Discover the Latest Innovations in Pump Technology

By:Admin

Company News & Blog

Major Benefits of Installing a Screw Pump for Your Industrial Needs

Screw Pump Installation Boosts Efficiency in Industrial ProcessesIndustrial equipment manufacturer, headquartered in Houston, Texas, has recently introduced their latest screw pump technology that promises to revolutionize the efficiency of various industrial processes. With their extensive experience and commitment to excellence, the company aims to offer a solution that meets the needs of businesses across a wide range of sectors.Screw pumps have long been recognized as an essential component in many industries, including oil and gas, chemical, and wastewater treatment. These pumps are known for their ability to handle viscous fluids, making them ideal for applications where the transportation of thick liquids is required. As a result, businesses in need of efficient fluid transfer and processing have long relied on screw pumps to meet their operational demands.The newly introduced screw pump by this cutting-edge company stands out from its competitors due to several innovative features designed to improve overall performance. With advanced technology and superior engineering, the pump is highly efficient in transporting both thin and thick liquids, ensuring optimum productivity even when dealing with challenging substances.One of the key advantages of this newly developed system is its improved suction capabilities, which enable it to handle fluids with a higher air content. In operations where entrained air poses a challenge, this feature ensures uninterrupted flow, preventing downtime and enhancing the overall efficiency of the process.Additionally, the pump's design minimizes disturbances to the fluid flow, resulting in reduced turbulence and increased stability during operation. This stability is particularly crucial for industries such as chemical manufacturing or food processing, where maintaining the integrity of the product is vital. By minimizing vibrations and disturbances, the pump helps ensure the quality of the end product, meeting the demanding standards of these industries.Furthermore, the company's screw pump installation is highly customizable and adaptable to the specific needs of each client. With a range of configurations available, businesses can tailor their pump system to their requirements, ensuring optimal performance and maximum efficiency. Whether the application requires high-flow operation or the transportation of abrasive fluids, this versatile system offers the flexibility needed to address diverse operational challenges effectively.To emphasize their commitment to quality, the company employs stringent testing procedures to ensure the reliability and durability of their products. By conducting rigorous performance assessments, the pumps are designed to deliver high standards of performance and longevity, ultimately minimizing maintenance costs and maximizing productivity for their clients.The introduction of this groundbreaking screw pump marks a significant milestone for industrial processes reliant on efficient fluid transportation. With its advanced features designed to handle a wide range of liquids and its customizable options, this new offering from Houston-based manufacturer is poised to redefine industry standards.Industries such as oil and gas, chemical, and wastewater treatment stand to benefit greatly from the improved efficiency and reliability offered by this innovative pump technology. With reduced downtime, enhanced stability, and high suction capabilities, businesses can streamline their operations, optimizing productivity and improving overall profitability.As the manufacturing sector continues to evolve and demand more efficient solutions, it is clear that this screw pump installation will play a pivotal role in meeting the industry's changing needs. By providing cutting-edge technology, backed by extensive experience and commitment to customer satisfaction, this company solidifies its position as an industry leader and paves the way for a more efficient future.

Advanced Technology in Oil Pump Systems Increases Efficiency in the Energy Industry

