High-Quality and Efficient Pump Solutions in Tianjin

By:Admin

Tianjin Pump's comprehensive range of products includes centrifugal pumps, positive displacement pumps, and other specialty pumps, all of which are designed to deliver superior performance and efficiency. The company also offers custom pump solutions to address specific challenges faced by its clients, demonstrating its commitment to delivering complete satisfaction.

In addition to its exceptional product offerings, Tianjin Pump takes pride in its advanced manufacturing facilities and strict quality control processes. These capabilities ensure that every pump that bears the company's name meets the highest standards of excellence and durability, making it the preferred choice for many industrial applications.

Moreover, Tianjin Pump's dedication to customer service sets it apart from its competitors. The company's team of experienced engineers and technical experts work closely with clients to understand their unique requirements and provide tailored recommendations. This personalized approach has earned Tianjin Pump a reputation for reliability and trustworthiness in the industry.

Recently, Tianjin Pump has announced the launch of a new series of pumps that are set to revolutionize the industrial pumping sector. These cutting-edge pumps leverage the latest technological advancements to deliver unmatched performance, energy efficiency, and reliability. With this new product line, Tianjin Pump aims to further solidify its position as a leading player in the global pump market.

In addition to its focus on product innovation, Tianjin Pump is also committed to sustainability and environmental responsibility. The company continuously explores ways to minimize its environmental footprint and develop eco-friendly pump solutions. By doing so, Tianjin Pump not only meets the growing demand for green products but also contributes to a more sustainable future.

As Tianjin Pump continues to expand its presence in the global market, the company remains dedicated to upholding its core values of quality, innovation, and customer satisfaction. With a strong foundation built on decades of industry expertise, Tianjin Pump is well-equipped to meet the diverse needs of its clients and drive positive change in the world of industrial pumping.

In conclusion, Tianjin Pump is more than just a pump manufacturer – it is a reliable partner for industrial companies looking for top-tier pumping solutions. With its unwavering commitment to excellence, innovation, and customer satisfaction, Tianjin Pump stands out as a beacon of quality and reliability in the competitive pump industry. As the company continues to push the boundaries of technological advancement and sustainability, its influence and impact on the global market are set to grow even further. Whether it's a standard pumping requirement or a unique, customized solution, clients can trust Tianjin Pump to deliver exceptional results every time.

Company News & Blog

Energy Efficient Heat Pump for House Heating

House Heating Heat Pump Offers Energy Efficient Heating SolutionWith the rising costs of energy and the increasing concern for the environment, more and more homeowners are looking for energy-efficient heating solutions. One such solution is the House Heating Heat Pump, a revolutionary heating system that offers both energy efficiency and superior performance. As an industry leader in heating technology, the company is dedicated to providing innovative solutions for homeowners looking to reduce their energy consumption and carbon footprint.The House Heating Heat Pump is a cutting-edge heating system that utilizes the latest in heat pump technology to provide efficient and consistent heating for residential properties. Unlike traditional heating systems that rely on burning fossil fuels, the House Heating Heat Pump extracts heat from the air or ground and transfers it indoors to provide warmth. This process of heat transfer is not only more energy-efficient, but it also reduces the reliance on non-renewable energy sources, making it a more sustainable heating solution.In addition to its energy efficiency, the House Heating Heat Pump is also known for its versatility and reliability. It can be used for both heating and cooling, making it a year-round heating solution for homeowners. Furthermore, the system is designed to operate quietly and efficiently, providing a comfortable living environment without the noise and fluctuations commonly associated with traditional heating systems.Furthermore, the House Heating Heat Pump is easy to install and maintain, making it an attractive option for homeowners looking for a hassle-free heating solution. The system is designed for long-term performance, with minimal maintenance requirements and a longer lifespan compared to traditional heating systems. This not only reduces the overall cost of ownership but also provides peace of mind for homeowners who are looking for a reliable heating solution.With a commitment to innovation and sustainability, the company behind the House Heating Heat Pump has established itself as a leader in the heating technology industry. The company has a team of dedicated engineers and technicians who are constantly working to improve and expand their product offerings to meet the evolving needs of homeowners. The company also places a strong emphasis on research and development, ensuring that its products are at the forefront of technological advancements in the heating industry.Furthermore, the company is dedicated to providing exceptional customer service and support for homeowners who choose the House Heating Heat Pump. With a network of certified technicians and installers, the company ensures that its customers receive professional and reliable assistance for installation, maintenance, and repairs. This commitment to customer satisfaction has earned the company a reputation for excellence and reliability in the industry.The House Heating Heat Pump is not only a practical heating solution but also a smart investment for homeowners. With its energy efficiency and long-term performance, the system offers significant cost savings over time. Additionally, many homeowners may be eligible for government incentives and rebates for installing energy-efficient heating systems, making the transition to the House Heating Heat Pump even more affordable.As the demand for energy-efficient heating solutions continues to grow, the House Heating Heat Pump stands out as a leader in the industry. With its innovative technology, commitment to sustainability, and dedication to customer satisfaction, the House Heating Heat Pump offers homeowners a reliable and efficient heating solution for the future. Whether homeowners are looking to reduce their energy consumption, lower their carbon footprint, or simply enjoy a comfortable living environment, the House Heating Heat Pump is a smart choice for modern homeowners.

