Efficient Single-Screw Pump: A Reliable Solution for Fluid Transfer

By:Admin

Established in 1998, our company has been a leading manufacturer in the field of fluid transfer equipment. We specialize in creating high-quality pumps and systems for various industries including oil and gas, chemical, food and beverage, and pharmaceutical. Our commitment to innovation and customer satisfaction has helped us build a strong reputation in the market. With a focus on reliability, efficiency, and durability, we continue to develop new technologies and solutions to meet the ever-changing needs of our clients.

[News Content]

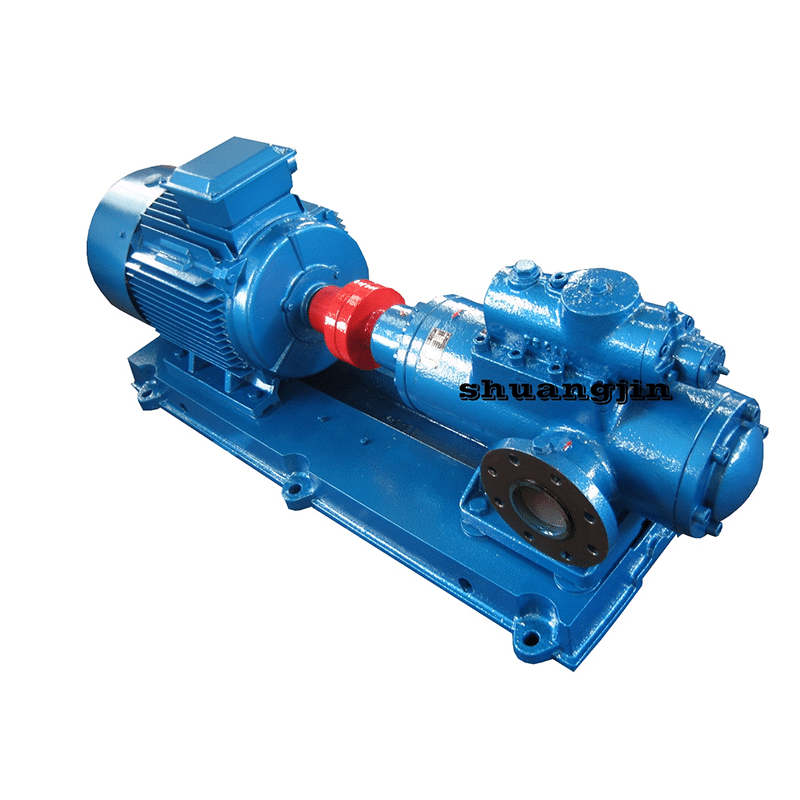

The single-screw-pump has been a game-changer in the fluid transfer industry, offering exceptional performance and reliability for various applications. Known for its ability to handle highly viscous fluids, abrasive materials, and delicate products with ease, this pump has become a popular choice among many industries. With its unique design and advanced technology, it has set a new standard for fluid transfer equipment.

One of the key features of the single-screw-pump is its ability to provide a steady and consistent flow rate, making it suitable for applications that require precise fluid handling. The pump's simple yet robust design allows for easy maintenance and minimal downtime, reducing the overall operational costs for our clients. Its versatility and efficiency make it an ideal solution for a wide range of pumping requirements.

With the increasing demand for reliable and efficient fluid transfer equipment, our company has been at the forefront of providing innovative solutions to meet the industry's needs. The single-screw-pump is a testament to our commitment to delivering high-performance products that exceed our customers' expectations. Its success in the market is a result of our relentless dedication to quality and continuous improvement.

In addition to its exceptional performance, the single-screw-pump also offers environmental benefits, such as reduced energy consumption and lower emissions. This aligns with our company's mission to develop sustainable and eco-friendly solutions that contribute to a greener future. By investing in advanced technology and engineering expertise, we aim to deliver products that not only meet the industry standards but also promote environmental responsibility.

Furthermore, our company provides comprehensive support and services to ensure the seamless integration of the single-screw-pump into our clients' operations. From initial consultation to installation, training, and ongoing maintenance, we strive to deliver a complete solution that meets the specific needs of each customer. Our team of experienced engineers and technicians are dedicated to providing unparalleled support and guidance, establishing long-term partnerships with our clients.

