Screw Pump vs Gear Pump: Understanding the Key Differences

By:Admin

As a leading manufacturer in the fluid handling industry, [Company Name] has been producing high-quality pumps for a wide range of applications. With a focus on technology and innovation, the company has established itself as a reliable provider of pumping solutions for various industries. One of the key products in their lineup is the screw pump, which has gained popularity for its unique design and efficient performance. In this article, we will explore the differences between screw pumps and gear pumps, and how [Company Name] has become a trusted name in the pump manufacturing industry.

Screw pumps and gear pumps are both types of positive displacement pumps, which means they are designed to move fluid by trapping a fixed amount of it and forcing it into the discharge pipe. However, there are some key differences between the two types of pumps that make them suitable for different applications.

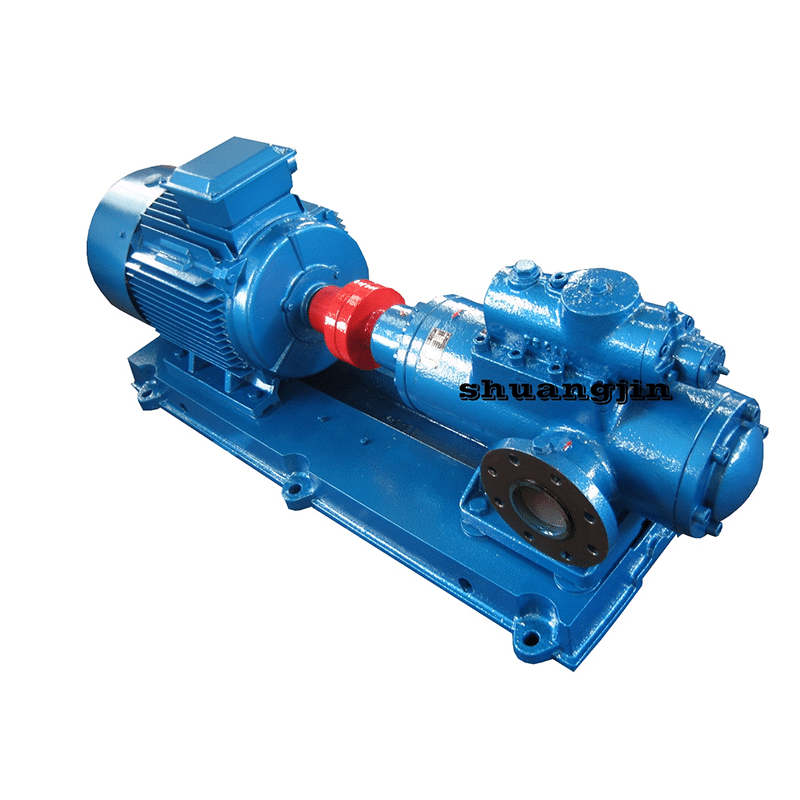

One of the main differences between screw pumps and gear pumps is their operating principle. Screw pumps utilize two intermeshing screws to move the fluid through the pump, while gear pumps use two gears to achieve the same result. This difference in design leads to some distinct advantages and disadvantages for each type of pump.

Screw pumps are known for their ability to handle high-viscosity fluids with ease. The intermeshing screws create a continuous flow of fluid, allowing for smooth and efficient pumping of thick and viscous liquids. This makes screw pumps ideal for applications where high-pressure and high-viscosity fluids need to be handled, such as in the oil and gas industry.

On the other hand, gear pumps are better suited for applications with lower viscosity fluids. The simple design of gear pumps makes them reliable and cost-effective for pumping low-viscosity fluids at moderate pressures. This makes gear pumps a popular choice for applications in industries such as chemical processing and food production.

In addition to their different operating principles, screw pumps and gear pumps also differ in terms of their maintenance requirements. Screw pumps generally require less maintenance compared to gear pumps, due to their fewer moving parts and a more straightforward design. This can result in lower operating costs and reduced downtime for maintenance and repairs. On the other hand, gear pumps may require more frequent maintenance and replacement of parts, which can increase the overall cost of ownership.

As a leading manufacturer in the pump industry, [Company Name] has extensive experience in designing and producing both screw pumps and gear pumps. Their engineering expertise and commitment to quality have made them a preferred supplier for companies looking for reliable pumping solutions. Their screw pumps are known for their robust construction and efficient performance, making them a popular choice for demanding applications in various industries.