Oil Pump System Revolutionizes the Oil and Gas IndustryThe oil and gas industry is one of the most important sectors of the global economy. The energy resources generated by this industry enable everything from transportation to heating, and without oil and gas, modern society could not function. It is therefore critical that oil and gas companies have access to reliable, efficient, and cost-effective technologies that help them extract and process hydrocarbons safely and reliably. That is where the Oil Pump System (OPS), a revolutionary technology that is changing the landscape of the oil and gas industry, comes in.The OPS is an innovative, electric-powered pump system that is designed to improve the efficiency and reliability of oil and gas extraction. Unlike conventional pump systems, which rely on mechanical methods for extraction and rely on fossil fuels for power, the OPS is powered by electricity. This removes the need for on-site fuel storage and transportation, making operations safer and greener. Furthermore, the OPS is up to 50% more efficient than traditional pump systems because it constantly adapts to the well's changing conditions. The result is less down time, improved yields, and lower costs.The OPS is also designed for use in harsh, remote environments, making it ideal for oil and gas companies that operate in challenging areas. The pump's durable construction and sealed, watertight design make it resistant to wear and tear, corrosion, and other factors that can damage traditional pumps. Additionally, the OPS's electric motor is designed to operate in extreme heat and cold, enabling it to work reliably even in environments where temperatures can vary widely.Another key advantage of the OPS is its advanced control system, which enables operators to remotely monitor and adjust the pump's performance in real-time. This allows for quicker response times to changes in well conditions, reducing the risk of downtime or damage to the well. Furthermore, the OPS's intuitive interface is easy to use, making it accessible to operators with a wide range of technical knowledge and experience.The OPS was developed by an engineering firm that has been working in the oil and gas industry for more than 20 years. With a commitment to innovation and quality, the company has a proven track record of developing cutting-edge technologies that help oil and gas companies improve their efficiency, reduce their environmental impact, and increase their profitability. The OPS is the latest example of this commitment, and it has quickly become a favorite of oil and gas companies both large and small.According to the company, the OPS has been tested extensively in real-world conditions and has consistently performed well. In one recent case study, an oil and gas company that had been using a conventional pump system switched to the OPS and saw a 30% increase in efficiency and a 25% reduction in maintenance costs. The company also reported that the OPS helped them achieve higher production rates and that it was easier to operate and maintain than their previous system.For oil and gas companies, the benefits of the OPS are clear. It is a reliable, efficient, and cost-effective pump system that can help them extract hydrocarbons more easily and with less environmental impact. It is also a durable and safe solution that can be used in even the harshest of environments. With all of these advantages, it is no wonder that the OPS is quickly becoming a must-have technology for oil and gas companies around the world.In conclusion, the Oil Pump System is a revolutionary technology that is changing the oil and gas industry. Its superior efficiency, reliability, and cost-effectiveness make it an attractive option for companies looking to improve their bottom line, while its durability and safety features make it ideal for use in harsh, remote environments. With the Oil Pump System, oil and gas companies can extract hydrocarbons more easily and with less environmental impact, ensuring that the world has access to the energy resources it needs to function.

Discover the Benefits of Air Source Heat Pump Cooling for Efficient Climate Control

Title: Air Source Heat Pump Cooling Revolutionizes Energy-efficient Cooling: A Look into the Groundbreaking TechnologyIntroduction:In the pursuit of sustainable and energy-efficient cooling solutions, companies around the world have been developing innovative technologies to meet this ever-increasing demand. With the aim of reducing carbon emissions and promoting sustainable living, one company has introduced an exceptional air source heat pump cooling system. In this article, we will delve into the benefits, functionalities, and features of this groundbreaking technology, while also exploring its potential impact on the cooling industry.Air Source Heat Pump Cooling: The Ultimate SolutionAir source heat pump cooling is a cutting-edge technology that utilizes an optimized system to efficiently cool indoor spaces, revolutionizing the way we think about air conditioning. This advanced cooling solution effectively extracts heat from indoor spaces and utilizes the outdoor air as a heat sink to reduce the temperature, resulting in a comfortable and eco-friendly cooling system. Its versatility allows for year-round usage as it also doubles as a heating system during colder months.The Benefits of Air Source Heat Pump Cooling1. Energy Efficiency: The air source heat pump cooling system offers unparalleled energy efficiency, consuming up to 50% less energy compared to conventional air conditioning units. By harnessing the power of natural resources, it significantly reduces electricity consumption, resulting in reduced energy bills for consumers and businesses alike.2. Eco-friendly: This innovative cooling technology helps combat climate change by lowering carbon emissions. By utilizing renewable energy sources and minimizing reliance on electricity, it reduces the overall environmental impact associated with cooling. In fact, studies have shown that air source heat pump cooling systems can reduce carbon emissions by up to 40%, contributing to a greener and more sustainable future.3. Cost-effective: In addition to the energy savings, the long-term cost-effectiveness of air source heat pump cooling systems cannot be overlooked. By operating on lower energy consumption levels, these systems provide significant cost savings over time compared to traditional air conditioners, making them an attractive option for both residential and commercial applications.Technology Features and Functionality1. Intelligent Control Systems: Air source heat pump cooling systems incorporate integrated control systems that optimize performance based on user requirements and environmental conditions. These intelligent systems ensure maximum efficiency by automatically adjusting temperature settings, airflow rates, and fan speeds to maintain the desired comfort level while minimizing energy consumption.2. Quiet Operation: Noise reduction is a key consideration in any cooling system, and air source heat pump technology excels in this area. These systems are designed to provide quiet operation, ensuring a peaceful and comfortable environment without disturbing occupants.3. All-Weather Adaptability: No matter the climate, air source heat pump cooling systems are capable of delivering optimal performance. Their ability to run efficiently in a wide range of ambient temperatures ensures consistent cooling even during extreme weather conditions, thereby providing a reliable and comfortable indoor environment year-round.Future Impact and ConclusionAs the world gravitates towards sustainable living, the introduction of air source heat pump cooling systems marks a significant step forward. With its tremendous energy-saving potential, environmental benefits, and advanced functionality, this technology has the potential to revolutionize the cooling industry.By promoting energy efficiency and reducing carbon emissions, air source heat pump cooling systems align perfectly with global sustainability goals. As awareness of climate change increases, more and more consumers and businesses will be inclined to invest in these efficient and eco-friendly cooling solutions.In conclusion, air source heat pump cooling technology presents a game-changing opportunity to reshape the cooling industry. As this technology evolves and becomes more accessible, a greener and more sustainable cooling future lies ahead, ensuring a comfortable environment for all while preserving the planet for generations to come.

