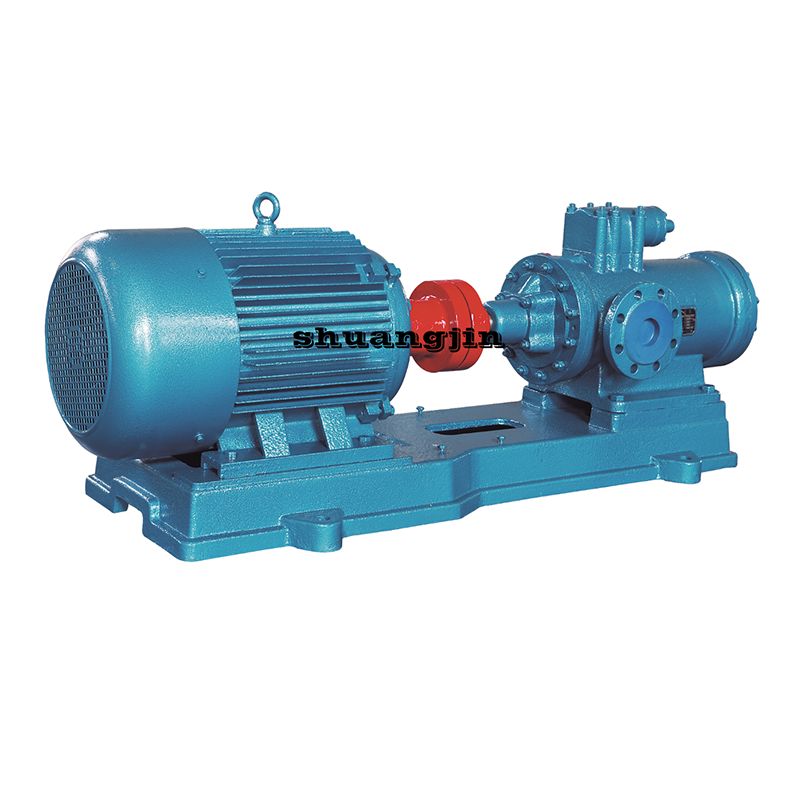

High-Quality Screw Pump Specifications for Industrial Use

By:Admin

{Company Name} is proud to announce the launch of their latest range of screw pumps, designed to meet the demanding requirements of industrial applications. These high-quality pumps are engineered to provide reliable and efficient performance, making them the ideal choice for a wide range of industries including oil and gas, petrochemical, marine, and more.

The new screw pump range from {Company Name} features a variety of specifications and configurations, ensuring that customers can find the perfect pump to meet their unique needs. With flow rates ranging from 5m³/h to 2000m³/h and pressure capabilities of up to 48 bar, these pumps are suitable for a diverse array of applications. Additionally, they are available in different materials such as cast iron, stainless steel, and bronze, providing versatility and durability.

One of the key features of the new screw pump range is its ability to handle a wide range of viscosities, from low to high. This makes them well-suited for transferring a variety of fluids, including light and heavy fuel oils, lubricating oils, hydraulic oils, and more. The pumps also offer smooth and pulsation-free flow, ensuring consistent and reliable operation.

{Company Name} has a long-standing reputation for delivering high-quality pumping solutions to their customers. With a focus on innovation and excellence, the company is dedicated to providing products that meet the highest standards of performance and reliability. This commitment is reflected in the design and engineering of the new screw pump range, which is built to deliver exceptional results in even the most challenging industrial environments.

In addition to their impressive technical specifications, the screw pumps from {Company Name} are also designed with ease of maintenance in mind. With simple and accessible components, these pumps are straightforward to service and repair, minimizing downtime and ensuring optimal productivity for the end user. This, combined with the pumps' robust construction, means that they offer a long and reliable service life.

{Company Name} takes great pride in their ability to provide comprehensive support and service to their customers. From initial consultation and product selection, through to installation, maintenance, and aftermarket support, the company is dedicated to ensuring that their clients receive the best possible experience. The launch of the new screw pump range is yet another example of {Company Name}'s commitment to meeting the evolving needs of their customers with innovative and reliable solutions.