In addition to screw pumps, [Company Name] also offers a wide range of gear pumps, designed to meet the needs of customers requiring reliable and cost-effective pumping solutions for low-viscosity fluids. The company’s gear pumps are built to withstand the rigors of industrial applications, while providing consistent and reliable performance.

In conclusion, screw pumps and gear pumps each have their unique advantages and are designed for specific applications. Companies like [Company Name] have leveraged their expertise to produce high-quality pumps that meet the diverse needs of their customers. With a strong focus on innovation and customer satisfaction, [Company Name] continues to be a trusted provider of pumping solutions for various industries around the world.

Company News & Blog

Highly Efficient Twin Screw Pump for Industrial Applications

Twin Screw Pump Generously Donated to Local Municipality to Support Water Distribution[City, State] - In a generous move to support the local community, a leading industrial equipment manufacturer has donated a state-of-the-art Twin Screw Pump to the [City] municipality. The [Company], known for its innovative and high-quality pumping solutions, has made this donation to aid in the efficient distribution of water to the residents of the city.The Twin Screw Pump, a highly advanced and reliable piece of equipment, is designed to handle a wide variety of fluids with ease. Its unique design allows for gentle pumping action, low pulsation, and a smooth flow, making it an ideal choice for the distribution of water in a municipal setting. With its robust construction and advanced technology, the pump is expected to significantly improve the efficiency and reliability of the city's water distribution system.The donation of the Twin Screw Pump comes as part of [Company]'s ongoing commitment to corporate social responsibility and giving back to the communities in which it operates. The company, which has a long history of supporting various charitable causes and initiatives, saw an opportunity to contribute to the well-being of the residents of [City] by providing them with a cutting-edge piece of equipment that will directly impact their daily lives."We are thrilled to be able to donate this Twin Screw Pump to the [City] municipality," said [Company spokesperson]. "Water distribution is a crucial aspect of urban life, and we are confident that our pump will help the city to improve the efficiency of its water infrastructure. It is our hope that this donation will not only benefit the city and its residents but also serve as a symbol of our commitment to being a responsible corporate citizen."The [City] municipality, which has been facing challenges with its aging water distribution system, has expressed its gratitude for the generous donation. The Twin Screw Pump will be installed at a key location within the city's water infrastructure, where it will be used to ensure the smooth and reliable distribution of water to homes and businesses."We are incredibly thankful to [Company] for their generous donation of the Twin Screw Pump," said [City official]. "This state-of-the-art equipment will undoubtedly make a positive impact on our water distribution system, allowing us to provide better service to our residents. We are truly grateful for [Company]'s support and commitment to our community."The installation of the Twin Screw Pump is expected to take place in the coming weeks, and the city's water department is already making preparations to integrate the new equipment into its existing infrastructure. Once operational, the pump is expected to deliver immediate improvements in the efficiency and reliability of the water distribution system, ultimately benefiting thousands of residents and businesses in the city.In addition to the donation of the pump, [Company] has also committed to providing training and technical support to the city's water department to ensure the proper operation and maintenance of the equipment. This ongoing support is expected to further enhance the long-term impact of the donation and help to maximize the benefits of the Twin Screw Pump for the city and its residents.The donation of the Twin Screw Pump by [Company] serves as a shining example of the positive impact that corporate generosity can have on local communities. By providing the city of [City] with a cutting-edge piece of equipment to improve its water distribution system, [Company] has demonstrated its dedication to being a responsible corporate citizen and making a meaningful difference in the lives of those it serves.

