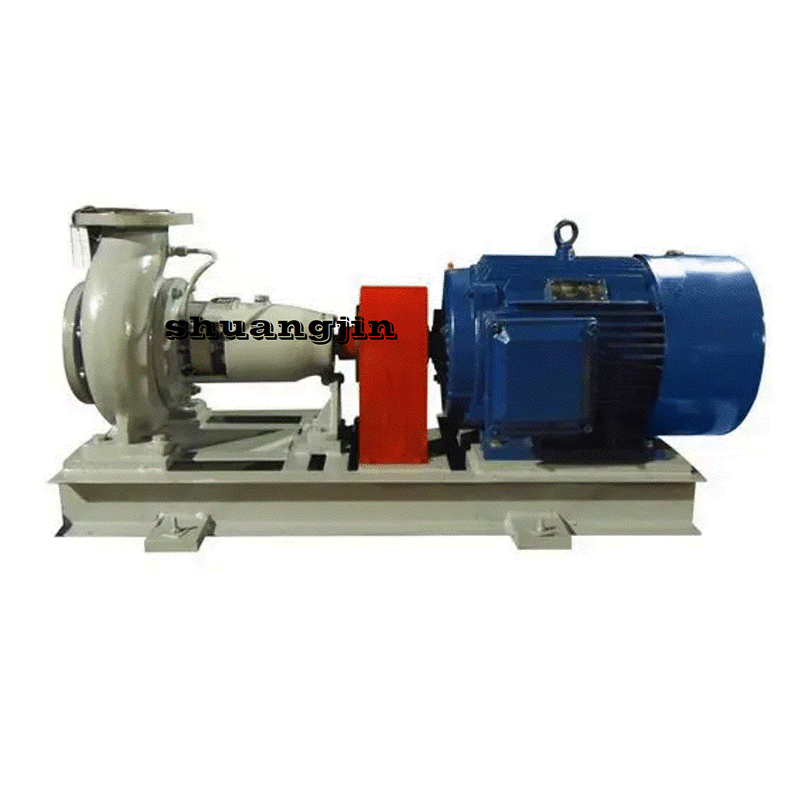

Durable Acid-Resistant Pump for Industrial Use

By:Admin

In the competitive world of industrial manufacturing, the ability to efficiently and safely transport corrosive substances is of utmost importance. This is where the Acid-Resistant Pump from {Company Name} comes into play, providing a revolutionary solution to the challenges of pumping acids and other corrosive materials.

{Company Name} is a leading provider of industrial pumping solutions, with a rich history of innovation and dedication to customer satisfaction. The company has earned a stellar reputation for its high-quality products and reliable service, making them a trusted partner for companies in a wide range of industries.

The Acid-Resistant Pump is the latest addition to {Company Name}'s extensive product lineup, and it has quickly become a game-changer for businesses that handle acids and other corrosive materials on a regular basis. This state-of-the-art pump is designed to withstand the harshest chemical environments, offering unparalleled durability and performance.

One of the key features that sets the Acid-Resistant Pump apart from traditional pumping solutions is its advanced materials and construction. Unlike standard pumps, which are prone to corrosion and degradation when exposed to acids, the Acid-Resistant Pump is specifically engineered to resist the damaging effects of corrosive substances. This not only extends the pump's lifespan but also minimizes the risk of leaks, spills, and other safety hazards.

In addition to its exceptional durability, the Acid-Resistant Pump is also known for its impressive efficiency and reliability. With a powerful motor and precision-engineered components, this pump delivers consistent performance even in the most challenging conditions. This means that businesses can count on the Acid-Resistant Pump to keep their operations running smoothly, without the risk of costly downtime or maintenance issues.

Furthermore, the Acid-Resistant Pump is designed with user-friendly features that make it easy to install, operate, and maintain. Its compact design and intuitive controls ensure that businesses can seamlessly integrate this pump into their existing processes, without the need for extensive modifications or specialized training. This not only saves time and resources but also enhances overall productivity and efficiency.

The benefits of the Acid-Resistant Pump are not limited to its technical specifications; {Company Name} is committed to providing comprehensive support and service to its customers. This includes expert guidance on selecting the right pump for specific applications, as well as ongoing maintenance and troubleshooting assistance. By partnering with {Company Name}, businesses can rest assured that they have a reliable ally in their quest for safe and efficient acid pumping solutions.

