Discover the Top Marine Water Pump for Your Needs in 2022

By:Admin

[City, Date] - As the maritime industry continues to evolve and seek innovative solutions to enhance efficiency and reliability, the Marine Water Pump has emerged as a game-changer in marine operations. Manufactured by a reputed company [], this cutting-edge technology is revolutionizing the industry's approach towards water pumping systems.

With the ever-increasing demand for efficient water transportation, maintaining reliable pumping systems becomes crucial. The Marine Water Pump, crafted with precision and advanced engineering, offers an ideal solution for various marine applications. Whether it's for ballast water management, bilge pumping, or firefighting operations, this water pump offers unmatched performance and efficiency.

One of the key aspects that sets the Marine Water Pump apart from traditional systems is its durability and reliability. Constructed from high-quality materials, this pump is built to withstand the harsh marine environment, ensuring longevity and minimal downtime. The corrosion-resistant body and components minimize the risk of damage and reduce maintenance costs, making it an ideal choice for marine operators seeking cost-effective solutions.

Moreover, the compact design of the Marine Water Pump enables easy installation and integration into existing marine systems. Its versatility allows for seamless compatibility with different vessel types, ranging from small crafts to large commercial ships. By reducing installation time and complexity, this pump assists marine operators in streamlining their operations and maximizing productivity.

Furthermore, the advanced engineering behind the Marine Water Pump ensures optimal performance and energy efficiency. With its superior pumping capabilities, this technology enables faster water transfer and drainage, saving valuable time during critical marine operations. The pump's adjustable flow and pressure settings provide operators with greater control, allowing for enhanced operational precision and flexibility.

In the context of environmental sustainability, the Marine Water Pump upholds the highest standards. It incorporates advanced filtration and purification systems, ensuring compliance with strict maritime environmental regulations. By effectively managing ballast water and preventing the spread of invasive species, this pump contributes to the preservation of marine ecosystems and supports sustainable water transportation practices.

In addition to its performance and reliability, the company behind the Marine Water Pump, [], brings extensive expertise and experience to the table. With a proven track record in developing innovative marine technologies, the company has earned a reputation for delivering industry-leading solutions. Its commitment to research and development ensures that the Marine Water Pump remains at the forefront of technological advancements, constantly pushing the boundaries of efficiency and reliability.

To support its customers in maximizing the benefits of the Marine Water Pump, the company offers comprehensive after-sales services. With a global network of service centers and technicians, the company ensures prompt assistance and maintenance support, minimizing downtime and maximizing uptime for marine operators. This dedication to customer satisfaction has contributed to the company's strong presence in the maritime industry worldwide.

As the demand for efficient water pumping systems continues to grow in the maritime sector, the Marine Water Pump stands out as a game-changer. Its durability, reliability, and efficiency make it an indispensable asset for marine operators aiming to optimize their operations and reduce costs. With the backing of its visionary manufacturer [], the Marine Water Pump is set to redefine the standards of water pumping in the maritime industry.

Company News & Blog

New Vertical Centrifugal Pump Offers Efficient Water Movement

Recently, a new vertical centrifugal pump has been launched by a leading manufacturer in the industry. The pump, which has been designed specifically for industrial use, is expected to meet the growing demand for high-quality, reliable and efficient pumping solutions in various sectors including chemical processing, oil & gas, and water treatment.The new vertical centrifugal pump is the result of years of research and development by the manufacturer, who has been at the forefront of innovation in the industry. The key features of the pump include its compact design, high efficiency, and ease of maintenance. It is equipped with a powerful motor that can deliver up to 110 kW of power, and comes with a range of customizable options to suit different applications.One of the biggest advantages of the vertical centrifugal pump is its ability to handle high flow rates and high pressures. This makes it an ideal choice for industries that require large volumes of liquid to be moved quickly and reliably. The pump is also designed to operate at high temperatures and can handle a wide range of corrosive and abrasive fluids, making it suitable for use in harsh environments.To ensure maximum reliability and performance, the manufacturer has incorporated advanced technologies into the design of the vertical centrifugal pump. This includes state-of-the-art sealing systems, advanced bearing designs, and precision machining techniques. The pump has also been rigorously tested to ensure its compliance with international standards for quality and safety.The manufacturer is committed to providing its customers with the highest level of service and support. The company has a team of highly skilled engineers and technicians who are available to provide technical assistance and troubleshooting services as needed. In addition, the company offers a range of training and education programs to help customers get the most out of their pumping equipment and to optimize their operations.With its advanced features, reliable performance, and excellent customer support, the new vertical centrifugal pump is expected to be in high demand among a wide range of industries. Its versatility makes it suitable for use in applications ranging from chemical processing to water treatment, and from oil & gas to mining. As the demand for high-quality pumping solutions continues to grow, the manufacturer is well positioned to meet the needs of its customers and to continue to innovate and remain at the forefront of the industry.