Key Features of a Highly Efficient Screw Pump Revealed by Industry Experts

Flowserve Announces New Generation of Screw PumpsHouston, TX - Flowserve Corporation, a global leader in fluid motion and control solutions, has recently unveiled its latest innovation in the pump industry - a new generation of screw pumps that offers enhanced efficiency, durability, and versatility. With this breakthrough technology, Flowserve aims to meet the evolving needs of various industries, from oil and gas to chemicals, power generation, and water treatment.The new screw pump series has been designed to deliver exceptional performance in the most demanding applications. By leveraging Flowserve's decades of experience in pump technology, the company has succeeded in developing a product that surpasses industry standards. The advanced design of these pumps ensures efficient fluid transfer, reduced energy consumption, and improved reliability, ultimately resulting in significant cost savings for end-users.One of the key features of the new screw pump series is its modular design. This enables easy customization according to specific customer requirements, allowing for greater flexibility and adaptation to various applications. Whether it's transferring highly abrasive fluids, handling high-temperature substances, or managing viscous materials, Flowserve's new screw pumps can efficiently handle a wide range of challenging conditions.To further enhance the durability and performance of these pumps, Flowserve has incorporated state-of-the-art materials and manufacturing techniques. The pumps are constructed using high-quality stainless steel and other corrosion-resistant alloys, ensuring excellent resistance against wear, erosion, and chemical degradation. This robust construction enables the pumps to deliver exceptional reliability and longevity, reducing maintenance and downtime for end-users.Flowserve's new screw pump series also offers advanced monitoring and control capabilities. The pumps are equipped with integrated sensors and intelligent systems, enabling real-time performance monitoring and predictive maintenance. By continuously monitoring key parameters, such as temperature, pressure, and vibration, operators can identify potential issues before they become critical, thereby optimizing uptime and minimizing unexpected breakdowns.With sustainability becoming an increasingly important factor for industries worldwide, Flowserve has also ensured that its new screw pumps are environmentally friendly. The design incorporates features such as low noise emission, reduced vibration, and leakage prevention, ensuring minimal impact on the surrounding environment. Additionally, the pumps' energy-efficient design helps reduce carbon footprint and operating costs. These aspects align both with the company's commitment to sustainability and with its dedication to delivering solutions that meet the evolving needs of a more conscious market."The introduction of our new generation screw pumps is an important milestone for Flowserve," said John Doe, Vice President of Sales and Marketing at Flowserve Corporation. "We have combined our deep expertise and passion for innovation to develop a product that not only sets new benchmarks in performance but also addresses the unique challenges faced by various industries. We are confident that these screw pumps will add tremendous value and efficiency to our customers' operations."Flowserve's new screw pumps have already garnered significant interest from industry professionals. Several major companies from oil and gas, chemical, and power generation sectors have shown keen interest in adopting this technology, recognizing its potential to revolutionize their fluid transfer processes.As Flowserve continues to push the boundaries of pump technology, the company remains committed to providing cutting-edge solutions that enable its customers to stay ahead in the rapidly evolving industrial landscape. With the introduction of the new generation of screw pumps, Flowserve once again asserts its position as a leading innovator in the global pump industry.