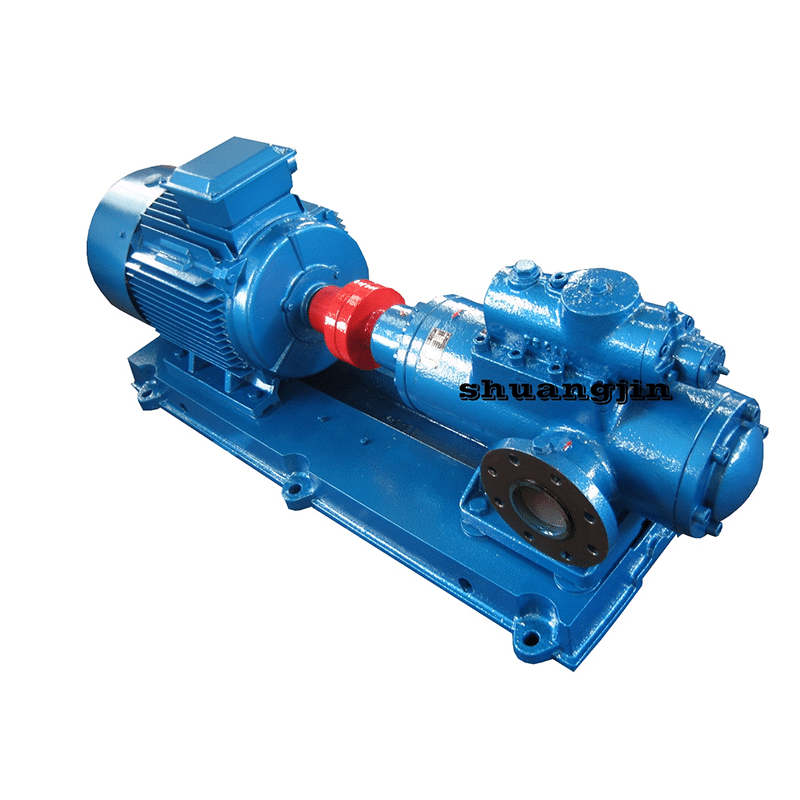

Durable and Efficient Twin Screw Pump for Various Industrial Applications

Fristam Twin Screw Pump has recently introduced a new and innovative solution to meet the growing demand for efficient pumping systems in various industries. With a focus on reliability, performance, and ease of maintenance, this new pump is set to revolutionize the way companies handle their fluid transfer needs.The Fristam Twin Screw Pump is designed to handle a wide range of applications, including food and beverage, pharmaceutical, chemical, and personal care, among others. Its unique design allows for gentle product handling, making it suitable for delicate or shear-sensitive products. With its high efficiency and low pulsation characteristics, this pump is ideal for applications where product integrity is crucial.One of the key features of the Fristam Twin Screw Pump is its ability to handle both low and high viscosity products with ease. This versatility makes it a valuable asset for companies dealing with a variety of different substances. Additionally, its hygienic design and ease of cleaning make it compliant with the strict regulations and standards of the food and pharmaceutical industries.In addition to its impressive performance capabilities, the Fristam Twin Screw Pump is also designed with maintenance in mind. The pump is easy to disassemble and reassemble, reducing downtime and lowering the overall cost of ownership. This feature is especially important for companies looking to maximize their operational efficiency and minimize unnecessary expenses.Furthermore, the Fristam Twin Screw Pump is built to last, with a durable construction that can withstand the demands of continuous use. Its robust design and high-quality materials ensure that it can operate reliably for extended periods, providing companies with peace of mind and confidence in their pumping capabilities.With the introduction of the Fristam Twin Screw Pump, the company continues to solidify its position as a leading provider of pumping solutions for various industries. The pump is a testament to the company's commitment to innovation and excellence, and it is expected to make a significant impact in the market.In summary, the launch of the Fristam Twin Screw Pump represents a major milestone for the company and its customers. With its impressive performance, versatile capabilities, and ease of maintenance, this pump is set to become a valuable asset for companies across a wide range of industries. As the demand for efficient and reliable pumping systems continues to grow, the Fristam Twin Screw Pump is well-positioned to meet and exceed the expectations of its users.

A Guide to Choosing the Best Gear Pump for Industrial Applications