The impact of the Acid-Resistant Pump has been felt across a wide range of industries, from chemical manufacturing and wastewater treatment to mining and beyond. Companies that have adopted this innovative pump have noted significant improvements in their operations, including enhanced safety, reduced maintenance costs, and increased productivity. The Acid-Resistant Pump has truly transformed the way businesses handle corrosive materials, setting a new standard for pumping solutions in the industrial sector.

Looking ahead, {Company Name} is poised to continue its legacy of innovation and excellence in the field of industrial pumping solutions. With a strong focus on research and development, the company is committed to pushing the boundaries of what is possible in terms of durability, efficiency, and environmental responsibility. The Acid-Resistant Pump is just the beginning of what promises to be an exciting journey of progress and breakthroughs.

In conclusion, the Acid-Resistant Pump from {Company Name} represents a significant leap forward in the world of industrial pumping solutions. Its unmatched durability, performance, and user-friendly design have made it a standout choice for businesses that need to transport corrosive materials safely and efficiently. With {Company Name}'s track record of excellence and dedication to customer satisfaction, the Acid-Resistant Pump is poised to make a lasting impact on the industrial sector, setting new standards for quality and reliability.

Company News & Blog

What is a Screw Pump and How Does it Work?

Screw pumps are a type of positive displacement pump that is widely used in various industries for pumping high viscosity fluids, including oil, sludge, grease, and other similar substances. They are known for their ability to handle a wide range of viscosities and are often used in applications where other types of pumps may struggle to perform efficiently.One of the leading manufacturers of screw pumps is {}. With a history dating back to over a century, {} has established itself as a pioneer in the field of fluid handling equipment. The company has a strong reputation for producing high-quality, reliable screw pumps that are used in a wide range of industries, including oil and gas, chemical processing, food and beverage, and wastewater treatment.Screw pumps work on the principle of two or more intermeshing screws that rotate in a closed chamber, thereby creating a pumping action. As the screws rotate, they trap fluid between the threads and the wall of the pump, pushing the fluid along the length of the screws and out through the discharge port. This results in a smooth, pulsation-free flow of the pumped fluid, making screw pumps ideal for applications where a constant flow rate is required.The design of screw pumps allows them to handle high viscosity fluids with ease, making them suitable for handling heavy oils, sludges, and other challenging materials. In addition, they are known for their ability to handle abrasive and corrosive fluids, making them a popular choice for demanding industrial applications.Furthermore, screw pumps are known for their high efficiency and low maintenance requirements. Their simple design and minimal moving parts make them easy to maintain, contributing to their long service life and reliability. This is particularly important in industries where downtime can be costly, making screw pumps a cost-effective choice for many businesses.With a comprehensive range of screw pumps available, {} is able to cater to the diverse needs of its customers across various industries. Its pumps are designed to meet the specific requirements of different applications, ensuring that customers can find a suitable solution for their fluid handling needs.In addition to manufacturing screw pumps, {} also offers a range of services to support its customers, including installation, maintenance, and repairs. The company's team of experienced engineers and technicians are on hand to provide expert advice and assistance, helping customers to get the most out of their screw pump systems.As a global leader in fluid handling technology, {} has a strong commitment to innovation and continuous improvement. The company invests heavily in research and development, constantly seeking ways to enhance the performance and reliability of its products. This dedication to innovation has allowed {} to stay ahead of the competition and maintain its position as a trusted provider of screw pumps and other fluid handling equipment.In conclusion, screw pumps are a versatile and reliable solution for handling high viscosity fluids in various industrial applications. With {}'s long-standing expertise and commitment to excellence, customers can trust in the quality and performance of its screw pumps to meet their fluid handling needs. Whether it's pumping oil, sludge, or other challenging materials, {}'s screw pumps are a top choice for businesses looking for efficient and reliable fluid handling solutions.

