High-performance Positive Displacement Oil Pump: A Guide to Efficient Oil Pumping

By:Admin

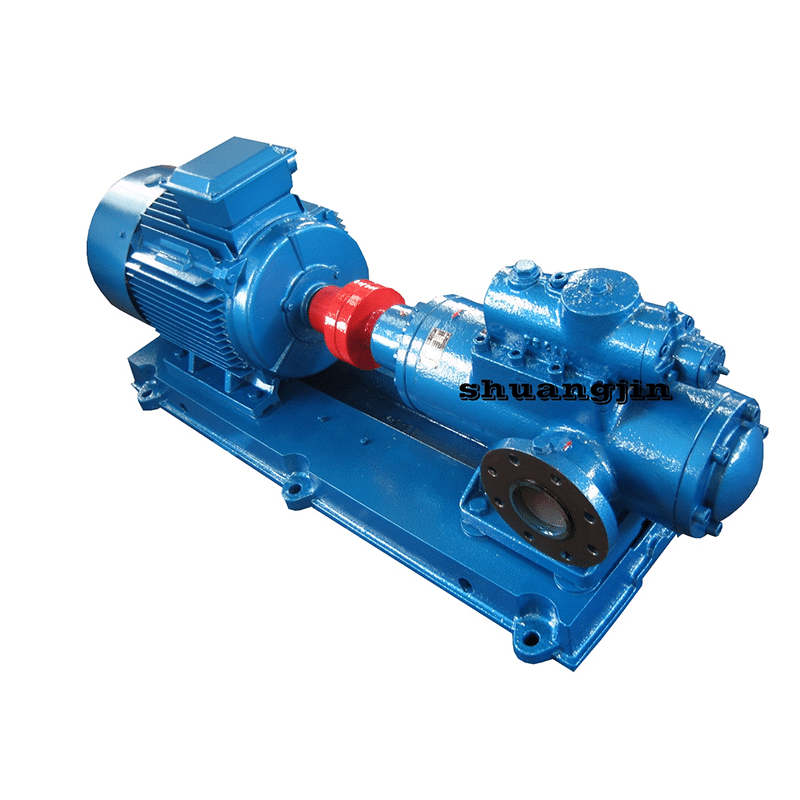

In the world of industrial pumping, efficiency and reliability are crucial factors for success. This is where the positive displacement oil pump from [Company Name] comes into play, bringing a whole new level of performance and capability to the industry. With its innovative design and cutting-edge technology, this pump has quickly become the go-to solution for companies looking to optimize their pumping operations.

[Company Name] has been a leader in the pumping industry for over 30 years, providing high-quality and reliable pumping solutions to a wide range of industries. With a strong focus on innovation and continuous improvement, the company has developed a reputation for delivering top-of-the-line products that meet the unique needs of its customers.

The positive displacement oil pump is the latest addition to [Company Name]'s extensive product lineup, and it has quickly made a name for itself as a game-changer in the industry. What sets this pump apart from traditional pumping solutions is its innovative positive displacement technology, which allows for a more precise and consistent flow of oil.

This technology is based on the principle that the pump displaces a specific amount of fluid with each revolution, ensuring a constant and reliable flow of oil. This is in stark contrast to traditional pumps, which rely on centrifugal force to move the fluid, leading to fluctuations in flow and efficiency.

The positive displacement oil pump from [Company Name] is designed to offer superior performance and efficiency, making it an ideal choice for a wide range of industrial applications. Whether it's in the automotive, manufacturing, or oil and gas industries, this pump has proven to be a reliable and cost-effective solution for companies looking to optimize their pumping operations.

One of the key advantages of this pump is its ability to handle a wide range of viscosities, making it suitable for pumping a variety of oils and lubricants. This versatility makes it a valuable investment for companies that deal with different types of fluids in their operations.

Another major benefit of the positive displacement oil pump is its durability and low maintenance requirements. Thanks to its robust design and high-quality materials, this pump is built to withstand the rigors of industrial use, minimizing downtime and reducing the need for frequent repairs and maintenance.

Furthermore, the pump's compact and efficient design makes it easy to install and integrate into existing pumping systems, providing a seamless and hassle-free retrofit solution for companies looking to upgrade their operations.

