Efficient Lubrication Oil Gear Pump for Smooth Operation

By:Admin

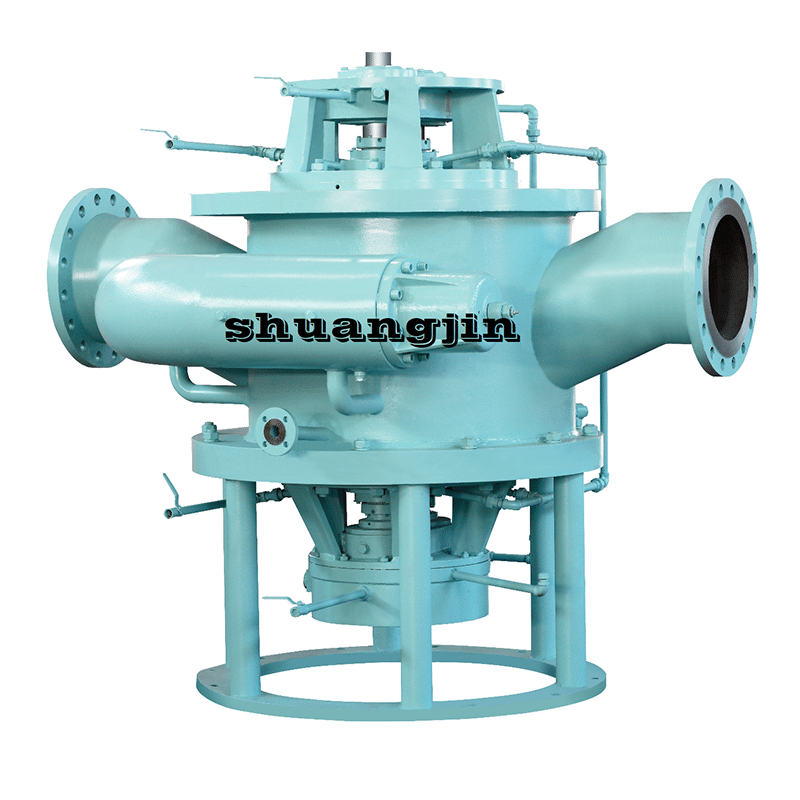

In the world of industrial machinery, proper lubrication is essential for smooth and efficient operation. This is where the gear pump [brand name removed] comes into play - a crucial component in ensuring that the moving parts of industrial equipment are well-lubricated and functioning at their best.

The gear pump plays a significant role in providing the necessary flow of lubrication oil to various components of machinery, reducing friction and wear, and preventing breakdowns. It is a critical element in the maintenance and smooth operation of heavy-duty machinery such as turbines, compressors, and other industrial equipment.

The pump is designed to handle a wide range of lubrication oils and operates with high efficiency and reliability. Its robust construction and design make it suitable for the demanding conditions of industrial applications, where it is often subjected to high temperatures, heavy loads, and continuous operation.

The [brand name removed] gear pump is designed with precision-engineered gears that ensure a consistent and smooth flow of lubrication oil, delivering the right amount of oil to the various parts of machinery where it is needed the most. This results in improved performance, extended machinery life, and reduced downtime due to maintenance and repairs.

[Company Name] is a leading manufacturer of industrial machinery components, including the highly regarded [brand name removed] gear pump. The company has a long history of providing high-quality products for a wide range of industrial applications, and its gear pump is no exception.

With a focus on innovation and excellence, [Company Name] has invested heavily in research and development to ensure that its gear pump meets the highest standards of performance and reliability. The company's commitment to quality and customer satisfaction has made its gear pump a trusted choice for industrial machinery operators worldwide.

The [brand name removed] gear pump is just one of the many products offered by [Company Name] to support the efficient and reliable operation of industrial machinery. The company provides a comprehensive range of components and solutions, including pumps, valves, filters, and fluid management systems, all designed to meet the diverse needs of industrial applications.