article regarding the features and benefits of an Oil Gear Pump for industrial applications.Oil Gear Pump: The Reliable Choice for Industrial ApplicationsAn oil gear pump is an industrial pump that is commonly used to transfer fluids such as oil, glycol, and water in a variety of industrial applications. The pump is designed to deliver a steady and continuous flow of fluid in a range of pressures and temperatures.One of the significant benefits of an oil gear pump is its high efficiency in transferring fluids. The pump has a positive displacement mechanism that eliminates wasteful fluid transfer, ensuring that fluids are transferred efficiently with minimal energy loss. This makes the oil gear pump an ideal solution for industries that require high levels of precision and accuracy in fluid transfer.Another benefit of the oil gear pump is its versatility. The pump can be used in a range of applications, including power generation, oil and gas, chemical processing, pulp and paper, and many others. The ability of the pump to handle different types of fluids and varying pressure levels makes it a reliable choice for many industries.Oil gear pumps are also known for their durability and reliability. The pump is made of robust materials that can withstand harsh industrial environments. The design of the pump allows for minimal maintenance, providing a long-lasting and reliable solution for fluid transfer applications.In addition to its durability, the oil gear pump is designed with safety in mind. The pump’s design eliminates the risk of leaks, ensuring that fluid transfer is safe and reliable. This is especially important in industries where safety is a top priority such as in the oil and gas industry, chemical processing, and pharmaceuticals.One of the leading companies that provide oil gear pumps is ATEX Pumps. The company specializes in providing pumps for industrial applications and has a range of oil gear pumps that are designed to meet the specific requirements of different industries.ATEX Pumps oil gear pumps are designed with high-quality materials, making them reliable and long-lasting. The pumps have a compact design that allows for easy installation and minimal maintenance. ATEX Pumps oil gear pumps are also customizable, allowing for pumps that meet specific flow rates, pressure requirements, and fluid types.Apart from oil gear pumps, ATEX Pumps provides a range of other pumps that are suitable for various industrial applications. These include centrifugal pumps, magnetic drive pumps, diaphragm pumps, and many others. ATEX Pumps also provides customized solutions that meet the unique requirements of different industries.In conclusion, an oil gear pump is a reliable and efficient solution for fluid transfer applications in various industries. Its high efficiency, versatility, durability, and safety features make it a popular choice for many industries. If you are looking for an oil gear pump for your industrial application, ATEX Pumps is an excellent choice for quality and reliability.