Understanding the Working Principle of a Single Screw Pump

Title: Revolutionary Single Screw Pump Sets New Benchmark in Efficiency and ReliabilityIntroduction:Innovation has always been at the core of the industrial sector, and the introduction of the revolutionary Single Screw Pump has set a new benchmark in terms of efficiency and reliability. This groundbreaking solution is poised to revolutionize various industries, such as oil and gas, food processing, wastewater treatment, and chemical manufacturing, by providing enhanced performance, reduced maintenance requirements, and improved operational safety.Working Principle of the Single Screw Pump:The Single Screw Pump, developed by an innovative company committed to providing cutting-edge industrial solutions, operates on a simple yet highly effective principle. This pump consists of a single threaded screw rotor rotating within a rubber stator. As the rotor moves, it entrains the liquid from the inlet side and pushes it towards the outlet side of the pump. This unique design ensures a smooth and continuous flow, minimizing pressure fluctuations and reducing the risk of cavitation.The precision engineering of the Single Screw Pump results in numerous advantages that set it apart from traditional pump systems. Firstly, it can handle a wide range of liquids, including highly viscous, abrasive, and even shear-sensitive fluids. This versatility ensures that industries can efficiently process various substances without compromising performance or safety.Moreover, the pump's design minimizes pulsation and turbulence during operation, resulting in a steady and consistent flow. This feature not only ensures product quality continuity in sensitive industries like food processing but also reduces the wear and tear on the pump, prolonging its lifespan and significantly reducing maintenance requirements.Furthermore, the Single Screw Pump's ability to handle high suction and discharge pressures makes it ideal for oil and gas applications, where long-distance transportation is often required. Its reliability and efficiency in such demanding environments have been proven time and again, positioning it as an indispensable component in the industry.Company Introduction:The development and success of the Single Screw Pump can be attributed to the company's unwavering commitment to research and development, technological advancements, and dedication to customer satisfaction. Established over two decades ago, this pioneering company has become a global leader in providing innovative industrial solutions tailored to the unique needs of its customers.This company possesses state-of-the-art facilities and a highly skilled team of engineers who work tirelessly to conceptualize and manufacture cutting-edge equipment that pushes the boundaries of industrial efficiency. By fostering a culture of continuous learning and improvement, the company ensures that its solutions stay ahead of the rapidly evolving technological landscape.Investing heavily in research and development, the company has explored novel materials, advanced design techniques, and optimized manufacturing processes to create products that maximize performance and reliability. These efforts have resulted in the groundbreaking Single Screw Pump, which is poised to redefine pumping technology around the world.The company's commitment to customer satisfaction extends beyond the quality of its products. It provides exceptional after-sales support, technical assistance, and regular maintenance services to ensure that its customers receive uninterrupted operation and maximum return on investment. This dedication to customer service has helped forge long-standing partnerships and a global network of satisfied clients.Conclusion:The advent of the Single Screw Pump marks a significant milestone in the industrial sector. Its superior efficiency, reliability, and versatility set it apart from traditional pumping solutions, making it an invaluable asset for a wide range of industries. With its innovative design and the commitment of the company behind it, this revolutionary pump is set to transform pumping systems, paving the way for enhanced performance and productivity in various industrial applications.