Leading Pump Manufacturer in Tianjin Unveils New Product Line

Tianjin Pump is a leading company in the field of industrial pump manufacturing and has been a key player in the industry for over three decades. The company is known for its high-quality products, innovative technologies, and commitment to customer satisfaction. With a strong focus on research and development, Tianjin Pump has consistently pushed the boundaries of what is possible in the world of pump technology.Recently, Tianjin Pump announced the launch of a new series of industrial pumps that are set to revolutionize the way various industries approach their pumping needs. The company's latest offering promises to deliver unmatched performance, reliability, and efficiency, setting a new standard for the industry as a whole.Founded in 1986, Tianjin Pump has grown to become a global leader in the design and manufacture of industrial pumps. The company's products are widely used in sectors such as oil and gas, power generation, water treatment, and chemical processing. With a strong emphasis on quality and precision engineering, Tianjin Pump has earned a reputation for delivering pumps that are durable, dependable, and capable of meeting the most demanding application requirements.At the core of Tianjin Pump's success is its ongoing commitment to innovation. The company invests heavily in research and development, constantly seeking new ways to improve its products and stay ahead of the competition. This dedication to pushing the boundaries of what is possible has resulted in a steady stream of groundbreaking products that have redefined the industry's expectations.One of the key features of Tianjin Pump's new series of industrial pumps is its advanced design, which incorporates the latest technologies to deliver superior performance and efficiency. These pumps are engineered to operate at peak efficiency, reducing energy consumption and minimizing operating costs for the end user. By leveraging cutting-edge materials and manufacturing techniques, Tianjin Pump has been able to develop pumps that offer unmatched durability and reliability, even in the most challenging operating conditions.In addition to their technical prowess, Tianjin Pump's new series of industrial pumps are also designed with ease of maintenance and serviceability in mind. This ensures that customers can rely on their pumps to deliver consistent performance over the long term, with minimal downtime and maintenance requirements. This focus on customer satisfaction is a testament to Tianjin Pump's commitment to delivering value beyond just the initial purchase of its products.With the launch of its new series of industrial pumps, Tianjin Pump is poised to further solidify its position as a global leader in the pump manufacturing industry. The company's unwavering dedication to innovation, quality, and customer satisfaction has set it apart from its competitors, and the latest offering is a testament to its ongoing commitment to pushing the boundaries of what is possible in the world of pump technology.As industries continue to evolve and demand for more efficient and reliable pumping solutions grows, Tianjin Pump is well-positioned to meet these challenges head-on. The company's new series of industrial pumps represents a significant leap forward in pump technology and is set to raise the bar for the industry as a whole. With its long history of excellence and a track record of delivering innovative, high-quality products, Tianjin Pump is set to continue leading the way in the world of industrial pump manufacturing for years to come.

The Key Principles of Pump Operation Explained

Pump Principle, a leading provider of industrial pump solutions, has recently introduced its latest line of innovative pumps designed to meet the diverse needs of the industrial sector. With a strong focus on efficiency, reliability, and sustainability, Pump Principle has quickly become a trusted partner for industries ranging from manufacturing and agriculture to oil and gas.Founded in 1995, Pump Principle has established itself as a pioneer in the field of pump technology. The company's commitment to research and development has resulted in a range of cutting-edge pump solutions that have set new standards in the industry. With a customer-centric approach, Pump Principle has built a strong reputation for delivering high-quality products and personalized service to its clients.One of the key principles that sets Pump Principle apart is its dedication to innovation. The company is constantly seeking out new technologies and methodologies to enhance the performance of its pumps. This commitment to innovation has led to the development of a range of pumps that are not only more efficient and reliable but also more environmentally friendly. Pump Principle's pumps are designed to minimize energy consumption and reduce waste, helping companies to lower their carbon footprint and contribute to a more sustainable future.One of the highlights of Pump Principle's latest line of pumps is its focus on versatility. The company understands that different industries have different needs when it comes to pump solutions, and therefore it has developed a range of pumps that can be customized to meet specific requirements. Whether it's a high-pressure pump for the oil and gas industry or a heavy-duty pump for the mining sector, Pump Principle has the expertise to tailor its products to suit a wide variety of applications.Furthermore, Pump Principle places a strong emphasis on durability and reliability. The company knows that industrial processes can be demanding, and therefore its pumps are built to withstand harsh operating conditions and deliver consistent performance over time. By using high-quality materials and rigorous testing processes, Pump Principle ensures that its pumps meet the highest standards of reliability, reducing downtime and maintenance costs for its clients.In addition to its focus on product excellence, Pump Principle is also committed to providing exceptional customer service. The company takes pride in its team of dedicated professionals who are always ready to assist clients with their pump needs. From initial consultation and product selection to installation and ongoing support, Pump Principle's experts work closely with clients to ensure that they receive the best possible pump solutions for their specific requirements.With a strong track record of success and a growing list of satisfied clients, Pump Principle continues to expand its presence in the industrial pump market. The company's unwavering commitment to quality, innovation, and customer service has positioned it as a preferred partner for companies looking for reliable and efficient pump solutions.As industries continue to evolve and demand more advanced technologies, Pump Principle is poised to remain at the forefront of the industry, driving innovation and setting new benchmarks for pump performance and sustainability. With its latest line of pumps, the company is well-positioned to meet the evolving needs of industrial clients, helping them to achieve greater efficiency, productivity, and environmental responsibility.In conclusion, Pump Principle's dedication to excellence and innovation has made it a trusted name in the industrial pump sector. With its latest line of versatile, reliable, and sustainable pumps, the company is well-equipped to address the diverse needs of industries and provide them with the cutting-edge pump solutions they require for their operations. As Pump Principle continues to grow and expand its reach, it remains committed to delivering high-quality products and exceptional service to its clients, solidifying its position as a leader in the industrial pump market.