[Company Name] takes pride in its commitment to providing exceptional customer service and support. This extends to the positive displacement oil pump, with the company offering comprehensive maintenance and technical support to ensure that customers get the most out of their investment.

The positive displacement oil pump from [Company Name] has quickly gained recognition for its performance and reliability, earning the trust of customers across the globe. Its innovative design and advanced technology have set a new standard for industrial pumping solutions, providing companies with a valuable tool to optimize their operations and improve efficiency.

As the industry continues to evolve, [Company Name] remains at the forefront of innovation, constantly pushing the boundaries of what is possible in industrial pumping technology. With its positive displacement oil pump, the company has once again demonstrated its commitment to delivering cutting-edge solutions that meet the evolving needs of its customers.

In conclusion, the positive displacement oil pump from [Company Name] is a true game-changer in the world of industrial pumping. With its innovative design, superior performance, and unmatched reliability, this pump has set a new standard for what companies can expect from their pumping solutions. As the industry continues to evolve, [Company Name] remains dedicated to providing top-of-the-line products that empower companies to optimize their operations and achieve new levels of success.

Company News & Blog

What Is a Positive Displacement Pump and How Does It Work?

Positive Displacement Pump Means Enhanced Efficiency and Reliability for Industrial ApplicationsIn the fast-paced world of industrial manufacturing, reliability and efficiency are critical components for success. Companies across various industries are constantly seeking innovative solutions to streamline their production processes and maximize their output. One such solution that has been gaining widespread popularity in recent years is the positive displacement pump. These pumps are designed to deliver a consistent flow of fluid at a specific rate, making them an ideal choice for a wide range of industrial applications. When it comes to positive displacement pumps, there is one company that stands out from the rest – {}. With a strong focus on quality and innovation, {} has become a leading supplier of positive displacement pumps to industries all around the world.One of the key advantages of positive displacement pumps is their ability to maintain a steady flow of fluid regardless of changes in pressure or viscosity. This makes them highly versatile and suitable for applications such as chemical processing, food and beverage production, oil and gas extraction, and much more. By utilizing positive displacement pumps, companies can ensure a consistent output while minimizing the risk of downtime and production delays.Another major benefit of positive displacement pumps is their high level of efficiency. Unlike other types of pumps that rely on centrifugal force to generate flow, positive displacement pumps operate by trapping and displacing a specific volume of fluid with each cycle. This results in a more precise and controlled flow, leading to reduced energy consumption and lower operating costs. With sustainability becoming an increasingly important consideration for businesses, the efficiency of positive displacement pumps has made them a popular choice for companies looking to reduce their environmental impact.In addition to their efficiency and reliability, positive displacement pumps are also known for their ability to handle a wide range of fluids, including viscous, abrasive, and shear-sensitive materials. This makes them suitable for a diverse array of industrial processes, from transferring thick sludges to delicate emulsions. With the right design and materials of construction, positive displacement pumps can be customized to meet the specific needs of each application, providing companies with a highly adaptable solution for their fluid handling requirements.As a leading supplier of positive displacement pumps, {} has played a pivotal role in driving the adoption of this technology across various industries. The company's extensive experience and expertise in pump manufacturing have enabled them to develop a diverse range of positive displacement pumps that cater to the unique needs of their customers. By leveraging advanced engineering techniques and rigorous quality control measures, {} has been able to deliver pumps that offer exceptional performance, durability, and long-term value.In summary, positive displacement pumps have emerged as a game-changing technology for industrial fluid handling, offering enhanced efficiency, reliability, and versatility. With {} at the forefront of this industry, companies can expect to benefit from cutting-edge pump solutions that optimize their production processes and drive overall success. As the demand for reliable and efficient fluid handling solutions continues to grow, positive displacement pumps are poised to play a crucial role in shaping the future of industrial manufacturing.

