Energy-Efficient Heating Pump System: A Sustainable Solution for Home Heating

By:Admin

In a world where energy consumption is at an all-time high, finding sustainable and efficient solutions for heating and cooling is more important than ever. With this in mind, we are proud to introduce our latest innovation in the realm of HVAC technology - the Heating Pump System (HPS) from [company name].

The HPS is a state-of-the-art heating and cooling solution that is designed to optimize energy efficiency and minimize environmental impact. It combines cutting-edge technology with a commitment to sustainability, making it an ideal choice for both residential and commercial applications.

At the heart of the HPS is a high-efficiency heat pump that is capable of providing both heating and cooling functions. This innovative system utilizes advanced compressor technology to transfer heat in and out of the building, resulting in significant energy savings compared to traditional HVAC systems. In fact, the HPS can achieve energy savings of up to 30% or more, making it a cost-effective and environmentally friendly option for any building.

In addition to its impressive energy efficiency, the HPS also offers a number of other benefits. One of the key advantages of this system is its ability to provide consistent and reliable heating and cooling, regardless of the external weather conditions. This is made possible by the system's advanced control algorithms, which are able to adapt to changing environmental factors in real-time.

Another noteworthy feature of the HPS is its versatility and scalability. Whether it is a small residential property or a large commercial building, the HPS can be customized to meet the specific heating and cooling needs of any space. This makes it an ideal solution for a wide range of applications, from single-family homes to office buildings and beyond.

Of course, no innovative product is complete without a commitment to quality and reliability. This is why the HPS from [company name] is built to the highest standards of craftsmanship and durability. Each component of the system is rigorously tested and inspected to ensure that it meets our strict quality control guidelines. As a result, customers can trust that they are investing in a heating and cooling solution that is built to last and deliver exceptional performance for years to come.

The introduction of the HPS represents a significant milestone for [company name]. With our unwavering commitment to innovation and sustainability, we are proud to offer this groundbreaking technology to our customers. This system not only represents a new era in energy efficiency, but it also underscores our dedication to providing cutting-edge solutions that prioritize environmental responsibility.

As we look to the future, we are excited to see the positive impact that the HPS will have on the heating and cooling industry. By providing a more sustainable and efficient alternative to traditional HVAC systems, we believe that the HPS has the potential to revolutionize the way we think about energy consumption in buildings.

In conclusion, the introduction of the Heating Pump System from [company name] marks a major advancement in the field of HVAC technology. With its unparalleled energy efficiency, reliability, and versatility, the HPS represents the future of sustainable heating and cooling solutions. We are confident that this innovative system will have a lasting and positive impact on the industry, and we look forward to the opportunity to bring its benefits to our customers.