As the market continues to evolve, our company remains committed to staying ahead of the curve by developing new and innovative products that address the evolving needs of our customers. The single-screw-pump is a prime example of our ability to anticipate industry trends and deliver cutting-edge solutions that drive efficiency and productivity. With a focus on continuous research and development, we aim to set new benchmarks in the fluid transfer industry and maintain our position as a leader in the market.

In conclusion, the single-screw-pump has made a significant impact in the fluid transfer industry, offering unmatched performance, reliability, and efficiency. With our dedication to quality and innovation, our company continues to drive the industry forward and set new standards for fluid transfer equipment. As we look toward the future, we remain committed to developing advanced solutions that empower our customers to succeed in their respective operations.

Company News & Blog

Top 5 Benefits of Heat Pump HVAC Systems You Need to Know

heat pump HVAC systems are gaining popularity in the market due to their energy-efficient and cost-effective nature. These systems are not only environmentally friendly but also provide an excellent solution for heating and cooling needs for residential and commercial spaces.One of the leading companies in the HVAC industry, ***(company name)***, has been at the forefront of the development and installation of heat pump systems. With a strong focus on innovation and sustainability, they have been able to provide cutting-edge solutions to their customers while reducing their carbon footprint.The company has established a reputation for delivering high-quality products and exceptional service to its clients. Their team of experienced technicians and engineers are dedicated to designing and installing HVAC systems that are tailored to the specific needs of each customer. With a commitment to staying ahead of the curve in terms of technology and industry standards, ***company name*** has become a trusted name in the HVAC market.One of the key advantages of heat pump HVAC systems is their ability to provide both heating and cooling, making them a versatile choice for any building. They work by transferring heat from one area to another, rather than generating heat directly, making them highly energy-efficient. This can result in significant cost savings for the long-term operation of the system.In addition to their energy efficiency, heat pump HVAC systems also have a lower environmental impact compared to traditional heating and cooling systems. By using electricity to move heat rather than generate it, these systems can significantly reduce greenhouse gas emissions and contribute to a greener and more sustainable environment.***company name*** has been at the forefront of promoting the benefits of heat pump HVAC systems and has been actively involved in educating the public about their advantages. They have organized workshops and seminars to raise awareness about the environmental benefits of these systems and have worked with local authorities to promote and incentivize the installation of heat pumps in buildings.Moreover, ***company name*** has also been actively involved in research and development to further improve the efficiency and performance of heat pump HVAC systems. Through collaborations with leading institutions and industry partners, they have been able to introduce innovative technologies and features that have set new standards in the HVAC market.As a result of their dedication to excellence and innovation, ***company name*** has seen a significant increase in demand for their heat pump HVAC systems. Customers have been drawn to the environmental and cost-saving benefits of these systems, and have been impressed with the expertise and professionalism of the ***company name*** team from initial consultation to installation and maintenance.With the growing focus on sustainability and energy efficiency, heat pump HVAC systems are set to play a crucial role in the future of heating and cooling solutions. And as a leading player in the industry, ***company name*** is well-positioned to continue its success and further expand its reach in providing top-of-the-line heat pump HVAC systems to its customers.In conclusion, heat pump HVAC systems are a game-changer in the industry, providing an efficient, cost-effective, and environmentally friendly solution for heating and cooling needs. And ***company name***, with its commitment to innovation and sustainability, has proven to be a leader in delivering high-quality heat pump HVAC systems to its customers. With the ever-increasing demand for energy-efficient solutions, the future looks bright for both heat pump systems and ***company name***.