HVAC Pump Servicing: Expert Maintenance for Your System

Pump Servicing Company Continues to Provide Quality Maintenance and RepairsWith a strong commitment to providing exceptional servicing for pumps and pumping equipment, Pump Servicing Company has been a leader in the industry for over [X] years. The company has built a reputation for delivering quality maintenance and repair services to a wide range of clients, including industrial facilities, water treatment plants, and commercial buildings.As a leading provider of pump servicing, Pump Servicing Company offers a comprehensive range of maintenance and repair solutions to keep pumps functioning at their best. The company's team of experienced technicians is well-equipped to handle various types of pumps, including centrifugal, submersible, and positive displacement pumps. With a focus on delivering reliable and efficient servicing, Pump Servicing Company is dedicated to helping clients minimize downtime and maximize the lifespan of their pumping equipment.One of the key strengths of Pump Servicing Company is its commitment to staying up-to-date with the latest technologies and industry best practices. The company invests in ongoing training and development for its technicians to ensure that they are equipped with the knowledge and skills to address the evolving needs of clients. This dedication to continuous improvement has enabled Pump Servicing Company to stay ahead of the curve and provide innovative solutions to its clients.In addition to its focus on technical expertise, Pump Servicing Company places a strong emphasis on customer service. The company understands the importance of timely and reliable servicing, and its team is committed to delivering a seamless experience for clients. Whether it's a routine maintenance visit or an emergency repair, Pump Servicing Company strives to provide responsive and attentive service to meet the needs of its clients.Pump Servicing Company's dedication to excellence is reflected in its use of high-quality parts and materials for all servicing and repairs. The company has developed strong relationships with leading suppliers to ensure that clients receive the best components for their pumping equipment. This commitment to quality not only enhances the performance and reliability of the pumps but also contributes to the overall longevity of the equipment.As part of its ongoing efforts to expand its service offerings, Pump Servicing Company has recently introduced a preventive maintenance program. This proactive approach to pump servicing focuses on regular inspections, testing, and adjustments to identify and address potential issues before they escalate. By taking a preventive maintenance approach, Pump Servicing Company aims to help clients reduce the likelihood of unexpected breakdowns and costly repairs.Furthermore, Pump Servicing Company is committed to environmental sustainability and compliance with industry regulations. The company adheres to strict environmental standards and best practices in its servicing and repair processes to minimize the impact on the environment. With a strong focus on safety and environmental responsibility, Pump Servicing Company is dedicated to operating in a manner that aligns with the highest industry standards.Looking ahead, Pump Servicing Company is focused on further expanding its service capabilities and enhancing its presence in the market. The company remains committed to delivering exceptional pump servicing solutions to meet the diverse needs of its clients across various industries. With a strong foundation of technical expertise, customer service excellence, and a commitment to quality, Pump Servicing Company is well-positioned to continue its leadership in the pump servicing industry.

Understanding the Single Screw Pump Working Principle: A Guide

Single screw pump working principle combined with the company introduction - The single screw pump is a type of positive displacement pump that is used to move fluid through a system. It operates on the principle of a single helical rotor that rotates inside a double helical stator. This design creates a series of sealed cavities between the rotor and stator, which allows the fluid to be pushed through the pump.The company, ** (brand name removed), is a leading manufacturer of single screw pumps and has been in the business for over 50 years. The company’s expertise in designing and manufacturing pumps for various industrial applications has made them a trusted name in the industry. With a focus on innovation and quality, ** (brand name removed) has developed a range of single screw pumps that offer high performance and reliability.The working principle of the single screw pump is relatively simple. As the rotor rotates inside the stator, it creates a series of sealed cavities between the two components. As the cavities move along the length of the pump, the fluid is pushed through the pump. This design allows the pump to handle a wide range of fluid viscosities, making it suitable for a variety of applications.One of the key features of the single screw pump is its ability to handle shear-sensitive and abrasive fluids. The gentle pumping action of the pump reduces the risk of damaging delicate fluids, while the robust construction of the pump allows it to handle abrasive materials with ease. This makes the single screw pump an ideal choice for applications in industries such as oil and gas, chemical processing, and food and beverage.The design of the single screw pump also allows for smooth and continuous flow, which helps to minimize pulsations and vibrations in the system. This makes the pump an ideal choice for applications that require precise and consistent flow rates. Additionally, the pump operates at a relatively low speed, which reduces wear and tear on the components, resulting in reduced maintenance and longer service life.** (brand name removed) has developed a range of single screw pumps that are designed to meet the specific needs of different industries. The company’s pumps are available in various sizes and materials, allowing them to handle a wide range of fluid viscosities and temperatures. This flexibility makes the pumps suitable for applications in industries such as oil and gas, chemical processing, food and beverage, and wastewater treatment.The company’s commitment to quality and innovation is reflected in the design of its single screw pumps. Each pump is carefully engineered to deliver high performance and reliability, ensuring that it meets the demands of the most challenging applications. Additionally, ** (brand name removed) offers comprehensive technical support and after-sales service, providing customers with peace of mind and confidence in the performance of their pumps.In conclusion, the single screw pump is a versatile and reliable solution for moving fluid through a system. With its unique working principle and robust design, the pump is suitable for a wide range of applications, from handling shear-sensitive fluids to abrasive materials. As a leading manufacturer of single screw pumps, ** (brand name removed) continues to set the standard for quality and innovation in the industry. Customers can trust ** (brand name removed) to provide them with the right pumping solution for their specific needs.