High-quality Gear Pumps for Industrial Use: Essential Details You Need to Know

Gear Pumps: The Ultimate Solution for Industrial Fluid HandlingIn the world of industrial fluid handling, gear pumps have proven to be an essential tool for a wide range of applications. From manufacturing to oil and gas, these pumps play a crucial role in keeping operations running smoothly. With their ability to handle high viscosity fluids and withstand demanding operating conditions, gear pumps have become the go-to choice for many industries.One company that has established itself as a leader in the gear pump industry is {}. With over 30 years of experience in the design and manufacturing of gear pumps, {} has earned a reputation for delivering high-quality, reliable products that meet the needs of their customers.The key to the success of {} lies in their commitment to innovation and continuous improvement. By investing in state-of-the-art technology and leveraging their team of experienced engineers, the company has been able to develop a wide range of gear pump solutions that set the standard for performance and reliability.One of the main advantages of {}'s gear pumps is their ability to handle a variety of fluids, including abrasive and corrosive substances. This versatility makes them an ideal choice for industries such as chemical processing, food and beverage, and pharmaceuticals, where the handling of different types of fluids is a common requirement.Another key feature of {}'s gear pumps is their exceptional durability. Built to withstand harsh operating conditions, their pumps are designed to deliver consistent performance and minimal downtime, even in the most demanding environments. This reliability has made them a trusted choice for industries where equipment failures can have serious consequences.In addition to their durability, {}'s gear pumps are also known for their efficiency. By optimizing the design and engineering of their pumps, the company has been able to minimize energy consumption and reduce overall operating costs for their customers. This focus on efficiency has not only helped businesses save money, but it has also contributed to reducing their environmental impact.One of the most innovative products in {}'s gear pump lineup is their compact and lightweight series, which is designed to meet the needs of applications where space is limited. Despite their small size, these pumps deliver exceptional performance and reliability, making them an ideal choice for industrial and mobile equipment where size and weight are critical factors.{}'s commitment to customer satisfaction is evident in their dedication to providing exceptional service and support. From the initial design phase to the installation and maintenance of their gear pumps, the company works closely with their customers to ensure that their unique requirements are met. This level of support has helped {} build long-lasting relationships with their clients and establish a strong reputation in the industry.Looking ahead, {} remains focused on advancing the capabilities of gear pumps and exploring new opportunities in the fluid handling market. By staying at the forefront of technology and innovation, the company is poised to continue delivering cutting-edge solutions that meet the evolving needs of their customers.In conclusion, gear pumps have become an indispensable tool for a wide range of industries, and {} has established itself as a leading provider of high-quality, reliable gear pump solutions. With their commitment to innovation, durability, efficiency, and customer satisfaction, {} is well-positioned to continue shaping the future of industrial fluid handling.

Screw Pump vs Gear Pump: Understanding the Key Differences

Title: Understanding the Differences Between Screw Pumps and Gear Pumps: A Closer Look at Pumping TechnologiesIntroduction:In the world of fluid transfer and pumping technologies, two commonly used pump types are screw pumps and gear pumps. Both these pumps play a crucial role in various industries, including oil and gas, chemical, food processing, and many others. However, understanding the differences between screw pumps and gear pumps is vital in order to determine the most suitable option for specific applications. This article aims to shed light on these differences, highlighting the unique features and advantages of each pumping technology.Screw Pumps:Screw pumps, also known as progressive cavity pumps, operate based on the principle of displacement. They consist of two main components – a helical rotor and a stator. The rotor, often in the shape of a screw, rotates within the stator, resulting in the transfer of fluids from the suction side to the discharge side.Screw pumps are recognized for their ability to handle highly viscous fluids, including heavy oils, sludge, and slurries. Their design features enable them to generate a smooth, non-pulsating flow, making them suitable for applications requiring precise control over fluid transfer. Furthermore, screw pumps exhibit low shear rates, making them ideal for handling shear-sensitive materials without damaging their integrity.One key advantage of screw pumps is their self-priming capability. They can effectively handle fluids with entrained air or gas, eliminating the need for additional priming mechanisms. Screw pumps also showcase excellent suction lift capability, enabling efficient pumping even when the fluid source is located below the pump.Gear Pumps:Gear pumps, on the other hand, utilize rotating gears to transfer fluids. They consist of two meshing gears – a drive gear and a driven gear. As the gears rotate, liquid is drawn into the pump and pushed through the outlet. Gear pumps are widely used in various industries due to their simplicity, compact size, and high efficiency.Gear pumps excel in applications requiring high flow rates and moderate pressures. Their smooth operation allows for noiseless performance, making them suitable for applications where noise reduction is essential. Additionally, gear pumps can handle clean fluids, as well as fluids containing small particulate matter without clogging or damage to the gears.One of the key advantages of gear pumps is their ability to provide consistent flow, even under varying pressures. This makes them ideal for applications where stable pressure levels are critical. Another noteworthy feature is their ability to operate efficiently over a wide range of viscosities, allowing flexibility in fluid transfer applications.Conclusion:In conclusion, understanding the differences between screw pumps and gear pumps is pivotal in selecting the appropriate pumping technology for specific industrial applications. Screw pumps are best suited for handling highly viscous fluids and shear-sensitive materials, offering self-priming capability and low shear rates. On the other hand, gear pumps excel in high flow rate applications, offering consistent flow even under varying pressures and versatility across a wide range of viscosities.As industries continue to advance, the demand for efficient fluid transfer technologies will persist. Both screw pumps and gear pumps provide reliable solutions, each with their unique set of advantages. It is crucial for industries to evaluate their specific requirements and consult with experts to make informed decisions regarding the selection of the most suitable pumping technology for enhanced productivity and operational success.