In addition to its high-quality products, [Company Name] is also known for its exceptional customer service and technical support. The company's team of experts is dedicated to helping customers find the right solutions for their specific machinery requirements, providing comprehensive support and guidance throughout the product selection, installation, and maintenance process.

As industries continue to evolve and demand for efficient and reliable machinery grows, the importance of high-quality components such as the [brand name removed] gear pump cannot be overstated. [Company Name] remains at the forefront of providing innovative solutions that meet the evolving needs of industrial applications, ensuring that machinery operates at its best for maximum productivity and reliability.

With a commitment to excellence and a track record of delivering high-quality products and support, [Company Name] and its [brand name removed] gear pump continue to play a crucial role in keeping industrial machinery running smoothly and efficiently. As the industrial landscape continues to evolve, [Company Name] is poised to be a trusted partner for businesses looking to maximize the performance and reliability of their machinery.

Company News & Blog

The Significance of Timing Gears in Screw Pumps: Exploring their Role and Function

Timing Gear in Screw Pump: A Revolutionary Advancement in Pump Technology[Company Name], a leading innovator in the field of pump technology, has recently unveiled a breakthrough development in screw pump design – the revolutionary Timing Gear. This state-of-the-art advancement is set to transform the way pumps function, offering enhanced efficiency, reliability, and durability.Traditional screw pump designs rely on a rotating helical screw to move fluids through the pump. While these pumps have proven to be effective for many applications, they often suffer from issues such as uneven fluid flow, excessive vibration, and premature wear of the screw and other internal components.With the introduction of the Timing Gear, [Company Name] aims to eliminate these drawbacks and create a new benchmark in screw pump performance. This innovative gear mechanism, which replaces the traditional single-helix screw, provides precise control over the flow of fluids, resulting in smoother operation and improved overall efficiency.One of the primary advantages of the Timing Gear is its ability to maintain a consistent flow rate, regardless of variations in input pressure or viscosity of the fluid being pumped. This feature makes it highly suitable for applications where a reliable and steady flow is crucial, such as in the oil and gas industry, chemical processing plants, and wastewater treatment facilities.Additionally, the Timing Gear significantly reduces unwanted vibrations that can cause excessive wear and tear on pump components. By incorporating advanced engineering principles, including precision machining and advanced materials, [Company Name] has ensured that their Timing Gear pumps operate with minimal noise and vibrations, thereby increasing their service life and reducing maintenance costs.Another noteworthy feature of the Timing Gear is its remarkable durability. The gear mechanism is designed to withstand high operating pressures and resist corrosion, making it suitable for use in harsh and demanding environments. Its robust construction ensures long-term reliability and reduced downtime, providing businesses with a cost-effective solution for their pumping needs.Furthermore, the Timing Gear’s design allows for easy maintenance and quick replacement of worn components. Its modular construction enables users to access and replace specific parts, reducing the need for extensive disassembly and minimizing downtime during servicing. Additionally, the gear’s simplicity of design enhances reliability, as fewer moving parts mean fewer opportunities for mechanical failures.[Company Name] has already received overwhelmingly positive feedback from early adopters of the Timing Gear. Companies that have integrated this groundbreaking technology into their pump systems have reported significant improvements in efficiency, productivity, and overall performance. Several industry experts have also praised this innovation, recognizing its potential to revolutionize the screw pump market.In conclusion, [Company Name]’s introduction of the Timing Gear has set a new standard in screw pump technology. With its precise flow control, reduced vibrations, exceptional durability, and ease of maintenance, this groundbreaking development promises to deliver a range of benefits to businesses across various sectors. As this revolutionary advancement gains traction in the industry, it is expected to redefine the capabilities and expectations of screw pumps, establishing [Company Name] as a leader in pump technology innovation.