Top Check Valve for Well Pump: A Comprehensive Guide

Check Valve For Well Pump Ensures Reliable and Efficient Water Flow{company name} is proud to announce the release of their high-quality check valve for well pumps, designed to enhance the performance and longevity of well water systems. With over [number] years of experience in manufacturing pump components, {company name} has built a reputation for delivering reliable and innovative solutions to meet the needs of the water industry. The new check valve is the latest addition to their product line, offering superior functionality and durability for well pump systems.The check valve plays a crucial role in maintaining the integrity of well water systems by preventing backflow and ensuring a consistent flow of water. {company name}'s check valve is designed with precision engineering and premium materials to provide reliable protection against water hammer, backflow, and other potential issues that can occur in well pump systems.One of the key features of {company name}'s check valve is its durable construction. Made from high-quality materials, the check valve is built to withstand the harsh conditions often found in well water systems. Its robust design ensures long-term performance and minimal maintenance, reducing the risk of downtime and costly repairs for well owners.In addition to its durability, the check valve is also designed for easy installation and compatibility with a wide range of well pump systems. {company name} understands the importance of convenience for their customers and has engineered the check valve to be user-friendly and versatile, allowing for seamless integration into existing well pump setups.Furthermore, the check valve is engineered for efficient water flow, helping to optimize the performance of well pump systems. By reducing the risk of backflow and water hammer, the check valve contributes to smoother water flow and more consistent water pressure, enhancing the overall efficiency of well water systems.{company name} prides itself on its commitment to product excellence and customer satisfaction. As part of their dedication to quality, the check valve for well pumps has undergone rigorous testing and quality control measures to ensure that it meets the highest standards for performance and reliability. Customers can have confidence in {company name}'s products, knowing that they are backed by extensive research, development, and testing processes.The release of the check valve for well pumps reflects {company name}'s ongoing commitment to innovation and technological advancement in the water industry. By continuously investing in research and development, {company name} strives to stay at the forefront of the market, offering cutting-edge solutions that address the evolving needs of well owners and water system operators.In addition to the check valve, {company name} offers a comprehensive range of pump components and accessories, catering to a diverse array of applications within the water industry. With a focus on quality, reliability, and performance, {company name} has established itself as a trusted provider of pump solutions, earning the trust and loyalty of customers worldwide.As the demand for efficient and reliable well pump systems continues to grow, {company name} remains at the forefront of delivering innovative solutions that empower well owners to maintain and optimize their water systems. The release of the check valve for well pumps underscores {company name}'s dedication to providing essential components that contribute to the long-term sustainability and performance of well water systems.For more information about {company name}'s check valve for well pumps or to explore their comprehensive range of pump components and accessories, please visit their official website or contact their customer service team. With a commitment to excellence and a passion for innovation, {company name} is poised to continue driving advancements in the water industry, supporting the needs of well owners and water system operators globally.

Common Disadvantages of Screw Pumps You Should Know

Screw pumps are widely used in various industries for pumping fluids such as water, oil, and chemicals. However, despite their effectiveness in many applications, they also come with certain disadvantages that can impact their efficiency and performance.One of the main disadvantages of screw pumps is their high initial cost. The initial investment required to purchase and install a screw pump can be significant, especially for large industrial applications. This can be a barrier for many companies, particularly small businesses or startups with limited capital.In addition to the high initial cost, screw pumps also require regular maintenance to keep them running smoothly. The rotating parts and seals in a screw pump can wear out over time, leading to potential leaks and inefficiencies. This means that companies using screw pumps need to allocate resources for ongoing maintenance and repair, adding to the overall cost of ownership.Another disadvantage of screw pumps is their sensitivity to the type of fluid being pumped. Some screw pumps may not be suitable for pumping certain types of abrasive or corrosive fluids, as this can lead to increased wear and tear on the pump components. This limits the versatility of screw pumps and may require companies to invest in alternative pumping solutions for different types of fluids.Furthermore, screw pumps can be less energy-efficient compared to other types of pumps. The rotating action of the screws can create friction and resistance, which in turn requires more power to operate the pump. This can lead to higher energy costs for companies using screw pumps, making them less economical in the long run.Despite these disadvantages, many companies still choose to use screw pumps for their applications due to their reliability and ability to handle high-viscosity fluids. One such company that has been a leader in the screw pump industry is {}.{} has been a trusted manufacturer and supplier of screw pumps for over 50 years. Their extensive experience and expertise in the industry have allowed them to develop a wide range of screw pumps suitable for various applications, from wastewater treatment to oil and gas production.With a focus on innovation and continuous improvement, {} has been able to address some of the disadvantages of screw pumps through their advanced pump designs and technology. They have incorporated features to enhance the durability and reliability of their screw pumps, reducing the need for frequent maintenance and repairs.Furthermore, {} has also invested in research and development to improve the energy efficiency of their screw pumps. Their cutting-edge designs and materials have helped to minimize the power consumption of their pumps, making them a more economical choice for companies looking to reduce their operating costs.In addition to their technical advancements, {} offers comprehensive support and services to their customers, including maintenance, repair, and spare parts. This ensures that companies can rely on their screw pumps to operate at peak performance with minimal downtime.While screw pumps may have certain disadvantages, companies like {} are working tirelessly to overcome these challenges and provide their customers with efficient and reliable pumping solutions. As the industry continues to evolve, it is likely that screw pumps will continue to play a vital role in various applications, supported by ongoing innovations and improvements from leading manufacturers like {}.