With their outstanding performance, durability, and versatility, the new screw pumps from {Company Name} are set to become an essential component in a wide variety of industrial applications. Whether it's in the transportation of fuels and lubricants, hydraulic machinery, marine applications, or any other demanding industrial process, these pumps are designed to deliver outstanding results.

For more information about the new screw pump range from {Company Name}, including detailed specifications and options, customers can contact the company directly or visit their website. With their proven track record of excellence and dedication to customer satisfaction, {Company Name} is the ideal partner for any industrial pumping needs.

Company News & Blog

The Significance of Timing Gears in Screw Pumps: Exploring their Role and Function

Timing Gear in Screw Pump: A Revolutionary Advancement in Pump Technology[Company Name], a leading innovator in the field of pump technology, has recently unveiled a breakthrough development in screw pump design – the revolutionary Timing Gear. This state-of-the-art advancement is set to transform the way pumps function, offering enhanced efficiency, reliability, and durability.Traditional screw pump designs rely on a rotating helical screw to move fluids through the pump. While these pumps have proven to be effective for many applications, they often suffer from issues such as uneven fluid flow, excessive vibration, and premature wear of the screw and other internal components.With the introduction of the Timing Gear, [Company Name] aims to eliminate these drawbacks and create a new benchmark in screw pump performance. This innovative gear mechanism, which replaces the traditional single-helix screw, provides precise control over the flow of fluids, resulting in smoother operation and improved overall efficiency.One of the primary advantages of the Timing Gear is its ability to maintain a consistent flow rate, regardless of variations in input pressure or viscosity of the fluid being pumped. This feature makes it highly suitable for applications where a reliable and steady flow is crucial, such as in the oil and gas industry, chemical processing plants, and wastewater treatment facilities.Additionally, the Timing Gear significantly reduces unwanted vibrations that can cause excessive wear and tear on pump components. By incorporating advanced engineering principles, including precision machining and advanced materials, [Company Name] has ensured that their Timing Gear pumps operate with minimal noise and vibrations, thereby increasing their service life and reducing maintenance costs.Another noteworthy feature of the Timing Gear is its remarkable durability. The gear mechanism is designed to withstand high operating pressures and resist corrosion, making it suitable for use in harsh and demanding environments. Its robust construction ensures long-term reliability and reduced downtime, providing businesses with a cost-effective solution for their pumping needs.Furthermore, the Timing Gear’s design allows for easy maintenance and quick replacement of worn components. Its modular construction enables users to access and replace specific parts, reducing the need for extensive disassembly and minimizing downtime during servicing. Additionally, the gear’s simplicity of design enhances reliability, as fewer moving parts mean fewer opportunities for mechanical failures.[Company Name] has already received overwhelmingly positive feedback from early adopters of the Timing Gear. Companies that have integrated this groundbreaking technology into their pump systems have reported significant improvements in efficiency, productivity, and overall performance. Several industry experts have also praised this innovation, recognizing its potential to revolutionize the screw pump market.In conclusion, [Company Name]’s introduction of the Timing Gear has set a new standard in screw pump technology. With its precise flow control, reduced vibrations, exceptional durability, and ease of maintenance, this groundbreaking development promises to deliver a range of benefits to businesses across various sectors. As this revolutionary advancement gains traction in the industry, it is expected to redefine the capabilities and expectations of screw pumps, establishing [Company Name] as a leader in pump technology innovation.