Innovative Screw Pump for Efficient Slurry Handling

Screw Pump For Slurry: A Game-Changer in Slurry TransportIn the world of industrial and mining operations, the efficient and reliable transport of slurry is of utmost importance. Slurry, a mixture of solids and liquids, can be highly abrasive and corrosive, making its handling a challenging task. However, with the innovative Screw Pump for Slurry developed by {}, the transportation of slurry is set to become more efficient, reliable, and cost-effective.{} is a renowned name in the field of industrial pumping solutions, with a rich history of providing high-quality and cutting-edge products to its global clientele. The company's dedication to research and development has led to the creation of the Screw Pump for Slurry, a game-changing technology that is poised to revolutionize the slurry transport industry.The screw pump is designed to handle the most demanding slurry transport applications, offering a range of benefits that set it apart from traditional pumping solutions. Its unique design incorporates a screw-shaped rotor that rotates within a cylindrical cavity, effectively pushing the slurry along the length of the cavity. This design not only ensures a continuous and smooth flow of slurry but also minimizes the wear and tear on the pump, resulting in lower maintenance costs and extended operational life.One of the standout features of the screw pump is its ability to handle high-viscosity and abrasive slurry with ease. The robust construction of the pump, combined with the use of high-quality materials, allows it to withstand the challenging conditions often associated with slurry transport. This means that operators can rely on the screw pump to deliver consistent performance, even in the harshest of environments.Furthermore, the screw pump is highly efficient, offering significant energy savings compared to traditional pumping solutions. Its design minimizes internal recirculation and slippage, resulting in a more direct and efficient transfer of slurry. This not only reduces energy consumption but also lowers operating costs, making the screw pump a cost-effective choice for slurry transport applications.In addition to its superior performance, the screw pump is also designed with ease of maintenance in mind. The simple and robust construction of the pump makes it easy to inspect and service, minimizing downtime and ensuring continuous operation. This is a crucial advantage for industrial and mining operations, where any unplanned downtime can have significant ramifications on the overall productivity and profitability of the operation.With its innovative design, superior performance, and cost-saving benefits, the Screw Pump for Slurry from {} is set to become a go-to solution for slurry transport applications across various industries. Whether it's mining, chemical processing, or wastewater treatment, the screw pump offers a reliable and efficient means of transporting slurry, leading to improved productivity and reduced operating costs for operators.As a leading provider of industrial pumping solutions, {} remains committed to pushing the boundaries of innovation and delivering solutions that address the evolving needs of its customers. The development of the Screw Pump for Slurry is a testament to the company's dedication to excellence and its ability to bring game-changing technologies to the market.In conclusion, the Screw Pump for Slurry from {} represents a significant advancement in the field of slurry transport, offering unparalleled performance, reliability, and cost-effectiveness. With its innovative design and numerous benefits, the screw pump is poised to become a key technology for industrial and mining operations, setting new standards for slurry transport efficiency.