The Significance of Timing Gears in Screw Pumps: Exploring their Role and Function

Timing Gear in Screw Pump: A Revolutionary Advancement in Pump Technology[Company Name], a leading innovator in the field of pump technology, has recently unveiled a breakthrough development in screw pump design – the revolutionary Timing Gear. This state-of-the-art advancement is set to transform the way pumps function, offering enhanced efficiency, reliability, and durability.Traditional screw pump designs rely on a rotating helical screw to move fluids through the pump. While these pumps have proven to be effective for many applications, they often suffer from issues such as uneven fluid flow, excessive vibration, and premature wear of the screw and other internal components.With the introduction of the Timing Gear, [Company Name] aims to eliminate these drawbacks and create a new benchmark in screw pump performance. This innovative gear mechanism, which replaces the traditional single-helix screw, provides precise control over the flow of fluids, resulting in smoother operation and improved overall efficiency.One of the primary advantages of the Timing Gear is its ability to maintain a consistent flow rate, regardless of variations in input pressure or viscosity of the fluid being pumped. This feature makes it highly suitable for applications where a reliable and steady flow is crucial, such as in the oil and gas industry, chemical processing plants, and wastewater treatment facilities.Additionally, the Timing Gear significantly reduces unwanted vibrations that can cause excessive wear and tear on pump components. By incorporating advanced engineering principles, including precision machining and advanced materials, [Company Name] has ensured that their Timing Gear pumps operate with minimal noise and vibrations, thereby increasing their service life and reducing maintenance costs.Another noteworthy feature of the Timing Gear is its remarkable durability. The gear mechanism is designed to withstand high operating pressures and resist corrosion, making it suitable for use in harsh and demanding environments. Its robust construction ensures long-term reliability and reduced downtime, providing businesses with a cost-effective solution for their pumping needs.Furthermore, the Timing Gear’s design allows for easy maintenance and quick replacement of worn components. Its modular construction enables users to access and replace specific parts, reducing the need for extensive disassembly and minimizing downtime during servicing. Additionally, the gear’s simplicity of design enhances reliability, as fewer moving parts mean fewer opportunities for mechanical failures.[Company Name] has already received overwhelmingly positive feedback from early adopters of the Timing Gear. Companies that have integrated this groundbreaking technology into their pump systems have reported significant improvements in efficiency, productivity, and overall performance. Several industry experts have also praised this innovation, recognizing its potential to revolutionize the screw pump market.In conclusion, [Company Name]’s introduction of the Timing Gear has set a new standard in screw pump technology. With its precise flow control, reduced vibrations, exceptional durability, and ease of maintenance, this groundbreaking development promises to deliver a range of benefits to businesses across various sectors. As this revolutionary advancement gains traction in the industry, it is expected to redefine the capabilities and expectations of screw pumps, establishing [Company Name] as a leader in pump technology innovation.

