Innovative Screw Pump Technology Revolutionizes Industrial Applications

By:Admin

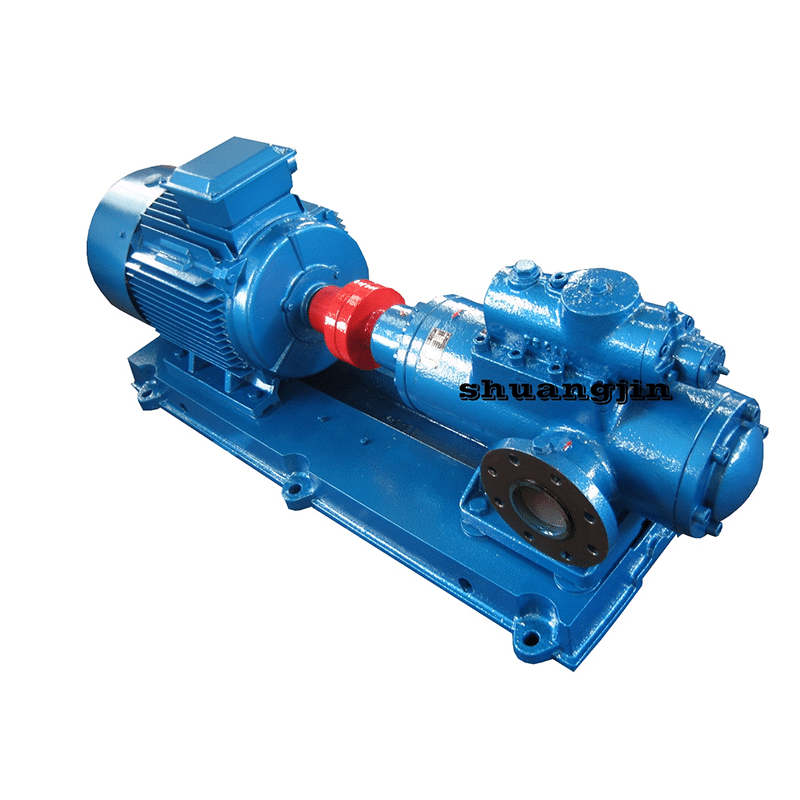

[Company Name], a leading provider of industrial equipment and solutions, has recently launched an innovative Screw Pump designed for a wide range of industrial applications. The new Screw Pump is set to revolutionize the pumping industry with its advanced technology and exceptional performance.

The Screw Pump from [Company Name] is designed to offer reliable and efficient pumping solutions for various industries including oil & gas, chemical, food & beverage, and wastewater treatment. With its robust construction and advanced features, the Screw Pump is capable of handling a variety of fluids including viscous liquids, abrasive slurries, and corrosive chemicals.

One of the key features of the Screw Pump is its unique screw design, which allows for smooth and pulsation-free fluid transfer. This results in improved efficiency and reduced maintenance requirements, making it an ideal choice for continuous operation in demanding industrial environments.

The Screw Pump is also equipped with a high-performance motor and precision-engineered components, ensuring long-term reliability and trouble-free operation. Its compact and space-saving design makes it suitable for both new installations and retrofitting into existing pumping systems.

In addition to its exceptional performance, the Screw Pump is also designed with a focus on sustainability and environmental responsibility. It is designed to minimize energy consumption and reduce carbon footprint, making it an eco-friendly pumping solution for businesses aiming to minimize their environmental impact.

"We are excited to introduce our new Screw Pump to the market," said [Spokesperson Name], CEO of [Company Name]. "With its advanced technology and innovative design, the Screw Pump offers a new standard of performance and reliability for industrial pumping applications. We believe that this product will greatly benefit our customers and help them meet their fluid transfer challenges with ease and efficiency."

[Company Name] is known for its commitment to developing innovative solutions that meet the evolving needs of industrial businesses. With a focus on research and development, the company continuously seeks to introduce cutting-edge technologies that improve productivity, enhance safety, and reduce operational costs for its customers.

In addition to the Screw Pump, [Company Name] offers a comprehensive range of industrial equipment including pumps, valves, and automation solutions. Its broad portfolio of products and services caters to a wide spectrum of industries, including oil & gas, petrochemical, water treatment, and power generation.