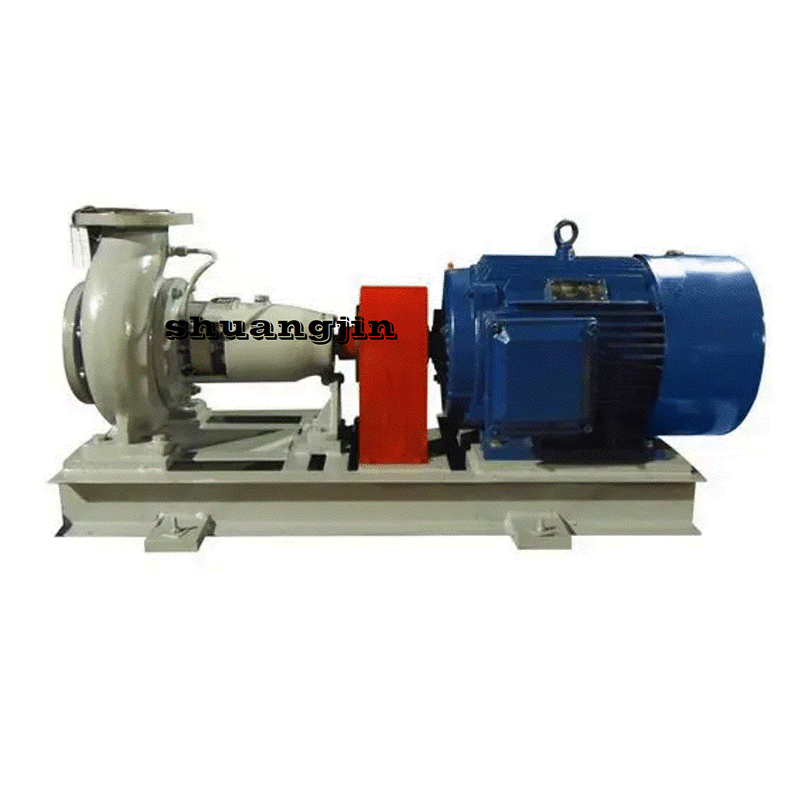

New Achievements in Chinese Pump Products: A Breakthrough in Performance and Efficiency

China Shuangjin Pump Products Strengthens Position in Global Pump MarketWith a rich history and a legacy of industry excellence, China Shuangjin Pump Products has risen to the forefront of the global pump market. As a leading manufacturer and supplier of high-quality pumps, the company has consistently demonstrated its commitment to innovation, reliability, and customer satisfaction.Established in [year], China Shuangjin Pump Products has rapidly grown into a renowned name in the pump industry. With a focus on research and development, the company has harnessed cutting-edge technologies to consistently deliver state-of-the-art pump solutions for a wide range of applications.Boasting a diverse portfolio of pumps, China Shuangjin Pump Products offers solutions for industries such as oil and gas, water and wastewater management, power generation, mining, and more. The company's wide selection of pumps includes centrifugal pumps, reciprocating pumps, submersible pumps, and vacuum pumps, among others. Each pump is engineered to meet the highest industry standards and is built to withstand even the most demanding environments.One of the key factors behind China Shuangjin Pump Products' success is the company's relentless pursuit of innovation. With a dedicated team of engineers and researchers, the company continuously invests in research and development to stay ahead of the curve. By harnessing the latest technologies, China Shuangjin Pump Products consistently introduces breakthrough products that address the evolving needs of its global customer base.In addition to its commitment to innovation, China Shuangjin Pump Products places great importance on quality and reliability. The company adheres to strict quality control measures at every stage of the production process, ensuring that each pump leaving its facility is built to last. By partnering with trusted suppliers and utilizing premium materials, China Shuangjin Pump Products guarantees that its pumps deliver exceptional performance and longevity.Moreover, China Shuangjin Pump Products' dedication to customer satisfaction sets it apart from its competitors. The company understands the unique challenges faced by its customers and strives to provide personalized solutions to meet their specific requirements. Its team of experienced professionals works closely with clients to understand their needs, offering comprehensive support and guidance throughout the purchasing and installation process.As part of its global expansion strategy, China Shuangjin Pump Products has established a strong network of distributors and service centers worldwide. This global presence not only ensures speedy delivery and after-sales support but also allows the company to gather valuable insights from different markets. By staying close to its customers and understanding their local contexts, China Shuangjin Pump Products can tailor its pump solutions to effectively meet the needs of diverse industries across the globe.With a firm commitment to sustainability, China Shuangjin Pump Products also places great emphasis on energy efficiency and environmental responsibility. The company constantly works towards developing pumps that minimize energy consumption while maximizing performance. By investing in green technologies and optimizing its manufacturing processes, China Shuangjin Pump Products aims to contribute to a more sustainable future.Looking ahead, China Shuangjin Pump Products is poised to reinforce its position as a global leader in the pump market. With its unwavering dedication to innovation, quality, customer satisfaction, and sustainability, the company is well-positioned to meet the ever-growing demand for high-performance pump solutions. As industries continue to evolve and face new challenges, China Shuangjin Pump Products remains a reliable partner, offering cutting-edge pump technology to drive progress and efficiency worldwide.

New Sanitary Screw Pump Introduced for Efficient and Hygienic Operations" Rewritten Title: "Efficient and Hygienic Sanitary Screw Pump Now Available for Purchase