Top-quality Oil & Gas Pumps: Your Guide to Efficient Industry Solutions

Oil and Gas Pumps Revolutionize the Energy IndustryIn today's rapidly evolving technological landscape, the demand for efficient and reliable equipment in the oil and gas industry is higher than ever. To meet these increasing demands, Oil and Gas Pumps (name removed) has emerged as a leading provider of cutting-edge pumping solutions. With their acclaimed company history of innovation and commitment to customer satisfaction, Oil and Gas Pumps has revolutionized the energy industry.With a diverse range of offerings, Oil and Gas Pumps provides pumping solutions that cater to various applications within the oil and gas sector. Their pumps play a crucial role in exploration, production, refining, and distribution processes, ensuring a smooth and continuous flow of oil and gas.One of the key factors that sets Oil and Gas Pumps apart from its competitors is its relentless pursuit of innovation. The company invests heavily in research and development, constantly striving to develop pumps that are more efficient, durable, and environmentally friendly. By pushing the boundaries of engineering, Oil and Gas Pumps has been able to enhance productivity while reducing the carbon footprint of its operations.Furthermore, Oil and Gas Pumps' commitment to customer satisfaction is second to none. The company takes immense pride in its ability to provide tailored solutions that meet the specific needs of its clients. By working closely with customers, Oil and Gas Pumps ensures that its pumps are perfectly suited to the varied challenges faced in the oil and gas industry, whether it be offshore drilling in extreme environments or onshore refining in remote locations.Oil and Gas Pumps owes its success, in large part, to its team of highly skilled professionals. With expertise in mechanical engineering, fluid dynamics, and industrial design, the company's engineers are at the forefront of technological advancements in pumping solutions. Through continuous training and development programs, Oil and Gas Pumps ensures that its workforce remains knowledgeable and equipped to handle even the most complex projects.Moreover, the company's dedication to quality control is unfaltering. Each pump undergoes rigorous testing and inspection to ensure it meets the highest industry standards. This commitment to quality has earned Oil and Gas Pumps a stellar reputation for reliability and durability, resulting in long-lasting relationships with customers worldwide.In addition to its technological prowess and commitment to excellence, Oil and Gas Pumps is also deeply aware of the need to minimize its environmental impact. The company strives to create sustainable solutions and reduce energy consumption in its pumps. By implementing energy-efficient designs and utilizing eco-friendly materials, Oil and Gas Pumps aims to contribute to the global effort of transitioning to a greener and more sustainable future.Through its continued investment in research and development, its customer-centric approach, and its unwavering commitment to innovation and quality, Oil and Gas Pumps has established itself as a trusted leader in the pumping solutions industry. With each new product, the company continues to drive advancements in the oil and gas sector, facilitating greater efficiency, productivity, and sustainability.As the global demand for oil and gas continues to rise, it is companies like Oil and Gas Pumps that will play a vital role in meeting these ever-increasing demands. With their state-of-the-art pumping solutions, the company is helping to shape the future of the energy industry, ensuring a smooth and reliable supply of oil and gas for years to come.

What Separates Centrifugal Pumps from Screw Pumps?