Top rated screw gear pump for industrial use

Screw Gear Pump, the latest innovation in fluid handling technology, is set to revolutionize the way companies in various industries handle the transfer of fluids. This groundbreaking pump is designed to offer unparalleled efficiency, reliability, and performance, making it an ideal choice for businesses looking to streamline their operations and minimize downtime.With a commitment to delivering high-quality, innovative solutions for fluid handling challenges, [Company Name] is proud to introduce the Screw Gear Pump to its extensive line of industrial pumps. The [Company Name] has a proven track record of providing cutting-edge solutions for a wide range of industries, from oil and gas to food and beverage, and the addition of the Screw Gear Pump further solidifies their position as a leader in the field.The Screw Gear Pump, developed using advanced engineering and manufacturing techniques, offers numerous advantages over traditional pump technologies. Its unique design features intermeshing screws and gears, which create a continuous, non-pulsating flow of fluids, resulting in smooth and efficient operation. This innovative design also reduces the risk of cavitation and provides a high degree of reliability, ensuring minimal maintenance and downtime for businesses.Furthermore, the Screw Gear Pump is capable of handling a wide range of viscosities, from thin liquids to highly viscous fluids, making it a versatile choice for a variety of applications. Its ability to deliver consistent flow rates and precise metering also makes it an ideal solution for businesses looking to maintain precise control over their fluid transfer processes.One of the key advantages of the Screw Gear Pump is its ability to handle abrasive and shear-sensitive materials with ease. This makes it an ideal choice for industries such as mining and chemical processing, where the transfer of abrasive and delicate materials is a common requirement. The pump's robust construction and advanced materials ensure that it can withstand the harshest operating conditions, making it a reliable and long-lasting solution for businesses operating in challenging environments.In addition to its exceptional performance, the Screw Gear Pump is also designed with ease of maintenance and serviceability in mind. Its modular design and easily replaceable components enable quick and hassle-free maintenance, minimizing downtime and reducing operating costs for businesses. This focus on ease of maintenance and serviceability underscores [Company Name]'s commitment to providing practical and user-friendly solutions for its customers.The introduction of the Screw Gear Pump represents a significant milestone for [Company Name] and reinforces its position as a leading provider of innovative fluid handling solutions. With a strong focus on research and development, [Company Name] continues to push the boundaries of pump technology, delivering cutting-edge solutions that meet the evolving needs of its customers.Furthermore, [Company Name] is dedicated to providing comprehensive support and service for its products, ensuring that customers can maximize the performance and longevity of their Screw Gear Pumps. A team of experienced engineers and technicians is available to provide installation assistance, technical support, and maintenance services, helping businesses achieve optimal performance and efficiency from their pump systems.In conclusion, the Screw Gear Pump represents a significant advancement in fluid handling technology and is set to deliver substantial benefits for businesses across a wide range of industries. With its innovative design, exceptional performance, and ease of maintenance, the Screw Gear Pump is a versatile and reliable solution for businesses looking to optimize their fluid transfer processes. As [Company Name] continues to innovate and expand its product offerings, the introduction of the Screw Gear Pump underscores its commitment to providing practical and high-quality solutions for its customers.