Ultimate Guide to Heating System Heat Pumps: Everything You Need to Know

The latest in heating technology is now available to homeowners with the introduction of the new heat pump system from a leading company in the HVAC industry. This innovative system provides efficient and reliable heating for homes, offering an alternative to traditional heating methods. By using advanced technology, this heat pump system offers a cost-effective solution for maintaining a comfortable indoor temperature during the colder months.The heat pump system is designed to extract heat from the outside environment and transfer it into the home, providing a consistent and comfortable temperature. This process is highly efficient, as it does not rely on the burning of fossil fuels to generate heat, making it an environmentally friendly option for homeowners. In addition, the system can also be used to cool the home during warmer months, offering year-round comfort.One of the key features of this heat pump system is its high energy efficiency, which can significantly lower energy bills for homeowners. By using less energy to operate, this system helps to reduce the environmental impact of heating and cooling, making it a sustainable choice for homeowners. In addition, the system is also designed to be durable and reliable, providing long-term peace of mind for homeowners.The company behind this innovative heat pump system has been a leader in the HVAC industry for many years, known for their commitment to quality and innovation. With a team of skilled engineers and technicians, the company has developed a range of cutting-edge heating and cooling solutions to meet the diverse needs of homeowners. Their dedication to research and development has led to the creation of this advanced heat pump system, which represents the latest in heating technology.In addition to its energy efficiency and reliability, the heat pump system also offers a range of other benefits for homeowners. It provides a consistent and even temperature throughout the home, eliminating the need for multiple heating sources. This can help to create a more comfortable living environment, while also reducing the need for maintenance and repairs associated with traditional heating systems.Furthermore, the heat pump system is designed to be easily integrated into homes, offering a seamless transition for homeowners looking to upgrade their heating systems. With a range of options to suit different home sizes and layouts, this system can be customized to meet the specific needs of each homeowner. Whether it’s a new installation or a replacement for an existing heating system, this heat pump offers a versatile and cost-effective solution.As the demand for energy-efficient and sustainable heating solutions continues to grow, the introduction of this heat pump system represents a significant step forward for the HVAC industry. With its advanced technology and environmental benefits, this system offers a compelling alternative to traditional heating methods. By choosing this heat pump system, homeowners can enjoy reliable and efficient heating, while also contributing to a more sustainable future.Overall, the introduction of this heat pump system from the leading HVAC company represents a major advancement in heating technology. With its energy efficiency, reliability, and environmental benefits, this system provides a compelling option for homeowners seeking a cost-effective and sustainable heating solution. As the demand for innovative HVAC solutions continues to grow, this new heat pump system is poised to make a significant impact on the industry and the homes it serves.