High-performance Positive Displacement Oil Pump: A Guide to Efficient Oil Pumping

Positive Displacement Oil Pump Revolutionizes Industrial Pumping TechnologyIn the world of industrial pumping, efficiency and reliability are crucial factors for success. This is where the positive displacement oil pump from [Company Name] comes into play, bringing a whole new level of performance and capability to the industry. With its innovative design and cutting-edge technology, this pump has quickly become the go-to solution for companies looking to optimize their pumping operations.[Company Name] has been a leader in the pumping industry for over 30 years, providing high-quality and reliable pumping solutions to a wide range of industries. With a strong focus on innovation and continuous improvement, the company has developed a reputation for delivering top-of-the-line products that meet the unique needs of its customers.The positive displacement oil pump is the latest addition to [Company Name]'s extensive product lineup, and it has quickly made a name for itself as a game-changer in the industry. What sets this pump apart from traditional pumping solutions is its innovative positive displacement technology, which allows for a more precise and consistent flow of oil.This technology is based on the principle that the pump displaces a specific amount of fluid with each revolution, ensuring a constant and reliable flow of oil. This is in stark contrast to traditional pumps, which rely on centrifugal force to move the fluid, leading to fluctuations in flow and efficiency.The positive displacement oil pump from [Company Name] is designed to offer superior performance and efficiency, making it an ideal choice for a wide range of industrial applications. Whether it's in the automotive, manufacturing, or oil and gas industries, this pump has proven to be a reliable and cost-effective solution for companies looking to optimize their pumping operations.One of the key advantages of this pump is its ability to handle a wide range of viscosities, making it suitable for pumping a variety of oils and lubricants. This versatility makes it a valuable investment for companies that deal with different types of fluids in their operations.Another major benefit of the positive displacement oil pump is its durability and low maintenance requirements. Thanks to its robust design and high-quality materials, this pump is built to withstand the rigors of industrial use, minimizing downtime and reducing the need for frequent repairs and maintenance.Furthermore, the pump's compact and efficient design makes it easy to install and integrate into existing pumping systems, providing a seamless and hassle-free retrofit solution for companies looking to upgrade their operations.[Company Name] takes pride in its commitment to providing exceptional customer service and support. This extends to the positive displacement oil pump, with the company offering comprehensive maintenance and technical support to ensure that customers get the most out of their investment.The positive displacement oil pump from [Company Name] has quickly gained recognition for its performance and reliability, earning the trust of customers across the globe. Its innovative design and advanced technology have set a new standard for industrial pumping solutions, providing companies with a valuable tool to optimize their operations and improve efficiency.As the industry continues to evolve, [Company Name] remains at the forefront of innovation, constantly pushing the boundaries of what is possible in industrial pumping technology. With its positive displacement oil pump, the company has once again demonstrated its commitment to delivering cutting-edge solutions that meet the evolving needs of its customers.In conclusion, the positive displacement oil pump from [Company Name] is a true game-changer in the world of industrial pumping. With its innovative design, superior performance, and unmatched reliability, this pump has set a new standard for what companies can expect from their pumping solutions. As the industry continues to evolve, [Company Name] remains dedicated to providing top-of-the-line products that empower companies to optimize their operations and achieve new levels of success.