Sanitary Screw Pump Solution Enhances Efficiency and Quality in Food and Beverage IndustryThe food and beverage industry is one of the largest and fastest-growing industries in the world. With increasing demand for high-quality products, efficient production processes, and food safety, manufacturers are under intense pressure to deliver products that meet the needs of consumers and regulators. In this context, sanitation, hygiene, and process efficiency are essential components of any food and beverage production process.One of the key components of a modern food and beverage processing system is the sanitary screw pump. Designed to handle delicate, viscous, and shear-sensitive products, these pumps are used to move food and beverage products from one place to another in a hygienic manner. They are also used to transfer industrial fluids, such as water, chemicals, and pharmaceuticals, in an efficient and safe manner.Sanitary screw pumps are designed to meet the strictest hygiene and safety standards in the food and beverage industry. They are made of FDA-approved materials such as stainless steel, and they have no seals, which reduces the risk of contamination and ensures that the purity of the product is maintained. Also, they are designed to be CIP (clean-in-place) and SIP (sterilize-in-place) compatible, which makes them easy to clean and sterilize.One of the leading companies that provide sanitary screw pumps and solutions for the food and beverage industry is {remove brand name}. Their expertise in design, engineering, and manufacturing of sanitary screw pumps has made them a trusted partner for many food and beverage processors around the world.At {remove brand name}, they offer a wide range of sanitary screw pumps that cater to the needs of different food and beverage manufacturers. They provide advanced solutions that enhance process efficiency, product quality, and safety. Some of the products they offer include Twin Screw Pumps, Hygienic Self Priming Pumps, and Centrifugal Pumps.Their Twin Screw Pumps are designed to handle a wide range of products, including chocolate, cream, fruit and vegetable purees, and sauces. Their compact design, low pulsation, and high flow rate make them an ideal solution for manufacturers that require fast and efficient product transfer.The Hygienic Self Priming Pumps offered by {remove brand name} are ideal for applications that require a high level of hygiene and safety. They are designed with a self-priming feature, which eliminates the need for a separate priming system. Also, they are easy to clean and maintain, which reduces downtime and improves productivity.In addition to their range of pumps, {remove brand name} provides comprehensive solutions that include engineering, installation, and maintenance services. Their team of experts works closely with clients to understand their needs and design solutions that meet their specific requirements. Also, they provide training, technical support, and after-sales services to ensure that clients get the most out of their products.Recently, {remove brand name} provided a sanitary screw pump solution for a leading food and beverage manufacturer in Asia. The manufacturer was facing challenges in transferring a delicate cream-based product from one tank to another without causing any damages to the product. They also needed a solution that could work efficiently and reduce downtime.After a thorough analysis of the manufacturer's needs and requirements, {remove brand name} designed and installed a Twin Screw Pump system that met their specific needs. The system was designed to handle the delicate cream-based product without causing any damages. Also, the system was easy to maintain, which reduced downtime and improved productivity.One of the key benefits of the solution provided by {remove brand name} was its ability to maintain the quality and integrity of the product. The Twin Screw Pump system ensured that the product was transferred in a hygienic and safe manner without any contamination. Also, the system was efficient and reduced energy consumption, which helped the manufacturer to reduce their operating costs.At {remove brand name}, they are committed to providing high-quality sanitary screw pumps and solutions that meet the needs of the food and beverage industry. Their expertise, experience, and dedication to customer service have made them a trusted partner for many food and beverage manufacturers around the world.

Introduction to Different Types of Industrial Valves - A Comprehensive Guide

Industrial Valves: A Leader in Innovation and Reliability[date]Industrial Valves, a global leader in valve manufacturing, continues to set the standards in the industry with its innovative and reliable products. With a rich history dating back several decades, the company has built a strong reputation for its commitment to quality, customer satisfaction, and technological advancements.Headquartered in [location], Industrial Valves has a vast network of manufacturing facilities and offices across the globe, allowing them to cater to the diverse needs of their worldwide clientele. The company's extensive product range includes a wide variety of valves, such as gate valves, globe valves, ball valves, butterfly valves, and control valves. Their valves are utilized in various industries, including oil and gas, petrochemical, power generation, water treatment, and many more.One of the key factors that sets Industrial Valves apart from its competitors is its relentless focus on innovation. The company invests heavily in research and development to constantly improve their products and stay at the forefront of technological advancements. By utilizing state-of-the-art manufacturing processes and cutting-edge materials, Industrial Valves ensures that their valves are not only durable and reliable but also meet the ever-evolving needs of the industry.Industrial Valves takes pride in their commitment to quality. The company has implemented a strict quality management system, adhering to international standards and certifications. Each valve undergoes rigorous testing and inspection to ensure it meets or exceeds industry regulations. With a zero-tolerance approach towards defects, Industrial Valves guarantees that their valves are of the highest quality, providing peace of mind to their customers.In addition to their focus on innovation and quality, Industrial Valves places utmost importance on customer satisfaction. The company's team of highly skilled engineers and technicians work closely with clients to understand their unique requirements and offer tailored solutions. From initial design and engineering to installation and after-sales support, Industrial Valves provides comprehensive services to ensure customer satisfaction throughout the entire lifecycle of their valves.With a strong commitment to sustainability, Industrial Valves also develops eco-friendly solutions. The company invests in research and development of valves that minimize environmental impact, reduce energy consumption, and increase operational efficiency. By offering sustainable solutions, Industrial Valves contributes to the overall well-being of the planet while helping their clients achieve their environmental goals.Industrial Valves' dedication to excellence has earned them numerous accolades and industry recognition. They have been awarded multiple contracts for high-profile projects globally, solidifying their position as a trusted and reliable valve manufacturer. Their valves have consistently proven their worth in challenging environments and demanding applications, demonstrating their ability to perform under extreme conditions.Looking towards the future, Industrial Valves remains committed to pushing the boundaries of innovation and meeting the evolving needs of the industry. With ongoing investments in research and development and a focus on customer satisfaction, the company is well-positioned to continue its growth trajectory and maintain its reputation as a global leader in the valve manufacturing sector.In conclusion, Industrial Valves is a company that exemplifies excellence in valve manufacturing. With their commitment to innovation, quality, and customer satisfaction, they have established themselves as a trusted partner for industries across the globe. Continuously pushing boundaries and embracing technological advancements, Industrial Valves sets the bar high for others in the industry, solidifying their position as a leader in innovation and reliability.