Twin Screw Pump: Latest Advancements and Applications in Pumping Technology

Alfa Laval Twin Screw Pump (brand name removed), an innovative and highly efficient pumping solution, is designed to meet the needs of various industries including food and beverage, pharmaceutical, marine, and oil and gas. With its advanced technology and superior performance, this pump is capable of handling a wide range of liquid transfer applications, making it an essential equipment in many industrial processes.The Alfa Laval Twin Screw Pump is renowned for its ability to handle both low and high viscosity liquids with ease, making it a versatile pumping solution for various industries. The pump’s unique design features two intermeshing screws that rotate in opposite directions, creating a continuous flow of liquid with minimal pulsation and shear force. This results in gentle and efficient product handling, making it ideal for pumping delicate and shear-sensitive fluids such as dairy products, pharmaceutical ingredients, and cosmetics.One of the key advantages of the Alfa Laval Twin Screw Pump is its ability to handle entrained air and gas, making it suitable for applications where aeration and foaming are common challenges. The pump’s robust construction and high suction capability allow for smooth and reliable operation even in demanding environments. This makes it an ideal choice for applications such as tank-to-tank transfer, product recovery, and CIP (clean-in-place) processes in the food and beverage industry.In addition to its exceptional performance, the Alfa Laval Twin Screw Pump is also designed for easy maintenance and cleaning. Its hygienic design features smooth surfaces and clean-in-place capabilities, ensuring that the pump can be quickly and thoroughly cleaned between product changeovers. This is essential for industries such as pharmaceutical and biotechnology, where product purity and sanitation are critical requirements.The Alfa Laval Twin Screw Pump is also suitable for marine and offshore applications, where reliable and efficient pumping solutions are essential for various onboard processes. Its compact and space-saving design makes it an ideal choice for installations with limited space, while its ability to handle high viscosity fuels and lubricants makes it a versatile solution for marine fuel transfer and lubrication systems.Moreover, the pump’s compliance with industry standards and regulations, such as EHEDG, 3-A, and FDA, ensures that it meets the stringent requirements of the food and pharmaceutical industries. This makes it a trusted and reliable pumping solution for critical processes where product safety and hygiene are of utmost importance.With its proven performance and versatility, the Alfa Laval Twin Screw Pump has established itself as a leading pumping solution in various industries. Its ability to handle a wide range of liquid transfer applications, combined with its gentle product handling and easy maintenance, makes it an essential equipment for many industrial processes. The pump’s advanced technology and hygienic design make it a reliable and efficient choice for industries that require high-quality and consistent liquid transfer solutions.In conclusion, the Alfa Laval Twin Screw Pump is a highly efficient and versatile pumping solution that meets the needs of various industries, including food and beverage, pharmaceutical, marine, and oil and gas. Its advanced technology, superior performance, and compliance with industry standards make it a trusted and reliable choice for critical liquid transfer processes. Whether it is for gentle product handling, efficient aeration handling, or easy maintenance and cleaning, this pump offers a comprehensive solution for a wide range of industrial applications.

Energy Efficient Heat Pump for House Heating

House Heating Heat Pump Offers Energy Efficient Heating SolutionWith the rising costs of energy and the increasing concern for the environment, more and more homeowners are looking for energy-efficient heating solutions. One such solution is the House Heating Heat Pump, a revolutionary heating system that offers both energy efficiency and superior performance. As an industry leader in heating technology, the company is dedicated to providing innovative solutions for homeowners looking to reduce their energy consumption and carbon footprint.The House Heating Heat Pump is a cutting-edge heating system that utilizes the latest in heat pump technology to provide efficient and consistent heating for residential properties. Unlike traditional heating systems that rely on burning fossil fuels, the House Heating Heat Pump extracts heat from the air or ground and transfers it indoors to provide warmth. This process of heat transfer is not only more energy-efficient, but it also reduces the reliance on non-renewable energy sources, making it a more sustainable heating solution.In addition to its energy efficiency, the House Heating Heat Pump is also known for its versatility and reliability. It can be used for both heating and cooling, making it a year-round heating solution for homeowners. Furthermore, the system is designed to operate quietly and efficiently, providing a comfortable living environment without the noise and fluctuations commonly associated with traditional heating systems.Furthermore, the House Heating Heat Pump is easy to install and maintain, making it an attractive option for homeowners looking for a hassle-free heating solution. The system is designed for long-term performance, with minimal maintenance requirements and a longer lifespan compared to traditional heating systems. This not only reduces the overall cost of ownership but also provides peace of mind for homeowners who are looking for a reliable heating solution.With a commitment to innovation and sustainability, the company behind the House Heating Heat Pump has established itself as a leader in the heating technology industry. The company has a team of dedicated engineers and technicians who are constantly working to improve and expand their product offerings to meet the evolving needs of homeowners. The company also places a strong emphasis on research and development, ensuring that its products are at the forefront of technological advancements in the heating industry.Furthermore, the company is dedicated to providing exceptional customer service and support for homeowners who choose the House Heating Heat Pump. With a network of certified technicians and installers, the company ensures that its customers receive professional and reliable assistance for installation, maintenance, and repairs. This commitment to customer satisfaction has earned the company a reputation for excellence and reliability in the industry.The House Heating Heat Pump is not only a practical heating solution but also a smart investment for homeowners. With its energy efficiency and long-term performance, the system offers significant cost savings over time. Additionally, many homeowners may be eligible for government incentives and rebates for installing energy-efficient heating systems, making the transition to the House Heating Heat Pump even more affordable.As the demand for energy-efficient heating solutions continues to grow, the House Heating Heat Pump stands out as a leader in the industry. With its innovative technology, commitment to sustainability, and dedication to customer satisfaction, the House Heating Heat Pump offers homeowners a reliable and efficient heating solution for the future. Whether homeowners are looking to reduce their energy consumption, lower their carbon footprint, or simply enjoy a comfortable living environment, the House Heating Heat Pump is a smart choice for modern homeowners.