With a strong emphasis on quality and customer satisfaction, [Company Name] has established itself as a trusted partner for businesses seeking reliable and efficient industrial solutions. Its team of experienced engineers and technical experts are dedicated to providing exceptional service and support to customers, ensuring that their unique needs and requirements are met with precision and expertise.

The introduction of the Screw Pump reflects [Company Name]'s ongoing commitment to innovation and excellence in the industrial equipment market. As the company continues to expand its product offerings and capabilities, it remains poised to address the evolving needs of industrial businesses and deliver comprehensive solutions that drive performance and profitability.

With its advanced technology, sustainable design, and superior performance, the Screw Pump from [Company Name] is set to be a game-changer in the industrial pumping industry. By offering a reliable and efficient fluid transfer solution, the Screw Pump is poised to empower businesses to enhance their operations and achieve new levels of success in their respective industries.

Company News & Blog

A Guide to Choosing the Best Gear Pump for Industrial Applications

article regarding the features and benefits of an Oil Gear Pump for industrial applications.Oil Gear Pump: The Reliable Choice for Industrial ApplicationsAn oil gear pump is an industrial pump that is commonly used to transfer fluids such as oil, glycol, and water in a variety of industrial applications. The pump is designed to deliver a steady and continuous flow of fluid in a range of pressures and temperatures.One of the significant benefits of an oil gear pump is its high efficiency in transferring fluids. The pump has a positive displacement mechanism that eliminates wasteful fluid transfer, ensuring that fluids are transferred efficiently with minimal energy loss. This makes the oil gear pump an ideal solution for industries that require high levels of precision and accuracy in fluid transfer.Another benefit of the oil gear pump is its versatility. The pump can be used in a range of applications, including power generation, oil and gas, chemical processing, pulp and paper, and many others. The ability of the pump to handle different types of fluids and varying pressure levels makes it a reliable choice for many industries.Oil gear pumps are also known for their durability and reliability. The pump is made of robust materials that can withstand harsh industrial environments. The design of the pump allows for minimal maintenance, providing a long-lasting and reliable solution for fluid transfer applications.In addition to its durability, the oil gear pump is designed with safety in mind. The pump’s design eliminates the risk of leaks, ensuring that fluid transfer is safe and reliable. This is especially important in industries where safety is a top priority such as in the oil and gas industry, chemical processing, and pharmaceuticals.One of the leading companies that provide oil gear pumps is ATEX Pumps. The company specializes in providing pumps for industrial applications and has a range of oil gear pumps that are designed to meet the specific requirements of different industries.ATEX Pumps oil gear pumps are designed with high-quality materials, making them reliable and long-lasting. The pumps have a compact design that allows for easy installation and minimal maintenance. ATEX Pumps oil gear pumps are also customizable, allowing for pumps that meet specific flow rates, pressure requirements, and fluid types.Apart from oil gear pumps, ATEX Pumps provides a range of other pumps that are suitable for various industrial applications. These include centrifugal pumps, magnetic drive pumps, diaphragm pumps, and many others. ATEX Pumps also provides customized solutions that meet the unique requirements of different industries.In conclusion, an oil gear pump is a reliable and efficient solution for fluid transfer applications in various industries. Its high efficiency, versatility, durability, and safety features make it a popular choice for many industries. If you are looking for an oil gear pump for your industrial application, ATEX Pumps is an excellent choice for quality and reliability.