High-Quality Industrial Pumps for Your Business Needs

Bornemann Pump, a leading global provider of industrial pumps, has announced its latest innovation in pump technology. The company, known for its high-quality and reliable products, has once again proved its dedication to excellence with the launch of a new line of pumps that are set to revolutionize the industry.With over 160 years of experience in the industry, Bornemann Pump has continuously strived to provide its customers with the most advanced and efficient pumping solutions. The company's commitment to research and development has enabled it to stay at the forefront of pump technology, ensuring that its products are always at the cutting edge of innovation.The new line of pumps, which have been developed using the latest technologies and engineering techniques, promises to deliver improved performance, reliability, and efficiency. These pumps are designed to meet the diverse needs of industries such as oil and gas, petrochemical, chemical, and food and beverage, among others. With their robust construction and advanced features, these pumps are expected to set new standards in pump technology and revolutionize the way industries approach fluid handling.One of the key features of the new pumps is their advanced design, which allows for increased efficiency and reduced energy consumption. This is particularly important in today's economic and environmental climate, as industries are constantly looking for ways to reduce their carbon footprint and operational costs. The new pumps from Bornemann Pump are set to address these issues head-on, offering businesses a sustainable and cost-effective solution for their pumping needs.In addition to improved efficiency, the new line of pumps also promises enhanced reliability. With their durable construction and advanced components, these pumps are designed to withstand the harshest operating conditions, ensuring that businesses can rely on them for continuous and trouble-free operation. This is crucial for industries where downtime can result in significant financial losses, making the reliability of equipment a top priority.Furthermore, Bornemann Pump's new line of pumps also boasts versatility, with the ability to handle a wide range of fluids, including corrosive, viscous, and abrasive media. This makes the pumps suitable for a variety of applications, allowing businesses to utilize them across different processes and industries without compromising performance or safety.The company's commitment to quality and excellence is further demonstrated by its industry-leading after-sales support and service. Bornemann Pump takes pride in offering comprehensive support to its customers, ensuring that they can maximize the performance and lifespan of their pumps. From installation and commissioning to maintenance and repairs, the company's team of experts is dedicated to providing the highest level of service, guaranteeing the long-term satisfaction and success of its clients.The launch of its new line of pumps is a testament to Bornemann Pump's unwavering dedication to pushing the boundaries of pump technology and providing its customers with the best solutions for their fluid handling needs. With a focus on innovation, performance, and reliability, the company continues to set the standard for excellence in the industry, cementing its position as a trusted and respected global leader in industrial pumps.Businesses across the world can now benefit from the cutting-edge technology and superior performance offered by Bornemann Pump's new line of pumps. With their advanced features, versatility, and exceptional support, these pumps are set to make a significant impact on industries, driving efficiency, sustainability, and profitability for years to come.