Powerful Mini Screw Pump for various industrial applications

Mini Screw Pump Revolutionizes Small-Scale Industrial PumpingIn today's rapidly advancing industrial landscape, the demand for efficient and reliable pumping solutions continues to grow. Whether it's for processing, transfer, or circulation of liquids, industries require pumps that can meet their specific needs with precision and ease. As a response to this demand, [Company Name] has introduced its latest innovation in pumping technology - the revolutionary Mini Screw Pump.The Mini Screw Pump is a game-changer in the realm of small-scale industrial pumping. With its compact size and powerful performance, it opens up new possibilities for industries that require a reliable and efficient pumping solution in a limited space. The pump is designed to handle a wide range of fluids, including viscous liquids, slurries, and non-Newtonian fluids, making it versatile for various industrial applications.One of the key features of the Mini Screw Pump is its innovative screw design, which allows for gentle pumping action and minimal pulsation. This not only ensures a steady flow of the pumped liquid but also reduces the risk of shearing or foaming, particularly important for delicate or shear-sensitive fluids. Additionally, the pump's high precision and accuracy make it suitable for metering and dosing applications, where consistency and reliability are paramount.The compact size of the Mini Screw Pump is another factor that sets it apart from traditional pumping solutions. Measuring just a fraction of the size of conventional pumps, this innovation is ideal for installations where space is limited, such as in OEM equipment, skid-mounted systems, and mobile units. Despite its small footprint, the pump delivers exceptional performance, thanks to its robust construction and state-of-the-art technology.Furthermore, the Mini Screw Pump is designed with ease of maintenance in mind. The pump's simple and accessible design allows for quick disassembly and reassembly, reducing downtime and maintenance costs. This, coupled with its durable components, ensures a long service life and reliable operation, contributing to a lower total cost of ownership for the end-user.[Company Name] has a longstanding reputation for delivering high-quality pumping solutions to a wide range of industries. With a focus on innovation, reliability, and customer satisfaction, the company has been at the forefront of pumping technology for decades. The Mini Screw Pump is a testament to this commitment, representing the latest advancement in the company's portfolio of pumping solutions."We are thrilled to introduce the Mini Screw Pump to the market," says [Spokesperson Name], [Title] at [Company Name]. "This innovation is the result of extensive research, development, and engineering expertise, aimed at addressing the evolving needs of our customers. We believe that the Mini Screw Pump will have a transformative impact on small-scale industrial pumping, offering unmatched performance, versatility, and efficiency."The Mini Screw Pump is set to disrupt the small-scale industrial pumping landscape, offering a compact yet powerful solution for a wide range of applications. With its gentle pumping action, precision, and reliability, this innovation is poised to become the go-to choice for industries that require efficient and dependable pumping in a limited space.As industries continue to evolve and adapt to new challenges, the need for innovative pumping solutions will only continue to grow. With the introduction of the Mini Screw Pump, [Company Name] has once again demonstrated its commitment to meeting these needs and pushing the boundaries of pumping technology. This latest innovation is set to redefine small-scale industrial pumping, setting new standards for performance, reliability, and efficiency.