Company News & Blog

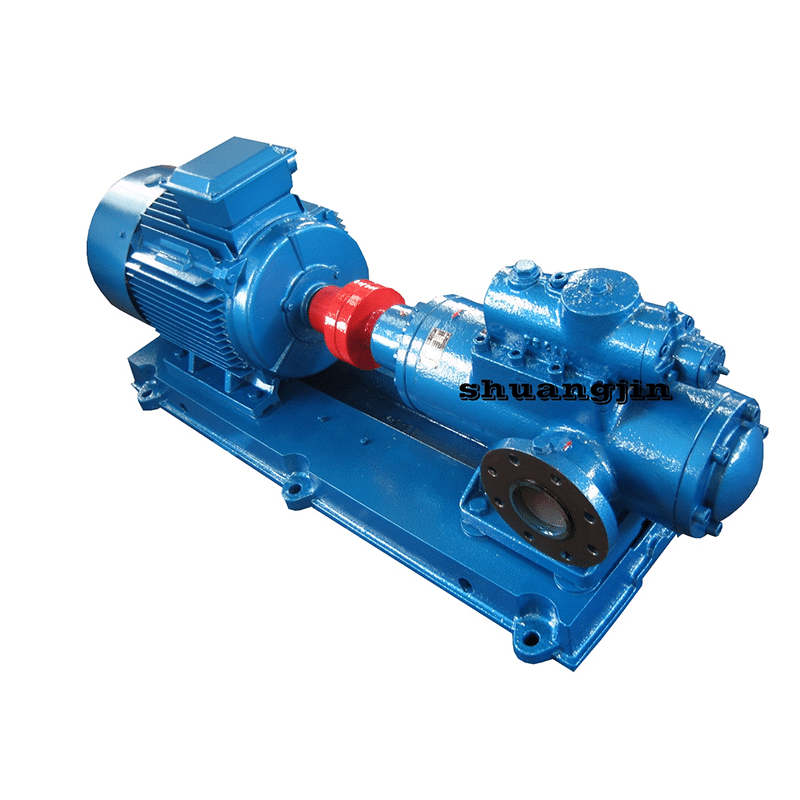

Efficient and Reliable Three-Screw Pump: A Comprehensive Guide

Title: Leading Pump Manufacturer Launches Next-Generation 3G Series Three-Screw PumpIntroduction:Houston, TX - In line with its commitment to innovation and delivering high-quality pumping solutions, a renowned pump manufacturer (company name withheld) has recently unveiled its latest addition to the market - the cutting-edge 3G Series Three-Screw Pump. This new product combines advanced technology and superior design features to provide exceptional performance across various industries. With a reputation built on excellence, the company aims to revolutionize the pumping industry once again.Body:1. Industry-leading Efficiency and Performance:The 3G Series Three-Screw Pump offers outstanding efficiency and performance, distinguishing it from its predecessors. Equipped with state-of-the-art technology, this pump delivers greater flow capacity and increased pressure capabilities. Its design ensures minimal energy consumption while maintaining maximum operational efficiency, making it the ideal choice for companies seeking to reduce costs and enhance productivity.2. Enhanced Reliability and Durability:One of the key advantages of the 3G Series Three-Screw Pump is its unmatched reliability and durability. Designed with precision engineering, this pump is built to withstand harsh operating conditions, including high temperatures and high-viscosity fluids. Its robust construction and specially formulated materials greatly contribute to its longevity, making it a cost-effective investment for businesses across various sectors.3. Versatile Applications and Adaptability:The 3G Series Three-Screw Pump caters to a wide range of applications, making it an incredibly versatile choice for industries such as chemical processing, oil and gas, power generation, marine, and wastewater treatment, among others. Its adaptability allows seamless integration into existing systems, ensuring a smooth transition and minimal disruption to operations. Furthermore, this pump can handle various fluids, from clean liquids to highly viscous and abrasive substances, without compromising its performance.4. Advanced Features and Intelligent Design:With a focus on advancing pumping technology, the 3G Series Three-Screw Pump incorporates several intelligent features. It utilizes state-of-the-art computational fluid dynamics (CFD) simulations to optimize flow paths, resulting in reduced noise and vibration levels. The innovative bearing design, combined with an advanced seal system, facilitates easy maintenance, minimizing downtime and associated costs. Additionally, the pump's compact footprint and modularity ensure easy installation, saving valuable space in crowded industrial environments.5. Commitment to Sustainability:Emphasizing its commitment to sustainability, the pump manufacturer has incorporated eco-friendly features into the 3G Series Three-Screw Pump. The pump's improved energy efficiency significantly reduces carbon emissions and overall environmental impact. It also utilizes recyclable materials in its construction, contributing to a circular economy. By choosing this pump, businesses can align their operations with global sustainability goals while maximizing their operational efficiency.Conclusion:The introduction of the 3G Series Three-Screw Pump by a renowned pump manufacturer marks a significant milestone in the pumping industry. With its advanced features, exceptional performance, and commitment to sustainability, this pump is poised to redefine pumping solutions across various sectors. By choosing this innovative product, businesses can enhance their operations, reduce costs, and contribute to a greener and more efficient future. As the demand for high-performance pumps continues to grow, the 3G Series Three-Screw Pump is set to become an industry benchmark for reliability, efficiency, and durability.

Discover Top Oil Gear Pump Distributors for Your Machinery Needs" could be rewritten as "Find Reliable Distributors for Your Oil Gear Pump Machinery