Twin Screw Pump: Latest Advancements and Applications in Pumping Technology

Alfa Laval Twin Screw Pump (brand name removed), an innovative and highly efficient pumping solution, is designed to meet the needs of various industries including food and beverage, pharmaceutical, marine, and oil and gas. With its advanced technology and superior performance, this pump is capable of handling a wide range of liquid transfer applications, making it an essential equipment in many industrial processes.The Alfa Laval Twin Screw Pump is renowned for its ability to handle both low and high viscosity liquids with ease, making it a versatile pumping solution for various industries. The pump’s unique design features two intermeshing screws that rotate in opposite directions, creating a continuous flow of liquid with minimal pulsation and shear force. This results in gentle and efficient product handling, making it ideal for pumping delicate and shear-sensitive fluids such as dairy products, pharmaceutical ingredients, and cosmetics.One of the key advantages of the Alfa Laval Twin Screw Pump is its ability to handle entrained air and gas, making it suitable for applications where aeration and foaming are common challenges. The pump’s robust construction and high suction capability allow for smooth and reliable operation even in demanding environments. This makes it an ideal choice for applications such as tank-to-tank transfer, product recovery, and CIP (clean-in-place) processes in the food and beverage industry.In addition to its exceptional performance, the Alfa Laval Twin Screw Pump is also designed for easy maintenance and cleaning. Its hygienic design features smooth surfaces and clean-in-place capabilities, ensuring that the pump can be quickly and thoroughly cleaned between product changeovers. This is essential for industries such as pharmaceutical and biotechnology, where product purity and sanitation are critical requirements.The Alfa Laval Twin Screw Pump is also suitable for marine and offshore applications, where reliable and efficient pumping solutions are essential for various onboard processes. Its compact and space-saving design makes it an ideal choice for installations with limited space, while its ability to handle high viscosity fuels and lubricants makes it a versatile solution for marine fuel transfer and lubrication systems.Moreover, the pump’s compliance with industry standards and regulations, such as EHEDG, 3-A, and FDA, ensures that it meets the stringent requirements of the food and pharmaceutical industries. This makes it a trusted and reliable pumping solution for critical processes where product safety and hygiene are of utmost importance.With its proven performance and versatility, the Alfa Laval Twin Screw Pump has established itself as a leading pumping solution in various industries. Its ability to handle a wide range of liquid transfer applications, combined with its gentle product handling and easy maintenance, makes it an essential equipment for many industrial processes. The pump’s advanced technology and hygienic design make it a reliable and efficient choice for industries that require high-quality and consistent liquid transfer solutions.In conclusion, the Alfa Laval Twin Screw Pump is a highly efficient and versatile pumping solution that meets the needs of various industries, including food and beverage, pharmaceutical, marine, and oil and gas. Its advanced technology, superior performance, and compliance with industry standards make it a trusted and reliable choice for critical liquid transfer processes. Whether it is for gentle product handling, efficient aeration handling, or easy maintenance and cleaning, this pump offers a comprehensive solution for a wide range of industrial applications.