Screw Pump Diagram: A Detailed Guide to Understanding How Screw Pumps Work

Screw Pump DiagramScrew pumps are a crucial component in a variety of industries, including oil and gas, water treatment, and food and beverage. They are used to move liquids or slurries and are known for their reliability and efficiency. One company at the forefront of screw pump technology is {}. Their innovative designs and high-quality products have made them a leading supplier in the industry.Screw pumps, also known as progressive cavity pumps, work by using a screw-shaped rotor to move fluid through the pump. As the rotor turns, it creates a series of small chambers between the screw and the pump housing. These chambers trap the fluid and move it along the length of the screw before releasing it at the outlet. This design allows for a smooth and consistent flow of fluid, making screw pumps ideal for applications where precise and continuous pumping is necessary.{} has been a key player in the screw pump industry for over 30 years. The company prides itself on its commitment to innovation and customer satisfaction. Their team of engineers and technical experts are constantly working to improve their products and develop new technologies to meet the evolving needs of their clients. With a focus on quality and reliability, {} has built a reputation for excellence in the industry.One of the key features of {}'s screw pump design is its ability to handle a wide range of viscosities and fluid types. Whether it's thick sludge in a wastewater treatment plant or high-viscosity crude oil in a refinery, their pumps are designed to deliver consistent performance and efficiency. This versatility makes {}'s screw pumps an attractive choice for a variety of industries and applications.In addition to their standard product line, {} also offers customized solutions to meet the specific needs of their clients. They work closely with customers to understand their requirements and develop tailored pump systems that deliver optimal performance and reliability. This dedication to customer service has helped {} build long-lasting relationships with clients around the world.Another important aspect of {}'s screw pump technology is its focus on energy efficiency. By optimizing their pump designs and utilizing advanced materials, they have been able to reduce energy consumption and operational costs for their clients. This commitment to sustainability and cost-effectiveness has made {} a trusted partner in the industry.As the demand for screw pumps continues to grow, {} remains at the forefront of the industry. Their ongoing investment in research and development and dedication to quality and customer satisfaction set them apart in the market. With a global network of sales and service partners, {} is well-positioned to meet the needs of their clients wherever they may be.In conclusion, screw pumps play a critical role in a wide range of industries, and {} has established itself as a leading supplier in the industry. With a focus on innovation, quality, and customer satisfaction, they have earned a reputation for excellence in the market. As the demand for screw pumps continues to grow, {} is well-positioned to meet the needs of their clients and drive the industry forward with their advanced technology and superior products.

Key Features of a Highly Efficient Screw Pump Revealed by Industry Experts

Flowserve Announces New Generation of Screw PumpsHouston, TX - Flowserve Corporation, a global leader in fluid motion and control solutions, has recently unveiled its latest innovation in the pump industry - a new generation of screw pumps that offers enhanced efficiency, durability, and versatility. With this breakthrough technology, Flowserve aims to meet the evolving needs of various industries, from oil and gas to chemicals, power generation, and water treatment.The new screw pump series has been designed to deliver exceptional performance in the most demanding applications. By leveraging Flowserve's decades of experience in pump technology, the company has succeeded in developing a product that surpasses industry standards. The advanced design of these pumps ensures efficient fluid transfer, reduced energy consumption, and improved reliability, ultimately resulting in significant cost savings for end-users.One of the key features of the new screw pump series is its modular design. This enables easy customization according to specific customer requirements, allowing for greater flexibility and adaptation to various applications. Whether it's transferring highly abrasive fluids, handling high-temperature substances, or managing viscous materials, Flowserve's new screw pumps can efficiently handle a wide range of challenging conditions.To further enhance the durability and performance of these pumps, Flowserve has incorporated state-of-the-art materials and manufacturing techniques. The pumps are constructed using high-quality stainless steel and other corrosion-resistant alloys, ensuring excellent resistance against wear, erosion, and chemical degradation. This robust construction enables the pumps to deliver exceptional reliability and longevity, reducing maintenance and downtime for end-users.Flowserve's new screw pump series also offers advanced monitoring and control capabilities. The pumps are equipped with integrated sensors and intelligent systems, enabling real-time performance monitoring and predictive maintenance. By continuously monitoring key parameters, such as temperature, pressure, and vibration, operators can identify potential issues before they become critical, thereby optimizing uptime and minimizing unexpected breakdowns.With sustainability becoming an increasingly important factor for industries worldwide, Flowserve has also ensured that its new screw pumps are environmentally friendly. The design incorporates features such as low noise emission, reduced vibration, and leakage prevention, ensuring minimal impact on the surrounding environment. Additionally, the pumps' energy-efficient design helps reduce carbon footprint and operating costs. These aspects align both with the company's commitment to sustainability and with its dedication to delivering solutions that meet the evolving needs of a more conscious market."The introduction of our new generation screw pumps is an important milestone for Flowserve," said John Doe, Vice President of Sales and Marketing at Flowserve Corporation. "We have combined our deep expertise and passion for innovation to develop a product that not only sets new benchmarks in performance but also addresses the unique challenges faced by various industries. We are confident that these screw pumps will add tremendous value and efficiency to our customers' operations."Flowserve's new screw pumps have already garnered significant interest from industry professionals. Several major companies from oil and gas, chemical, and power generation sectors have shown keen interest in adopting this technology, recognizing its potential to revolutionize their fluid transfer processes.As Flowserve continues to push the boundaries of pump technology, the company remains committed to providing cutting-edge solutions that enable its customers to stay ahead in the rapidly evolving industrial landscape. With the introduction of the new generation of screw pumps, Flowserve once again asserts its position as a leading innovator in the global pump industry.