10 Essential Factors to Consider When Choosing a Pump

article.Allweiler Pump Rebrands as ACI FluidsLeading global pump manufacturer, Allweiler Pump, has officially rebranded as ACI Fluids, following the acquisition by the American industrial conglomerate, Cameron Corporation. The exciting new development will see ACI Fluids bolster their state-of-the-art product portfolio, expand their global network, and continue to offer world-class services to customers across multiple industries.ACI Fluids has a rich history of innovation, with over 150 years of experience in the pump industry. Over the years, the company has established itself as a name to be reckoned with and has become synonymous with reliability and quality. As the company takes on a new identity, it seeks to build on its legacy and scale new heights of success.ACI Fluids offers an extensive range of pumps that cater to a variety of industrial applications. Its portfolio includes centrifugal, positive displacement, and gear pumps, among others. The company has a reputation for manufacturing pumps that are durable, efficient, and operate at peak performance even under challenging conditions. ACI Fluids' product range serves industries such as oil and gas, marine, chemical, food and beverage, and water and wastewater.The acquisition of Allweiler Pump by Cameron Corporation presents numerous opportunities for ACI Fluids to expand its presence in different markets. The synergy created by the acquisition will allow the company to leverage the technological expertise and operational efficiency of both organizations. This development will translate to more significant investments in research and development, enhancing engineering capabilities, expanding product lines, and exploring new avenues of growth.ACI Fluids' mission is to be a reliable partner to its customers by offering exceptional customer service and technical support. Its team of experienced engineers and technicians work closely with customers to provide customized solutions that meet their unique requirements. The company's commitment to customer satisfaction is evident from the testimonials of its satisfied customers, who have attested to the quality of its products and services.The appointment of Kevin Snee as President of ACI Fluids marks a significant milestone in the company's growth. Kevin joins the company with a wealth of industry experience, having previously served as Senior Vice President of Global Sales and Marketing at Blackmer. In his new role, Kevin will be responsible for driving the company's strategic vision, leading its growth initiatives, and developing strong customer relationships.Kevin's appointment comes at a time when ACI Fluids is looking to strengthen its presence in emerging markets such as Asia and the Middle East. He sees these regions as critical to the company's growth and is committed to investing resources to expand the company's footprint. Kevin also plans to continue building on the company's primary focus of delivering exceptional products and services to its customers.In conclusion, the rebranding of Allweiler Pump to ACI Fluids is a significant development in the pump industry. With a history rooted in innovation and a reputation for quality, ACI Fluids is poised for growth under the leadership of Kevin Snee. As it expands its product portfolio, leverages new technologies, and explores new markets, ACI Fluids remains committed to its core values of reliability, quality, and superior customer service.