Oil Gear Pump Distributors Expands its Reach in the Global MarketOil Gear Pump Distributors, a leading supplier of high-quality oil gear pumps, is proud to announce its expansion into new markets. With a commitment to providing reliable and efficient solutions, the company aims to meet the increasing demand for oil gear pumps worldwide.Established in 2005, Oil Gear Pump Distributors has quickly become a trusted name in the industry. They specialize in manufacturing and distributing oil gear pumps, ensuring that customers receive only the best products. With a focus on innovation, the company continuously invests in research and development to enhance the performance of their pumps.The company's success can be attributed to its dedicated team of professionals who understand the unique requirements of various industries. Through their expertise, Oil Gear Pump Distributors has been able to develop a wide range of pumps suitable for applications in the automotive, oil and gas, power generation, and other industrial sectors.Recognizing the importance of quality control, Oil Gear Pump Distributors adheres to rigorous standards at every stage of production. The pumps undergo thorough testing to guarantee their reliability and efficiency. By using state-of-the-art manufacturing processes and high-quality materials, the company ensures that their pumps are built to withstand even the most demanding conditions.As part of their expansion plan, Oil Gear Pump Distributors has established partnerships with key distributors worldwide. These partnerships allow the company to tap into new markets and offer their products on a global scale. By working closely with these distributors, the company can better understand local preferences and requirements, ensuring that their products are tailored to meet the specific needs of different regions.One of the major reasons behind the growing popularity of Oil Gear Pump Distributors' pumps is their versatility. The company offers a wide range of pump configurations, including external gear pumps, internal gear pumps, and gerotor pumps. Customers can choose from different sizes, materials, and flow rates to find the perfect pump for their application.In addition to their product range, Oil Gear Pump Distributors also prides itself on its exceptional customer service. The company's dedicated support team is committed to providing timely assistance and guidance to customers. From product selection to after-sales support, they ensure that every customer receives the attention they deserve.With their expansion into new markets, Oil Gear Pump Distributors aims to become a global leader in the industry. By offering high-quality products, exceptional customer service, and a focus on innovation, they are well-positioned to meet the evolving demands of various industries worldwide.As the global demand for oil gear pumps continues to rise, Oil Gear Pump Distributors is prepared to meet the industry's needs and exceed customer expectations. With their commitment to excellence, the company is confident in its ability to provide reliable and efficient solutions for all pumping requirements.Oil Gear Pump Distributors' expansion into new markets is a testament to their dedication to growth and their commitment to becoming a global leader in the industry. By offering high-quality pump solutions and exceptional customer service, the company is poised for continued success in the ever-evolving global market.

Essential Check Valve for Well Pump: A Key Component for Smooth Pump Operation

Title: Advanced Check Valve for Well Pump Revolutionizing Water Management SystemsIntroduction:The use of reliable and efficient check valves in well pumps is crucial for the effective management of water resources. Among the leading pioneers in this domain, a renowned company has emerged with its groundbreaking check valve technology, poised to revolutionize water management systems. With stringent quality standards and a commitment to innovation, this company aims to improve the reliability and performance of well pumps, ensuring a sustainable water supply for communities around the globe.(Company Name), A Driving Force in Water Management Solutions:With years of expertise in the field, (Company Name) has garnered a reputation as a leading manufacturer of high-quality check valves and related water management solutions. From residential to industrial applications, their product range caters to the diverse needs of customers worldwide. Equipped with state-of-the-art facilities and an experienced team of engineers, the company is driven by a mission to deliver robust, sustainable, and innovative solutions to enhance water management practices.Check Valve for Well Pump: A Game-Changing Technology:The latest breakthrough from (Company Name) is their cutting-edge check valve, designed specifically for well pumps. Engineered with advanced features, this device offers unparalleled reliability, efficiency, and longevity. The check valve's unique design and construction make it highly resistant to corrosion, ensuring consistent performance even in the harshest environments. Its superior sealing capability prevents backflow, reducing the risk of water contamination and promoting healthier water resources.Key Features and Benefits:1. Durability: Constructed from high-quality materials, the check valve guarantees exceptional durability, extending the lifespan of well pumps and reducing maintenance costs.2. Corrosion Resistance: The use of corrosion-resistant materials ensures the longevity of the valve, protecting it from harmful elements and maintaining optimal performance.3. Flawless Operation: The advanced design promotes smooth and stable water flow, preventing water hammer and reducing the risk of system failures.4. Easy Installation: The valve's user-friendly design simplifies installation, minimizing downtime and ensuring hassle-free integration with existing well pump systems.5. Energy Efficiency: With its streamlined design, the check valve optimizes energy consumption by reducing unnecessary pressure fluctuations, contributing to energy savings and lower operating costs.Environmental Sustainability and Social Responsibility:Addressing the global need for sustainable water management, (Company Name) adheres to environmentally friendly practices throughout their manufacturing processes. They prioritize the use of eco-friendly materials, minimizing the impact on natural resources. Furthermore, their dedication to social responsibility extends to leveraging innovative technologies that support water conservation efforts and improving the overall well-being of communities worldwide.Partnership with Global Water Organizations:Recognizing the importance of collaboration in water resource management, (Company Name) actively partners with global water organizations to promote knowledge-sharing, research, and innovation. By actively participating in industry conferences, workshops, and seminars, they contribute to shaping the future of sustainable water management practices.Conclusion:The check valve from (Company Name) represents a significant advancement in the field of well pump technology, offering enhanced performance, durability, and sustainability. By incorporating this state-of-the-art valve into water management systems, communities can achieve improved efficiency, reduced energy consumption, and increased reliability. (Company Name)'s commitment to innovation and social responsibility is set to reshape the landscape of water management, facilitating a sustainable future for generations to come.