Top Industrial Vacuum Pump Options for 2022

Industrial Vacuum Pump is revolutionizing the manufacturing industry with its innovative and high-performance vacuum pumps. These pumps are designed to meet the demanding needs of various industries, including automotive, food and beverage, pharmaceutical, and more. With their advanced technology and precision engineering, Industrial Vacuum Pump is the go-to solution for companies looking to enhance their production processes and efficiency.Founded in 1998, Industrial Vacuum Pump has built a reputation for excellence in the field of vacuum pump manufacturing. The company has a state-of-the-art manufacturing facility with a team of highly skilled engineers and technicians who are dedicated to producing top-quality vacuum pumps. With an emphasis on research and development, Industrial Vacuum Pump continuously strives to stay ahead of the curve in terms of technology and innovation.One of the key factors that sets Industrial Vacuum Pump apart from its competitors is its commitment to quality and reliability. The company adheres to strict quality control measures at every stage of the manufacturing process to ensure that each vacuum pump meets the highest standards. This dedication to quality has earned Industrial Vacuum Pump the trust and loyalty of its customers worldwide.Industrial Vacuum Pump offers a wide range of vacuum pumps to cater to the diverse needs of its clients. From dry screw vacuum pumps to oil-sealed rotary vane pumps, the company's product lineup is designed to deliver exceptional performance and efficiency. These pumps are capable of handling a variety of applications, including vacuum packaging, material handling, degassing, and more.Moreover, Industrial Vacuum Pump's dedication to customer satisfaction is evident in its comprehensive after-sales support. The company provides expert technical support and maintenance services to ensure that its customers' vacuum pumps continue to operate at peak performance. This commitment to customer service has made Industrial Vacuum Pump a trusted partner for businesses around the globe.In addition to its product excellence, Industrial Vacuum Pump is also committed to environmental sustainability. The company understands the importance of minimizing its environmental footprint and, as such, it strives to develop energy-efficient vacuum pumps that reduce power consumption and waste. Furthermore, Industrial Vacuum Pump is dedicated to waste reduction and recycling initiatives within its manufacturing processes.The success of Industrial Vacuum Pump can be attributed to its unwavering commitment to innovation, quality, and customer satisfaction. The company's continuous efforts to push the boundaries of vacuum pump technology have positioned it as a global leader in the industry. With a strong focus on research and development, Industrial Vacuum Pump is poised to continue setting new benchmarks for excellence in the manufacturing sector.Looking to the future, Industrial Vacuum Pump aims to further expand its global presence and reach new markets. The company is committed to staying at the forefront of technological advancements and providing cutting-edge solutions to meet the evolving needs of industries worldwide. With a clear vision and a dedication to excellence, Industrial Vacuum Pump is set to continue revolutionizing the manufacturing industry for years to come.In conclusion, Industrial Vacuum Pump has established itself as a leading provider of high-performance vacuum pumps. With a relentless focus on quality, innovation, and customer satisfaction, the company has earned the trust of businesses worldwide. As it continues to push the boundaries of vacuum pump technology, Industrial Vacuum Pump is well-poised for a future of continued success and excellence.