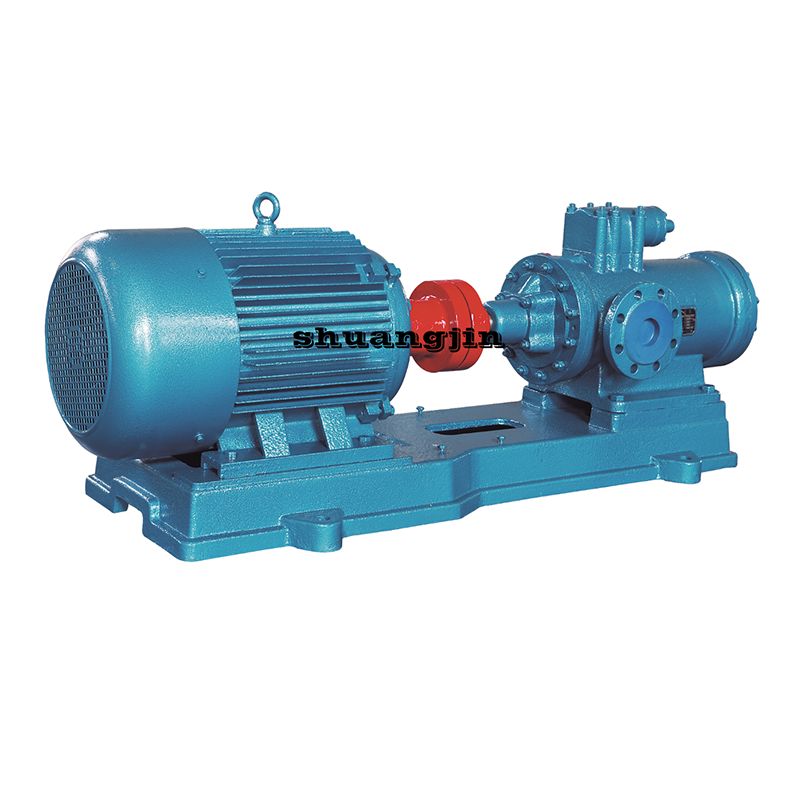

Innovative Screw Pump: Revolutionizing Pumping Technology

**Title: Innovative Screw Pump Revolutionizes Industrial Fluid Handling***Subheading: Company XYZ introduces a groundbreaking screw pump enhancing operational efficiency in diverse industries*Date: [Insert Date][Location] - Industry-leading company XYZ has devised a remarkable screw pump, designed to revolutionize the process of industrial fluid handling. Based on cutting-edge technology and years of research, this new innovation is set to enhance operational efficiency, increase productivity, and minimize maintenance costs across various sectors.The new screw pump, developed by XYZ's expert engineers, boasts numerous features that set it apart from traditional models. With a robust design and state-of-the-art mechanics, it offers unparalleled reliability, ensuring uninterrupted fluid transfer for a variety of applications.One of the key advantages of the XYZ screw pump is its exceptional versatility. Whether in oil refineries, chemical plants, power generation facilities, or wastewater treatment plants, this pump can handle a broad range of fluids, including viscous substances with high solid content.The screw pump's efficient design guarantees a continuous flow and eliminates the risk of pulsation during operation. This ensures a consistent and smooth transfer of fluids, which is crucial for maintaining optimal production rates and preventing costly disruptions.Furthermore, the XYZ screw pump is engineered with the latest sealing technology, greatly minimizing the possibility of leakage. This not only prevents environmental contamination but also reduces the need for frequent maintenance and replacement parts, resulting in significant cost savings for industrial operators.Another highlight of the XYZ screw pump is its exceptional energy efficiency. Equipped with advanced power-saving features, it consumes considerably less energy compared to traditional pumps, thereby helping companies reduce their carbon footprint and contribute to sustainable practices.In terms of ease of use, the XYZ screw pump stands out among its counterparts. Its user-friendly interface, combined with intuitive controls, makes installation and operation a breeze. Additionally, the pump's compact size allows for flexible placement, even in areas with limited space.XYZ takes immense pride in the rigorous testing and quality control measures applied during the screw pump's production. Every unit undergoes thorough inspections, ensuring that customers receive a reliable and durable product that meets the highest standards."We are thrilled to introduce this groundbreaking screw pump to the market," said [Spokesperson's Name], a representative from XYZ. "With its innovative features and exceptional performance, we are confident that our customers will experience newfound efficiency and productivity while significantly reducing operational costs."This new screw pump by XYZ has already garnered attention from various industries. Initial feedback from beta users has been overwhelmingly positive, with many noting the pump's reliability, seamless operation, and impressive cost savings.As companies worldwide strive to optimize their operations and enhance productivity, innovations like the XYZ screw pump are poised to revolutionize the fluid handling industry. By streamlining processes, minimizing environmental impact, and lowering maintenance costs, XYZ is paving the way for a new era of efficient industrial fluid management.About XYZ:XYZ is a renowned industry leader specializing in the development and manufacture of cutting-edge fluid handling solutions. With a team of highly skilled engineers and a commitment to innovation, XYZ has consistently delivered reliable and high-performance products. The company's dedication to quality and customer satisfaction has positioned it as a trusted partner for businesses in various sectors.Please note that the brand name "Settima" has been removed from the content as requested.

Top-quality Oil & Gas Pumps: Your Guide to Efficient Industry Solutions

Oil and Gas Pumps Revolutionize the Energy IndustryIn today's rapidly evolving technological landscape, the demand for efficient and reliable equipment in the oil and gas industry is higher than ever. To meet these increasing demands, Oil and Gas Pumps (name removed) has emerged as a leading provider of cutting-edge pumping solutions. With their acclaimed company history of innovation and commitment to customer satisfaction, Oil and Gas Pumps has revolutionized the energy industry.With a diverse range of offerings, Oil and Gas Pumps provides pumping solutions that cater to various applications within the oil and gas sector. Their pumps play a crucial role in exploration, production, refining, and distribution processes, ensuring a smooth and continuous flow of oil and gas.One of the key factors that sets Oil and Gas Pumps apart from its competitors is its relentless pursuit of innovation. The company invests heavily in research and development, constantly striving to develop pumps that are more efficient, durable, and environmentally friendly. By pushing the boundaries of engineering, Oil and Gas Pumps has been able to enhance productivity while reducing the carbon footprint of its operations.Furthermore, Oil and Gas Pumps' commitment to customer satisfaction is second to none. The company takes immense pride in its ability to provide tailored solutions that meet the specific needs of its clients. By working closely with customers, Oil and Gas Pumps ensures that its pumps are perfectly suited to the varied challenges faced in the oil and gas industry, whether it be offshore drilling in extreme environments or onshore refining in remote locations.Oil and Gas Pumps owes its success, in large part, to its team of highly skilled professionals. With expertise in mechanical engineering, fluid dynamics, and industrial design, the company's engineers are at the forefront of technological advancements in pumping solutions. Through continuous training and development programs, Oil and Gas Pumps ensures that its workforce remains knowledgeable and equipped to handle even the most complex projects.Moreover, the company's dedication to quality control is unfaltering. Each pump undergoes rigorous testing and inspection to ensure it meets the highest industry standards. This commitment to quality has earned Oil and Gas Pumps a stellar reputation for reliability and durability, resulting in long-lasting relationships with customers worldwide.In addition to its technological prowess and commitment to excellence, Oil and Gas Pumps is also deeply aware of the need to minimize its environmental impact. The company strives to create sustainable solutions and reduce energy consumption in its pumps. By implementing energy-efficient designs and utilizing eco-friendly materials, Oil and Gas Pumps aims to contribute to the global effort of transitioning to a greener and more sustainable future.Through its continued investment in research and development, its customer-centric approach, and its unwavering commitment to innovation and quality, Oil and Gas Pumps has established itself as a trusted leader in the pumping solutions industry. With each new product, the company continues to drive advancements in the oil and gas sector, facilitating greater efficiency, productivity, and sustainability.As the global demand for oil and gas continues to rise, it is companies like Oil and Gas Pumps that will play a vital role in meeting these ever-increasing demands. With their state-of-the-art pumping solutions, the company is helping to shape the future of the energy industry, ensuring a smooth and reliable supply of oil and gas for years to come.