Centrifugal pumps and screw pumps are two common types of pumps used in various industrial applications. Although they both serve the purpose of moving fluids from one place to another, there are significant differences between the two in terms of their design, operation, and performance.A centrifugal pump uses a rotating impeller to create a suction force that draws fluid into the pump. The impeller then spins, forcing the fluid to the outer edges where it is then discharges through the pump's outlet. The velocity of the fluid is increased as it passes through the impeller, which increases the pressure of the fluid, allowing it to be moved more effectively through the system.On the other hand, a screw pump operates by using a rotating screw-shaped rotor to push the fluid through a stationary screw-shaped stator. The screws are designed to mesh together, and as they rotate, they create a series of sealed cavities that move the fluid through the pump and out through the discharge port. Unlike centrifugal pumps, the pressure generated by screw pumps is relatively constant, which makes them ideal for pumping high viscosity fluids, such as oil and sludge.While centrifugal pumps are suitable for a wide range of applications, including water treatment, chemical processing, and mining, screw pumps excel in moving fluids that are highly viscous and contain solids. They are often used in the oil and gas industry, marine transport, and other heavy-duty applications that require consistent, high-pressure flow.When choosing between a centrifugal pump and a screw pump, it's important to consider a variety of factors, such as the fluid being pumped, the flow rate needed, and the desired pressure. Additionally, the operational cost, maintenance requirements, and power consumption should also be taken into account.{} is a leading manufacturer of industrial pumps and fluid-handling equipment, with a comprehensive range of products designed to meet the needs of various industries worldwide. They provide a wide range of centrifugal and screw pumps, each designed to deliver optimal performance and reliability.For instance, the company's centrifugal pumps are engineered to provide high-efficiency pumping, low energy consumption, and long-term reliability, making them ideal for applications that require high flow rates and low-to-medium pressures. They are available in various designs, including end-suction, split-case, and vertical turbine pumps, to meet the specific requirements of different applications.Similarly, the company's screw pumps are designed to handle fluids with high viscosity, suspended solids, and abrasives, making them well-suited for industries such as wastewater treatment, chemical processing, and food and beverage. Their screw pumps come in various designs, including single-screw and twin-screw models, to accommodate different flow rates and pressure requirements.In addition to centrifugal and screw pumps, {} offers a wide range of other fluid-handling solutions, including mixers, agitators, valves, and filtration systems. They also provide related services, such as installation, commissioning, maintenance, and repair, to ensure that their customers' equipment always operates at peak performance.Overall, when it comes to choosing between a centrifugal pump and a screw pump, it ultimately comes down to the specific requirements of the application. {} offers a comprehensive range of pumps and fluid-handling solutions that are designed to meet the needs of different industries and applications, ensuring that their customers are able to find the perfect solution for their specific needs.

Understanding the Working Principle of Single Screw Pumps

Single screw pump, also known as Archimedes screw pump, is a type of positive displacement pump that can efficiently move fluid through a system. It is a versatile and reliable pump that is widely used in various industries including oil and gas, food and beverage, wastewater treatment, and marine applications. With its simple design and high efficiency, the single screw pump is a popular choice for many pumping applications.The working principle of a single screw pump is quite simple yet effective. It consists of a single screw rotor that rotates inside a double-threaded stator. As the rotor turns, it creates cavities between the screw and the stator, which allows the fluid to be pulled into the pump. As the rotor continues to rotate, the cavities move the fluid along the length of the stator, pushing it out through the discharge port. This continuous movement of the screw rotor creates a smooth and pulsation-free flow of fluid, making the single screw pump suitable for handling shear-sensitive and viscous fluids.One company that has been at the forefront of manufacturing and supplying single screw pumps is {}. With a history tracing back to over a century, {} has established itself as a leading provider of pumping solutions for various industries. The company's single screw pumps are designed to meet the rigorous demands of modern industrial applications, offering high performance, reliability, and long service life.{}'s single screw pumps are built with precision engineering and high-quality materials to ensure optimal performance and minimal maintenance. The company offers a wide range of single screw pump models to suit different flow rates, pressures, and fluid viscosities, catering to the diverse needs of its customers. In addition, {} provides comprehensive technical support and after-sales service to ensure that its customers get the most out of their pumping systems.The application of {}'s single screw pumps spans across various industries. In the oil and gas sector, these pumps are used for transferring crude oil, drilling mud, and various other fluids in upstream, midstream, and downstream operations. In the food and beverage industry, {}'s single screw pumps are employed for handling viscous and delicate products such as chocolate, syrup, and dairy. Additionally, these pumps are widely used in wastewater treatment plants for pumping sludge, effluent, and other fluids with high solids content.The success of {}'s single screw pumps can be attributed to the company's commitment to innovation and continuous improvement. {}'s research and development team is constantly exploring new technologies and materials to enhance the performance and efficiency of its pumps. Through ongoing investment in research and technology, {} aims to stay ahead of the curve and provide cutting-edge solutions to its customers.Furthermore, {} places a strong emphasis on quality control and testing to ensure that its single screw pumps meet the highest standards of reliability and durability. The company's manufacturing facilities are equipped with state-of-the-art equipment and processes to produce pumps that are robust, efficient, and capable of withstanding harsh operating conditions.In conclusion, single screw pumps are an integral part of many industrial processes, and {} has been a key player in providing high-quality pumping solutions to a wide range of industries. With its proven track record and commitment to excellence, {} continues to be a trusted partner for businesses looking for reliable and efficient single screw pumps. As the demand for advanced pumping technology continues to grow, {} is well-positioned to lead the way with its innovative and reliable pumping solutions.