Highly Efficient Multiphase Twin Screw Pump for Optimal Performance

The Multiphase Twin Screw pump is revolutionizing the pumping industry with its innovative design and superior performance. This cutting-edge pump is a game-changer for a wide range of industries, including oil and gas, petrochemical, and food processing.The Multiphase Twin Screw pump is designed and manufactured by a leading company in the pumping industry. With over 50 years of experience, the company has established itself as a trusted and reliable provider of high-quality pumping solutions. The company's commitment to innovation and excellence is evident in the development of the Multiphase Twin Screw pump, which is set to redefine the industry standard for pumping technology.One of the key features of the Multiphase Twin Screw pump is its ability to handle multiphase fluid streams with ease. This pump is capable of efficiently and effectively handling liquids, gases, and solids, making it an ideal solution for a wide range of challenging pumping applications. Whether it's pumping crude oil and natural gas in the oil and gas industry or transferring food products in the food processing industry, the Multiphase Twin Screw pump delivers exceptional performance and reliability.In addition to its multiphase capabilities, the Multiphase Twin Screw pump is also renowned for its high efficiency and low maintenance requirements. The pump's advanced design minimizes energy consumption and reduces operating costs, making it a cost-effective solution for businesses looking to optimize their pumping operations. Furthermore, the pump's robust construction and durable components ensure long-term reliability and minimal downtime, maximizing productivity and profitability for its users.The Multiphase Twin Screw pump is also highly versatile and customizable, allowing it to be tailored to the specific needs and requirements of each individual application. With a wide range of sizes, materials, and configurations available, this pump can be adapted to suit a variety of pumping tasks, from small-scale processing to large-scale industrial operations. Its compact design and ease of installation further enhance its versatility, making it a practical solution for a diverse range of pumping challenges.The company behind the Multiphase Twin Screw pump is committed to providing exceptional service and support to its customers. With a global network of sales and service centers, the company offers responsive assistance and technical expertise to ensure the success of every pump installation. From initial consultation and design to after-sales support and maintenance, the company's team of experts is dedicated to delivering comprehensive solutions and maximum value to its customers.Overall, the Multiphase Twin Screw pump stands out as a superior pumping solution that is setting new standards for performance, efficiency, and versatility. With its innovative design, exceptional capabilities, and unwavering reliability, this pump is poised to make a significant impact across a wide range of industries. As the company continues to advance its pumping technology, the Multiphase Twin Screw pump is sure to remain at the forefront of the industry, driving progress and delivering value to businesses around the world.

Efficient and Environmentally-Friendly Heat Pump Cooling Systems: The Future of Home Cooling

Heat Pump Cooling Systems have been gaining popularity in the HVAC industry in recent years. These systems offer an innovative and energy-efficient way to cool homes and businesses, making them a popular choice for environmentally conscious consumers. One company at the forefront of this technology is {}. With a commitment to sustainability and cutting-edge innovation, {} has been a leader in the development and manufacturing of Heat Pump Cooling Systems for residential and commercial use.The company's Heat Pump Cooling Systems are designed to provide reliable and efficient cooling solutions for a wide range of applications. Whether it's a small residential property or a large commercial building, {}'s systems are tailored to meet the specific cooling needs of their customers.One of the main advantages of {}'s Heat Pump Cooling Systems is their high energy efficiency. Unlike traditional air conditioning systems that rely on electricity to generate cool air, heat pump systems transfer heat from one place to another, using significantly less energy in the process. This not only reduces the environmental impact of cooling, but also helps to lower energy bills for consumers.In addition to their energy efficiency, {}'s Heat Pump Cooling Systems are also known for their reliability and durability. The company's commitment to quality and performance means that customers can trust that their cooling systems will operate smoothly and efficiently for years to come.Furthermore, {} offers a range of options for customers to choose from, ensuring that there is a cooling solution to fit every need and budget. Whether it's a ductless mini-split system for a single room or a centralized system for a large commercial space, {} has the expertise and technology to provide a custom solution for their customers.Another key feature of {}'s Heat Pump Cooling Systems is their eco-friendly design. The company prioritizes sustainability in all aspects of their business, from manufacturing processes to product design. By choosing {}'s cooling systems, customers can feel good about reducing their carbon footprint and contributing to a cleaner, healthier planet.Furthermore, {} takes pride in its customer service and support. The company's team of experts is dedicated to guiding customers through the process of selecting, installing, and maintaining their Heat Pump Cooling Systems. With a focus on customer satisfaction, {} ensures that their customers receive the best possible experience from start to finish.With a growing emphasis on environmental responsibility and energy efficiency, {}'s Heat Pump Cooling Systems are poised to continue making an impact in the HVAC industry. As more and more consumers prioritize sustainability and cost savings, the demand for innovative cooling solutions like those offered by {} is expected to rise.In conclusion, {} is leading the way in the development and manufacturing of Heat Pump Cooling Systems that are energy-efficient, reliable, and environmentally friendly. With a commitment to quality, innovation, and customer satisfaction, the company is well-positioned to meet the growing demand for sustainable cooling solutions in the residential and commercial markets. As the HVAC industry continues to evolve, {} remains dedicated to providing cutting-edge technology and superior performance in their Heat Pump Cooling Systems.