The Importance of Lube Oil Pump Function for Machinery

The function of a lube oil pump is vital to the smooth operation of various machinery and equipment, delivering lubrication to prevent wear and tear on moving parts. Today, we are taking a closer look at the importance of lube oil pumps in the industry, and how {} has become a leading provider in this critical area.{} is a well-established company that specializes in the design and manufacture of lube oil pumps for a wide range of industrial applications. With a strong commitment to quality and reliability, they have built a solid reputation as a trusted supplier in the industry. The company's lube oil pumps are known for their superior performance, efficiency, and durability, making them the go-to choice for many businesses and organizations.The function of a lube oil pump is to deliver lubricant at the required pressure to various parts of the machinery, such as bearings, gears, and other moving components. This helps to reduce friction, heat, and wear, thereby extending the lifespan of the equipment and ensuring smooth, efficient operation. Without a properly functioning lube oil pump, machinery can suffer from increased wear and potential breakdowns, leading to costly repairs and downtime.One of the key features of {}'s lube oil pumps is their ability to operate reliably in demanding environments and under high pressure conditions. This ensures that the lubrication system is able to meet the needs of the machinery, providing consistent and effective lubrication to all critical components. In addition, the pumps are designed to be highly efficient, helping to minimize energy consumption and reduce operating costs for businesses.With a strong focus on innovation and continuous improvement, {} is constantly working to enhance the performance of their lube oil pumps. They invest heavily in research and development, utilizing the latest technologies and engineering expertise to design pumps that meet the evolving needs of the industry. This dedication to innovation has allowed {} to stay ahead of the competition and maintain their position as a leading provider of lube oil pumps.In addition to their technical expertise, {} is also known for their exceptional customer service and support. They work closely with their clients to understand their specific requirements and provide customized solutions to meet their needs. Whether it's a standard pump or a customized solution, {} is committed to delivering high-quality products that exceed customer expectations.The importance of a reliable lube oil pump cannot be overstated in the industrial sector. Machinery and equipment are crucial assets for businesses, and proper lubrication is essential to keeping them running smoothly and efficiently. With {}'s lube oil pumps, businesses can have peace of mind knowing that their equipment is receiving the lubrication it needs to operate at its best.As technology continues to advance and industries become more demanding, the need for reliable and high-performance lube oil pumps will only continue to grow. {} is well-positioned to meet this demand, thanks to their industry-leading expertise, commitment to quality, and dedication to customer satisfaction. With {}'s lube oil pumps, businesses can be confident in the reliability and performance of their machinery, helping them to operate more efficiently and effectively.In conclusion, lube oil pumps play a critical role in the smooth operation of machinery and equipment in various industries. {} has established itself as a leading provider in this important area, delivering high-quality pumps that are known for their reliability, performance, and efficiency. With a strong focus on innovation and customer satisfaction, {} is well-positioned to continue meeting the evolving needs of the industry and providing businesses with the lubrication solutions they need to succeed.

What is a Screw Pump and How Does it Work?

Screw pumps are a type of positive displacement pump that is widely used in various industries for pumping high viscosity fluids, including oil, sludge, grease, and other similar substances. They are known for their ability to handle a wide range of viscosities and are often used in applications where other types of pumps may struggle to perform efficiently.One of the leading manufacturers of screw pumps is {}. With a history dating back to over a century, {} has established itself as a pioneer in the field of fluid handling equipment. The company has a strong reputation for producing high-quality, reliable screw pumps that are used in a wide range of industries, including oil and gas, chemical processing, food and beverage, and wastewater treatment.Screw pumps work on the principle of two or more intermeshing screws that rotate in a closed chamber, thereby creating a pumping action. As the screws rotate, they trap fluid between the threads and the wall of the pump, pushing the fluid along the length of the screws and out through the discharge port. This results in a smooth, pulsation-free flow of the pumped fluid, making screw pumps ideal for applications where a constant flow rate is required.The design of screw pumps allows them to handle high viscosity fluids with ease, making them suitable for handling heavy oils, sludges, and other challenging materials. In addition, they are known for their ability to handle abrasive and corrosive fluids, making them a popular choice for demanding industrial applications.Furthermore, screw pumps are known for their high efficiency and low maintenance requirements. Their simple design and minimal moving parts make them easy to maintain, contributing to their long service life and reliability. This is particularly important in industries where downtime can be costly, making screw pumps a cost-effective choice for many businesses.With a comprehensive range of screw pumps available, {} is able to cater to the diverse needs of its customers across various industries. Its pumps are designed to meet the specific requirements of different applications, ensuring that customers can find a suitable solution for their fluid handling needs.In addition to manufacturing screw pumps, {} also offers a range of services to support its customers, including installation, maintenance, and repairs. The company's team of experienced engineers and technicians are on hand to provide expert advice and assistance, helping customers to get the most out of their screw pump systems.As a global leader in fluid handling technology, {} has a strong commitment to innovation and continuous improvement. The company invests heavily in research and development, constantly seeking ways to enhance the performance and reliability of its products. This dedication to innovation has allowed {} to stay ahead of the competition and maintain its position as a trusted provider of screw pumps and other fluid handling equipment.In conclusion, screw pumps are a versatile and reliable solution for handling high viscosity fluids in various industrial applications. With {}'s long-standing expertise and commitment to excellence, customers can trust in the quality and performance of its screw pumps to meet their fluid handling needs. Whether it's pumping oil, sludge, or other challenging materials, {}'s screw pumps are a top choice for businesses looking for efficient and reliable fluid handling solutions.