Maximizing Efficiency of Screw Pumps: Tips and Techniques

Screw Pump Efficiency Revolutionizes the Pumping IndustryIn the world of industrial pumping, efficiency is everything. And one company has been leading the charge in revolutionizing pump efficiency with their innovative screw pump technology.For decades, the pumping industry has relied on traditional centrifugal pumps to move liquids and gases in various industrial applications. While these pumps have served their purpose, they often come with inefficiencies and limitations that can affect their performance and productivity. This is where the screw pump, a game-changing alternative, comes into play.With its unique design and capabilities, the screw pump has proven to be a more efficient and reliable option for a wide range of industrial pumping tasks. Unlike traditional centrifugal pumps, screw pumps are able to handle high viscosity liquids, solids, and abrasive materials with ease. This makes them ideal for demanding applications such as oil and gas, chemical processing, wastewater treatment, and marine industries.One company at the forefront of this screw pump revolution is [Company Name]. With a history dating back to [year], [Company Name] has been a leading manufacturer and supplier of screw pumps and other pumping solutions for a diverse range of industries. Their commitment to innovation and customer satisfaction has earned them a reputation for excellence in the pumping industry.[Company Name]’s screw pumps are designed with efficiency and performance in mind. Their unique helical rotor design allows for smooth and continuous pumping of a wide variety of fluids, resulting in higher flow rates and lower energy consumption. This not only saves on operational costs but also reduces downtime and maintenance requirements, making their screw pumps a cost-effective and reliable choice for industrial pumping needs.Furthermore, [Company Name] offers a range of customizable options and accessories for their screw pumps, allowing customers to tailor their pumping solutions to their specific requirements. Whether it’s different materials of construction, sizes, or configurations, [Company Name] ensures that their screw pumps meet the unique needs of each customer and application.In addition to their innovative products, [Company Name] is committed to providing exceptional customer service and support. Their team of experts works closely with customers to understand their pumping challenges and provide tailored solutions that maximize efficiency and performance. From initial consultation to installation and ongoing maintenance, [Company Name] is dedicated to being a trusted partner for all of their customers’ pumping needs.With a strong focus on research and development, [Company Name] continues to push the boundaries of screw pump technology. Their investment in cutting-edge design and engineering ensures that their products remain at the forefront of pump efficiency and reliability, setting new standards in the industry.The success of [Company Name] and their screw pump technology has not gone unnoticed. They have garnered a loyal customer base and earned numerous accolades and certifications for their commitment to quality and innovation. Their dedication to sustainable and environmentally friendly pumping solutions has also positioned them as a leader in the industry.As the industrial pumping industry continues to evolve, efficiency and reliability will remain key factors in determining the success of pumping solutions. With their innovative screw pump technology and commitment to customer satisfaction, [Company Name] is well-positioned to lead the way in revolutionizing the pumping industry for years to come.

