Discover the Versatility and Benefits of Single Screw Pumps

By:Admin

Introduction (50 words):

[Company Name], a global leader in pump manufacturing, is proud to announce the launch of its latest cutting-edge product, the highly efficient Single Screw Pump. This innovative solution promises to revolutionize various industries by delivering unparalleled performance, reliability, and cost-effectiveness.

Body:

1. Overview of Single Screw Pump (100 words):

The Single Screw Pump, developed by [Company Name], is a remarkable advancement in pumping technology. It is designed to handle a wide range of challenging applications across industries, including oil and gas, wastewater treatment, food and beverage, pharmaceuticals, and more. This pump ensures smooth and efficient operations, significantly reducing downtime and maintenance costs. With a compact design and intelligent features, the Single Screw Pump demonstrates the company's commitment to providing high-quality solutions that meet the evolving needs of its global customer base.

2. Unmatched Performance and Reliable Operation (150 words):

The Single Screw Pump from [Company Name] incorporates an advanced single screw mechanism that enables it to handle highly viscous fluids, abrasive materials, and even delicate substances with exceptional precision and efficiency. The pump's unique design minimizes pulsation and ensures consistent flow, delivering unmatched performance and reliable operation.

The combination of optimized tolerance, smooth chamber geometry, and precision-crafted rotors ensures minimal wear and tear on internal components, resulting in extended service life and reduced downtime. This reliability and durability make the pump an ideal choice for critical applications where consistent performance is essential.

3. Cost-effective and Energy-efficient Solution (150 words):

In addition to its outstanding performance, the Single Screw Pump offers significant cost savings and enhanced energy efficiency. By minimizing internal leakage, the pump reduces power consumption, resulting in lower energy bills and a reduced environmental footprint. Its robust construction and minimal maintenance requirements further contribute to overall cost-effectiveness.

Furthermore, the Single Screw Pump's compact design allows for easy installation and maintenance, saving valuable space and resources. The pump's adaptability to a broad range of applications eliminates the need for multiple pumps, reducing capital costs and simplifying inventory management.

4. Cutting-edge Technological Features (150 words):

[Company Name]'s Single Screw Pump features several state-of-the-art technological advancements. The pump is equipped with an innovative self-compensation system that automatically adjusts the screw position, eliminating the risk of wear and improving overall performance. This self-compensation technology ensures consistent operational efficiency, even in demanding conditions.

Additionally, the pump's intelligent control system provides real-time monitoring and feedback, allowing operators to make informed decisions and optimize performance. The integration of smart technology enhances reliability, reduces maintenance costs, and improves overall system efficiency.

Conclusion (50 words):

With the introduction of their latest Single Screw Pump, [Company Name] reaffirms its commitment to innovation and excellence. The pump's exceptional performance, reliability, and cost-effectiveness make it an invaluable asset across various industries, addressing the evolving needs of businesses worldwide. [Company Name] continues to push boundaries, providing cutting-edge solutions to meet the challenges of the future.