Screw Pump vs Gear Pump: Understanding the Key Differences

Title: Understanding the Differences Between Screw Pumps and Gear Pumps: A Closer Look at Pumping TechnologiesIntroduction:In the world of fluid transfer and pumping technologies, two commonly used pump types are screw pumps and gear pumps. Both these pumps play a crucial role in various industries, including oil and gas, chemical, food processing, and many others. However, understanding the differences between screw pumps and gear pumps is vital in order to determine the most suitable option for specific applications. This article aims to shed light on these differences, highlighting the unique features and advantages of each pumping technology.Screw Pumps:Screw pumps, also known as progressive cavity pumps, operate based on the principle of displacement. They consist of two main components – a helical rotor and a stator. The rotor, often in the shape of a screw, rotates within the stator, resulting in the transfer of fluids from the suction side to the discharge side.Screw pumps are recognized for their ability to handle highly viscous fluids, including heavy oils, sludge, and slurries. Their design features enable them to generate a smooth, non-pulsating flow, making them suitable for applications requiring precise control over fluid transfer. Furthermore, screw pumps exhibit low shear rates, making them ideal for handling shear-sensitive materials without damaging their integrity.One key advantage of screw pumps is their self-priming capability. They can effectively handle fluids with entrained air or gas, eliminating the need for additional priming mechanisms. Screw pumps also showcase excellent suction lift capability, enabling efficient pumping even when the fluid source is located below the pump.Gear Pumps:Gear pumps, on the other hand, utilize rotating gears to transfer fluids. They consist of two meshing gears – a drive gear and a driven gear. As the gears rotate, liquid is drawn into the pump and pushed through the outlet. Gear pumps are widely used in various industries due to their simplicity, compact size, and high efficiency.Gear pumps excel in applications requiring high flow rates and moderate pressures. Their smooth operation allows for noiseless performance, making them suitable for applications where noise reduction is essential. Additionally, gear pumps can handle clean fluids, as well as fluids containing small particulate matter without clogging or damage to the gears.One of the key advantages of gear pumps is their ability to provide consistent flow, even under varying pressures. This makes them ideal for applications where stable pressure levels are critical. Another noteworthy feature is their ability to operate efficiently over a wide range of viscosities, allowing flexibility in fluid transfer applications.Conclusion:In conclusion, understanding the differences between screw pumps and gear pumps is pivotal in selecting the appropriate pumping technology for specific industrial applications. Screw pumps are best suited for handling highly viscous fluids and shear-sensitive materials, offering self-priming capability and low shear rates. On the other hand, gear pumps excel in high flow rate applications, offering consistent flow even under varying pressures and versatility across a wide range of viscosities.As industries continue to advance, the demand for efficient fluid transfer technologies will persist. Both screw pumps and gear pumps provide reliable solutions, each with their unique set of advantages. It is crucial for industries to evaluate their specific requirements and consult with experts to make informed decisions regarding the selection of the most suitable pumping technology for enhanced productivity and operational success.