Discover the Latest Advancements in Pump Technology

Title: Advanced Pump Technologies Revolutionizing Industrial and Municipal Application IndustriesIntroduction:In the world of industrial and municipal applications, where efficiency, durability, and reliability are paramount, every element of the system has to be perfectly aligned to ensure seamless operations. One company that has been at the forefront of developing cutting-edge pumping solutions is Bornemann Pump (brand name removed), a global leader in pump technology. With a rich history spanning several decades, the company has been revolutionizing various industries with its advanced pump technologies. In this article, we will explore the contributions of Bornemann Pump and how it continues to enhance the performance and productivity of industrial and municipal sectors worldwide.1. A Legacy of Excellence:Bornemann Pump, with its headquarters in Germany, has emerged as a trusted name in the global pumping industry since its establishment in 1853. With over 150 years of expertise, the company has perfected the art of engineering precision pumping solutions, gaining international recognition for their exceptional quality, reliability, and longevity. Bornemann Pump's commitment to innovation has resulted in numerous patents and industry accolades, positioning them as a preferred choice among industry professionals.2. Application Diversity:The comprehensive range of Bornemann Pump's products caters to various industries, including chemical, oil and gas, food and beverage, pharmaceutical, shipbuilding, and wastewater management. From transferring aggressive fluids to handling cryogenics, Bornemann Pump's pumps are designed to meet the diverse requirements of these industries. The company's pumps ensure seamless handling of fluids, reduce downtime, and optimize energy consumption, thus enhancing overall operational efficiency.3. Twin Screw Pump Technology:One of the key innovations introduced by Bornemann Pump is the twin screw pump technology, which has revolutionized fluid transfer applications across industries. The company's twin screw pumps are capable of handling a wide range of fluid viscosities, making them ideal for transferring both low and high-viscosity liquids. This versatile pump technology ensures gentle product handling while delivering consistent and accurate flow rates.4. Hygienic Solutions for Food and Beverage Industry:Bornemann Pump's expertise in the food and beverage industry has resulted in the development of hygienic pump solutions. These pumps comply with stringent sanitary regulations and are designed to handle delicate fluids, ensuring the preservation of product quality, taste, and integrity. The company's hygienic pumps are widely used for transferring beverages, dairy products, sauces, and other food items without compromising on safety and cleanliness.5. Eco-Friendly Solutions for Wastewater Management:With the growing focus on environmental sustainability, Bornemann Pump has ventured into providing eco-friendly solutions for wastewater management. The company's progressive cavity pumps are designed to efficiently handle sewage and sludge, reducing energy consumption and minimizing environmental impact. Bornemann Pump's wastewater management solutions offer reliable performance, enhanced longevity, and reduced maintenance, making them ideal for both municipal and industrial applications.6. Continuous Research and Development:Bornemann Pump prides itself on its continued investment in research and development to meet the evolving demands of the industry. The company's dedicated team of engineers and technicians collaborate with leading scientific institutions to explore new avenues for pump technology. By incorporating state-of-the-art materials and advanced manufacturing techniques, Bornemann Pump ensures that its products remain at the forefront of innovation and deliver exceptional performance.Conclusion:Bornemann Pump's relentless pursuit of excellence has positioned the company as a frontrunner in the global pumping industry. With its advanced pump technologies and commitment to customer satisfaction, the company has successfully catered to the diverse needs of various industries, enabling seamless operations and improved productivity. As Bornemann Pump continues to innovate and refine its products, it will undoubtedly play an instrumental role in shaping the future of industrial and municipal applications worldwide.