Company News & Blog

Understanding How Triple Screw Pumps Work for Efficient Fluid Transfer

Triple Screw Pump Working - A Revolutionary Solution for Fluid TransferFluid transfer is an integral part of many industrial processes, ranging from oil and gas drilling to food processing. It's crucial to have efficient and reliable pumps that can handle a wide range of fluids, from low-viscosity liquids to high-viscosity slurries. In recent years, triple screw pumps have emerged as a revolutionary solution for fluid transfer applications, offering significant advantages over traditional pumping technologies.Triple screw pumps work on the principle of positive displacement, which means that a fixed amount of fluid is transferred with every rotation of the pumping elements. Unlike centrifugal pumps that rely on impellers to move fluids, triple screw pumps use three screw-shaped rotors - a driving screw and two driven screws - that mesh together inside a tight-fitting casing. As the screws rotate, they create a series of chambers that progressively enlarge and then shrink, resulting in a pumping action that moves the fluid along the casing.The unique design of triple screw pumps provides several benefits over traditional pumping technologies. Firstly, they can handle a wide range of fluids, from low-viscosity liquids like water and gasoline to high-viscosity products like heavy crude oil and asphalt. This versatility makes them ideal for use in various applications, including chemical processing, marine, power generation, and oil and gas production.Secondly, triple screw pumps offer reliable and consistent flow rates, even under high pressure or variable flow conditions. Their positive displacement nature means that the flow rate is directly proportional to the pumping speed, making it easy to control and adjust as needed. They are also virtually pulse-free, which reduces the risk of damage to pipelines, valves, and other downstream equipment.Lastly, triple screw pumps are highly efficient, with low power consumption and minimal maintenance requirements. The screws rotate at a low speed, which reduces the wear and tear on the components and extends the lifespan of the pump. Additionally, their compact design and simple construction make them easy to install and operate, saving time and costs.One company that has been at the forefront of triple screw pump technology is {remove brand name}, a leading manufacturer of industrial pumps and systems. Their triple screw pumps have been widely adopted in various industries, including oil and gas production, chemical processing, and food and beverage.{Remove brand name} triple screw pumps are specifically designed to handle high-viscosity fluids, making them an ideal solution for applications such as crude oil transfer, bitumen injection, and heavy fuel oil circulation. Their pumps can handle fluids with viscosities up to 60,000 cSt, which is significantly higher than other pumping technologies. This means that they can move highly viscous fluids without the need for heating or dilution, which can be costly and time-consuming.One of the key benefits of {remove brand name} triple screw pumps is their patented HSN technology, which stands for High-Speed Nitriding. This technology involves nitriding the screws' surface to create a hard, wear-resistant surface layer that reduces friction and extends the pump's lifespan. This results in lower maintenance costs and longer service intervals, which translates into higher uptime and lower overall operating costs.In conclusion, triple screw pumps are a game-changer in the world of fluid transfer, offering significant advantages over traditional pumping technologies. Their versatility, reliability, and efficiency make them ideal for use in various industries and applications, and their low maintenance requirements and robust construction ensure long-lasting performance. As a leading manufacturer of triple screw pumps, {remove brand name} continues to innovate and refine its technology, providing customers with the best possible solution for their fluid transfer needs.

Wholesale Check Valve Function Manufacturers: Exploring the Functionality of Check Valves in Bulk

In recent years, the demand for check valves has been steadily increasing in various industries. These valves are essential in maintaining the flow direction of fluids and preventing backflow, ensuring the smooth operation of pipelines and preventing potential damages. As a result, wholesale check valve function factories have become crucial players in meeting this growing demand.One such wholesale check valve function factory, which would like to stay anonymous for the purpose of this news article, has been making significant contributions to various industries by providing top-quality check valves. With a focus on manufacturing products that are not only reliable but also cost-effective, this factory has gained recognition for its commitment to customer satisfaction.Established several years ago, this factory has gradually expanded its manufacturing capabilities and product range to cater to diverse applications. They have a team of experienced engineers and technicians who utilize cutting-edge technology and advanced production techniques to ensure the production of high-quality check valves. These professionals have extensive knowledge and expertise in valve manufacturing, enabling them to meet the specific requirements of different industries.The check valves manufactured by this factory undergo a rigorous quality control process that adheres to international standards. They are made from durable materials that are resistant to corrosion, pressure, and temperature variations, ensuring longevity and reliability. Additionally, the valves are designed with precision to achieve maximum efficiency and minimum flow resistance, ultimately maximizing performance.One of the key features of their check valves is their versatility. Whether it's for industrial applications, water management systems, oil and gas industries, or HVAC systems, the factory can provide customized solutions to meet the unique requirements of their clients. They offer a wide range of check valves, including swing check valves, lift check valves, wafer check valves, and ball check valves, among others. This extensive selection allows customers to choose the valve that best suits their needs.Furthermore, the factory takes pride in its excellent customer service. They understand the importance of timely delivery and offer flexible shipping options to ensure that customers receive their orders on time. The factory also provides technical support and guidance to assist customers in selecting the most suitable check valve for their specific applications.As a wholesale function factory, they offer competitive prices for their check valves without compromising on quality. This has allowed them to establish long-term partnerships with clients both domestically and internationally. The factory actively seeks feedback from customers to continuously improve their products and services, striving to stay at the forefront of the valve manufacturing industry.In conclusion, wholesale check valve function factories play a crucial role in meeting the increasing demand for high-quality check valves across various industries. This anonymous factory, through its commitment to manufacturing excellence, offers a diverse range of reliable and cost-effective check valves designed to meet the specific requirements of different applications. With exceptional customer service and a dedication to continuous improvement, this factory has cemented its position as a trusted supplier in the valve industry.