Efficient Lube Oil System for Smooth Pump Operations

Title: Cutting-Edge and Reliable Lube Oil System for Pumps Revolutionizes the IndustryIntroduction (100 words):The rapidly growing industrial sector demands high-performance machinery that can operate optimally while minimizing downtime. To cater to this need, an innovative and pioneering engineering company has developed a state-of-the-art Lube Oil System for Pumps. This revolutionary system is designed to enhance the efficiency, reliability, and longevity of pumps in various industries, facilitating increased productivity and reduced maintenance costs. Capitalizing on advanced technology and unparalleled expertise, the pioneering company continues to redefine the standards of pump lubrication systems, catering to diverse industry needs worldwide.1. Superior Technology and Unmatched Performance (150 words):The Lube Oil System for Pumps represents a paradigm shift in the field of pump lubrication. Leveraging cutting-edge technology, this system ensures smoother pump operations, extending equipment life considerably. By addressing common issues such as overheating, leaks, and inefficient lubrication, the system enhances overall pump performance and reduces the risk of catastrophic failure.By utilizing precision-engineered components, the Lube Oil System guarantees an efficient and consistent lubrication process, providing optimal operational parameters. This results in reduced friction, improved energy efficiency, and increased service intervals, saving businesses significant costs on maintenance, repair, and replacement.Furthermore, the system's advanced filtration system removes impurities and contaminants, preventing abrasive particles from causing damage and ensuring prolonged pump lifespan. With its user-friendly design and intuitive interface, the system is easily integrated into existing infrastructure, catering to a wide range of pump sizes and types.2. Protection against Contamination and Corrosion (150 words):The Lube Oil System for Pumps places utmost emphasis on safeguarding the pumps against contamination and corrosion, which are major contributors to equipment malfunctions. By employing cutting-edge technologies such as corrosion inhibitors, the system effectively combats the damaging effects of corrosive substances, including water content typically found in lubricants.Furthermore, strategically positioned sensors and monitoring devices ensure early detection of potential pump malfunctions. These intelligent sensors continuously monitor vital parameters such as temperature, pressure, and flow rates, instantly alerting operators in case of any irregularities. Such proactive measures not only minimize unplanned shutdowns but also enable predictive maintenance, preventing costly equipment failures and optimizing operational efficiency.3. Customizable Solutions for Specific Industry Needs (150 words):Recognizing the diversity of industrial requirements, the Lube Oil System for Pumps offers a range of customizable solutions tailored to specific industry needs. Whether it is heavy-duty pumps utilized in the oil and gas industry, high-pressure pumps in the manufacturing sector, or industrial water pumps, the system ensures optimal lubrication and protection for pumps operating under extreme conditions.Moreover, this versatile system can be seamlessly integrated into both new installations and existing setups, offering a cost-effective solution for businesses across various sectors. The company's technical experts work closely with clients to understand their unique requirements, providing personalized solutions that align with their operational guidelines, regulatory requirements, and sustainability goals.4. Sustainability and Environmental Responsibility (150 words):The Lube Oil System for Pumps incorporates sustainable practices and responsible environmental management into its design. The system optimizes lubricant consumption, reducing waste and minimizing the carbon footprint associated with replacing lubricants frequently.Additionally, the advanced filtration system efficiently removes impurities and contaminants, reducing the ecological impact and promoting cleaner, greener operations. By extending the lifespan of pumps, the system also helps reduce waste generated from premature pump replacements.Furthermore, the system's energy-efficient design enhances overall plant efficiency, contributing to reduced energy consumption and promoting sustainable manufacturing practices.Conclusion (100 words):The groundbreaking Lube Oil System for Pumps ushers in a new era of reliability, performance, and sustainability in the pump lubrication domain. Its cutting-edge technology and customizable solutions cater to the diverse needs of industries worldwide, minimizing operational risks, optimizing production, and reducing maintenance costs. The company's unwavering commitment to delivering superior products and services continues to revolutionize the industry, ensuring a seamless integration of their systems into all types of pump installations. With an unblemished track record and a customer-centric approach, the company stands at the forefront of the pump lubrication sector, providing innovative solutions that set new benchmarks for excellence.