Understanding the Purpose and Function of Check Valves in Plumbing Systems

Check Valves: Supporting Fluid Control in Diverse Industries Check valves play an essential role in fluid control systems of various industries. A check valve, also known as a one-way valve or non-return valve, ensures the flow of fluid in a single direction. The valve automatically closes when the flow tries to reverse, preventing backflow and protecting pumps, compressors, and other system components from damage. Check valves can be found in different types, sizes, materials, and configurations to accommodate the specific requirements of different applications. They can be classified based on their design, such as swing, lift, ball, disc, piston, or diaphragm check valves. They can also be classified based on their application, such as in-line, wafer, flanged, threaded, or soldered check valves. Check valves can be made of various materials, including brass, stainless steel, PVC, titanium, and others, depending on factors such as the fluid type, temperature, pressure, and environment. Check valves find applications in many industries that handle fluids or gases, such as oil and gas, water and wastewater, chemical, pharmaceutical, food and beverage, power generation, marine, and HVAC. For example, check valves prevent backflow in pipelines that transport oil or gas, reducing the risk of contamination and avoiding the loss of valuable resources. In water and wastewater treatment systems, check valves prevent reverse flow that could damage pumps or inject chemicals into the wrong tanks. In the chemical industry, check valves ensure the proper flow of corrosive or hazardous fluids, preventing leaks or explosions. In the food and beverage industry, check valves maintain the quality and hygiene of the products by preventing cross-contamination. In power generation plants, check valves protect boilers, turbines, and heat exchangers from damage caused by steam or water backflow. In marine applications, check valves prevent seawater from entering the ship or offshore platforms, avoiding corrosion and environmental hazards. In HVAC systems, check valves ensure the proper circulation of air or water, reducing energy waste and improving comfort. One of the leading companies that offer check valves is a trusted manufacturer with a worldwide reputation for quality and innovation. The company has been in the business of fluid control products for more than a century, providing a wide range of valves, regulators, and fittings for various industries. The company's check valves are designed and manufactured to meet the highest standards of performance, safety, and reliability, and are certified by international organizations such as ISO, API, and ASME. The company's check valves incorporate advanced features that enhance their functionality and durability. Some of these features include: - Silent operation: The company's check valves use a spring-loaded disc mechanism that allows for silent operation, avoiding the slamming noise that other types of check valves can make. The check valves also have a low cracking pressure, meaning that they open with minimal pressure from the downstream fluid, ensuring that the system starts smoothly. - Easy maintenance: The company's check valves are designed for easy disassembly and cleaning, allowing for quick and hassle-free maintenance. The check valves have a threaded bonnet that can be removed without special tools, and the internals can be accessed and removed easily. - High flow capacity: The company's check valves are engineered to provide high flow capacity with low pressure drop, allowing for efficient fluid transfer and reducing energy consumption. The check valves have a streamlined flow path that minimizes turbulence and erosion, extending the valve's lifespan and reducing the risk of leakage. - Wide compatibility: The company's check valves are compatible with a wide range of fluids, including corrosive, abrasive, and high-temperature ones. The check valves can also handle different pressures, from low to high, depending on the application. The company offers check valves in various configurations, such as swing, lift, and ball check valves, and in different materials, such as bronze, stainless steel, and PVC. Some of the company's check valves are designed for specific applications, such as its double-door foot valve for well water systems, its sanitary ball check valve for food and beverage processing, and its high-pressure lift check valve for oil and gas pipelines. Customers can count on the company's technical expertise and customer support to choose the right check valve for their specific needs. The company's engineers provide customized solutions for complex fluid control challenges, and its customer service team offers prompt and efficient assistance for any inquiries, orders, or after-sales needs. In conclusion, check valves are vital components of fluid control systems in diverse industries. They provide essential protection against backflow, ensuring the safe and efficient operation of pumps, compressors, and other equipment. The company's check valves combine advanced features, high-quality materials, and expert engineering to deliver superior performance and reliability in different applications. With its global presence and customer-oriented approach, the company is a trusted partner for fluid control solutions.