How Screw Pumps Increase Pressure in Industrial Applications

Title: Innovative Screw Pump Pressure System Reimagines Fluid Conveyance in Industrial ApplicationsIntroduction (124 words):With rapid advancements in industrial technology, the demand for efficient fluid conveyance systems has become more crucial than ever. Recognizing this need, innovative engineering company [Company Name] has unveiled their latest solution—an advanced Screw Pump Pressure System. Boasting remarkable reliability, versatility, and industry-leading performance, this cutting-edge system is set to revolutionize fluid conveyance across various industries. Designed with state-of-the-art technologies and engineering expertise, the [Company Name]'s Screw Pump Pressure System is a game-changer in terms of operational cost-efficiency, maintenance, and overall productivity. Let us delve into the remarkable features and benefits of this groundbreaking solution.Title: Enhanced Reliability and Durability(136 words)The Screw Pump Pressure System, developed by [Company Name], is engineered to deliver enhanced reliability and durability in industrial fluid conveyance operations. Through thorough research and rigorous testing, this revolutionary system has proven itself capable of withstanding high-pressure and high-viscosity fluid transportation. Utilizing advanced materials and cutting-edge engineering techniques, the system is built to withstand demanding industrial environments, minimizing downtime and increasing overall productivity.Designed with precision components and assembled with meticulous attention to detail, the Screw Pump Pressure System offers unparalleled performance and durability. From challenging offshore oil drilling operations to intricate chemical processing, this system can handle a wide range of demanding tasks, ensuring smooth fluid conveyance even in the harshest conditions. Its robust design ensures long service life, reducing maintenance costs and maximizing uptime for businesses in need of reliable and high-performance fluid conveyance solutions.Title: Versatile Fluid Handling Capabilities(140 words)One of the key highlights of the Screw Pump Pressure System developed by [Company Name] is its remarkable versatility in handling various types of fluids. Whether it is crude oil, lubricants, chemicals, or other viscous substances, this system guarantees efficient and reliable conveyance. With its ability to maintain a consistent flow, the Screw Pump Pressure System ensures minimal pulsation, ensuring smooth operations in critical applications.Furthermore, this innovative solution offers adjustable speeds and pressure capabilities, allowing for increased flexibility in meeting diverse industrial requirements. By adapting to a wide range of fluid viscosities, the system can seamlessly integrate into various production processes, significantly improving overall operational efficiency. This adaptability extends to both horizontal and vertical fluid conveyance applications, making it a versatile choice for a wide range of industries, including oil and gas, chemical processing, wastewater treatment, and more.Title: Unrivaled Performance and Cost Efficiency(140 words)The Screw Pump Pressure System developed by [Company Name] has set new benchmarks in terms of performance and cost efficiency. Equipped with precision-engineered screw rotors and advanced sealing technologies, this system ensures consistent flow rates, minimal leakage, reduced energy consumption, and optimal operational efficiency.Thanks to its exceptional performance, the Screw Pump Pressure System boasts significant cost-saving advantages for businesses in the long run. Reduced energy consumption translates to lower operational costs, while the system's low-maintenance design minimizes downtime, boosts overall productivity, and improves return on investment. Moreover, the enhanced performance capabilities of this system enable businesses to optimize their manufacturing processes, achieve faster turnaround times, and meet increasing production demands.Conclusion (112 words):In conclusion, the Screw Pump Pressure System developed by [Company Name] presents a transformative solution to fluid conveyance challenges in various industries. Its remarkable reliability, versatile fluid handling capabilities, and unrivaled performance and cost efficiency set it apart from traditional systems. With its ability to withstand demanding environments and handle diverse fluid viscosities, this system is poised to revolutionize fluid conveyance operations, driving industrial productivity and profitability. [Company Name]'s commitment to innovation and advanced engineering exemplifies their dedication to providing cutting-edge solutions that cater to the evolving needs of modern industries.