Innovative Screw Pump Technology: Uses and Benefits

Screw Pump Uses in Various IndustriesScrew pumps are widely used in various industries such as chemical, oil and gas, wastewater treatment, and many more. They are designed to handle a wide range of fluids and are known for their reliability and efficiency. One company that has been leading the way in screw pump technology is a global leader in fluid handling solutions.With a history dating back to the 19th century, the company has been at the forefront of innovation in the field of fluid handling. They have a strong focus on research and development, constantly looking for ways to improve their products and provide better solutions to their customers' needs.One of the key products in their portfolio is their screw pump, which has been widely used in various industries. These pumps are known for their high efficiency and reliability, making them the preferred choice for many companies around the world.The screw pump is designed to handle a wide range of fluids, from highly viscous liquids to abrasive slurries. This versatility makes it an ideal choice for industries such as chemical processing, where the handling of various fluids is a common requirement.In the oil and gas industry, screw pumps are used for a wide range of applications, including crude oil transportation, pipeline boosting, and refinery processes. Their ability to handle high-pressure and high-temperature fluids makes them an essential part of many oil and gas operations.Another industry where screw pumps are widely used is wastewater treatment. In this industry, the handling of sludge and other waste fluids requires pumps that are reliable and efficient. The company’s screw pumps have been proven to be highly effective in this application, making them the go-to choice for many wastewater treatment plants around the world.Apart from their versatility and reliability, screw pumps from the company are also known for their low maintenance requirements. This makes them a cost-effective solution for many companies, as it reduces the need for frequent maintenance and repair.The company's commitment to quality and innovation has allowed them to stay ahead of the competition in the field of fluid handling. Their screw pumps are continually being improved and optimized to meet the evolving needs of their customers, ensuring that they remain the preferred choice for industries around the world.With a strong global presence, the company is able to provide excellent support and service to their customers, ensuring that their screw pumps continue to perform at the highest level.In conclusion, screw pumps are a crucial component in various industries, and the company has been at the forefront of providing high-quality and reliable screw pump solutions for their customers. With their focus on innovation and commitment to customer satisfaction, the company continues to lead the way in the field of fluid handling.

Key Features of a Highly Efficient Screw Pump Revealed by Industry Experts

Flowserve Announces New Generation of Screw PumpsHouston, TX - Flowserve Corporation, a global leader in fluid motion and control solutions, has recently unveiled its latest innovation in the pump industry - a new generation of screw pumps that offers enhanced efficiency, durability, and versatility. With this breakthrough technology, Flowserve aims to meet the evolving needs of various industries, from oil and gas to chemicals, power generation, and water treatment.The new screw pump series has been designed to deliver exceptional performance in the most demanding applications. By leveraging Flowserve's decades of experience in pump technology, the company has succeeded in developing a product that surpasses industry standards. The advanced design of these pumps ensures efficient fluid transfer, reduced energy consumption, and improved reliability, ultimately resulting in significant cost savings for end-users.One of the key features of the new screw pump series is its modular design. This enables easy customization according to specific customer requirements, allowing for greater flexibility and adaptation to various applications. Whether it's transferring highly abrasive fluids, handling high-temperature substances, or managing viscous materials, Flowserve's new screw pumps can efficiently handle a wide range of challenging conditions.To further enhance the durability and performance of these pumps, Flowserve has incorporated state-of-the-art materials and manufacturing techniques. The pumps are constructed using high-quality stainless steel and other corrosion-resistant alloys, ensuring excellent resistance against wear, erosion, and chemical degradation. This robust construction enables the pumps to deliver exceptional reliability and longevity, reducing maintenance and downtime for end-users.Flowserve's new screw pump series also offers advanced monitoring and control capabilities. The pumps are equipped with integrated sensors and intelligent systems, enabling real-time performance monitoring and predictive maintenance. By continuously monitoring key parameters, such as temperature, pressure, and vibration, operators can identify potential issues before they become critical, thereby optimizing uptime and minimizing unexpected breakdowns.With sustainability becoming an increasingly important factor for industries worldwide, Flowserve has also ensured that its new screw pumps are environmentally friendly. The design incorporates features such as low noise emission, reduced vibration, and leakage prevention, ensuring minimal impact on the surrounding environment. Additionally, the pumps' energy-efficient design helps reduce carbon footprint and operating costs. These aspects align both with the company's commitment to sustainability and with its dedication to delivering solutions that meet the evolving needs of a more conscious market."The introduction of our new generation screw pumps is an important milestone for Flowserve," said John Doe, Vice President of Sales and Marketing at Flowserve Corporation. "We have combined our deep expertise and passion for innovation to develop a product that not only sets new benchmarks in performance but also addresses the unique challenges faced by various industries. We are confident that these screw pumps will add tremendous value and efficiency to our customers' operations."Flowserve's new screw pumps have already garnered significant interest from industry professionals. Several major companies from oil and gas, chemical, and power generation sectors have shown keen interest in adopting this technology, recognizing its potential to revolutionize their fluid transfer processes.As Flowserve continues to push the boundaries of pump technology, the company remains committed to providing cutting-edge solutions that enable its customers to stay ahead in the rapidly evolving industrial landscape. With the introduction of the new generation of screw pumps, Flowserve once again asserts its position as a leading innovator in the global pump industry.