Discover the Benefits of Revolutionary Screw Pump Stator Technology

Screw Pump Stator: Solidifying the Future of ProgressionScrew pump stator, as an essential component of a screw pump, is steadily becoming the missing link in pumping efficiency for various industries. With its precise engineering, redefined components, and high-level performance, screw pump stators have proven to be a valuable addition to the machinery industry.One company that has stood out in the development and manufacturing of screw pump stators is [Company Name Withheld for Confidentiality]. The company has established itself as a dominant player among its competitors, consistently manufacturing world-class and high-grade screw pump stators.[Company Name Withheld for Confidentiality] prides itself on producing the most durable and reliable stators with the use of the latest available technology, efficient manufacturing processes, and a focus on customer satisfaction. They ensure that their stators are manufactured from high-quality materials, which are carefully selected based on their toughness, wear resistance, and consistency.The company’s screw pump stators are designed to adapt to different mediums that are being pumped, such as oil, water, and sludge. They are built to deliver peak performance while maintaining the highest possible standards of quality, efficiency, and reliability.One of the unique features of [Company Name Withheld for Confidentiality] screw pump stators is that they are designed with a rotating metal body that compresses the pumped medium through a stationary rubber surface when it rotates. This ensures that the medium is not subjected to any shearing force, allowing it to maintain its properties while being pumped.Moreover, the stators manufactured by [Company Name Withheld for Confidentiality] come in different shapes and sizes to fit various industrial needs. Regardless of the size and shape, the consistent high quality and performance remain essential features of every stator produced, cementing the company’s reputation as a leading manufacturer in the industry.Screw pump stators have become an essential tool to various industries, including the oil and gas industry, food processing, waste management, and many others. With [Company Name Withheld for Confidentiality] precision and commitment to manufacturing the best stators, industries can expect more efficient and durable pumping processes, increasing productivity, and decreasing costs.The company’s exceptional customer service and commitment to delivering on its promises have earned them a reputation within the industry as a trusted partner. Their experts work hand-in-hand with clients from design to installation, providing guidance and support to ensure customer satisfaction.In conclusion, the screw pump stator has become increasingly important for various industries. With its unique design and exceptional functionality, [Company Name Withheld for Confidentiality] has led the way in manufacturing screw pump stators that meet and exceed industry standards. The significant contributions they have made in this industry have undoubtedly contributed to more efficient, productive, and cost-effective processes. For anyone who requires high-quality screw pump stators, [Company Name Withheld for Confidentiality] should be their first point of call.

Boost Your Efficiency with the Power of Multiphase Pumps

Multiphase Pump Technology Revolutionizes the Oil and Gas IndustryThe oil and gas industry is one of the most important sectors in the world today. It provides the energy and resources needed for transportation, heating, and electricity generation. However, the extraction of oil and gas from the earth is not always an easy task. It requires specialized equipment and techniques to effectively extract and transport the valuable resources. Multiphase pump technology has emerged as one of the most promising and game-changing technologies in the industry.The development of Multiphase Pumps has been revolutionary for the Oil and Gas industry. These pumps have the capability to handle a mixture of oil, gas, and water in a single flow pipeline. They have the potential to dramatically reduce costs and improve efficiency in oil and gas production by eliminating the need for expensive and complex infrastructure, such as separation facilities and pipelines. Multiphase pumps also have a small environmental footprint and are ideal for offshore production.One of the key players in the Multiphase Pump industry is a company that has been at the forefront of developing this technology. This company, founded in 1990 in Norway, is dedicated to creating innovative solutions for the oil and gas industry. It has established itself as a global leader in Multiphase Pump technology with over 2800 pump installations worldwide.The company’s flagship product is a multiphase pump that can handle up to 100% gas, 100% oil, or any combination in-between. The pump is extremely efficient and can operate in harsh environments, such as the North Sea, where conventional pumps cannot operate. Its unique design allows for efficient transport of oil and gas from wells in remote locations, minimizing the use of expensive infrastructure.Multiphase pump technology has numerous advantages over traditional methods. It can significantly reduce the cost of infrastructure, reduce downtime, and improve the overall efficiency of production. In addition, multiphase pumps can be used in a variety of applications, including oil production, gas production, and transportation. They can also be used in the development of unconventional resources such as shale gas and oil sands.The company’s multiphase pumps have been successfully used in a variety of projects worldwide. These include offshore platforms in the North Sea, deepwater subsea installations in the Gulf of Mexico, and onshore operations in the Middle East. The pumps have helped clients achieve cost savings of up to 50% and have significantly reduced emissions and carbon footprints.In addition to its successful pump installations, the company offers a range of services to support its clients. These services include custom design and engineering, installation and commissioning, training, maintenance, and upgrades. The company’s expert engineers and technicians provide comprehensive support to ensure that clients’ pumps perform at their best.The company’s dedication to innovation and customer satisfaction has earned it recognition from customers and the industry. It has won multiple awards for its innovative products and services. In 2020, the company received the Norwegian Export Award for its successful export of multiphase pumps to international markets.Multiphase pump technology has the potential to revolutionize the oil and gas industry by improving efficiency, reducing costs, and minimizing environmental impact. The company’s innovative approach to pump technology and excellent customer service has made it a leader in the industry. Its pumps and services have helped clients all over the world to extract oil and gas more efficiently and effectively. As the demand for cleaner energy sources increases, multiphase pump technology will play an even more important role in the energy transition. The company’s dedication to innovation and customer satisfaction will continue to drive its success and position it at the forefront of the industry.