High-Quality Pumps Make Waves in the Industry

Inoxpa Pumps, a leading manufacturer of industrial pumps and fluid handling equipment, is making waves in the industry with its innovative and high-quality products. The company, which was founded in the 1970s, has established itself as a trusted and reliable provider of pumping solutions for a wide range of industries, including food and beverage, pharmaceutical, and chemical processing.One of the key factors that sets Inoxpa Pumps apart from its competitors is its commitment to research and development. The company has a dedicated team of engineers and technical experts who are constantly working to improve and innovate their products. This focus on innovation has led to the development of a number of cutting-edge pumping solutions that offer higher efficiency, greater reliability, and lower operating costs.Inoxpa Pumps offers a comprehensive range of pumping solutions to suit a variety of applications. The company's product line includes centrifugal pumps, positive displacement pumps, and rotary lobe pumps, among others. These pumps are designed to handle a wide range of fluids, from thin, non-viscous liquids to highly viscous and abrasive substances. Inoxpa Pumps also offers a range of accessories and spare parts, ensuring that customers have everything they need to keep their pumping systems running smoothly.Inoxpa Pumps has a strong focus on quality and reliability, and all of its products are manufactured to the highest standards. The company's state-of-the-art manufacturing facilities are equipped with the latest technology and machinery, allowing them to produce pumps that are not only efficient and reliable but also durable and long-lasting. Inoxpa Pumps also has a rigorous quality control process in place, ensuring that every pump that leaves their facilities meets their strict standards for performance and reliability.One of the key strengths of Inoxpa Pumps is its customer service and support. The company has a global network of sales and service partners, ensuring that customers all over the world have access to the support and assistance they need. Inoxpa Pumps also offers a range of after-sales services, including maintenance and repair, as well as technical support and training. This commitment to customer support has helped the company build a strong reputation for reliability and dependability.Inoxpa Pumps is also committed to sustainability and environmental responsibility. The company is constantly striving to reduce its environmental impact and has implemented a number of initiatives to promote sustainability throughout its operations. This includes the use of energy-efficient manufacturing processes, the development of eco-friendly products, and the implementation of waste reduction and recycling programs.Inoxpa Pumps has established itself as a trusted and reliable provider of pumping solutions for a wide range of industries, and its innovative products and commitment to quality and customer service have set it apart as a leader in the industry. With its focus on research and development, quality manufacturing, and sustainability, Inoxpa Pumps is well-positioned to continue its success in the years to come.