How to Select the Best Pump for Your Needs

All Pump is a leading global company in the pump industry, specializing in the design, manufacture, and distribution of high-quality pumps for various applications. With a strong focus on innovation and customer satisfaction, All Pump has established itself as a trusted partner for businesses across a wide range of industries.The company offers a comprehensive range of pumps, including centrifugal pumps, diaphragm pumps, submersible pumps, and many more. These products are widely used in industries such as agriculture, mining, construction, and manufacturing, where reliable and efficient pumping solutions are essential.One of the key strengths of All Pump is its commitment to excellence in engineering and manufacturing. The company operates state-of-the-art production facilities, equipped with advanced technology and automated processes to ensure the highest level of precision and quality in every pump it produces.In addition to its focus on product quality, All Pump also places a strong emphasis on customer service and support. The company's team of experienced professionals works closely with customers to understand their specific requirements and provide tailored solutions that meet their needs. This personalized approach has earned All Pump a reputation for delivering not just pumps, but comprehensive pumping solutions that add value to businesses.Recently, All Pump made headlines with the launch of its latest innovation in pump technology. The new pump boasts a unique design that offers improved performance, energy efficiency, and durability compared to existing models on the market. With this breakthrough, All Pump aims to set a new standard in the industry and provide its customers with a competitive edge.In a statement, the company's CEO expressed excitement about the new product, emphasizing that it reflects All Pump's ongoing commitment to pushing the boundaries of what is possible in pump technology. "We are dedicated to continuously innovating and exploring new ways to improve our products and better serve our customers," the CEO said. "With this latest innovation, we are confident that we are staying true to that commitment and setting a new benchmark for pump performance and reliability."The new pump is expected to be particularly well-received in industries where demanding operating conditions require pumps to perform at their best. Whether it's handling abrasive materials in mining operations or transferring corrosive chemicals in chemical processing plants, the new pump from All Pump is designed to deliver exceptional performance and longevity, reducing downtime and maintenance costs for businesses.To support the launch of the new product, All Pump has also announced that it will be offering comprehensive training and technical support to its customers. This initiative is part of the company's ongoing efforts to empower its customers with the knowledge and skills they need to maximize the value of All Pump products and optimize their pumping operations.Looking ahead, All Pump remains committed to advancing pump technology and expanding its range of solutions to meet the evolving needs of its customers. Whether it's through strategic partnerships, ongoing research and development, or continuous improvement of its manufacturing processes, the company is dedicated to maintaining its position as a leader in the pump industry.With its track record of delivering high-quality products, unparalleled customer support, and a relentless pursuit of innovation, All Pump is well-positioned to continue thriving in the global pump market and making meaningful contributions to the industries it serves.

The Versatile Applications of Screw Pumps

Industrial pumps are an essential component in many manufacturing and processing operations. One type of pump that is widely used in various industries is the screw pump. Screw pumps are positive displacement pumps that use rotating screws to move fluid or liquid along the screw's axis. These pumps are known for their ability to handle a wide range of viscosity and are often used in applications where high pressure and high flow rates are required.One of the leading manufacturers of screw pumps is {}, a company that prides itself on its innovative and high-quality pump solutions. With a strong focus on research and development, {} has been able to provide efficient and reliable screw pump products to its customers worldwide.The uses of screw pumps are varied, and they can be found in a wide range of industries, including oil and gas, chemical processing, food and beverage, and water treatment.In the oil and gas industry, screw pumps are commonly used for the transfer of crude oil and refined products. With their ability to handle high viscosity fluids, screw pumps are well-suited for moving heavy oils and other petroleum products from one location to another.In chemical processing plants, screw pumps are used for the transfer of acids, solvents, and other corrosive chemicals. The robust design of screw pumps makes them a reliable choice for handling aggressive and potentially hazardous substances.In the food and beverage industry, screw pumps are utilized for the transfer of various liquid products, such as dairy, juice, and syrups. The hygienic design of screw pumps makes them suitable for use in food processing applications, where cleanliness and sanitation are paramount.In water treatment facilities, screw pumps are used for the transfer of wastewater, sludge, and other fluids. The ability of screw pumps to handle high solids content and abrasive materials makes them a popular choice for these demanding applications.One of the key advantages of screw pumps is their ability to operate at low pulsation levels, which results in a smooth and steady flow of fluid. This makes them suitable for use in applications where precise and consistent fluid transfer is required.Additionally, screw pumps are known for their high efficiency and low maintenance requirements, making them a cost-effective choice for many industrial applications.With their versatility and reliability, it is no wonder that screw pumps are an essential component in various industries. As technology and manufacturing processes continue to evolve, the demand for high-performing pumps like screw pumps is expected to grow.As a leading manufacturer of screw pumps, {} has been at the forefront of delivering innovative pump solutions to its customers. With a strong focus on quality and performance, {} has earned a reputation for providing reliable and efficient screw pumps that meet the needs of diverse industries.The company's commitment to research and development has enabled it to continually improve and innovate its screw pump products, ensuring that they remain at the forefront of pump technology.With a global presence and a dedication to customer satisfaction, {} is well-positioned to meet the growing demand for screw pumps in the industrial sector. Whether it is for oil and gas, chemical processing, food and beverage, or water treatment, {} has the expertise and capabilities to deliver high-quality screw pump solutions to its customers.In conclusion, the uses of screw pumps are diverse and vital to many industries, and with a company like {} leading the way in pump innovation, the future looks bright for this essential piece of industrial equipment.