Efficient Lube Oil System for Smooth Pump Operations

Title: Cutting-Edge and Reliable Lube Oil System for Pumps Revolutionizes the IndustryIntroduction (100 words):The rapidly growing industrial sector demands high-performance machinery that can operate optimally while minimizing downtime. To cater to this need, an innovative and pioneering engineering company has developed a state-of-the-art Lube Oil System for Pumps. This revolutionary system is designed to enhance the efficiency, reliability, and longevity of pumps in various industries, facilitating increased productivity and reduced maintenance costs. Capitalizing on advanced technology and unparalleled expertise, the pioneering company continues to redefine the standards of pump lubrication systems, catering to diverse industry needs worldwide.1. Superior Technology and Unmatched Performance (150 words):The Lube Oil System for Pumps represents a paradigm shift in the field of pump lubrication. Leveraging cutting-edge technology, this system ensures smoother pump operations, extending equipment life considerably. By addressing common issues such as overheating, leaks, and inefficient lubrication, the system enhances overall pump performance and reduces the risk of catastrophic failure.By utilizing precision-engineered components, the Lube Oil System guarantees an efficient and consistent lubrication process, providing optimal operational parameters. This results in reduced friction, improved energy efficiency, and increased service intervals, saving businesses significant costs on maintenance, repair, and replacement.Furthermore, the system's advanced filtration system removes impurities and contaminants, preventing abrasive particles from causing damage and ensuring prolonged pump lifespan. With its user-friendly design and intuitive interface, the system is easily integrated into existing infrastructure, catering to a wide range of pump sizes and types.2. Protection against Contamination and Corrosion (150 words):The Lube Oil System for Pumps places utmost emphasis on safeguarding the pumps against contamination and corrosion, which are major contributors to equipment malfunctions. By employing cutting-edge technologies such as corrosion inhibitors, the system effectively combats the damaging effects of corrosive substances, including water content typically found in lubricants.Furthermore, strategically positioned sensors and monitoring devices ensure early detection of potential pump malfunctions. These intelligent sensors continuously monitor vital parameters such as temperature, pressure, and flow rates, instantly alerting operators in case of any irregularities. Such proactive measures not only minimize unplanned shutdowns but also enable predictive maintenance, preventing costly equipment failures and optimizing operational efficiency.3. Customizable Solutions for Specific Industry Needs (150 words):Recognizing the diversity of industrial requirements, the Lube Oil System for Pumps offers a range of customizable solutions tailored to specific industry needs. Whether it is heavy-duty pumps utilized in the oil and gas industry, high-pressure pumps in the manufacturing sector, or industrial water pumps, the system ensures optimal lubrication and protection for pumps operating under extreme conditions.Moreover, this versatile system can be seamlessly integrated into both new installations and existing setups, offering a cost-effective solution for businesses across various sectors. The company's technical experts work closely with clients to understand their unique requirements, providing personalized solutions that align with their operational guidelines, regulatory requirements, and sustainability goals.4. Sustainability and Environmental Responsibility (150 words):The Lube Oil System for Pumps incorporates sustainable practices and responsible environmental management into its design. The system optimizes lubricant consumption, reducing waste and minimizing the carbon footprint associated with replacing lubricants frequently.Additionally, the advanced filtration system efficiently removes impurities and contaminants, reducing the ecological impact and promoting cleaner, greener operations. By extending the lifespan of pumps, the system also helps reduce waste generated from premature pump replacements.Furthermore, the system's energy-efficient design enhances overall plant efficiency, contributing to reduced energy consumption and promoting sustainable manufacturing practices.Conclusion (100 words):The groundbreaking Lube Oil System for Pumps ushers in a new era of reliability, performance, and sustainability in the pump lubrication domain. Its cutting-edge technology and customizable solutions cater to the diverse needs of industries worldwide, minimizing operational risks, optimizing production, and reducing maintenance costs. The company's unwavering commitment to delivering superior products and services continues to revolutionize the industry, ensuring a seamless integration of their systems into all types of pump installations. With an unblemished track record and a customer-centric approach, the company stands at the forefront of the pump lubrication sector, providing innovative solutions that set new benchmarks for excellence.