Highly efficient centrifugal pumps revolutionizing industry operations

Centrifugal Pump Technology Boosts Efficiency and ProductivityIn today’s highly competitive world, businesses are clamoring for ways to improve their efficiency and productivity. One of the most often overlooked areas of improvement is in the realm of industrial pumps. Companies like [BRAND NAME REMOVED] are harnessing centrifugal pump technology to give businesses a powerful edge in their quest for increased output and profitability.Centrifugal pumps are well-known for their ability to transfer fluids from one location to another across different types of systems. They accomplish this through the use of a rotating impeller that is surrounded by a casing. As the impeller spins, it creates a force that pulls fluid in through the center of the pump, accelerates it, and then creates a high-pressure discharge at the outer circumference of the pump.This technology is incredibly versatile, utilized in a wide range of industries such as agriculture, mining, oil & gas, and water treatment. The reason centrifugal pumps are so popular is that they are reliable, efficient, energy-saving, and require minimal maintenance.[BRAND NAME REMOVED] understands the importance of this technology and has created a range of centrifugal pumps that are tailor-made for all kinds of industrial applications. Their pumps are manufactured using the highest-quality materials and the most advanced engineering techniques to provide optimal performance and durability.One of the company’s most successful products is the (REMOVED) Series Centrifugal Pump, which is designed to handle a wide range of fluids, including highly abrasive and corrosive liquids. The pump is also equipped with a sturdy bearing assembly and seals that are fully interchangeable with other leading brands, making it easy to integrate into existing systems.As a result of its highly efficient design, this centrifugal pump consumes less energy, which translates to significant cost savings for the user. Additionally, its compact size means it can be installed in tight spaces, a valuable feature for businesses looking to maximize their facility’s layout.Another innovative feature of the (REMOVED) Series Centrifugal Pump is its suction and discharge ports, which can be adjusted to eight different directions, making it ideal for tight installation spaces and versatile enough to be adapted to various system configurations.In summary, centrifugal pump technology is an indispensable tool for businesses that value reliability, efficiency, energy savings, and durability. [BRAND NAME REMOVED] understands this and has developed a line of pumps that can be tailored to any industrial application. With their commitment to quality and innovation, [BRAND NAME REMOVED] is an excellent choice for businesses looking for a competitive edge.

Discover the Benefits of Air Source Heat Pump Cooling for Efficient Climate Control

Title: Air Source Heat Pump Cooling Revolutionizes Energy-efficient Cooling: A Look into the Groundbreaking TechnologyIntroduction:In the pursuit of sustainable and energy-efficient cooling solutions, companies around the world have been developing innovative technologies to meet this ever-increasing demand. With the aim of reducing carbon emissions and promoting sustainable living, one company has introduced an exceptional air source heat pump cooling system. In this article, we will delve into the benefits, functionalities, and features of this groundbreaking technology, while also exploring its potential impact on the cooling industry.Air Source Heat Pump Cooling: The Ultimate SolutionAir source heat pump cooling is a cutting-edge technology that utilizes an optimized system to efficiently cool indoor spaces, revolutionizing the way we think about air conditioning. This advanced cooling solution effectively extracts heat from indoor spaces and utilizes the outdoor air as a heat sink to reduce the temperature, resulting in a comfortable and eco-friendly cooling system. Its versatility allows for year-round usage as it also doubles as a heating system during colder months.The Benefits of Air Source Heat Pump Cooling1. Energy Efficiency: The air source heat pump cooling system offers unparalleled energy efficiency, consuming up to 50% less energy compared to conventional air conditioning units. By harnessing the power of natural resources, it significantly reduces electricity consumption, resulting in reduced energy bills for consumers and businesses alike.2. Eco-friendly: This innovative cooling technology helps combat climate change by lowering carbon emissions. By utilizing renewable energy sources and minimizing reliance on electricity, it reduces the overall environmental impact associated with cooling. In fact, studies have shown that air source heat pump cooling systems can reduce carbon emissions by up to 40%, contributing to a greener and more sustainable future.3. Cost-effective: In addition to the energy savings, the long-term cost-effectiveness of air source heat pump cooling systems cannot be overlooked. By operating on lower energy consumption levels, these systems provide significant cost savings over time compared to traditional air conditioners, making them an attractive option for both residential and commercial applications.Technology Features and Functionality1. Intelligent Control Systems: Air source heat pump cooling systems incorporate integrated control systems that optimize performance based on user requirements and environmental conditions. These intelligent systems ensure maximum efficiency by automatically adjusting temperature settings, airflow rates, and fan speeds to maintain the desired comfort level while minimizing energy consumption.2. Quiet Operation: Noise reduction is a key consideration in any cooling system, and air source heat pump technology excels in this area. These systems are designed to provide quiet operation, ensuring a peaceful and comfortable environment without disturbing occupants.3. All-Weather Adaptability: No matter the climate, air source heat pump cooling systems are capable of delivering optimal performance. Their ability to run efficiently in a wide range of ambient temperatures ensures consistent cooling even during extreme weather conditions, thereby providing a reliable and comfortable indoor environment year-round.Future Impact and ConclusionAs the world gravitates towards sustainable living, the introduction of air source heat pump cooling systems marks a significant step forward. With its tremendous energy-saving potential, environmental benefits, and advanced functionality, this technology has the potential to revolutionize the cooling industry.By promoting energy efficiency and reducing carbon emissions, air source heat pump cooling systems align perfectly with global sustainability goals. As awareness of climate change increases, more and more consumers and businesses will be inclined to invest in these efficient and eco-friendly cooling solutions.In conclusion, air source heat pump cooling technology presents a game-changing opportunity to reshape the cooling industry. As this technology evolves and becomes more accessible, a greener and more sustainable cooling future lies ahead, ensuring a comfortable environment for all while preserving the planet for generations to come.