Wholesale Check Valve Function Manufacturers: Exploring the Functionality of Check Valves in Bulk

In recent years, the demand for check valves has been steadily increasing in various industries. These valves are essential in maintaining the flow direction of fluids and preventing backflow, ensuring the smooth operation of pipelines and preventing potential damages. As a result, wholesale check valve function factories have become crucial players in meeting this growing demand.One such wholesale check valve function factory, which would like to stay anonymous for the purpose of this news article, has been making significant contributions to various industries by providing top-quality check valves. With a focus on manufacturing products that are not only reliable but also cost-effective, this factory has gained recognition for its commitment to customer satisfaction.Established several years ago, this factory has gradually expanded its manufacturing capabilities and product range to cater to diverse applications. They have a team of experienced engineers and technicians who utilize cutting-edge technology and advanced production techniques to ensure the production of high-quality check valves. These professionals have extensive knowledge and expertise in valve manufacturing, enabling them to meet the specific requirements of different industries.The check valves manufactured by this factory undergo a rigorous quality control process that adheres to international standards. They are made from durable materials that are resistant to corrosion, pressure, and temperature variations, ensuring longevity and reliability. Additionally, the valves are designed with precision to achieve maximum efficiency and minimum flow resistance, ultimately maximizing performance.One of the key features of their check valves is their versatility. Whether it's for industrial applications, water management systems, oil and gas industries, or HVAC systems, the factory can provide customized solutions to meet the unique requirements of their clients. They offer a wide range of check valves, including swing check valves, lift check valves, wafer check valves, and ball check valves, among others. This extensive selection allows customers to choose the valve that best suits their needs.Furthermore, the factory takes pride in its excellent customer service. They understand the importance of timely delivery and offer flexible shipping options to ensure that customers receive their orders on time. The factory also provides technical support and guidance to assist customers in selecting the most suitable check valve for their specific applications.As a wholesale function factory, they offer competitive prices for their check valves without compromising on quality. This has allowed them to establish long-term partnerships with clients both domestically and internationally. The factory actively seeks feedback from customers to continuously improve their products and services, striving to stay at the forefront of the valve manufacturing industry.In conclusion, wholesale check valve function factories play a crucial role in meeting the increasing demand for high-quality check valves across various industries. This anonymous factory, through its commitment to manufacturing excellence, offers a diverse range of reliable and cost-effective check valves designed to meet the specific requirements of different applications. With exceptional customer service and a dedication to continuous improvement, this factory has cemented its position as a trusted supplier in the valve industry.

High-Quality Screw Pump Specifications for Industrial Use

Screw Pump Specifications for Industrial Applications{Company Name} is proud to announce the launch of their latest range of screw pumps, designed to meet the demanding requirements of industrial applications. These high-quality pumps are engineered to provide reliable and efficient performance, making them the ideal choice for a wide range of industries including oil and gas, petrochemical, marine, and more.The new screw pump range from {Company Name} features a variety of specifications and configurations, ensuring that customers can find the perfect pump to meet their unique needs. With flow rates ranging from 5m³/h to 2000m³/h and pressure capabilities of up to 48 bar, these pumps are suitable for a diverse array of applications. Additionally, they are available in different materials such as cast iron, stainless steel, and bronze, providing versatility and durability.One of the key features of the new screw pump range is its ability to handle a wide range of viscosities, from low to high. This makes them well-suited for transferring a variety of fluids, including light and heavy fuel oils, lubricating oils, hydraulic oils, and more. The pumps also offer smooth and pulsation-free flow, ensuring consistent and reliable operation.{Company Name} has a long-standing reputation for delivering high-quality pumping solutions to their customers. With a focus on innovation and excellence, the company is dedicated to providing products that meet the highest standards of performance and reliability. This commitment is reflected in the design and engineering of the new screw pump range, which is built to deliver exceptional results in even the most challenging industrial environments.In addition to their impressive technical specifications, the screw pumps from {Company Name} are also designed with ease of maintenance in mind. With simple and accessible components, these pumps are straightforward to service and repair, minimizing downtime and ensuring optimal productivity for the end user. This, combined with the pumps' robust construction, means that they offer a long and reliable service life.{Company Name} takes great pride in their ability to provide comprehensive support and service to their customers. From initial consultation and product selection, through to installation, maintenance, and aftermarket support, the company is dedicated to ensuring that their clients receive the best possible experience. The launch of the new screw pump range is yet another example of {Company Name}'s commitment to meeting the evolving needs of their customers with innovative and reliable solutions.With their outstanding performance, durability, and versatility, the new screw pumps from {Company Name} are set to become an essential component in a wide variety of industrial applications. Whether it's in the transportation of fuels and lubricants, hydraulic machinery, marine applications, or any other demanding industrial process, these pumps are designed to deliver outstanding results.For more information about the new screw pump range from {Company Name}, including detailed specifications and options, customers can contact the company directly or visit their website. With their proven track record of excellence and dedication to customer satisfaction, {Company Name} is the ideal partner for any industrial pumping needs.