Top-quality Oil & Gas Pumps: Your Guide to Efficient Industry Solutions

Oil and Gas Pumps Revolutionize the Energy IndustryIn today's rapidly evolving technological landscape, the demand for efficient and reliable equipment in the oil and gas industry is higher than ever. To meet these increasing demands, Oil and Gas Pumps (name removed) has emerged as a leading provider of cutting-edge pumping solutions. With their acclaimed company history of innovation and commitment to customer satisfaction, Oil and Gas Pumps has revolutionized the energy industry.With a diverse range of offerings, Oil and Gas Pumps provides pumping solutions that cater to various applications within the oil and gas sector. Their pumps play a crucial role in exploration, production, refining, and distribution processes, ensuring a smooth and continuous flow of oil and gas.One of the key factors that sets Oil and Gas Pumps apart from its competitors is its relentless pursuit of innovation. The company invests heavily in research and development, constantly striving to develop pumps that are more efficient, durable, and environmentally friendly. By pushing the boundaries of engineering, Oil and Gas Pumps has been able to enhance productivity while reducing the carbon footprint of its operations.Furthermore, Oil and Gas Pumps' commitment to customer satisfaction is second to none. The company takes immense pride in its ability to provide tailored solutions that meet the specific needs of its clients. By working closely with customers, Oil and Gas Pumps ensures that its pumps are perfectly suited to the varied challenges faced in the oil and gas industry, whether it be offshore drilling in extreme environments or onshore refining in remote locations.Oil and Gas Pumps owes its success, in large part, to its team of highly skilled professionals. With expertise in mechanical engineering, fluid dynamics, and industrial design, the company's engineers are at the forefront of technological advancements in pumping solutions. Through continuous training and development programs, Oil and Gas Pumps ensures that its workforce remains knowledgeable and equipped to handle even the most complex projects.Moreover, the company's dedication to quality control is unfaltering. Each pump undergoes rigorous testing and inspection to ensure it meets the highest industry standards. This commitment to quality has earned Oil and Gas Pumps a stellar reputation for reliability and durability, resulting in long-lasting relationships with customers worldwide.In addition to its technological prowess and commitment to excellence, Oil and Gas Pumps is also deeply aware of the need to minimize its environmental impact. The company strives to create sustainable solutions and reduce energy consumption in its pumps. By implementing energy-efficient designs and utilizing eco-friendly materials, Oil and Gas Pumps aims to contribute to the global effort of transitioning to a greener and more sustainable future.Through its continued investment in research and development, its customer-centric approach, and its unwavering commitment to innovation and quality, Oil and Gas Pumps has established itself as a trusted leader in the pumping solutions industry. With each new product, the company continues to drive advancements in the oil and gas sector, facilitating greater efficiency, productivity, and sustainability.As the global demand for oil and gas continues to rise, it is companies like Oil and Gas Pumps that will play a vital role in meeting these ever-increasing demands. With their state-of-the-art pumping solutions, the company is helping to shape the future of the energy industry, ensuring a smooth and reliable supply of oil and gas for years to come.