Top 10 Efficient Pumps for the Oil and Gas Sector

Title: Advancements in Pumping Technology Revolutionize the Oil and Gas IndustryIntroduction:The oil and gas industry is witnessing a remarkable transformation with the introduction of advanced pumping technology, leading to increased efficiency and productivity. Cutting-edge pumps, such as those offered by renowned manufacturers, are revolutionizing the sector by providing innovative solutions and improved performance. This article will delve into the recent advancements in pumping technology and how these developments are reshaping the oil and gas industry.1. Importance of Pumps in the Oil and Gas Industry:Pumps play a vital role in the oil and gas industry, facilitating the extraction, transportation, and processing of hydrocarbons. They are used to transfer crude oil, refined products, and natural gas through vast pipelines spanning great distances. In addition, pumps are crucial for artificial lift systems, enhancing production from oil wells by efficiently extracting the oil or gas from reservoirs. In this context, the continuous evolution of pumps is instrumental in maximizing the industry's productivity.2. Integration of Advanced Technologies in Pump Design: Recent advancements in technology have revolutionized pump design, resulting in more efficient and reliable operations. Companies, such as {}, have incorporated state-of-the-art technologies into their pumps, offering enhanced performance and durability. These advancements include:a. Sensor-based Monitoring Systems: Pumps are now equipped with sensor-based monitoring systems that provide real-time data to operators. This allows for seamless monitoring of pump performance, early detection of abnormalities, and timely maintenance, thereby minimizing downtime and reducing maintenance costs.b. Predictive Maintenance: With the implementation of machine learning algorithms, pumps can now predict potential failures and schedule maintenance before breakdowns occur. This proactive approach reduces unplanned downtime, ensuring uninterrupted operations and enhancing productivity.c. Energy Efficiency: Pumps are being designed with energy-efficient features, such as variable frequency drives, which regulate the pump speed based on demand. This prevents unnecessary energy consumption and reduces operational costs, contributing to a more sustainable and eco-friendly oil and gas industry.3. Increased Reliability and Performance:The integration of advanced technologies in pump design has significantly improved reliability and performance. Modern pumps can handle harsh operating conditions, such as extreme temperatures and corrosive environments, without compromising efficiency. Additionally, these pumps have increased flow rates, allowing for faster and more efficient transportation of oil and gas across pipelines.The durability of these pumps is further enhanced by the utilization of robust materials and advanced coatings that prevent corrosion and erosion. As a result, maintenance requirements are reduced, while the lifespan of the pumps is extended, ensuring uninterrupted operations in critical installations.4. Remote Monitoring and Control:The digitalization of the oil and gas industry has paved the way for remote monitoring and control of pumping systems. Operators can now remotely manage and monitor multiple pumps, reducing the need for on-site personnel. This not only enhances safety but also improves operational efficiency, as real-time data analytics enable optimized decision-making for improved productivity.5. Environmental Considerations:As sustainability gains prominence, pumps designed for the oil and gas industry now focus on reducing environmental impact. Advanced technologies, such as smart sensors and energy efficiency features, play a vital role in minimizing carbon footprint and optimizing resource consumption. By choosing pumps that prioritize eco-friendly operations, companies can contribute to the reduction of environmental pollution and the conservation of natural resources.Conclusion:The integration of advanced pumping technology in the oil and gas industry has resulted in significant improvements in efficiency, reliability, and sustainability. Companies like {} are leading the way in reshaping the sector, offering cutting-edge pump solutions designed to meet the evolving needs of the industry. These advancements not only increase productivity but also contribute to a more environmentally conscious and efficient oil and gas sector.

