective, and you will save a considerable amount of money in maintenance and repairs.2. Efficient PerformanceScrew pumps are designed for maximum efficiency. They can handle high and low viscosity liquids, making it easy to move anything from crude oil to food products. Their design optimizes the flow of liquid, reducing pulsations and ensuring smooth, continuous flow.3. High Suction CapabilityScrew pumps can handle high suction, making it easy to transfer liquids of different viscosities. They can handle everything from light fuel oils to heavy crude oil.4. Can Handle Multiple ViscositiesScrew pumps are suitable for transferring liquids of different viscosities. They are often used in the oil and gas industry, where they can be used to transfer crude oil, diesel fuel, and heavy oil.5. They Are VersatileScrew pumps are highly versatile. They are used in a variety of industries for many different purposes, making them ideal for any application that requires the movement of liquids.6. Reduced Noise LevelScrew pumps are relatively quiet, making them ideal for indoor settings where noise levels need to be kept to a minimum.How to Select the Right Screw PumpSelecting the right screw pump is essential to ensure that you get the desired results. The best way to select the right screw pump is to work with a reputable and experienced manufacturer. When selecting a screw pump, you need to consider factors such as:1. The Viscosity of the LiquidThe viscosity of the liquid you are transferring is a crucial factor when selecting a screw pump. You need to ensure that the pump you choose can handle the viscosity of the liquid.2. Temperature of the LiquidConsider the temperature of the liquid you will be transferring. Screw pumps are suitable for liquid temperatures of up to 350 degrees Celsius.3. Characteristics of the LiquidConsider the characteristics of the liquid you will be transferring. The physical characteristics of the liquid will impact the type of screw pump you choose.ConclusionScrew pumps are essential for many industries. They are versatile, efficient, and cost-effective, making them the perfect solution for moving liquids of various viscosities. When selecting a screw pump, it's essential to choose an experienced and reputable manufacturer to ensure that you get the desired results.

Top Acid-Resistant Pump Options for Industrial Applications in Tianjin

Title: Tianjin Acid-Resistant Pump: A Reliable Solution for Industrial Liquid HandlingIntroduction:Tianjin Acid-Resistant Pump is a leading manufacturer and supplier of high-quality acid-resistant pumps for various industrial applications. With an impeccable track record and a commitment to excellence, the company has earned a reputation for delivering reliable and innovative solutions for liquid handling challenges in corrosive environments. This news article will delve into the exceptional features and advantages offered by Tianjin Acid-Resistant Pump, highlighting the company's commitment to customer satisfaction and its contributions to industrial growth.1. Superior Features of Tianjin Acid-Resistant Pump:Tianjin Acid-Resistant Pump stands out in the market due to its exceptional features that ensure efficient and reliable performance in corrosive environments. These features include:a) Strong Acid Resistance: The pumps are manufactured using high-quality acid-resistant materials, such as fluoroplastic and stainless steel, which are specifically designed to withstand the corrosive nature of acids and other aggressive liquids.b) Optimal Efficiency: With advanced impeller designs and precision engineering, Tianjin Acid-Resistant Pump offers maximum efficiency in terms of energy consumption and fluid flow. These pumps ensure minimal process downtime and reduced maintenance costs.c) Versatile Applications: The acid-resistant pumps from Tianjin find applications in various industries such as chemical, pharmaceutical, mining, wastewater treatment, and metal processing. Their adaptability in handling different corrosive liquids makes them an ideal choice for a wide range of industrial needs.2. Commitment to Customer Satisfaction:Tianjin Acid-Resistant Pump prioritizes customer satisfaction by providing personalized solutions tailored to meet specific requirements. The company's team of experienced engineers and technical professionals offer expert guidance and support throughout the entire process, from selecting the right pump to after-sales services. Customers can rely on Tianjin Acid-Resistant Pump for prompt delivery, comprehensive technical support, and reliable solutions.3. Contributing to Industrial Growth:Tianjin Acid-Resistant Pump plays a crucial role in supporting various industries by providing efficient and reliable liquid handling solutions. Some notable contributions include:a) Safety and Environmental Protection: The acid-resistant pumps help industries ensure the safety of their operations while handling corrosive liquids, preventing accidental leaks and minimizing environmental risks.b) Enhancing Efficiency: The superior design and performance of Tianjin Acid-Resistant Pump's products help industries optimize their operations by providing consistent fluid flow, reducing energy consumption, and minimizing maintenance requirements.c) Enabling Innovation: The acid-resistant pumps from Tianjin facilitate the development of new processes and technologies in industries by offering robust and reliable liquid handling solutions, thus increasing productivity and contributing to overall industrial growth.4. Vision for the Future:Tianjin Acid-Resistant Pump aims to continuously improve its product offerings and expand its global presence. The company invests in research and development to stay at the forefront of technological advancements and develop innovative solutions that address the evolving needs of industries. By building strong partnerships with clients and fostering a culture of excellence, Tianjin Acid-Resistant Pump strives to become the preferred choice for acid-resistant pumps worldwide.Conclusion:Tianjin Acid-Resistant Pump's commitment to providing high-quality acid-resistant pumps and exceptional customer service has positioned the company as a reliable solution for industrial liquid handling needs. With their superior features and versatile applications, these pumps ensure efficient and safe operations in corrosive environments. As industries continue to evolve and demand more reliable liquid handling solutions, Tianjin Acid-Resistant Pump is poised to meet these challenges and contribute to the growth and progress of industries worldwide.