Top Acid-Resistant Pump Options for Industrial Applications in Tianjin

Title: Tianjin Acid-Resistant Pump: A Reliable Solution for Industrial Liquid HandlingIntroduction:Tianjin Acid-Resistant Pump is a leading manufacturer and supplier of high-quality acid-resistant pumps for various industrial applications. With an impeccable track record and a commitment to excellence, the company has earned a reputation for delivering reliable and innovative solutions for liquid handling challenges in corrosive environments. This news article will delve into the exceptional features and advantages offered by Tianjin Acid-Resistant Pump, highlighting the company's commitment to customer satisfaction and its contributions to industrial growth.1. Superior Features of Tianjin Acid-Resistant Pump:Tianjin Acid-Resistant Pump stands out in the market due to its exceptional features that ensure efficient and reliable performance in corrosive environments. These features include:a) Strong Acid Resistance: The pumps are manufactured using high-quality acid-resistant materials, such as fluoroplastic and stainless steel, which are specifically designed to withstand the corrosive nature of acids and other aggressive liquids.b) Optimal Efficiency: With advanced impeller designs and precision engineering, Tianjin Acid-Resistant Pump offers maximum efficiency in terms of energy consumption and fluid flow. These pumps ensure minimal process downtime and reduced maintenance costs.c) Versatile Applications: The acid-resistant pumps from Tianjin find applications in various industries such as chemical, pharmaceutical, mining, wastewater treatment, and metal processing. Their adaptability in handling different corrosive liquids makes them an ideal choice for a wide range of industrial needs.2. Commitment to Customer Satisfaction:Tianjin Acid-Resistant Pump prioritizes customer satisfaction by providing personalized solutions tailored to meet specific requirements. The company's team of experienced engineers and technical professionals offer expert guidance and support throughout the entire process, from selecting the right pump to after-sales services. Customers can rely on Tianjin Acid-Resistant Pump for prompt delivery, comprehensive technical support, and reliable solutions.3. Contributing to Industrial Growth:Tianjin Acid-Resistant Pump plays a crucial role in supporting various industries by providing efficient and reliable liquid handling solutions. Some notable contributions include:a) Safety and Environmental Protection: The acid-resistant pumps help industries ensure the safety of their operations while handling corrosive liquids, preventing accidental leaks and minimizing environmental risks.b) Enhancing Efficiency: The superior design and performance of Tianjin Acid-Resistant Pump's products help industries optimize their operations by providing consistent fluid flow, reducing energy consumption, and minimizing maintenance requirements.c) Enabling Innovation: The acid-resistant pumps from Tianjin facilitate the development of new processes and technologies in industries by offering robust and reliable liquid handling solutions, thus increasing productivity and contributing to overall industrial growth.4. Vision for the Future:Tianjin Acid-Resistant Pump aims to continuously improve its product offerings and expand its global presence. The company invests in research and development to stay at the forefront of technological advancements and develop innovative solutions that address the evolving needs of industries. By building strong partnerships with clients and fostering a culture of excellence, Tianjin Acid-Resistant Pump strives to become the preferred choice for acid-resistant pumps worldwide.Conclusion:Tianjin Acid-Resistant Pump's commitment to providing high-quality acid-resistant pumps and exceptional customer service has positioned the company as a reliable solution for industrial liquid handling needs. With their superior features and versatile applications, these pumps ensure efficient and safe operations in corrosive environments. As industries continue to evolve and demand more reliable liquid handling solutions, Tianjin Acid-Resistant Pump is poised to meet these challenges and contribute to the growth and progress of industries worldwide.