High-performance Twin Screw Pump for Industrial Applications

Today, {company name} introduces its latest innovation in the field of industrial pumping - the new Twin Screw Pump. This revolutionary pumping technology is set to offer a new level of efficiency and reliability for a wide range of industrial applications, setting a new standard in the industry.The Twin Screw Pump is designed to handle a variety of viscous, abrasive, or shear-sensitive fluids, making it an ideal pumping solution for industries such as food and beverage, pharmaceutical, chemical, and cosmetic. The pump’s twin screw design ensures gentle handling of the product, making it suitable for delicate materials that require careful handling.One of the key features of the Twin Screw Pump is its ability to maintain a consistent flow rate and pressure, even when dealing with challenging materials. This level of consistency is crucial for industries that rely on precise and reliable pumping performance to ensure product quality and process efficiency.In addition to its high performance, the Twin Screw Pump is also designed for ease of maintenance and cleaning. Its simple design and minimal moving parts make it easy to disassemble and clean, reducing downtime and ensuring maximum productivity.The {company name} Twin Screw Pump is also equipped with advanced features to enhance its reliability and longevity. Its robust construction and high-quality materials ensure it can withstand the demands of the toughest industrial environments, providing years of reliable service.Furthermore, this pump is designed for versatility, with the ability to handle a wide range of viscosities and temperatures. This makes it a versatile solution for a variety of applications, providing a single pumping solution for multiple needs within an industrial facility.With its innovative design and advanced features, the introduction of the {company name} Twin Screw Pump is set to make a significant impact in the industrial pumping market. It represents a new standard in pumping technology, offering a level of efficiency, reliability, and versatility that is unrivaled in the industry.{company name} is proud to introduce this groundbreaking pumping solution to the market, continuing its commitment to providing innovative and reliable equipment for the industrial sector. With its extensive experience and expertise in pump manufacturing, {company name} is well-positioned to deliver top-quality pumping solutions that meet the evolving needs of the industry.As industries continue to demand higher performance and more reliable equipment, the introduction of the {company name} Twin Screw Pump is a testament to {company name}'s dedication to innovation and excellence. This pump is set to provide a new level of efficiency and reliability for a wide range of industrial applications, setting a new standard in the industry.