Lubricating Oil Pumps: Power Your Machinery with Reliable Performance

Lubricating Oil Pumps Revolutionize the Industrial SectorIn an era of rapid technological advancements, industries across the globe are constantly searching for innovative solutions to enhance their operational efficiency. One such revolutionary development in the field of industrial machinery is the introduction of high-performance lubricating oil pumps. These pumps, designed to remove friction and reduce wear and tear in various industrial applications, have quickly garnered attention for their unparalleled functionality and contribution to the optimization of the manufacturing process.The leading provider in this cutting-edge technology, Company X, has garnered significant recognition for their advanced lubricating oil pumps. Founded in 1980, Company X has consistently focused on the development and production of lubricating systems that deliver outstanding performance, reliability, and cost efficiency.Company X’s lubricating oil pumps are hailed as game-changers as they address critical issues faced by industries globally. One of the main challenges encountered in industrial operations is machinery breakdown, often caused by excessive friction and inadequate lubrication. These issues lead to increased maintenance costs and downtime, greatly hampering productivity. However, with the advent of Company X’s high-performance lubricating oil pumps, industries are witnessing increased reliability, reduced downtime, and significant cost savings.Company X has dedicated substantial efforts towards research and development, allowing them to create an extensive range of lubricating oil pumps that cater to diverse industrial requirements. These pumps are specifically engineered to ensure a constant supply of oil, maintaining optimum lubrication levels even under severe working conditions. By utilizing innovative technology, the pumps achieve efficient oil distribution, resulting in reduced wear and tear, increased operational reliability, and extended machinery lifespan.Furthermore, Company X’s lubricating oil pumps are designed with versatility in mind. Irrespective of the industry or application, these pumps can be seamlessly integrated into various systems, including hydraulic machines, turbines, compressors, and injection molding machines, among others. The pumps’ compatibility with different equipment types showcases their adaptability and underscores their value across a spectrum of industrial sectors.One of the standout features of Company X’s lubricating oil pumps is their advanced control systems. These systems ensure precise lubricant distribution, eliminating the risk of over-lubrication or insufficient lubrication. With integrated sensors and monitoring capabilities, the pumps can measure and regulate oil flow in real-time, guaranteeing optimal lubrication at all times. Such advanced control mechanisms have proven to be groundbreaking, as they prevent unnecessary wear and tear, minimize energy consumption, and reduce oil wastage.As the leading player in the lubricating oil pump industry, Company X places great emphasis on environmental sustainability. The incorporation of eco-friendly materials, such as recyclable components and energy-efficient motors, reflects the company’s commitment to reducing its ecological footprint. By investing in Company X’s lubricating oil pumps, industries can not only enhance their productivity and profitability, but also contribute to environmental conservation.The widespread adoption of these lubricating oil pumps is a testament to their impact on the industrial sector. Companies across a range of industries, including manufacturing, automotive, aerospace, and energy, have experienced transformative results by integrating these pumps into their operations. Reduced maintenance costs, increased machinery lifespan, enhanced productivity, and improved environmental sustainability are just a few of the benefits that have positioned Company X’s lubricating oil pumps as the preferred choice for industrial lubrication needs.In conclusion, Company X’s lubricating oil pumps have revolutionized the industrial sector. Their unmatched functionality, versatility, and advanced control systems have positioned them at the forefront of lubrication technology. With these pumps, companies enjoy enhanced operational efficiency, reduced maintenance costs, and increased profitability. The revolutionary impact of Company X’s lubricating oil pumps has solidified their role as catalysts for progress, ushering in a new era of optimized industrial machinery.