Top Acid-Resistant Pump Options for Industrial Applications in Tianjin

Title: Tianjin Acid-Resistant Pump: A Reliable Solution for Industrial Liquid HandlingIntroduction:Tianjin Acid-Resistant Pump is a leading manufacturer and supplier of high-quality acid-resistant pumps for various industrial applications. With an impeccable track record and a commitment to excellence, the company has earned a reputation for delivering reliable and innovative solutions for liquid handling challenges in corrosive environments. This news article will delve into the exceptional features and advantages offered by Tianjin Acid-Resistant Pump, highlighting the company's commitment to customer satisfaction and its contributions to industrial growth.1. Superior Features of Tianjin Acid-Resistant Pump:Tianjin Acid-Resistant Pump stands out in the market due to its exceptional features that ensure efficient and reliable performance in corrosive environments. These features include:a) Strong Acid Resistance: The pumps are manufactured using high-quality acid-resistant materials, such as fluoroplastic and stainless steel, which are specifically designed to withstand the corrosive nature of acids and other aggressive liquids.b) Optimal Efficiency: With advanced impeller designs and precision engineering, Tianjin Acid-Resistant Pump offers maximum efficiency in terms of energy consumption and fluid flow. These pumps ensure minimal process downtime and reduced maintenance costs.c) Versatile Applications: The acid-resistant pumps from Tianjin find applications in various industries such as chemical, pharmaceutical, mining, wastewater treatment, and metal processing. Their adaptability in handling different corrosive liquids makes them an ideal choice for a wide range of industrial needs.2. Commitment to Customer Satisfaction:Tianjin Acid-Resistant Pump prioritizes customer satisfaction by providing personalized solutions tailored to meet specific requirements. The company's team of experienced engineers and technical professionals offer expert guidance and support throughout the entire process, from selecting the right pump to after-sales services. Customers can rely on Tianjin Acid-Resistant Pump for prompt delivery, comprehensive technical support, and reliable solutions.3. Contributing to Industrial Growth:Tianjin Acid-Resistant Pump plays a crucial role in supporting various industries by providing efficient and reliable liquid handling solutions. Some notable contributions include:a) Safety and Environmental Protection: The acid-resistant pumps help industries ensure the safety of their operations while handling corrosive liquids, preventing accidental leaks and minimizing environmental risks.b) Enhancing Efficiency: The superior design and performance of Tianjin Acid-Resistant Pump's products help industries optimize their operations by providing consistent fluid flow, reducing energy consumption, and minimizing maintenance requirements.c) Enabling Innovation: The acid-resistant pumps from Tianjin facilitate the development of new processes and technologies in industries by offering robust and reliable liquid handling solutions, thus increasing productivity and contributing to overall industrial growth.4. Vision for the Future:Tianjin Acid-Resistant Pump aims to continuously improve its product offerings and expand its global presence. The company invests in research and development to stay at the forefront of technological advancements and develop innovative solutions that address the evolving needs of industries. By building strong partnerships with clients and fostering a culture of excellence, Tianjin Acid-Resistant Pump strives to become the preferred choice for acid-resistant pumps worldwide.Conclusion:Tianjin Acid-Resistant Pump's commitment to providing high-quality acid-resistant pumps and exceptional customer service has positioned the company as a reliable solution for industrial liquid handling needs. With their superior features and versatile applications, these pumps ensure efficient and safe operations in corrosive environments. As industries continue to evolve and demand more reliable liquid handling solutions, Tianjin Acid-Resistant Pump is poised to meet these challenges and contribute to the growth and progress of industries worldwide.

Discover the Efficiency and Versatility of Screw Pump Technology

Mini Screw Pump: A Revolutionary Solution for Fluid Transfer ApplicationsFluid transfer is a critical process in numerous industries, including chemical, pharmaceuticals, oil and gas, and food and beverage. In most cases, this process requires the use of high-quality pumps that can transport liquids and gasses from one point to another effectively.One such pump that has gained immense popularity in recent times is the Mini Screw Pump. As the name suggests, this pump is relatively small in size but boasts unmatched performance, making it an ideal choice for a wide range of fluid transfer applications.Designed and manufactured by one of the leading companies in the industry, the Mini Screw Pump stands out due to its unique helical rotor design. This design allows the pump to overcome various challenges posed by other popular pump types, such as centrifugal pumps.Most centrifugal pumps have impellers that spin on a shaft to create a fluid flow. Although these pumps are highly effective, they often struggle in situations where the liquid contains entrained air or gases. The entrained air tends to accumulate in the pump casing, eventually blocking the impeller and disrupting the fluid flow.The Mini Screw Pump, on the other hand, has a self-priming feature that eliminates the need for external priming. Additionally, the pump's helical rotor and stator design enable it to handle fluid transfer applications that contain air or gas entrainment.One of the main advantages of the Mini Screw Pump is its ability to handle various types of fluids, including abrasive, viscous, and corrosive liquids. This feature makes it an ideal choice for industries that require the transfer of challenging fluids.Furthermore, the pump's simple design and minimal mechanical parts make it easy to maintain and repair, reducing downtime and maintenance costs.To ensure optimal performance, each Mini Screw Pump is rigorously tested and checked to meet the highest industry standards. The company employs advanced testing equipment and quality control measures to ensure that each pump is defect-free and can deliver unparalleled results.The Mini Screw Pump is versatile, reliable, and efficient, making it a must-have for industries that require fluid transfer applications. Its unique design and outstanding performance make it the preferred choice for various industries, including chemical, pharmaceutical, oil and gas, and food and beverage.In conclusion, the Mini Screw Pump is a revolutionary solution that is set to change the fluid transfer industry's landscape. Its superior design, performance, and reliability make it the go-to pump for industries that require high-quality fluid transfer applications. With its ability to handle challenging fluids, the Mini Screw Pump is a game-changer that has earned its spot as one of the most effective pumps in the market.