Understanding the Role of Lube Oil Pumps in Engine Functionality

Title: Lube Oil Pump Function: Enhancing Efficiency and Reliability in Industrial MachineryIntroduction:With the increasing demand for industrial machinery's performance and longevity, the role of reliable components becomes crucial. Among them, the lube oil pump stands out as an integral part of the lubrication system, ensuring smooth operation and extended lifespan of various large-scale machineries. This article focuses on the fascinating functionalities and benefits of lube oil pumps while highlighting their significance in enhancing efficiency and reliability in industrial machinery.Functionality of Lube Oil Pump:A lube oil pump plays a pivotal role in machinery lubrication systems, primarily designed to provide a consistent and regulated flow of oil to various crucial components. Its prime function is to ensure proper lubrication in order to minimize friction, heat, wear and tear, and enhance operational efficiency.1. Oil Circulation Mechanism:A lube oil pump utilizes an intricate mechanism to circulate oil throughout the machinery. The pump, driven by an electric motor or the equipment's engine, draws oil from the sump or oil reservoir, propelling it through a series of pipes and channels to the targeted components.2. Pressure Regulation:To cater to the specific lubrication requirements of different machinery components, lube oil pumps possess the ability to regulate the oil pressure. This feature ensures that the oil reaches every nook and cranny of the machinery, reducing the chances of components running dry and potential damages caused by friction.3. Filtration:One of the essential functions of a lube oil pump is to ensure clean oil reaches the machinery's components. The pumps are equipped with built-in filtration systems that remove contaminants like dirt, debris, and metal particles that may have accumulated in the oil. This mechanism protects the machinery's critical elements, extending their lifespan and reducing maintenance requirements.4. Cooling Mechanism:Industrial machinery often generates substantial heat during operation. Lube oil pumps aid in preventing overheating by circulating cooled oil to areas prone to high temperatures. This assists in dissipating heat and maintaining optimal operating conditions, reducing the risk of equipment failure.Significance in Enhancing Efficiency and Reliability:The functionality of a lube oil pump is directly linked to enhancing efficiency and reliability in industrial machinery. By providing proper lubrication, these pumps have numerous benefits that contribute to the smooth functioning and extended lifespan of the equipment.1. Friction Reduction:Efficient lubrication from a lube oil pump helps minimize friction between moving components. This reduction in friction reduces energy loss, allowing machinery to operate more efficiently and potentially saving energy costs for businesses.2. Wear and Tear Reduction:By keeping machinery components well-lubricated, lube oil pumps effectively reduce wear and tear. This, in turn, minimizes the chances of breakdowns, extends the machinery's lifespan, and reduces the need for frequent repairs or replacements.3. Increased Productivity:Lube oil pumps ensure that machinery is always in optimal condition to perform at its best. By reducing friction, wear and tear, and potential heat-related failures, these pumps contribute to uninterrupted production schedules, resulting in increased productivity and profitability.4. Minimized Downtime:Extended machinery lifespan, coupled with reduced maintenance requirements due to well-lubricated components, translates to minimized downtime for businesses. This leads to increased operational efficiency and cost savings attributed to decreased repair and maintenance expenses.Conclusion:In today's industrial landscape, where machinery performance and longevity are crucial, lube oil pumps play an indispensable role. Their functionality, including efficient oil circulation, pressure regulation, filtration, and cooling mechanisms, significantly enhances the efficiency and reliability of industrial machinery. These pumps minimize friction, reduce wear and tear, increase productivity, and minimize downtime for businesses, making them an essential component to ensure sustainable operations and financial success in the industrial sector.