High-Quality Rotor Screw Pump for Efficient Pumping

Rotor Screw Pump, a leading manufacturer of industrial pumping solutions, has recently launched a new series of screw pumps designed to meet the growing demand for reliable and efficient pumping systems in the global market.The new series of screw pumps are the result of extensive research and development efforts, aimed at providing customers with innovative pumping solutions that deliver superior performance and durability. The company's commitment to excellence is reflected in the quality and reliability of their products, making them the preferred choice for a wide range of industrial applications.With a legacy of over 50 years in the industry, Rotor Screw Pump has earned a solid reputation for delivering high-quality pumping solutions that meet the diverse needs of their customers. The company's state-of-the-art manufacturing facilities and advanced engineering capabilities ensure that they stay ahead of the curve in terms of product innovation and performance.The new series of screw pumps feature a robust design that allows for seamless operation even in the most demanding environments. The pumps are equipped with advanced technologies that optimize efficiency and reduce energy consumption, making them an eco-friendly choice for businesses looking to minimize their environmental footprint.In addition to their superior performance, the new series of screw pumps are also designed for easy installation and maintenance, helping customers minimize downtime and maximize productivity. The pumps are built to withstand the rigors of industrial operations, delivering reliable performance day in and day out."We are excited to introduce our new series of screw pumps to the global market," said a spokesperson for Rotor Screw Pump. "These pumps represent the culmination of our decades of experience and expertise in the industry, and we are confident that they will set a new standard for performance and reliability in industrial pumping."The company's dedication to customer satisfaction is evident in their comprehensive support services, which include technical assistance, maintenance, and repair. Rotor Screw Pump's team of experts is committed to helping customers find the right pumping solutions for their specific needs, and ensuring that their equipment operates at peak efficiency at all times.With a strong focus on innovation and continuous improvement, Rotor Screw Pump is poised to remain at the forefront of the industry, providing customers with cutting-edge pumping solutions that deliver exceptional value. The company's new series of screw pumps is a testament to their ongoing commitment to excellence and their determination to meet the evolving needs of the market.As the global demand for effective pumping solutions continues to grow, Rotor Screw Pump is well positioned to capitalize on the opportunities that lie ahead. With their proven track record of delivering high-quality products and unparalleled customer support, the company is set to solidify its position as a trusted partner for businesses seeking reliable and efficient pumping solutions.The launch of the new series of screw pumps marks the beginning of an exciting new chapter for Rotor Screw Pump, as the company looks to expand its presence in key markets around the world. With their dedication to innovation and customer satisfaction, the company is well positioned to make a significant impact in the global pumping industry.

High-Quality Screw Pump Assembly for Efficient Operations

[Screw Pump Assembly] is a crucial component in various industries, from oil and gas to water treatment and chemical processing. It plays a vital role in conveying fluids and is essential for the smooth operation of many systems. With the increasing demand for reliable and efficient screw pump assemblies, it is important for companies to provide high-quality products to meet the needs of the market.One company that has been at the forefront of providing top-notch screw pump assemblies is [Company Name]. With a strong focus on innovation and customer satisfaction, [Company Name] has established itself as a leader in the industry. The company's commitment to excellence and continuous improvement has made it a trusted partner for many businesses around the world.[Company Name] takes pride in its state-of-the-art manufacturing facilities, where the latest technology and advanced processes are employed to ensure the highest quality products. The company's team of highly skilled engineers and technicians are dedicated to developing innovative solutions and pushing the boundaries of screw pump assembly technology.In addition to its focus on quality and innovation, [Company Name] also places a strong emphasis on customer service. The company works closely with its clients to understand their specific needs and provide customized solutions that meet their requirements. Whether it's a standard screw pump assembly or a custom-designed system, [Company Name] is committed to delivering products that exceed expectations.Furthermore, [Company Name] is dedicated to sustainability and environmental responsibility. The company is constantly looking for ways to reduce its environmental impact and promote sustainable practices throughout its operations. This commitment is reflected in the design and engineering of its products, as well as its efforts to minimize waste and energy consumption.With a strong track record of success and a commitment to excellence, [Company Name] has earned the trust and confidence of its customers. The company's screw pump assemblies are known for their durability, reliability, and performance, making them the top choice for businesses across a wide range of industries.Looking ahead, [Company Name] is poised to continue its growth and success in the screw pump assembly market. The company is constantly investing in research and development to further enhance its products and services, and it remains dedicated to meeting the evolving needs of its customers.In conclusion, [Company Name] is a leading provider of high-quality screw pump assemblies, known for its commitment to excellence, innovation, and customer satisfaction. With a strong focus on quality, sustainability, and customer service, the company has established itself as a trusted partner for businesses across the globe. As the demand for reliable and efficient screw pump assemblies continues to grow, [Company Name] is well-positioned to meet the needs of the market and drive the industry forward.