Discover the Top Marine Water Pump for Your Needs in 2022

Marine Water Pump Enhances Efficiency and Reliability in Marine Operations[City, Date] - As the maritime industry continues to evolve and seek innovative solutions to enhance efficiency and reliability, the Marine Water Pump has emerged as a game-changer in marine operations. Manufactured by a reputed company [], this cutting-edge technology is revolutionizing the industry's approach towards water pumping systems.With the ever-increasing demand for efficient water transportation, maintaining reliable pumping systems becomes crucial. The Marine Water Pump, crafted with precision and advanced engineering, offers an ideal solution for various marine applications. Whether it's for ballast water management, bilge pumping, or firefighting operations, this water pump offers unmatched performance and efficiency.One of the key aspects that sets the Marine Water Pump apart from traditional systems is its durability and reliability. Constructed from high-quality materials, this pump is built to withstand the harsh marine environment, ensuring longevity and minimal downtime. The corrosion-resistant body and components minimize the risk of damage and reduce maintenance costs, making it an ideal choice for marine operators seeking cost-effective solutions.Moreover, the compact design of the Marine Water Pump enables easy installation and integration into existing marine systems. Its versatility allows for seamless compatibility with different vessel types, ranging from small crafts to large commercial ships. By reducing installation time and complexity, this pump assists marine operators in streamlining their operations and maximizing productivity.Furthermore, the advanced engineering behind the Marine Water Pump ensures optimal performance and energy efficiency. With its superior pumping capabilities, this technology enables faster water transfer and drainage, saving valuable time during critical marine operations. The pump's adjustable flow and pressure settings provide operators with greater control, allowing for enhanced operational precision and flexibility.In the context of environmental sustainability, the Marine Water Pump upholds the highest standards. It incorporates advanced filtration and purification systems, ensuring compliance with strict maritime environmental regulations. By effectively managing ballast water and preventing the spread of invasive species, this pump contributes to the preservation of marine ecosystems and supports sustainable water transportation practices.In addition to its performance and reliability, the company behind the Marine Water Pump, [], brings extensive expertise and experience to the table. With a proven track record in developing innovative marine technologies, the company has earned a reputation for delivering industry-leading solutions. Its commitment to research and development ensures that the Marine Water Pump remains at the forefront of technological advancements, constantly pushing the boundaries of efficiency and reliability.To support its customers in maximizing the benefits of the Marine Water Pump, the company offers comprehensive after-sales services. With a global network of service centers and technicians, the company ensures prompt assistance and maintenance support, minimizing downtime and maximizing uptime for marine operators. This dedication to customer satisfaction has contributed to the company's strong presence in the maritime industry worldwide.As the demand for efficient water pumping systems continues to grow in the maritime sector, the Marine Water Pump stands out as a game-changer. Its durability, reliability, and efficiency make it an indispensable asset for marine operators aiming to optimize their operations and reduce costs. With the backing of its visionary manufacturer [], the Marine Water Pump is set to redefine the standards of water pumping in the maritime industry.

Wholesale Check Valve Function Manufacturers: Exploring the Functionality of Check Valves in Bulk

In recent years, the demand for check valves has been steadily increasing in various industries. These valves are essential in maintaining the flow direction of fluids and preventing backflow, ensuring the smooth operation of pipelines and preventing potential damages. As a result, wholesale check valve function factories have become crucial players in meeting this growing demand.One such wholesale check valve function factory, which would like to stay anonymous for the purpose of this news article, has been making significant contributions to various industries by providing top-quality check valves. With a focus on manufacturing products that are not only reliable but also cost-effective, this factory has gained recognition for its commitment to customer satisfaction.Established several years ago, this factory has gradually expanded its manufacturing capabilities and product range to cater to diverse applications. They have a team of experienced engineers and technicians who utilize cutting-edge technology and advanced production techniques to ensure the production of high-quality check valves. These professionals have extensive knowledge and expertise in valve manufacturing, enabling them to meet the specific requirements of different industries.The check valves manufactured by this factory undergo a rigorous quality control process that adheres to international standards. They are made from durable materials that are resistant to corrosion, pressure, and temperature variations, ensuring longevity and reliability. Additionally, the valves are designed with precision to achieve maximum efficiency and minimum flow resistance, ultimately maximizing performance.One of the key features of their check valves is their versatility. Whether it's for industrial applications, water management systems, oil and gas industries, or HVAC systems, the factory can provide customized solutions to meet the unique requirements of their clients. They offer a wide range of check valves, including swing check valves, lift check valves, wafer check valves, and ball check valves, among others. This extensive selection allows customers to choose the valve that best suits their needs.Furthermore, the factory takes pride in its excellent customer service. They understand the importance of timely delivery and offer flexible shipping options to ensure that customers receive their orders on time. The factory also provides technical support and guidance to assist customers in selecting the most suitable check valve for their specific applications.As a wholesale function factory, they offer competitive prices for their check valves without compromising on quality. This has allowed them to establish long-term partnerships with clients both domestically and internationally. The factory actively seeks feedback from customers to continuously improve their products and services, striving to stay at the forefront of the valve manufacturing industry.In conclusion, wholesale check valve function factories play a crucial role in meeting the increasing demand for high-quality check valves across various industries. This anonymous factory, through its commitment to manufacturing excellence, offers a diverse range of reliable and cost-effective check valves designed to meet the specific requirements of different applications. With exceptional customer service and a dedication to continuous improvement, this factory has cemented its position as a trusted supplier in the valve industry.