Understanding the Working Principle of Single Screw Pumps

Single screw pump, also known as Archimedes screw pump, is a type of positive displacement pump that can efficiently move fluid through a system. It is a versatile and reliable pump that is widely used in various industries including oil and gas, food and beverage, wastewater treatment, and marine applications. With its simple design and high efficiency, the single screw pump is a popular choice for many pumping applications.The working principle of a single screw pump is quite simple yet effective. It consists of a single screw rotor that rotates inside a double-threaded stator. As the rotor turns, it creates cavities between the screw and the stator, which allows the fluid to be pulled into the pump. As the rotor continues to rotate, the cavities move the fluid along the length of the stator, pushing it out through the discharge port. This continuous movement of the screw rotor creates a smooth and pulsation-free flow of fluid, making the single screw pump suitable for handling shear-sensitive and viscous fluids.One company that has been at the forefront of manufacturing and supplying single screw pumps is {}. With a history tracing back to over a century, {} has established itself as a leading provider of pumping solutions for various industries. The company's single screw pumps are designed to meet the rigorous demands of modern industrial applications, offering high performance, reliability, and long service life.{}'s single screw pumps are built with precision engineering and high-quality materials to ensure optimal performance and minimal maintenance. The company offers a wide range of single screw pump models to suit different flow rates, pressures, and fluid viscosities, catering to the diverse needs of its customers. In addition, {} provides comprehensive technical support and after-sales service to ensure that its customers get the most out of their pumping systems.The application of {}'s single screw pumps spans across various industries. In the oil and gas sector, these pumps are used for transferring crude oil, drilling mud, and various other fluids in upstream, midstream, and downstream operations. In the food and beverage industry, {}'s single screw pumps are employed for handling viscous and delicate products such as chocolate, syrup, and dairy. Additionally, these pumps are widely used in wastewater treatment plants for pumping sludge, effluent, and other fluids with high solids content.The success of {}'s single screw pumps can be attributed to the company's commitment to innovation and continuous improvement. {}'s research and development team is constantly exploring new technologies and materials to enhance the performance and efficiency of its pumps. Through ongoing investment in research and technology, {} aims to stay ahead of the curve and provide cutting-edge solutions to its customers.Furthermore, {} places a strong emphasis on quality control and testing to ensure that its single screw pumps meet the highest standards of reliability and durability. The company's manufacturing facilities are equipped with state-of-the-art equipment and processes to produce pumps that are robust, efficient, and capable of withstanding harsh operating conditions.In conclusion, single screw pumps are an integral part of many industrial processes, and {} has been a key player in providing high-quality pumping solutions to a wide range of industries. With its proven track record and commitment to excellence, {} continues to be a trusted partner for businesses looking for reliable and efficient single screw pumps. As the demand for advanced pumping technology continues to grow, {} is well-positioned to lead the way with its innovative and reliable pumping solutions.

Innovative Triple Screw Pump Technology: Revolutionizing Industrial Fluid Transfer

Triple Screw Pump Offers High-Level Performance for Industrial Applications{Company Name} is proud to introduce the triple screw pump, a high-level performance solution for industrial applications. With the ability to handle viscous fluids while providing smooth and continuous flow, this reliable pump is ideal for a variety of industrial processes.One of the significant advantages of this pump is its high efficiency. It can achieve up to 90% efficiency while still being able to handle high-viscosity fluids such as crude oil, asphalt, and bitumen. This makes it an ideal solution for industries that require a high level of performance in their fluid handling processes.Another key feature of the triple screw pump is its ability to maintain consistent flow, even with varying inlet pressures. The screw design creates a clearing action within the pump, which means that there is a minimal risk of clogging or blockages, even with thicker fluids.The triple screw pump has been designed with ease of use in mind, making it an ideal choice for operators who need a low-maintenance solution. A self-priming design enables the pump to start and stop without the need for manual intervention, and it requires minimal disassembly for cleaning and servicing.Moreover, the pump has a compact footprint, which makes it easy to install and integrate into existing systems. Its low noise and vibration levels make it an ideal solution for applications where noise pollution and vibration could be an issue.It is recommended for industries that deal with liquid transfer, applications that need high pressure, high viscosity, and high temperature. Additionally, the triple screw pump is ideal for applications that involve feeding multiple points at once, as it can operate on a different number of pressures and flows.Furthermore, the triple screw pump is highly customizable, which means that it can be tailored to meet the specific needs of individual applications. Customization options include different materials of construction, various sealing systems, and different RPMs to suit the application's requirements.{Company Name} CEO, {Name}, stated "We are thrilled to offer this high-performance solution to our customers. The triple screw pump is an ideal choice for industries that require consistency and reliability in their fluid handling processes."In conclusion, the Triple Screw Pump offers high-level performance for industrial applications. With its high efficiency, consistent flow, low maintenance requirement, and customizable design, it is ideal for industries that deal with high-pressure, high-viscosity, and high-temperature applications. Operators can use it to feed multiple points at once while achieving a smooth and continuous flow.