Highly Efficient Screw Pump: Everything You Need to Know

{Company Introduction} is proud to introduce the latest addition to its product line - the 3 Screw Pump. This innovative pump is designed to provide efficient and reliable performance in a wide range of industrial and commercial applications.The 3 Screw Pump is a positive displacement pump that is ideal for handling a variety of fluids, including lubricants, hydraulic oils, and other viscous liquids. With its unique design and precision engineering, this pump offers a number of advantages over other types of pumps, including high efficiency, low noise levels, and minimal pulsation.One of the key features of the 3 Screw Pump is its high level of reliability. The pump is constructed from high-quality materials, and its design has been optimized for maximum durability and longevity. This means that it can withstand the rigors of continuous operation in demanding environments, making it an ideal choice for a wide range of industries.In addition to its reliability, the 3 Screw Pump also offers exceptional performance. Its advanced design allows for smooth, continuous fluid flow, which helps to minimize wear and tear on the pump and other system components. This, in turn, can lead to lower maintenance costs and extended equipment life, making the pump a cost-effective solution for businesses of all sizes.Another advantage of the 3 Screw Pump is its versatility. It can be customized to meet the specific needs of individual applications, with options available for different flow rates, pressure levels, and materials of construction. This makes it suitable for use in a wide variety of industries, including oil and gas, chemical processing, power generation, and more.To ensure that customers get the most out of their investment, {Company Name} provides comprehensive support and service for the 3 Screw Pump. This includes expert technical assistance, maintenance and repair services, and access to a wide range of spare parts and accessories. With this level of support, customers can have confidence in the long-term performance of their pump.In addition to its technical capabilities, the 3 Screw Pump also reflects {Company Name}'s commitment to sustainability and environmental responsibility. The pump is designed to minimize energy consumption and waste, helping businesses to reduce their carbon footprint and comply with regulatory requirements. This can provide additional cost savings and reputational benefits for customers who choose the 3 Screw Pump."We are extremely excited to offer the 3 Screw Pump to our customers," said {Spokesperson Name}, {Job Title} at {Company Name}. "This pump represents the latest in pump technology, and we believe it will deliver significant value to businesses across a wide range of industries. With its combination of high performance, reliability, and efficiency, we are confident that the 3 Screw Pump will quickly become the pump of choice for forward-thinking companies."For businesses looking to improve their fluid handling processes, the 3 Screw Pump from {Company Name} offers a compelling solution. With its advanced design, exceptional performance, and comprehensive support, this pump is well positioned to meet the needs of today's industrial and commercial applications.