Understanding the Working Principle of Screw Vacuum Pumps

Screw vacuum pumps are a crucial piece of equipment in many industrial and manufacturing processes. They work on the principle of using two interlocking screws to compress and push air out of the system, creating a vacuum. This technology is vital for a range of applications, including food processing, pharmaceutical manufacturing, and even in the production of semiconductors.One company that is at the forefront of screw vacuum pump technology is {}. With a history dating back over 100 years in the vacuum pump industry, they have established themselves as a leader in the field. Their commitment to innovation and quality has made their screw vacuum pumps a popular choice for many businesses around the world.The working principle of their screw vacuum pumps is simple yet effective. The pumps consist of two screw rotors that rotate in opposite directions within a cylindrical housing. As the screws turn, they trap air between the threads and the housing, gradually reducing the volume of the trapped air. This compression process causes the air to be forced out of the system, creating a vacuum.The efficiency of the screw vacuum pump is due to the precise engineering of the screws and the housing. The screws must fit perfectly within the housing to prevent any backflow of air and maintain a consistent compression process. Additionally, the screws are designed to have a small clearance between each other and the housing, ensuring minimal leakage and maximum efficiency.One of the key advantages of using a screw vacuum pump is its ability to handle a wide range of operating pressures and vacuum levels. This makes it a versatile option for many different applications, from removing air and moisture in food processing to creating a high vacuum for semiconductor manufacturing.In addition to their working principle, {}'s screw vacuum pumps are known for their reliability and durability. The company's commitment to quality is evident in their manufacturing processes, where every pump is meticulously tested and inspected to ensure it meets their rigorous standards. This dedication to quality has earned them a reputation for producing long-lasting and high-performing equipment.Furthermore, {} offers a range of screw vacuum pumps to suit various needs and specifications. Whether it's a small-scale operation or a large industrial plant, they have a pump that can deliver the required vacuum level with efficiency. Their pumps are also designed to be energy-efficient, helping businesses reduce their overall energy consumption and operating costs.Another notable feature of {}'s screw vacuum pumps is their low maintenance requirements. Thanks to their robust design and high-quality components, these pumps are built to withstand the rigors of continuous operation with minimal need for maintenance. This ensures that businesses can rely on their equipment to keep running smoothly without interruptions.In conclusion, screw vacuum pumps are an essential technology for many industries, and {} is a leading provider of these pumps with a strong focus on quality, innovation, and reliability. With their advanced working principle and commitment to customer satisfaction, businesses can trust {} to provide them with the vacuum solutions they need to keep their operations running smoothly and efficiently.

How to Choose the Best Oil Pumps on the Market

[Title]: Global Pumps for Oil Market Witnesses Steady Growth as Demand Increases[Introduction]:The global pumps for oil market has been witnessing a steady growth trajectory in recent years, primarily fueled by increasing oil extraction activities across the globe. With rising energy needs and growing exploration and production activities in both conventional and unconventional oilfields, the demand for efficient and reliable pumps for oil has been on the rise. These pumps play a crucial role in facilitating the extraction, transportation, and refining processes of oil, making them an essential component of the oil and gas industry.[Paragraph 1]:The market for pumps for oil is expected to expand at a substantial CAGR over the forecast period of [period]. This growth can be attributed to several factors, such as the increasing number of oil and gas exploration projects, the rising adoption of advanced pumping technologies, and the continuous investment in the development of new oilfields. Additionally, the growth of offshore oil exploration activities has further fueled the demand for pumps that can withstand harsh marine environments.[Paragraph 2]:One of the key players operating in the global pumps for oil market is [company name]. With over [number] years of experience, the company has established itself as a trusted manufacturer and supplier of high-quality pumps designed specifically for oil applications. The pumps are known for their efficiency, durability, and reliability, making them a preferred choice among oil industry operators worldwide.[Paragraph 3]:[Company name] offers a wide range of pumps for oil, including centrifugal pumps, reciprocating pumps, and rotary pumps. These pumps are engineered to meet the unique requirements of different stages of oil extraction and processing, ensuring optimal performance and productivity. The company's cutting-edge technology and innovative designs enable the pumps to handle various viscosities of oil while maintaining high efficiency levels.[Paragraph 4]:One of the standout features of [company name]'s pumps for oil is their robust construction, which enables them to withstand the harsh operating conditions often encountered in oilfields. The pumps are designed to handle corrosive fluids, high temperatures, and abrasive materials, ensuring long service life and minimizing downtime. Moreover, the company's commitment to quality and adherence to international standards ensure that their pumps deliver consistent results even in the most challenging environments.[Paragraph 5]:In addition to their superior performance, [company name]'s pumps for oil also prioritize sustainability and environmental considerations. The company has made significant investments in research and development to enhance energy efficiency and reduce carbon emissions associated with oil pumping operations. These initiatives have garnered praise from industry experts, positioning [company name] as a responsible and eco-friendly solution provider.[Paragraph 6]:Geographically, [company name] has a well-established presence in major oil-producing regions, including North America, the Middle East, and Asia. The company's extensive distribution network and strategic partnerships ensure timely delivery and support to customers, regardless of their location. This widespread reach allows [company name] to cater to the diverse needs of oil industry operators globally, adding to its market dominance.[Paragraph 7]:Looking ahead, the global pumps for oil market is poised for significant growth as oil extraction activities expand and become more technologically advanced. With the increasing focus on renewable energy sources and the transition toward a greener future, the development of more efficient and sustainable pumps for oil will play a pivotal role in meeting the world's energy needs. As a leading player in the industry, [company name] remains committed to continuous innovation and delivering cutting-edge solutions that help shape the future of oil pumping technology.[Conclusion]:As the global demand for oil continues to rise, the pumps for oil market is expected to witness steady growth. With [company name] at the forefront of pump manufacturing, oil industry operators can rely on their expertise to provide reliable and efficient solutions. By combining advanced technology, durable construction, and environmental consciousness, [company name] stands as a key player in the global pumps for oil market, poised to meet the evolving needs of the oil and gas industry.