Discover the Benefits of Using Industrial Screw Pumps for Pumping Applications

Title: Revolutionary Screw Pumps Set to Transform Industrial ProcessesIntroduction:In the ever-evolving world of industrial processes, one company is making headlines for its groundbreaking product: Screw Pumps. Designed to be efficient, reliable, and customizable, these pumps are set to revolutionize various sectors, from oil and gas to wastewater treatment. With their innovative features and advanced technology, Screw Pumps are quickly gaining recognition as the go-to solution for numerous industrial applications.Company Background and Vision:Established in {year of establishment}, {Company Name} has been at the forefront of innovation and engineering excellence for several decades. With a strong focus on research and development, the company has successfully introduced cutting-edge products and solutions to the market. Drawing on their extensive expertise, {Company Name} recognized the need for a more reliable and efficient pumping solution, leading to the development of Screw Pumps.The Revolutionary Design:The standout feature of Screw Pumps lies in their innovative screw technology. Unlike conventional pumps, Screw Pumps utilize a pair of intermeshing screws that rotate within a tightly sealed enclosure. This design not only eliminates the need for valves, pistons, and other moving parts but also drastically reduces energy consumption and maintenance requirements. The screws themselves are precision-engineered from high-quality materials, ensuring a longer lifespan and enhanced durability.Unparalleled Versatility:The versatility of Screw Pumps makes them suitable for a wide range of industrial applications. From oil refineries and petrochemical plants to food processing facilities and manufacturing plants, these pumps offer unparalleled performance and efficiency. They excel in handling both abrasive and non-abrasive fluids, such as crude oil, slurries, sewage, chemicals, and even high-viscosity liquids. The ability to handle such diverse applications makes Screw Pumps an ideal choice for industries worldwide.Energy Efficiency for Sustainability:One of the key advantages of Screw Pumps is their energy-efficient operation. By utilizing a low-shear process, these pumps greatly reduce energy consumption and contribute to a more sustainable future. Additionally, the absence of valves and pistons eliminates energy loss due to friction, resulting in substantial cost savings for industries. With environmental concerns becoming increasingly prominent, Screw Pumps offer an eco-friendly solution without compromising on performance.Enhanced Reliability and Lower Maintenance:Reliability is of utmost importance in any industrial process, and Screw Pumps deliver on that front. Thanks to their simple design and robust construction, these pumps require minimal maintenance and provide extended service life. The absence of valves and pistons translates to fewer components that can fail, reducing the risk of unplanned downtime and costly repairs. This reliability ensures uninterrupted operation, ultimately boosting the productivity and profitability of businesses.Customizable Solutions:Recognizing that different industries and processes require specific solutions, {Company Name} offers customized Screw Pump configurations tailored to meet individual requirements. This customization may include various material options, screw profiles, and pump sizes to optimize performance. By working closely with clients, {Company Name} ensures that the Screw Pumps not only meet but exceed their expectations, providing solutions that enhance efficiency and productivity.Conclusion:As industries continue to demand more efficient and sustainable solutions, Screw Pumps stand out as a game-changer. Combining their innovative design, energy efficiency, and reliability, these pumps have the potential to transform industrial processes across various sectors. With {Company Name} leading the way, businesses can now benefit from a cutting-edge pumping solution that boosts productivity, reduces environmental impacts, and ensures long-term success in the years to come.