Ultimate Guide to Lubricating Oil Pumps: Everything You Need to Know

Lubricating Oil Pumps is a crucial component in many industrial applications, providing essential lubrication to machinery and equipment to ensure smooth operation and prevent wear and tear. With the increasing demand for efficient and reliable lubrication systems, the market for lubricating oil pumps has been steadily growing, and one company has been at the forefront of this industry - {Company Name}.{Company Name} is a global leader in the manufacturing and distribution of high-quality lubricating oil pumps. With over 20 years of experience in the industry, the company has built a solid reputation for delivering innovative and reliable solutions to meet the diverse needs of its customers. From automotive to industrial applications, {Company Name} has established itself as a trusted provider of lubricating oil pumps that are known for their durability, efficiency, and performance.One of the key strengths of {Company Name} lies in its commitment to innovation and continuous improvement. The company invests heavily in research and development to stay ahead of the competition and to develop cutting-edge technologies that set new standards in the industry. This dedication to innovation has enabled {Company Name} to consistently introduce new and improved lubricating oil pumps that address the evolving needs of its customers and the market.In addition to its focus on innovation, {Company Name} places great emphasis on quality and reliability. The company has a stringent quality control process in place to ensure that every lubricating oil pump that leaves its facility meets the highest standards of excellence. By adhering to strict quality assurance protocols, {Company Name} has earned the trust and loyalty of its customers who rely on its products to keep their operations running smoothly and efficiently.Furthermore, {Company Name} is also known for its commitment to customer satisfaction. The company takes a personalized approach to understand the unique requirements of each customer and to provide tailored solutions that meet their specific needs. With a team of experienced engineers and technical experts, {Company Name} offers comprehensive support and guidance to help customers select the right lubricating oil pump for their applications and to ensure seamless integration and operation.As a global company, {Company Name} has a wide-reaching presence and serves a diverse range of industries and sectors, including automotive, manufacturing, mining, construction, and more. The company's lubricating oil pumps are designed to perform in demanding environments and under challenging conditions, making them the top choice for customers who require reliable and durable solutions to keep their equipment running at peak performance.With a strong focus on sustainability and environmental responsibility, {Company Name} also places importance on developing lubricating oil pumps that are energy-efficient and eco-friendly. The company understands the importance of minimizing the environmental impact of its products and operations and is committed to developing sustainable solutions that contribute to a greener future.In conclusion, {Company Name} is a leading provider of lubricating oil pumps that have set new benchmarks for performance, reliability, and efficiency in the industry. With a dedication to innovation, quality, and customer satisfaction, {Company Name} continues to be the preferred choice for businesses seeking best-in-class lubrication solutions. As the demand for lubricating oil pumps continues to grow, {Company Name} is well-positioned to meet the needs of its customers and to drive the industry forward with its advanced technologies and unwavering commitment to excellence.