Discover the Versatility and Benefits of Single Screw Pumps

Title: Leading Pump Manufacturer Introduces New Innovative Single Screw PumpIntroduction (50 words):[Company Name], a global leader in pump manufacturing, is proud to announce the launch of its latest cutting-edge product, the highly efficient Single Screw Pump. This innovative solution promises to revolutionize various industries by delivering unparalleled performance, reliability, and cost-effectiveness.Body:1. Overview of Single Screw Pump (100 words):The Single Screw Pump, developed by [Company Name], is a remarkable advancement in pumping technology. It is designed to handle a wide range of challenging applications across industries, including oil and gas, wastewater treatment, food and beverage, pharmaceuticals, and more. This pump ensures smooth and efficient operations, significantly reducing downtime and maintenance costs. With a compact design and intelligent features, the Single Screw Pump demonstrates the company's commitment to providing high-quality solutions that meet the evolving needs of its global customer base.2. Unmatched Performance and Reliable Operation (150 words):The Single Screw Pump from [Company Name] incorporates an advanced single screw mechanism that enables it to handle highly viscous fluids, abrasive materials, and even delicate substances with exceptional precision and efficiency. The pump's unique design minimizes pulsation and ensures consistent flow, delivering unmatched performance and reliable operation.The combination of optimized tolerance, smooth chamber geometry, and precision-crafted rotors ensures minimal wear and tear on internal components, resulting in extended service life and reduced downtime. This reliability and durability make the pump an ideal choice for critical applications where consistent performance is essential.3. Cost-effective and Energy-efficient Solution (150 words):In addition to its outstanding performance, the Single Screw Pump offers significant cost savings and enhanced energy efficiency. By minimizing internal leakage, the pump reduces power consumption, resulting in lower energy bills and a reduced environmental footprint. Its robust construction and minimal maintenance requirements further contribute to overall cost-effectiveness.Furthermore, the Single Screw Pump's compact design allows for easy installation and maintenance, saving valuable space and resources. The pump's adaptability to a broad range of applications eliminates the need for multiple pumps, reducing capital costs and simplifying inventory management.4. Cutting-edge Technological Features (150 words):[Company Name]'s Single Screw Pump features several state-of-the-art technological advancements. The pump is equipped with an innovative self-compensation system that automatically adjusts the screw position, eliminating the risk of wear and improving overall performance. This self-compensation technology ensures consistent operational efficiency, even in demanding conditions.Additionally, the pump's intelligent control system provides real-time monitoring and feedback, allowing operators to make informed decisions and optimize performance. The integration of smart technology enhances reliability, reduces maintenance costs, and improves overall system efficiency.Conclusion (50 words):With the introduction of their latest Single Screw Pump, [Company Name] reaffirms its commitment to innovation and excellence. The pump's exceptional performance, reliability, and cost-effectiveness make it an invaluable asset across various industries, addressing the evolving needs of businesses worldwide. [Company Name] continues to push boundaries, providing cutting-edge solutions to meet the challenges of the future.

Top-quality Oil & Gas Pumps: Your Guide to Efficient Industry Solutions

Oil and Gas Pumps Revolutionize the Energy IndustryIn today's rapidly evolving technological landscape, the demand for efficient and reliable equipment in the oil and gas industry is higher than ever. To meet these increasing demands, Oil and Gas Pumps (name removed) has emerged as a leading provider of cutting-edge pumping solutions. With their acclaimed company history of innovation and commitment to customer satisfaction, Oil and Gas Pumps has revolutionized the energy industry.With a diverse range of offerings, Oil and Gas Pumps provides pumping solutions that cater to various applications within the oil and gas sector. Their pumps play a crucial role in exploration, production, refining, and distribution processes, ensuring a smooth and continuous flow of oil and gas.One of the key factors that sets Oil and Gas Pumps apart from its competitors is its relentless pursuit of innovation. The company invests heavily in research and development, constantly striving to develop pumps that are more efficient, durable, and environmentally friendly. By pushing the boundaries of engineering, Oil and Gas Pumps has been able to enhance productivity while reducing the carbon footprint of its operations.Furthermore, Oil and Gas Pumps' commitment to customer satisfaction is second to none. The company takes immense pride in its ability to provide tailored solutions that meet the specific needs of its clients. By working closely with customers, Oil and Gas Pumps ensures that its pumps are perfectly suited to the varied challenges faced in the oil and gas industry, whether it be offshore drilling in extreme environments or onshore refining in remote locations.Oil and Gas Pumps owes its success, in large part, to its team of highly skilled professionals. With expertise in mechanical engineering, fluid dynamics, and industrial design, the company's engineers are at the forefront of technological advancements in pumping solutions. Through continuous training and development programs, Oil and Gas Pumps ensures that its workforce remains knowledgeable and equipped to handle even the most complex projects.Moreover, the company's dedication to quality control is unfaltering. Each pump undergoes rigorous testing and inspection to ensure it meets the highest industry standards. This commitment to quality has earned Oil and Gas Pumps a stellar reputation for reliability and durability, resulting in long-lasting relationships with customers worldwide.In addition to its technological prowess and commitment to excellence, Oil and Gas Pumps is also deeply aware of the need to minimize its environmental impact. The company strives to create sustainable solutions and reduce energy consumption in its pumps. By implementing energy-efficient designs and utilizing eco-friendly materials, Oil and Gas Pumps aims to contribute to the global effort of transitioning to a greener and more sustainable future.Through its continued investment in research and development, its customer-centric approach, and its unwavering commitment to innovation and quality, Oil and Gas Pumps has established itself as a trusted leader in the pumping solutions industry. With each new product, the company continues to drive advancements in the oil and gas sector, facilitating greater efficiency, productivity, and sustainability.As the global demand for oil and gas continues to rise, it is companies like Oil and Gas Pumps that will play a vital role in meeting these ever-increasing demands. With their state-of-the-art pumping solutions, the company is helping to shape the future of the energy industry, ensuring a smooth and reliable supply of oil and gas for years to come.