Discover the Top Marine Water Pump for Your Needs in 2022

Marine Water Pump Enhances Efficiency and Reliability in Marine Operations[City, Date] - As the maritime industry continues to evolve and seek innovative solutions to enhance efficiency and reliability, the Marine Water Pump has emerged as a game-changer in marine operations. Manufactured by a reputed company [], this cutting-edge technology is revolutionizing the industry's approach towards water pumping systems.With the ever-increasing demand for efficient water transportation, maintaining reliable pumping systems becomes crucial. The Marine Water Pump, crafted with precision and advanced engineering, offers an ideal solution for various marine applications. Whether it's for ballast water management, bilge pumping, or firefighting operations, this water pump offers unmatched performance and efficiency.One of the key aspects that sets the Marine Water Pump apart from traditional systems is its durability and reliability. Constructed from high-quality materials, this pump is built to withstand the harsh marine environment, ensuring longevity and minimal downtime. The corrosion-resistant body and components minimize the risk of damage and reduce maintenance costs, making it an ideal choice for marine operators seeking cost-effective solutions.Moreover, the compact design of the Marine Water Pump enables easy installation and integration into existing marine systems. Its versatility allows for seamless compatibility with different vessel types, ranging from small crafts to large commercial ships. By reducing installation time and complexity, this pump assists marine operators in streamlining their operations and maximizing productivity.Furthermore, the advanced engineering behind the Marine Water Pump ensures optimal performance and energy efficiency. With its superior pumping capabilities, this technology enables faster water transfer and drainage, saving valuable time during critical marine operations. The pump's adjustable flow and pressure settings provide operators with greater control, allowing for enhanced operational precision and flexibility.In the context of environmental sustainability, the Marine Water Pump upholds the highest standards. It incorporates advanced filtration and purification systems, ensuring compliance with strict maritime environmental regulations. By effectively managing ballast water and preventing the spread of invasive species, this pump contributes to the preservation of marine ecosystems and supports sustainable water transportation practices.In addition to its performance and reliability, the company behind the Marine Water Pump, [], brings extensive expertise and experience to the table. With a proven track record in developing innovative marine technologies, the company has earned a reputation for delivering industry-leading solutions. Its commitment to research and development ensures that the Marine Water Pump remains at the forefront of technological advancements, constantly pushing the boundaries of efficiency and reliability.To support its customers in maximizing the benefits of the Marine Water Pump, the company offers comprehensive after-sales services. With a global network of service centers and technicians, the company ensures prompt assistance and maintenance support, minimizing downtime and maximizing uptime for marine operators. This dedication to customer satisfaction has contributed to the company's strong presence in the maritime industry worldwide.As the demand for efficient water pumping systems continues to grow in the maritime sector, the Marine Water Pump stands out as a game-changer. Its durability, reliability, and efficiency make it an indispensable asset for marine operators aiming to optimize their operations and reduce costs. With the backing of its visionary manufacturer [], the Marine Water Pump is set to redefine the standards of water pumping in the maritime industry.