Top 10 Efficient Pumps for the Oil and Gas Sector

Title: Advancements in Pumping Technology Revolutionize the Oil and Gas IndustryIntroduction:The oil and gas industry is witnessing a remarkable transformation with the introduction of advanced pumping technology, leading to increased efficiency and productivity. Cutting-edge pumps, such as those offered by renowned manufacturers, are revolutionizing the sector by providing innovative solutions and improved performance. This article will delve into the recent advancements in pumping technology and how these developments are reshaping the oil and gas industry.1. Importance of Pumps in the Oil and Gas Industry:Pumps play a vital role in the oil and gas industry, facilitating the extraction, transportation, and processing of hydrocarbons. They are used to transfer crude oil, refined products, and natural gas through vast pipelines spanning great distances. In addition, pumps are crucial for artificial lift systems, enhancing production from oil wells by efficiently extracting the oil or gas from reservoirs. In this context, the continuous evolution of pumps is instrumental in maximizing the industry's productivity.2. Integration of Advanced Technologies in Pump Design: Recent advancements in technology have revolutionized pump design, resulting in more efficient and reliable operations. Companies, such as {}, have incorporated state-of-the-art technologies into their pumps, offering enhanced performance and durability. These advancements include:a. Sensor-based Monitoring Systems: Pumps are now equipped with sensor-based monitoring systems that provide real-time data to operators. This allows for seamless monitoring of pump performance, early detection of abnormalities, and timely maintenance, thereby minimizing downtime and reducing maintenance costs.b. Predictive Maintenance: With the implementation of machine learning algorithms, pumps can now predict potential failures and schedule maintenance before breakdowns occur. This proactive approach reduces unplanned downtime, ensuring uninterrupted operations and enhancing productivity.c. Energy Efficiency: Pumps are being designed with energy-efficient features, such as variable frequency drives, which regulate the pump speed based on demand. This prevents unnecessary energy consumption and reduces operational costs, contributing to a more sustainable and eco-friendly oil and gas industry.3. Increased Reliability and Performance:The integration of advanced technologies in pump design has significantly improved reliability and performance. Modern pumps can handle harsh operating conditions, such as extreme temperatures and corrosive environments, without compromising efficiency. Additionally, these pumps have increased flow rates, allowing for faster and more efficient transportation of oil and gas across pipelines.The durability of these pumps is further enhanced by the utilization of robust materials and advanced coatings that prevent corrosion and erosion. As a result, maintenance requirements are reduced, while the lifespan of the pumps is extended, ensuring uninterrupted operations in critical installations.4. Remote Monitoring and Control:The digitalization of the oil and gas industry has paved the way for remote monitoring and control of pumping systems. Operators can now remotely manage and monitor multiple pumps, reducing the need for on-site personnel. This not only enhances safety but also improves operational efficiency, as real-time data analytics enable optimized decision-making for improved productivity.5. Environmental Considerations:As sustainability gains prominence, pumps designed for the oil and gas industry now focus on reducing environmental impact. Advanced technologies, such as smart sensors and energy efficiency features, play a vital role in minimizing carbon footprint and optimizing resource consumption. By choosing pumps that prioritize eco-friendly operations, companies can contribute to the reduction of environmental pollution and the conservation of natural resources.Conclusion:The integration of advanced pumping technology in the oil and gas industry has resulted in significant improvements in efficiency, reliability, and sustainability. Companies like {} are leading the way in reshaping the sector, offering cutting-edge pump solutions designed to meet the evolving needs of the industry. These advancements not only increase productivity but also contribute to a more environmentally conscious and efficient oil and gas sector.