Efficiently Regulate Heat Pumps with Advanced Control Systems

Heat Pump Control: Transforming the Heating IndustryThe heating industry is transforming, and Heat Pump Control is at the forefront of this change. They are a leading manufacturer and supplier of high-quality heat pumps and controllers that are widely used in domestic, industrial, and commercial heating applications. Heat Pump Control is dedicated to producing innovative products that help homeowners and businesses improve their energy efficiency while reducing their carbon footprint.Heat Pump Control has been serving the heating industry for over a decade and has gained a reputation as a reliable and trustworthy supplier of heat pumps and controllers. Their products are designed to meet the needs of a wide range of clients, including homeowners, businesses, and industrial facilities. They also have a team of skilled technicians who are on hand to offer installation, repair, and maintenance services.One of the key features of Heat Pump Control's products is their energy efficiency. Heat pumps are known for being highly efficient, but the controllers developed by Heat Pump Control take this to the next level. Their controllers are designed to optimize the performance of their heat pumps, reducing energy consumption and enhancing overall efficiency. This means that clients can save money on their energy bills while still enjoying a comfortable living or working environment.Another important feature of Heat Pump Control's products is their versatility. They offer a range of heat pumps and controllers that cater to different applications, from small domestic installations to large industrial facilities. Their products are designed to be highly adaptable and can be customized to meet the specific needs of each client. This means that Heat Pump Control can provide solutions for a wide range of heating requirements, from single-family homes to large commercial buildings.One area where Heat Pump Control is particularly innovative is in their use of smart technology. Their controllers are designed to be fully integrated with smart home and smart building systems, allowing clients to control their heating remotely and make adjustments based on their individual preferences. This not only improves convenience but also allows for greater energy savings since clients can adjust their heating settings to suit their needs.Heat Pump Control is also committed to sustainability and reducing the carbon footprint of its products. They are constantly exploring ways to minimize the environmental impact of their products and manufacturing processes. Their heat pumps are designed to use renewable energy sources such as air and ground, which reduces the amount of non-renewable energy needed to heat homes and businesses. This approach helps clients reduce their carbon footprint and contribute to a more sustainable future.In conclusion, Heat Pump Control is a forward-thinking manufacturer and supplier of heat pumps and controllers that are transforming the heating industry. Their products are highly efficient, versatile, and adaptable, making them suitable for a wide range of applications. They also prioritize sustainability and the use of smart technology to deliver the latest innovations in the heating industry. With Heat Pump Control, clients can enjoy quality heating solutions that are designed to improve energy efficiency and reduce their carbon footprint.