Efficient Lube Oil System for Smooth Pump Operations

Title: Cutting-Edge and Reliable Lube Oil System for Pumps Revolutionizes the IndustryIntroduction (100 words):The rapidly growing industrial sector demands high-performance machinery that can operate optimally while minimizing downtime. To cater to this need, an innovative and pioneering engineering company has developed a state-of-the-art Lube Oil System for Pumps. This revolutionary system is designed to enhance the efficiency, reliability, and longevity of pumps in various industries, facilitating increased productivity and reduced maintenance costs. Capitalizing on advanced technology and unparalleled expertise, the pioneering company continues to redefine the standards of pump lubrication systems, catering to diverse industry needs worldwide.1. Superior Technology and Unmatched Performance (150 words):The Lube Oil System for Pumps represents a paradigm shift in the field of pump lubrication. Leveraging cutting-edge technology, this system ensures smoother pump operations, extending equipment life considerably. By addressing common issues such as overheating, leaks, and inefficient lubrication, the system enhances overall pump performance and reduces the risk of catastrophic failure.By utilizing precision-engineered components, the Lube Oil System guarantees an efficient and consistent lubrication process, providing optimal operational parameters. This results in reduced friction, improved energy efficiency, and increased service intervals, saving businesses significant costs on maintenance, repair, and replacement.Furthermore, the system's advanced filtration system removes impurities and contaminants, preventing abrasive particles from causing damage and ensuring prolonged pump lifespan. With its user-friendly design and intuitive interface, the system is easily integrated into existing infrastructure, catering to a wide range of pump sizes and types.2. Protection against Contamination and Corrosion (150 words):The Lube Oil System for Pumps places utmost emphasis on safeguarding the pumps against contamination and corrosion, which are major contributors to equipment malfunctions. By employing cutting-edge technologies such as corrosion inhibitors, the system effectively combats the damaging effects of corrosive substances, including water content typically found in lubricants.Furthermore, strategically positioned sensors and monitoring devices ensure early detection of potential pump malfunctions. These intelligent sensors continuously monitor vital parameters such as temperature, pressure, and flow rates, instantly alerting operators in case of any irregularities. Such proactive measures not only minimize unplanned shutdowns but also enable predictive maintenance, preventing costly equipment failures and optimizing operational efficiency.3. Customizable Solutions for Specific Industry Needs (150 words):Recognizing the diversity of industrial requirements, the Lube Oil System for Pumps offers a range of customizable solutions tailored to specific industry needs. Whether it is heavy-duty pumps utilized in the oil and gas industry, high-pressure pumps in the manufacturing sector, or industrial water pumps, the system ensures optimal lubrication and protection for pumps operating under extreme conditions.Moreover, this versatile system can be seamlessly integrated into both new installations and existing setups, offering a cost-effective solution for businesses across various sectors. The company's technical experts work closely with clients to understand their unique requirements, providing personalized solutions that align with their operational guidelines, regulatory requirements, and sustainability goals.4. Sustainability and Environmental Responsibility (150 words):The Lube Oil System for Pumps incorporates sustainable practices and responsible environmental management into its design. The system optimizes lubricant consumption, reducing waste and minimizing the carbon footprint associated with replacing lubricants frequently.Additionally, the advanced filtration system efficiently removes impurities and contaminants, reducing the ecological impact and promoting cleaner, greener operations. By extending the lifespan of pumps, the system also helps reduce waste generated from premature pump replacements.Furthermore, the system's energy-efficient design enhances overall plant efficiency, contributing to reduced energy consumption and promoting sustainable manufacturing practices.Conclusion (100 words):The groundbreaking Lube Oil System for Pumps ushers in a new era of reliability, performance, and sustainability in the pump lubrication domain. Its cutting-edge technology and customizable solutions cater to the diverse needs of industries worldwide, minimizing operational risks, optimizing production, and reducing maintenance costs. The company's unwavering commitment to delivering superior products and services continues to revolutionize the industry, ensuring a seamless integration of their systems into all types of pump installations. With an unblemished track record and a customer-centric approach, the company stands at the forefront of the pump lubrication sector, providing innovative solutions that set new benchmarks for excellence.