Effective Maintenance Tips for Screw Pumps

Title: Expert Tips for Screw Pump MaintenanceIntroduction:Screw pumps are vital components in a wide range of industries, including oil and gas, petrochemicals, wastewater treatment, and food processing, among others. These pumps play a crucial role in ensuring the smooth flow of liquids or semi-solid materials in various industrial processes. However, like any other mechanical equipment, regular maintenance is essential to keep screw pumps operating at optimal efficiency.In this article, we will discuss expert tips for screw pump maintenance, utilizing our industry knowledge and experience to provide valuable insights. Our aim is to help businesses maximize their operational efficiency, reduce downtime, and extend the lifespan of screw pumps, ultimately saving costs in the long run.Understanding Screw Pump Components:Before delving into maintenance procedures, it is essential to have a basic understanding of screw pump components. Screw pumps typically consist of three main parts:1. Rotors: These are the primary moving components responsible for transferring fluid. Two or more rotors with intermeshing threads create a sealed cavity that moves fluid from the pump's inlet to its outlet.2. Stator: The fixed component surrounding the rotors, the stator provides a tight seal to prevent leakage and assists in fluid movement.3. Housing: The casing that encloses the rotors and stators, ensuring a secure and stable operation.Expert Tips for Screw Pump Maintenance:1. Regular Inspection and Cleaning: - Schedule routine inspections to identify signs of wear, damage, or leakage in the pump and its parts. - Clean the pump regularly by flushing it with an appropriate cleaning agent to remove any accumulated debris or contaminants.2. Lubrication: - Ensure the rotor and stator are adequately lubricated to reduce friction, heat, and wear. - Use compatible lubricants recommended by the pump manufacturer for optimal performance.3. Shaft Alignment: - Misalignment can cause undue stress on the pump's components, leading to premature failure. - Regularly check and correct any misalignment issues to maintain smooth operation.4. Sealing System: - Inspect and replace worn or damaged seals regularly to prevent fluid leakage, ensuring efficient pump performance. - Utilize high-quality, chemical-resistant seals suitable for the specific fluid being pumped.5. Temperature and Vibration Monitoring: - Monitor the pump's operating temperature and vibrations using appropriate sensors. - Abnormal readings can indicate potential issues, such as overheating or mechanical imbalance, requiring immediate attention.6. Regular Bearing Maintenance: - Lubricate bearings as per the manufacturer's guidelines to minimize friction and prevent premature wear. - Monitor bearing condition and replace if signs of damage or deterioration are evident.7. Overload Protection: - Install overload protection devices to safeguard the pump against excessive loads, preventing potential damage.8. Spare Parts Inventory: - Maintain a stock of essential spare parts to minimize downtime in the event of failure or breakdown. - Consult with product experts to identify critical components that require immediate replacement availability.By following these expert tips, businesses can optimize the performance and longevity of their screw pumps, ensuring uninterrupted operation and maximizing efficiency.Company Introduction: {Insert company introduction here}Conclusion:Proactive maintenance of screw pumps is crucial for businesses relying on these mechanical systems to achieve smooth operations in various industries. Regular inspection, cleaning, lubrication, and addressing misalignment are just a few essential maintenance practices to keep screw pumps in optimal condition. Following these expert tips and leveraging the knowledge and experience of the company would assist businesses in reducing downtime, minimizing repairs, and extending the lifespan of their screw pumps, ultimately leading to increased operational and cost efficiencies.

A Guide to Choosing the Best Gear Pump for Industrial Applications

article regarding the features and benefits of an Oil Gear Pump for industrial applications.Oil Gear Pump: The Reliable Choice for Industrial ApplicationsAn oil gear pump is an industrial pump that is commonly used to transfer fluids such as oil, glycol, and water in a variety of industrial applications. The pump is designed to deliver a steady and continuous flow of fluid in a range of pressures and temperatures.One of the significant benefits of an oil gear pump is its high efficiency in transferring fluids. The pump has a positive displacement mechanism that eliminates wasteful fluid transfer, ensuring that fluids are transferred efficiently with minimal energy loss. This makes the oil gear pump an ideal solution for industries that require high levels of precision and accuracy in fluid transfer.Another benefit of the oil gear pump is its versatility. The pump can be used in a range of applications, including power generation, oil and gas, chemical processing, pulp and paper, and many others. The ability of the pump to handle different types of fluids and varying pressure levels makes it a reliable choice for many industries.Oil gear pumps are also known for their durability and reliability. The pump is made of robust materials that can withstand harsh industrial environments. The design of the pump allows for minimal maintenance, providing a long-lasting and reliable solution for fluid transfer applications.In addition to its durability, the oil gear pump is designed with safety in mind. The pump’s design eliminates the risk of leaks, ensuring that fluid transfer is safe and reliable. This is especially important in industries where safety is a top priority such as in the oil and gas industry, chemical processing, and pharmaceuticals.One of the leading companies that provide oil gear pumps is ATEX Pumps. The company specializes in providing pumps for industrial applications and has a range of oil gear pumps that are designed to meet the specific requirements of different industries.ATEX Pumps oil gear pumps are designed with high-quality materials, making them reliable and long-lasting. The pumps have a compact design that allows for easy installation and minimal maintenance. ATEX Pumps oil gear pumps are also customizable, allowing for pumps that meet specific flow rates, pressure requirements, and fluid types.Apart from oil gear pumps, ATEX Pumps provides a range of other pumps that are suitable for various industrial applications. These include centrifugal pumps, magnetic drive pumps, diaphragm pumps, and many others. ATEX Pumps also provides customized solutions that meet the unique requirements of different industries.In conclusion, an oil gear pump is a reliable and efficient solution for fluid transfer applications in various industries. Its high efficiency, versatility, durability, and safety features make it a popular choice for many industries. If you are looking for an oil gear pump for your industrial application, ATEX Pumps is an excellent choice for quality and reliability.