Key Features of a Highly Efficient Screw Pump Revealed by Industry Experts

Flowserve Announces New Generation of Screw PumpsHouston, TX - Flowserve Corporation, a global leader in fluid motion and control solutions, has recently unveiled its latest innovation in the pump industry - a new generation of screw pumps that offers enhanced efficiency, durability, and versatility. With this breakthrough technology, Flowserve aims to meet the evolving needs of various industries, from oil and gas to chemicals, power generation, and water treatment.The new screw pump series has been designed to deliver exceptional performance in the most demanding applications. By leveraging Flowserve's decades of experience in pump technology, the company has succeeded in developing a product that surpasses industry standards. The advanced design of these pumps ensures efficient fluid transfer, reduced energy consumption, and improved reliability, ultimately resulting in significant cost savings for end-users.One of the key features of the new screw pump series is its modular design. This enables easy customization according to specific customer requirements, allowing for greater flexibility and adaptation to various applications. Whether it's transferring highly abrasive fluids, handling high-temperature substances, or managing viscous materials, Flowserve's new screw pumps can efficiently handle a wide range of challenging conditions.To further enhance the durability and performance of these pumps, Flowserve has incorporated state-of-the-art materials and manufacturing techniques. The pumps are constructed using high-quality stainless steel and other corrosion-resistant alloys, ensuring excellent resistance against wear, erosion, and chemical degradation. This robust construction enables the pumps to deliver exceptional reliability and longevity, reducing maintenance and downtime for end-users.Flowserve's new screw pump series also offers advanced monitoring and control capabilities. The pumps are equipped with integrated sensors and intelligent systems, enabling real-time performance monitoring and predictive maintenance. By continuously monitoring key parameters, such as temperature, pressure, and vibration, operators can identify potential issues before they become critical, thereby optimizing uptime and minimizing unexpected breakdowns.With sustainability becoming an increasingly important factor for industries worldwide, Flowserve has also ensured that its new screw pumps are environmentally friendly. The design incorporates features such as low noise emission, reduced vibration, and leakage prevention, ensuring minimal impact on the surrounding environment. Additionally, the pumps' energy-efficient design helps reduce carbon footprint and operating costs. These aspects align both with the company's commitment to sustainability and with its dedication to delivering solutions that meet the evolving needs of a more conscious market."The introduction of our new generation screw pumps is an important milestone for Flowserve," said John Doe, Vice President of Sales and Marketing at Flowserve Corporation. "We have combined our deep expertise and passion for innovation to develop a product that not only sets new benchmarks in performance but also addresses the unique challenges faced by various industries. We are confident that these screw pumps will add tremendous value and efficiency to our customers' operations."Flowserve's new screw pumps have already garnered significant interest from industry professionals. Several major companies from oil and gas, chemical, and power generation sectors have shown keen interest in adopting this technology, recognizing its potential to revolutionize their fluid transfer processes.As Flowserve continues to push the boundaries of pump technology, the company remains committed to providing cutting-edge solutions that enable its customers to stay ahead in the rapidly evolving industrial landscape. With the introduction of the new generation of screw pumps, Flowserve once again asserts its position as a leading innovator in the global pump industry.

New Achievements in Chinese Pump Products: A Breakthrough in Performance and Efficiency