Screw Pump Manual: A Comprehensive Guide for Effective Pump Operation

Bornemann, a leading provider of pumping solutions, has recently released its latest edition of the Screw Pump Manual. The manual, which provides comprehensive information about the company's screw pump products, has been designed to offer valuable insights and guidance to customers and professionals in the industry.The manual covers a wide range of topics related to screw pumps, including the technology behind them, their applications, maintenance and troubleshooting, and selection criteria. It also includes detailed specifications and performance data for Bornemann's screw pump models, helping users to make informed decisions when choosing a pump for their specific requirements."We are delighted to announce the release of our new Screw Pump Manual, which represents our ongoing commitment to providing our customers with the tools and information they need to succeed," said a spokesperson for Bornemann. "This comprehensive resource is the result of our decades of experience and expertise in the pump industry, and we believe it will be a valuable asset for anyone involved in the specification, operation, and maintenance of screw pumps."Bornemann, founded in 1853, has a long-standing reputation for delivering high-quality, reliable pumping solutions to a diverse range of industries, including oil and gas, chemical processing, food and beverage, and marine. The company's screw pumps are known for their robust construction, efficient performance, and versatility, making them the ideal choice for demanding applications in various industrial settings.In addition to its extensive product range, Bornemann also offers a range of services to support its customers, including technical support, maintenance and repair, and custom engineering solutions. The company's team of experts is dedicated to ensuring that customers receive the highest level of support and assistance, from initial pump selection to ongoing maintenance and after-sales service.The release of the new Screw Pump Manual is part of Bornemann's broader strategy to provide value-added resources to its customers, equipping them with the knowledge and tools they need to achieve operational excellence and maximize the performance of their pumping systems. By consolidating its expertise and best practices into a comprehensive and accessible format, Bornemann aims to empower its customers to make informed decisions and optimize the efficiency and reliability of their pumping operations."We see the Screw Pump Manual as an extension of our commitment to partnership and collaboration with our customers," the spokesperson added. "Our goal is to not only deliver high-quality products but also to be a trusted advisor and resource for our customers, helping them to overcome challenges and achieve their goals. We believe that by sharing our knowledge and expertise, we can contribute to the success of our customers and the industries they serve."Bornemann's Screw Pump Manual is now available for download on the company's website and will also be distributed to its customers and partners around the world. The company encourages professionals in the pump industry to take advantage of this valuable resource and leverage its insights to enhance their understanding of screw pump technology and its applications.As Bornemann continues to innovate and expand its offerings, the release of the new Screw Pump Manual reaffirms the company's position as a trusted leader in the pumping industry, dedicated to delivering exceptional value and support to its customers. With its commitment to excellence and customer satisfaction, Bornemann is well-positioned to continue driving success for its customers and contributing to the advancement of pumping technology and practices.

Basic Screw Pump Maintenance Procedure for Longevity and Efficiency

Screw Pump Maintenance ProcedureScrew pumps are an essential part of many industrial processes, including chemical, petrochemical, and wastewater treatment plants. Proper maintenance of these pumps is crucial to ensure their efficient and reliable operation. To help facility managers and maintenance personnel, () has shared a comprehensive maintenance procedure for screw pumps.The maintenance procedure begins with a thorough inspection of the pump and its components. This includes checking for any signs of wear and tear, corrosion, leaks, and abnormal noise or vibrations. The pump should also be inspected for any signs of contamination or blockages that could affect its performance.After the initial inspection, the next step is to check the pump's lubrication system. This includes inspecting the oil level, quality, and pressure, as well as the condition of the lubrication system components such as the oil filter and cooler. Proper lubrication is essential for the smooth operation of the pump and to prevent excessive wear on its moving parts.The maintenance procedure also includes inspecting and, if necessary, replacing the pump's seals and gaskets. These components are critical for preventing leaks and ensuring the pump operates at peak efficiency. Additionally, the alignment and clearance of the pump's rotors and casing should be checked and adjusted as needed to maintain optimal performance.Another important aspect of screw pump maintenance is the inspection and maintenance of the pump's drive system, including the motor, coupling, and gearbox. Any signs of wear or damage should be addressed promptly to prevent further issues that could lead to costly repairs or downtime.In addition to regular inspections and maintenance, facility managers and maintenance personnel should also prioritize keeping detailed records of all maintenance activities and any issues encountered during the pump's operation. This documentation is essential for tracking the pump's performance over time and identifying any trends or patterns that could indicate potential problems.() is dedicated to providing reliable and efficient screw pumps for various industrial applications. With over 20 years of experience in the industry, they have established a reputation for delivering high-quality pumps that meet the needs of their customers. In addition to manufacturing and supplying screw pumps, they also offer comprehensive maintenance services and support to help their customers maximize the lifespan and performance of their pumps.As part of their commitment to customer satisfaction, () regularly shares valuable resources, such as maintenance procedures and best practices, to help their customers better understand and care for their equipment. They also offer training programs and on-site support to ensure that their customers have the knowledge and skills to maintain their pumps effectively.By sharing this maintenance procedure, () aims to empower facility managers and maintenance personnel with the knowledge and tools they need to keep their screw pumps operating at peak performance. Proper maintenance not only extends the lifespan of the pumps but also reduces the risk of unexpected downtime and costly repairs, ultimately contributing to a more efficient and productive operation.In conclusion, screw pump maintenance is a critical aspect of ensuring the reliable and efficient operation of industrial processes. With a comprehensive maintenance procedure and the support of a reliable pump supplier like (), facility managers and maintenance personnel can take proactive measures to keep their screw pumps in optimal condition and minimize the risk of unexpected issues.