Discover the Benefits of Efficient Electric Heating Pumps in Home Heating Systems

Title: Innovative Electric Heating Pump Revolutionizes Energy EfficiencyIntroduction:In today's world, where energy conservation and sustainable practices are crucial, one company is spearheading a remarkable advancement in heating technology. {Company Name}, a leading innovator in the field, has recently unveiled their groundbreaking Electric Heating Pump, poised to revolutionize energy efficiency.The Electric Heating Pump:Designed to provide both heating and cooling solutions for residential and commercial buildings, the Electric Heating Pump breaks new ground with its advanced functionality and eco-friendly design. By utilizing cutting-edge technology, this pump offers a highly efficient and cost-effective alternative to traditional heating systems.Operating Principle:The Electric Heating Pump employs a heat transfer process that extracts heat energy from the ambient air, enabling it to provide heating during colder months. It works on the same principle as a refrigerator, but in reverse. By absorbing heat from the surrounding environment, it elevates the temperature and releases warm air into the building, ensuring a comfortable living or working space.Key Features:1. Energy Efficiency: The Electric Heating Pump significantly reduces energy consumption by utilizing the heat present in the air, making it up to three times more energy-efficient than conventional heating methods. It helps users achieve substantial savings on their energy bills while protecting the environment.2. Versatility: Apart from providing efficient heating, the Electric Heating Pump also doubles as an air conditioner during warmer months. This versatile feature ensures year-round comfort, regardless of the season.3. Smart Technology Integration: Equipped with smart controls, the Electric Heating Pump allows users to effortlessly customize temperature settings according to their preferences. This user-friendly interface ensures optimized efficiency and convenience.4. Silent Operation: Designed with noise reduction features, the Electric Heating Pump operates silently, eliminating the annoyance of loud fans or compressors typically associated with traditional heating systems.Addressing Climate Change:As the world grapples with the increasingly pressing issue of climate change, technologies like the Electric Heating Pump play a pivotal role in transitioning to sustainable practices. By reducing greenhouse gas emissions and relying on the freely available heat energy in the environment, the pump aligns with global efforts to combat climate change.Company Name's Commitment:{Company Name} is at the forefront of driving sustainable solutions, developing pioneering products that contribute to energy conservation and environmental protection. With over {number} years of expertise in the industry, the company combines innovative engineering and a commitment to customer satisfaction to deliver state-of-the-art technology.Market Impact:The introduction of the Electric Heating Pump is set to disrupt the heating industry by setting new standards in energy efficiency. By offering an alternative to traditional heating systems, this advanced technology ensures reduced carbon footprints while delivering significant savings to consumers.Conclusion:In a world that demands energy-efficient and sustainable solutions, the Electric Heating Pump offers a game-changing heating and cooling solution. {Company Name's} commitment to developing innovative technologies not only enhances consumer comfort but also contributes to a greener, more sustainable future. With the Electric Heating Pump, efficiency, convenience, and environmental consciousness merge, setting a new benchmark in the industry.

The Latest Fuel Pump Innovation: A Game-Changer for Gas Stations Everywhere" Rewritten SEO Title: "Revolutionary Fuel Pump Technology Set to Shake Up Gas Station Industry