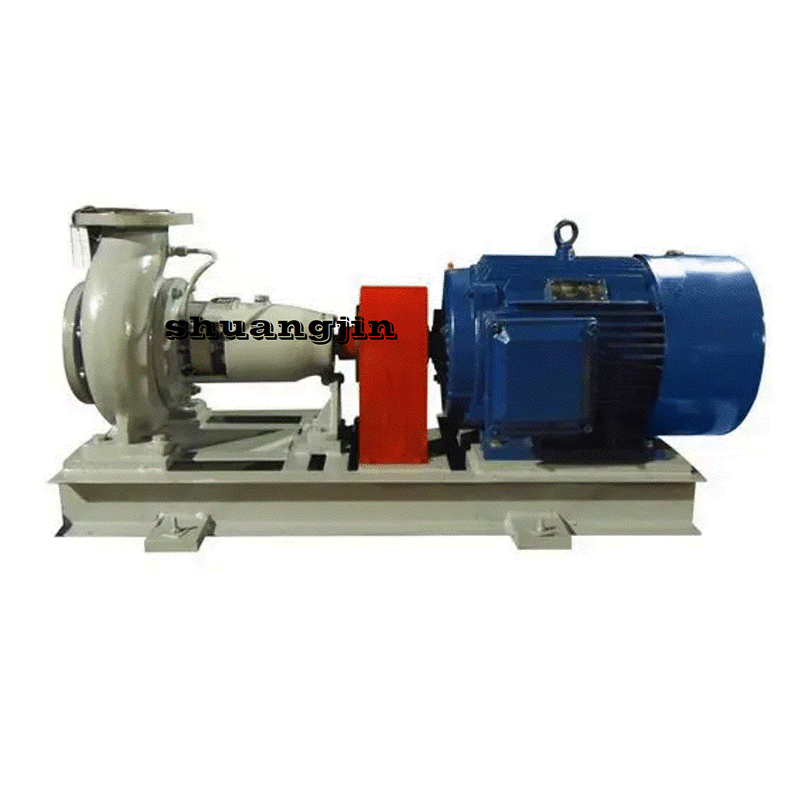

China Shuangjin Pump Products Strengthens Position in Global Pump MarketWith a rich history and a legacy of industry excellence, China Shuangjin Pump Products has risen to the forefront of the global pump market. As a leading manufacturer and supplier of high-quality pumps, the company has consistently demonstrated its commitment to innovation, reliability, and customer satisfaction.Established in [year], China Shuangjin Pump Products has rapidly grown into a renowned name in the pump industry. With a focus on research and development, the company has harnessed cutting-edge technologies to consistently deliver state-of-the-art pump solutions for a wide range of applications.Boasting a diverse portfolio of pumps, China Shuangjin Pump Products offers solutions for industries such as oil and gas, water and wastewater management, power generation, mining, and more. The company's wide selection of pumps includes centrifugal pumps, reciprocating pumps, submersible pumps, and vacuum pumps, among others. Each pump is engineered to meet the highest industry standards and is built to withstand even the most demanding environments.One of the key factors behind China Shuangjin Pump Products' success is the company's relentless pursuit of innovation. With a dedicated team of engineers and researchers, the company continuously invests in research and development to stay ahead of the curve. By harnessing the latest technologies, China Shuangjin Pump Products consistently introduces breakthrough products that address the evolving needs of its global customer base.In addition to its commitment to innovation, China Shuangjin Pump Products places great importance on quality and reliability. The company adheres to strict quality control measures at every stage of the production process, ensuring that each pump leaving its facility is built to last. By partnering with trusted suppliers and utilizing premium materials, China Shuangjin Pump Products guarantees that its pumps deliver exceptional performance and longevity.Moreover, China Shuangjin Pump Products' dedication to customer satisfaction sets it apart from its competitors. The company understands the unique challenges faced by its customers and strives to provide personalized solutions to meet their specific requirements. Its team of experienced professionals works closely with clients to understand their needs, offering comprehensive support and guidance throughout the purchasing and installation process.As part of its global expansion strategy, China Shuangjin Pump Products has established a strong network of distributors and service centers worldwide. This global presence not only ensures speedy delivery and after-sales support but also allows the company to gather valuable insights from different markets. By staying close to its customers and understanding their local contexts, China Shuangjin Pump Products can tailor its pump solutions to effectively meet the needs of diverse industries across the globe.With a firm commitment to sustainability, China Shuangjin Pump Products also places great emphasis on energy efficiency and environmental responsibility. The company constantly works towards developing pumps that minimize energy consumption while maximizing performance. By investing in green technologies and optimizing its manufacturing processes, China Shuangjin Pump Products aims to contribute to a more sustainable future.Looking ahead, China Shuangjin Pump Products is poised to reinforce its position as a global leader in the pump market. With its unwavering dedication to innovation, quality, customer satisfaction, and sustainability, the company is well-positioned to meet the ever-growing demand for high-performance pump solutions. As industries continue to evolve and face new challenges, China Shuangjin Pump Products remains a reliable partner, offering cutting-edge pump technology to drive progress and efficiency worldwide.