Introduction to Different Types of Industrial Valves - A Comprehensive Guide

Industrial Valves: A Leader in Innovation and Reliability[date]Industrial Valves, a global leader in valve manufacturing, continues to set the standards in the industry with its innovative and reliable products. With a rich history dating back several decades, the company has built a strong reputation for its commitment to quality, customer satisfaction, and technological advancements.Headquartered in [location], Industrial Valves has a vast network of manufacturing facilities and offices across the globe, allowing them to cater to the diverse needs of their worldwide clientele. The company's extensive product range includes a wide variety of valves, such as gate valves, globe valves, ball valves, butterfly valves, and control valves. Their valves are utilized in various industries, including oil and gas, petrochemical, power generation, water treatment, and many more.One of the key factors that sets Industrial Valves apart from its competitors is its relentless focus on innovation. The company invests heavily in research and development to constantly improve their products and stay at the forefront of technological advancements. By utilizing state-of-the-art manufacturing processes and cutting-edge materials, Industrial Valves ensures that their valves are not only durable and reliable but also meet the ever-evolving needs of the industry.Industrial Valves takes pride in their commitment to quality. The company has implemented a strict quality management system, adhering to international standards and certifications. Each valve undergoes rigorous testing and inspection to ensure it meets or exceeds industry regulations. With a zero-tolerance approach towards defects, Industrial Valves guarantees that their valves are of the highest quality, providing peace of mind to their customers.In addition to their focus on innovation and quality, Industrial Valves places utmost importance on customer satisfaction. The company's team of highly skilled engineers and technicians work closely with clients to understand their unique requirements and offer tailored solutions. From initial design and engineering to installation and after-sales support, Industrial Valves provides comprehensive services to ensure customer satisfaction throughout the entire lifecycle of their valves.With a strong commitment to sustainability, Industrial Valves also develops eco-friendly solutions. The company invests in research and development of valves that minimize environmental impact, reduce energy consumption, and increase operational efficiency. By offering sustainable solutions, Industrial Valves contributes to the overall well-being of the planet while helping their clients achieve their environmental goals.Industrial Valves' dedication to excellence has earned them numerous accolades and industry recognition. They have been awarded multiple contracts for high-profile projects globally, solidifying their position as a trusted and reliable valve manufacturer. Their valves have consistently proven their worth in challenging environments and demanding applications, demonstrating their ability to perform under extreme conditions.Looking towards the future, Industrial Valves remains committed to pushing the boundaries of innovation and meeting the evolving needs of the industry. With ongoing investments in research and development and a focus on customer satisfaction, the company is well-positioned to continue its growth trajectory and maintain its reputation as a global leader in the valve manufacturing sector.In conclusion, Industrial Valves is a company that exemplifies excellence in valve manufacturing. With their commitment to innovation, quality, and customer satisfaction, they have established themselves as a trusted partner for industries across the globe. Continuously pushing boundaries and embracing technological advancements, Industrial Valves sets the bar high for others in the industry, solidifying their position as a leader in innovation and reliability.

Wholesale Check Valve Function Manufacturers: Exploring the Functionality of Check Valves in Bulk