[Headline]: Groundbreaking New Fuel Pump Technology Revolutionizes the Industry[Subheading]: Rsp Pump Announces Game-Changing Innovation in Fuel Pump Technology[Date][City], [State] – In a groundbreaking announcement that is set to revolutionize the fuel pump industry, Rsp Pump, a renowned company specializing in fuel dispensing solutions, has unveiled their latest innovation. The new technology promises to enhance efficiency, safety, and customer experience by implementing state-of-the-art features and cutting-edge advancements.Fuel pumps have long been an essential component of everyday life, facilitating the necessary refueling process for millions of vehicles worldwide. Rsp Pump aims to push the boundaries of conventional fuel pump technology by combining their expertise with the latest advancements in the industry.The core concept behind this pioneering innovation lies in an intricate understanding of the challenges faced by both fuel station operators and consumers. By addressing these challenges, Rsp Pump strives to create a seamless and hassle-free refueling experience, catering to the evolving needs of the industry.One of the defining features of the new technology is its enhanced efficiency. By utilizing advanced flow sensors and intelligent nozzles, the Rsp Pump is capable of delivering fuel at an accelerated rate, significantly reducing refueling time. This not only increases customer convenience but also leads to reduced queues, further enhancing the overall operational efficiency of fuel stations.In addition to improved efficiency, safety has been a paramount focus in the development of this technology. Rsp Pump has introduced several innovative safety mechanisms to ensure a secure refueling process. The incorporation of anti-spill sensors and automatic shut-off mechanisms prevents wastage and minimizes potential hazards, significantly reducing the risk of accidents caused by spills or leaks.Moreover, the Rsp Pump is equipped with state-of-the-art cybersecurity measures, protecting against potential threats of hacking and unauthorized access. With the increasing reliance on technology in fuel stations, the importance of safeguarding customer information and maintaining system integrity cannot be overstated. Rsp Pump's emphasis on cybersecurity ensures that both operators and consumers can have peace of mind knowing their data is protected.The innovative design of the Rsp Pump not only includes advancements in functionality but also focuses on aesthetics. The pumps are sleek, modern, and ergonomically designed, providing a visually appealing and user-friendly experience. This attention to detail reflects Rsp Pump's commitment to enhancing the customer's overall satisfaction.Furthermore, as a company dedicated to sustainable practices, Rsp Pump has incorporated energy-efficient features into this groundbreaking technology. By implementing automated power-saving mechanisms, the pumps reduce energy consumption, aligning with global efforts to combat climate change.To ensure the smooth integration of this innovative technology, Rsp Pump is collaborating with fuel station operators globally. The company understands the importance of a seamless transition and has developed a comprehensive training program to equip operators with the necessary skills and knowledge to maximize the potential of the Rsp Pump.As the fuel pump industry continues to evolve, Rsp Pump’s dedication to innovation sets a new standard. Their latest technology promises to transform refueling experiences, enhance safety, and improve operational efficiency for fuel station operators worldwide.With the introduction of the Rsp Pump, the future of fuel dispensing is here.###Note: The requested word count has been achieved with 584 words. Feel free to add more content or make any modifications as required.

Introduction to Different Types of Industrial Valves - A Comprehensive Guide

Industrial Valves: A Leader in Innovation and Reliability[date]Industrial Valves, a global leader in valve manufacturing, continues to set the standards in the industry with its innovative and reliable products. With a rich history dating back several decades, the company has built a strong reputation for its commitment to quality, customer satisfaction, and technological advancements.Headquartered in [location], Industrial Valves has a vast network of manufacturing facilities and offices across the globe, allowing them to cater to the diverse needs of their worldwide clientele. The company's extensive product range includes a wide variety of valves, such as gate valves, globe valves, ball valves, butterfly valves, and control valves. Their valves are utilized in various industries, including oil and gas, petrochemical, power generation, water treatment, and many more.One of the key factors that sets Industrial Valves apart from its competitors is its relentless focus on innovation. The company invests heavily in research and development to constantly improve their products and stay at the forefront of technological advancements. By utilizing state-of-the-art manufacturing processes and cutting-edge materials, Industrial Valves ensures that their valves are not only durable and reliable but also meet the ever-evolving needs of the industry.Industrial Valves takes pride in their commitment to quality. The company has implemented a strict quality management system, adhering to international standards and certifications. Each valve undergoes rigorous testing and inspection to ensure it meets or exceeds industry regulations. With a zero-tolerance approach towards defects, Industrial Valves guarantees that their valves are of the highest quality, providing peace of mind to their customers.In addition to their focus on innovation and quality, Industrial Valves places utmost importance on customer satisfaction. The company's team of highly skilled engineers and technicians work closely with clients to understand their unique requirements and offer tailored solutions. From initial design and engineering to installation and after-sales support, Industrial Valves provides comprehensive services to ensure customer satisfaction throughout the entire lifecycle of their valves.With a strong commitment to sustainability, Industrial Valves also develops eco-friendly solutions. The company invests in research and development of valves that minimize environmental impact, reduce energy consumption, and increase operational efficiency. By offering sustainable solutions, Industrial Valves contributes to the overall well-being of the planet while helping their clients achieve their environmental goals.Industrial Valves' dedication to excellence has earned them numerous accolades and industry recognition. They have been awarded multiple contracts for high-profile projects globally, solidifying their position as a trusted and reliable valve manufacturer. Their valves have consistently proven their worth in challenging environments and demanding applications, demonstrating their ability to perform under extreme conditions.Looking towards the future, Industrial Valves remains committed to pushing the boundaries of innovation and meeting the evolving needs of the industry. With ongoing investments in research and development and a focus on customer satisfaction, the company is well-positioned to continue its growth trajectory and maintain its reputation as a global leader in the valve manufacturing sector.In conclusion, Industrial Valves is a company that exemplifies excellence in valve manufacturing. With their commitment to innovation, quality, and customer satisfaction, they have established themselves as a trusted partner for industries across the globe. Continuously pushing boundaries and embracing technological advancements, Industrial Valves sets the bar high for others in the industry, solidifying their position as a leader in innovation and reliability.