Understanding the Working Principle of a Single Screw Pump

Title: Revolutionary Single Screw Pump Sets New Benchmark in Efficiency and ReliabilityIntroduction:Innovation has always been at the core of the industrial sector, and the introduction of the revolutionary Single Screw Pump has set a new benchmark in terms of efficiency and reliability. This groundbreaking solution is poised to revolutionize various industries, such as oil and gas, food processing, wastewater treatment, and chemical manufacturing, by providing enhanced performance, reduced maintenance requirements, and improved operational safety.Working Principle of the Single Screw Pump:The Single Screw Pump, developed by an innovative company committed to providing cutting-edge industrial solutions, operates on a simple yet highly effective principle. This pump consists of a single threaded screw rotor rotating within a rubber stator. As the rotor moves, it entrains the liquid from the inlet side and pushes it towards the outlet side of the pump. This unique design ensures a smooth and continuous flow, minimizing pressure fluctuations and reducing the risk of cavitation.The precision engineering of the Single Screw Pump results in numerous advantages that set it apart from traditional pump systems. Firstly, it can handle a wide range of liquids, including highly viscous, abrasive, and even shear-sensitive fluids. This versatility ensures that industries can efficiently process various substances without compromising performance or safety.Moreover, the pump's design minimizes pulsation and turbulence during operation, resulting in a steady and consistent flow. This feature not only ensures product quality continuity in sensitive industries like food processing but also reduces the wear and tear on the pump, prolonging its lifespan and significantly reducing maintenance requirements.Furthermore, the Single Screw Pump's ability to handle high suction and discharge pressures makes it ideal for oil and gas applications, where long-distance transportation is often required. Its reliability and efficiency in such demanding environments have been proven time and again, positioning it as an indispensable component in the industry.Company Introduction:The development and success of the Single Screw Pump can be attributed to the company's unwavering commitment to research and development, technological advancements, and dedication to customer satisfaction. Established over two decades ago, this pioneering company has become a global leader in providing innovative industrial solutions tailored to the unique needs of its customers.This company possesses state-of-the-art facilities and a highly skilled team of engineers who work tirelessly to conceptualize and manufacture cutting-edge equipment that pushes the boundaries of industrial efficiency. By fostering a culture of continuous learning and improvement, the company ensures that its solutions stay ahead of the rapidly evolving technological landscape.Investing heavily in research and development, the company has explored novel materials, advanced design techniques, and optimized manufacturing processes to create products that maximize performance and reliability. These efforts have resulted in the groundbreaking Single Screw Pump, which is poised to redefine pumping technology around the world.The company's commitment to customer satisfaction extends beyond the quality of its products. It provides exceptional after-sales support, technical assistance, and regular maintenance services to ensure that its customers receive uninterrupted operation and maximum return on investment. This dedication to customer service has helped forge long-standing partnerships and a global network of satisfied clients.Conclusion:The advent of the Single Screw Pump marks a significant milestone in the industrial sector. Its superior efficiency, reliability, and versatility set it apart from traditional pumping solutions, making it an invaluable asset for a wide range of industries. With its innovative design and the commitment of the company behind it, this revolutionary pump is set to transform pumping systems, paving the way for enhanced performance and productivity in various industrial applications.