High-Performance Pump System Innovates Water Management Solutions

Pcm Pump, a renowned global leader in providing pumping solutions, has come up with an innovative product to meet the ever-growing demands of the industry. The company has introduced a state-of-the-art pump that promises to revolutionize the pumping industry by delivering superior performance, reliability, and efficiency.Pcm Pump has been a trusted name in the pumping industry for over several decades. The company has a rich heritage of providing cutting-edge pumping solutions to a wide range of industries including oil and gas, food and beverage, mining, wastewater, and many others. With a strong focus on innovation and customer satisfaction, Pcm Pump has established itself as a market leader in the pumping industry.The latest product from Pcm Pump is a result of extensive research, development, and engineering expertise of the company. The new pump is designed to address the key challenges faced by the industry such as increasing demand for higher flow rates, improved energy efficiency, and reduced maintenance downtime. The pump features advanced technology and robust construction, making it suitable for a wide range of applications in diverse industries.One of the key highlights of the new pump is its superior performance. The pump is designed to deliver high flow rates and exceptional efficiency, making it an ideal choice for critical pumping applications. With its advanced design and engineering, the pump ensures reliable and consistent performance, even in the most demanding operating conditions. This ensures that the customers can rely on the pump for uninterrupted operations and maximum productivity.In addition to performance, the new pump also offers unmatched reliability. Pcm Pump understands the importance of reliability in critical pumping applications, and hence, the new pump is built to withstand the toughest operating conditions. The pump is constructed using high-quality materials and precision engineering, making it highly durable and dependable. This means that the customers can count on the pump to deliver consistent performance, day in and day out.Energy efficiency is another key focus area for Pcm Pump, and the new pump is designed with this in mind. The pump is equipped with advanced technology to minimize energy consumption while maximizing pumping efficiency. This not only helps in reducing operating costs but also contributes to environmental sustainability. With the new pump, customers can expect to achieve significant energy savings without compromising on performance.Furthermore, the new pump is designed for ease of maintenance, reducing downtime and operational costs for the customers. Pcm Pump has incorporated innovative features in the pump to facilitate easy maintenance and servicing, ensuring that the pump remains in top condition and delivers optimal performance throughout its service life.The introduction of this innovative pump further cements Pcm Pump's position as a leading provider of pumping solutions. The company's commitment to innovation, quality, and customer satisfaction is evident in the new product, which is set to raise the bar in the pumping industry.With its superior performance, reliability, efficiency, and ease of maintenance, the new pump from Pcm Pump is poised to make a significant impact in the industry. The company is confident that the new product will meet the evolving needs of the industry and set new benchmarks for pumping solutions.As Pcm Pump continues to push the boundaries of pumping technology, the new pump is a testament to the company's dedication to excellence and innovation. With its rich legacy and expertise in the pumping industry, Pcm Pump is well positioned to lead the way in delivering advanced pumping solutions to its customers around the world.

Innovative Screw Pump Design for Efficient Fluid Transfer

Screw Pump Design Revolutionizes Industrial Pumping TechnologyIn the world of industrial pumping technology, one company has been making waves with its innovative and efficient screw pump design. The company, known for its cutting-edge engineering solutions, has recently introduced a new screw pump that promises to revolutionize the industry.The new screw pump design incorporates state-of-the-art technology, making it more efficient and reliable than traditional pumping systems. The pump's unique design features a screw-shaped rotor that rotates inside a stator, creating a continuous flow of fluid. This design not only increases the pump's overall efficiency but also reduces wear and tear, ultimately leading to lower maintenance costs for industrial facilities.By utilizing advanced materials and precision manufacturing techniques, the company has been able to achieve a level of performance with its screw pump that was previously unattainable. With improved efficiency and reduced energy consumption, industrial facilities can expect to see a significant reduction in their operating costs.Furthermore, the company's dedication to excellence is evident in the attention to detail and quality control measures that go into the production of each screw pump. This commitment to quality has earned the company a sterling reputation within the industry, and its products are known for their reliability and durability.In addition to the new screw pump design, the company also offers a wide range of pumping solutions tailored to meet the specific needs of various industries. Whether it's handling abrasive materials, high-pressure applications, or corrosive fluids, the company's engineering team works closely with clients to develop customized pumping solutions that deliver outstanding performance.One of the key advantages of partnering with the company is its extensive experience in the field of industrial pumping. With a team of highly skilled engineers and technicians, the company is able to provide expert guidance and support throughout the entire process, from initial design to installation and maintenance.Furthermore, the company understands the importance of sustainability and environmental responsibility in today's industrial landscape. As a result, its pumping solutions are designed with energy efficiency in mind, helping clients reduce their carbon footprint and achieve their sustainability goals.With a global presence and a track record of success, the company has established itself as a leader in the industrial pumping industry. From oil and gas to chemical processing, its pumping solutions are relied upon by some of the most demanding industrial operations around the world.Looking ahead, the company remains committed to ongoing research and development, continuously striving to improve its products and stay ahead of the curve. By investing in innovation and cutting-edge technology, the company is well-positioned to continue setting new standards for industrial pumping solutions.In conclusion, the introduction of the new screw pump design by the company represents a significant milestone in the world of industrial pumping technology. With its unparalleled efficiency, reliability, and commitment to quality, the company is poised to make a lasting impact on the industry for years to come. As industrial facilities continue to seek more efficient and sustainable pumping solutions, the company's innovative approach is sure to be met with great enthusiasm.