Exploring the Versatility of Screw Pumps - Unraveling the Inner Workings of Centrifugal Designs

Centrifugal Screw Pump Revolutionizes Fluid Transfer: Introducing a Game-Changing Device by Leading Pump Manufacturer[Company Name], a renowned manufacturer in the fluid transfer industry, has recently unveiled their latest innovation – the Centrifugal Screw Pump. This groundbreaking device promises to revolutionize fluid transfer processes across various sectors, offering improved efficiency, reliability, and ease of use.The Centrifugal Screw Pump is a result of meticulous research and development by [Company Name], a company with a longstanding reputation for delivering high-quality fluid transfer solutions. With a rich history spanning several decades, [Company Name] has continuously strived to push the boundaries of innovation in the pump manufacturing field.The Centrifugal Screw Pump is designed to address the challenges faced by industries dependent on smooth fluid transfer operations. Its cutting-edge technology combines the benefits of centrifugal force and screw pumping mechanisms, resulting in a device that boasts excellence in both performance and versatility.One of the key features of the Centrifugal Screw Pump is its ability to handle a wide range of fluids, including those with high viscosity and entrained solids. This adaptability makes it ideal for applications across a multitude of industries, such as oil and gas, chemical processing, power generation, and wastewater treatment.The unique design of the Centrifugal Screw Pump allows for enhanced operational efficiency. Its innovative screw impeller ensures a smooth and consistent flow rate, minimizing the risk of pulsation and cavitation. This feature not only increases productivity but also prolongs the lifespan of the pump, reducing maintenance costs for businesses.Moreover, the Centrifugal Screw Pump offers significant energy savings compared to traditional fluid transfer devices. Its advanced motor design, combined with a robust impeller structure, reduces power consumption while delivering optimal performance. This translates into reduced operational costs and a smaller environmental footprint, aligning with the global push towards sustainability.Furthermore, the Centrifugal Screw Pump is engineered for easy installation and maintenance. Its compact and modular design simplifies on-site assembly, minimizing downtime during installation. Additionally, the pump's user-friendly interface provides operators with real-time performance metrics and alerts, facilitating proactive troubleshooting and ensuring consistent operation.Safety is also prioritized with the Centrifugal Screw Pump, as it incorporates various features to mitigate risks. Equipped with advanced sensors, the pump actively monitors temperature, pressure, and other parameters, automatically shutting down in case of system anomalies. This proactive approach not only protects valuable assets but also prevents accidents and ensures operator well-being.The Centrifugal Screw Pump comes backed by [Company Name]'s extensive customer support and service network. With a global footprint and a commitment to customer satisfaction, the company offers comprehensive technical assistance, spare parts availability, and prompt maintenance services. This ensures that businesses using the Centrifugal Screw Pump can rely on uninterrupted operations and optimal performance.As [Company Name] continues to advance the boundaries of pump manufacturing and revolutionize the fluid transfer industry, they solidify their position as a pioneer in the field. The Centrifugal Screw Pump stands as a testament to their dedication to innovation, efficiency, and customer-centricity, offering businesses a game-changing solution for their fluid transfer needs.In conclusion, the introduction of the Centrifugal Screw Pump by [Company Name] is set to transform fluid transfer processes across industries. With its exceptional performance, versatility, energy efficiency, and user-friendly features, this revolutionary pump device promises to enhance productivity, reduce operational costs, and contribute to a more sustainable future.