Innovative Screw Pump Technology: Uses and Benefits

Screw Pump Uses in Various IndustriesScrew pumps are widely used in various industries such as chemical, oil and gas, wastewater treatment, and many more. They are designed to handle a wide range of fluids and are known for their reliability and efficiency. One company that has been leading the way in screw pump technology is a global leader in fluid handling solutions.With a history dating back to the 19th century, the company has been at the forefront of innovation in the field of fluid handling. They have a strong focus on research and development, constantly looking for ways to improve their products and provide better solutions to their customers' needs.One of the key products in their portfolio is their screw pump, which has been widely used in various industries. These pumps are known for their high efficiency and reliability, making them the preferred choice for many companies around the world.The screw pump is designed to handle a wide range of fluids, from highly viscous liquids to abrasive slurries. This versatility makes it an ideal choice for industries such as chemical processing, where the handling of various fluids is a common requirement.In the oil and gas industry, screw pumps are used for a wide range of applications, including crude oil transportation, pipeline boosting, and refinery processes. Their ability to handle high-pressure and high-temperature fluids makes them an essential part of many oil and gas operations.Another industry where screw pumps are widely used is wastewater treatment. In this industry, the handling of sludge and other waste fluids requires pumps that are reliable and efficient. The company’s screw pumps have been proven to be highly effective in this application, making them the go-to choice for many wastewater treatment plants around the world.Apart from their versatility and reliability, screw pumps from the company are also known for their low maintenance requirements. This makes them a cost-effective solution for many companies, as it reduces the need for frequent maintenance and repair.The company's commitment to quality and innovation has allowed them to stay ahead of the competition in the field of fluid handling. Their screw pumps are continually being improved and optimized to meet the evolving needs of their customers, ensuring that they remain the preferred choice for industries around the world.With a strong global presence, the company is able to provide excellent support and service to their customers, ensuring that their screw pumps continue to perform at the highest level.In conclusion, screw pumps are a crucial component in various industries, and the company has been at the forefront of providing high-quality and reliable screw pump solutions for their customers. With their focus on innovation and commitment to customer satisfaction, the company continues to lead the way in the field of fluid handling.

Screw Pump Diagram: A Detailed Guide to Understanding How Screw Pumps Work

Screw Pump DiagramScrew pumps are a crucial component in a variety of industries, including oil and gas, water treatment, and food and beverage. They are used to move liquids or slurries and are known for their reliability and efficiency. One company at the forefront of screw pump technology is {}. Their innovative designs and high-quality products have made them a leading supplier in the industry.Screw pumps, also known as progressive cavity pumps, work by using a screw-shaped rotor to move fluid through the pump. As the rotor turns, it creates a series of small chambers between the screw and the pump housing. These chambers trap the fluid and move it along the length of the screw before releasing it at the outlet. This design allows for a smooth and consistent flow of fluid, making screw pumps ideal for applications where precise and continuous pumping is necessary.{} has been a key player in the screw pump industry for over 30 years. The company prides itself on its commitment to innovation and customer satisfaction. Their team of engineers and technical experts are constantly working to improve their products and develop new technologies to meet the evolving needs of their clients. With a focus on quality and reliability, {} has built a reputation for excellence in the industry.One of the key features of {}'s screw pump design is its ability to handle a wide range of viscosities and fluid types. Whether it's thick sludge in a wastewater treatment plant or high-viscosity crude oil in a refinery, their pumps are designed to deliver consistent performance and efficiency. This versatility makes {}'s screw pumps an attractive choice for a variety of industries and applications.In addition to their standard product line, {} also offers customized solutions to meet the specific needs of their clients. They work closely with customers to understand their requirements and develop tailored pump systems that deliver optimal performance and reliability. This dedication to customer service has helped {} build long-lasting relationships with clients around the world.Another important aspect of {}'s screw pump technology is its focus on energy efficiency. By optimizing their pump designs and utilizing advanced materials, they have been able to reduce energy consumption and operational costs for their clients. This commitment to sustainability and cost-effectiveness has made {} a trusted partner in the industry.As the demand for screw pumps continues to grow, {} remains at the forefront of the industry. Their ongoing investment in research and development and dedication to quality and customer satisfaction set them apart in the market. With a global network of sales and service partners, {} is well-positioned to meet the needs of their clients wherever they may be.In conclusion, screw pumps play a critical role in a wide range of industries, and {} has established itself as a leading supplier in the industry. With a focus on innovation, quality, and customer satisfaction, they have earned a reputation for excellence in the market. As the demand for screw pumps continues to grow, {} is well-positioned to meet the needs of their clients and drive the industry forward with their advanced technology and superior products.