Discover the Efficiency and Versatility of Screw Pump Technology

Mini Screw Pump: A Revolutionary Solution for Fluid Transfer ApplicationsFluid transfer is a critical process in numerous industries, including chemical, pharmaceuticals, oil and gas, and food and beverage. In most cases, this process requires the use of high-quality pumps that can transport liquids and gasses from one point to another effectively.One such pump that has gained immense popularity in recent times is the Mini Screw Pump. As the name suggests, this pump is relatively small in size but boasts unmatched performance, making it an ideal choice for a wide range of fluid transfer applications.Designed and manufactured by one of the leading companies in the industry, the Mini Screw Pump stands out due to its unique helical rotor design. This design allows the pump to overcome various challenges posed by other popular pump types, such as centrifugal pumps.Most centrifugal pumps have impellers that spin on a shaft to create a fluid flow. Although these pumps are highly effective, they often struggle in situations where the liquid contains entrained air or gases. The entrained air tends to accumulate in the pump casing, eventually blocking the impeller and disrupting the fluid flow.The Mini Screw Pump, on the other hand, has a self-priming feature that eliminates the need for external priming. Additionally, the pump's helical rotor and stator design enable it to handle fluid transfer applications that contain air or gas entrainment.One of the main advantages of the Mini Screw Pump is its ability to handle various types of fluids, including abrasive, viscous, and corrosive liquids. This feature makes it an ideal choice for industries that require the transfer of challenging fluids.Furthermore, the pump's simple design and minimal mechanical parts make it easy to maintain and repair, reducing downtime and maintenance costs.To ensure optimal performance, each Mini Screw Pump is rigorously tested and checked to meet the highest industry standards. The company employs advanced testing equipment and quality control measures to ensure that each pump is defect-free and can deliver unparalleled results.The Mini Screw Pump is versatile, reliable, and efficient, making it a must-have for industries that require fluid transfer applications. Its unique design and outstanding performance make it the preferred choice for various industries, including chemical, pharmaceutical, oil and gas, and food and beverage.In conclusion, the Mini Screw Pump is a revolutionary solution that is set to change the fluid transfer industry's landscape. Its superior design, performance, and reliability make it the go-to pump for industries that require high-quality fluid transfer applications. With its ability to handle challenging fluids, the Mini Screw Pump is a game-changer that has earned its spot as one of the most effective pumps in the market.

10 Essential Factors to Consider When Choosing a Pump

article.Allweiler Pump Rebrands as ACI FluidsLeading global pump manufacturer, Allweiler Pump, has officially rebranded as ACI Fluids, following the acquisition by the American industrial conglomerate, Cameron Corporation. The exciting new development will see ACI Fluids bolster their state-of-the-art product portfolio, expand their global network, and continue to offer world-class services to customers across multiple industries.ACI Fluids has a rich history of innovation, with over 150 years of experience in the pump industry. Over the years, the company has established itself as a name to be reckoned with and has become synonymous with reliability and quality. As the company takes on a new identity, it seeks to build on its legacy and scale new heights of success.ACI Fluids offers an extensive range of pumps that cater to a variety of industrial applications. Its portfolio includes centrifugal, positive displacement, and gear pumps, among others. The company has a reputation for manufacturing pumps that are durable, efficient, and operate at peak performance even under challenging conditions. ACI Fluids' product range serves industries such as oil and gas, marine, chemical, food and beverage, and water and wastewater.The acquisition of Allweiler Pump by Cameron Corporation presents numerous opportunities for ACI Fluids to expand its presence in different markets. The synergy created by the acquisition will allow the company to leverage the technological expertise and operational efficiency of both organizations. This development will translate to more significant investments in research and development, enhancing engineering capabilities, expanding product lines, and exploring new avenues of growth.ACI Fluids' mission is to be a reliable partner to its customers by offering exceptional customer service and technical support. Its team of experienced engineers and technicians work closely with customers to provide customized solutions that meet their unique requirements. The company's commitment to customer satisfaction is evident from the testimonials of its satisfied customers, who have attested to the quality of its products and services.The appointment of Kevin Snee as President of ACI Fluids marks a significant milestone in the company's growth. Kevin joins the company with a wealth of industry experience, having previously served as Senior Vice President of Global Sales and Marketing at Blackmer. In his new role, Kevin will be responsible for driving the company's strategic vision, leading its growth initiatives, and developing strong customer relationships.Kevin's appointment comes at a time when ACI Fluids is looking to strengthen its presence in emerging markets such as Asia and the Middle East. He sees these regions as critical to the company's growth and is committed to investing resources to expand the company's footprint. Kevin also plans to continue building on the company's primary focus of delivering exceptional products and services to its customers.In conclusion, the rebranding of Allweiler Pump to ACI Fluids is a significant development in the pump industry. With a history rooted in innovation and a reputation for quality, ACI Fluids is poised for growth under the leadership of Kevin Snee. As it expands its product portfolio, leverages new technologies, and explores new markets, ACI Fluids remains committed to its core values of reliability, quality, and superior customer service.