In recent years, the demand for check valves has been steadily increasing in various industries. These valves are essential in maintaining the flow direction of fluids and preventing backflow, ensuring the smooth operation of pipelines and preventing potential damages. As a result, wholesale check valve function factories have become crucial players in meeting this growing demand.One such wholesale check valve function factory, which would like to stay anonymous for the purpose of this news article, has been making significant contributions to various industries by providing top-quality check valves. With a focus on manufacturing products that are not only reliable but also cost-effective, this factory has gained recognition for its commitment to customer satisfaction.Established several years ago, this factory has gradually expanded its manufacturing capabilities and product range to cater to diverse applications. They have a team of experienced engineers and technicians who utilize cutting-edge technology and advanced production techniques to ensure the production of high-quality check valves. These professionals have extensive knowledge and expertise in valve manufacturing, enabling them to meet the specific requirements of different industries.The check valves manufactured by this factory undergo a rigorous quality control process that adheres to international standards. They are made from durable materials that are resistant to corrosion, pressure, and temperature variations, ensuring longevity and reliability. Additionally, the valves are designed with precision to achieve maximum efficiency and minimum flow resistance, ultimately maximizing performance.One of the key features of their check valves is their versatility. Whether it's for industrial applications, water management systems, oil and gas industries, or HVAC systems, the factory can provide customized solutions to meet the unique requirements of their clients. They offer a wide range of check valves, including swing check valves, lift check valves, wafer check valves, and ball check valves, among others. This extensive selection allows customers to choose the valve that best suits their needs.Furthermore, the factory takes pride in its excellent customer service. They understand the importance of timely delivery and offer flexible shipping options to ensure that customers receive their orders on time. The factory also provides technical support and guidance to assist customers in selecting the most suitable check valve for their specific applications.As a wholesale function factory, they offer competitive prices for their check valves without compromising on quality. This has allowed them to establish long-term partnerships with clients both domestically and internationally. The factory actively seeks feedback from customers to continuously improve their products and services, striving to stay at the forefront of the valve manufacturing industry.In conclusion, wholesale check valve function factories play a crucial role in meeting the increasing demand for high-quality check valves across various industries. This anonymous factory, through its commitment to manufacturing excellence, offers a diverse range of reliable and cost-effective check valves designed to meet the specific requirements of different applications. With exceptional customer service and a dedication to continuous improvement, this factory has cemented its position as a trusted supplier in the valve industry.

Understanding the Functionality of Screw Pumps: A Comprehensive Guide

In the world of fluid transfer, screw pumps have been a staple for their excellent efficiency and ability to handle viscous fluids. In simple terms, a screw pump works by utilizing two or more screws, rotating in opposite directions, to move fluids by creating suction as the screws turn. The principle of operation of a screw pump is straightforward, yet highly effective, making it an essential tool for many industries.One company that has been at the forefront of the screw pump industry for several years is a leading global brand. This company's focus on research and development has led to significant advancements in screw pump technology, making their products more reliable, durable, and efficient. With a wide range of pumps available in different sizes and for various applications, this brand caters to clients across diverse industries, including oil and gas, food and beverage, pharmaceuticals, and wastewater treatment.So, how does a screw pump work? A screw pump is made up of a screw spindle, a screw housing, and a number of flanges. The spindle is made up of two or more helical screws that rotate in the opposite direction. The screws are tightly fitted inside the housing, leaving a narrow chamber where the fluid is pumped. As the screws spin, they create a vacuum in the chamber, pulling the fluid from the inlet through the screw thread and pushing it out through the outlet. The screw pump's efficiency is based on the screws' geometry, which allows it to handle fluids of varying viscosities with minimal wear and tear.One of the most significant advantages of a screw pump is its versatility in handling delicate fluids. Unlike other pump types, screw pumps have a gentle way of handling the fluid, which means no shearing or foaming occurs during the pumping process. This feature makes it an ideal choice for food and beverage industries, where preserving the quality of the product is critical.Another benefit of screw pumps is their ability to handle high-viscosity fluids easily. The geometry of the screw pump allows it to move thick fluids with ease without clogging the system. This feature makes it an ideal choice for industries like oil and gas, where pumping thick crude oil is a standard operation. Additionally, screw pumps are known for their low energy consumption and high-pressure capabilities, making them a cost-effective and reliable choice for applications where consistent flow rates are required.Despite the screw pump's many strengths, maintenance is essential to ensure the pump's long-term operational efficiency. Regular cleaning of the pump's interior, especially the screws, is necessary to prevent clogging and ensure it operates correctly. Additionally, the pump's seal should be checked regularly to ensure no leaks occur, resulting in product loss or pump failure.In conclusion, screw pumps are essential tools in the world of fluid transfer. With their gentle handling of fluids, ability to handle high-viscosity fluids, and low energy consumption, screw pumps have become a go-to choice for many industries globally. The focus on research and development from companies like the leading global brand has led to significant advancements in screw pump technology. This creates ever more efficient, reliable, and affordable pumping solutions across the globe. Regular maintenance is crucial to ensure the pump's efficiency and longevity. However, with their many advantages, screw pumps will continue to play a vital role in many industries for the foreseeable future.