Maximizing the Efficiency of Screw Pumps: Important Factors to Consider

Screw Pump Efficiency Boosts Productivity for Global Machinery ManufacturerThe global machinery manufacturing industry relies on high-performance equipment to drive productivity and meet the demands of a competitive market. Every aspect of the manufacturing process plays a critical role in ensuring efficient and reliable operations. That's why the integration of advanced technology, such as the latest screw pump efficiency solutions, has become a game-changer for companies like {company name}.{Company name} is a leading provider of machinery and equipment for various industries, including automotive, construction, and agriculture. With a history spanning over 50 years, the company has built a reputation for delivering innovative and high-quality products that meet the evolving needs of its customers worldwide.One of the key factors driving {company name}'s success is its commitment to leveraging cutting-edge technology to enhance the performance of its machinery. This commitment is evident in the company's recent adoption of state-of-the-art screw pump technology, which has significantly improved the efficiency and reliability of its products.Screw pumps are a vital component in many industrial applications, including hydraulic systems and fluid transfer processes. These pumps are known for their ability to deliver a steady flow of fluid under high pressure, making them ideal for a wide range of manufacturing operations. By upgrading to the latest screw pump efficiency solutions, {company name} has been able to optimize the performance of its machinery, resulting in increased productivity and cost savings for its customers.The decision to invest in advanced screw pump technology was driven by {company name}'s commitment to delivering best-in-class products to its customers. By partnering with leading manufacturers of screw pump solutions, the company has been able to integrate the latest innovations into its machinery, thereby enhancing their performance and reliability.The results of this investment have been remarkable. {Company name}'s customers have reported significant improvements in the efficiency and productivity of their operations since the adoption of the new screw pump technology. This has translated into tangible benefits, such as reduced downtime, lower maintenance costs, and increased overall output for their businesses.In addition to the direct impact on customer operations, the integration of advanced screw pump technology has also positioned {company name} as a leader in innovation within the machinery manufacturing industry. By staying at the forefront of technological advancements, the company has been able to differentiate itself from competitors and solidify its reputation as a trusted provider of high-performance machinery and equipment.The success of {company name}'s adoption of screw pump efficiency solutions serves as a testament to the importance of investing in advanced technology to drive business growth and meet the needs of an evolving market. By prioritizing innovation and collaboration with industry-leading partners, {company name} has been able to deliver tangible value to its customers and strengthen its position as a global leader in the machinery manufacturing industry.Looking ahead, {company name} remains committed to leveraging the latest advancements in technology to continue driving productivity and efficiency for its customers. The company's dedication to innovation and customer satisfaction ensures that it will remain at the forefront of the industry, providing cutting-edge solutions that empower businesses to thrive in a competitive global market.

Discover the Benefits of Single Screw Pumps for Industrial Applications

The world of industrial pumps is constantly evolving, with companies vying to produce the best product for their customers. One such company is a leading manufacturer of Single Screw Pumps, which has gained a reputation for producing some of the best and most reliable pumps on the market.Single Screw Pumps are positive displacement pumps, which means they operate by trapping a fixed amount of fluid and then displacing it into the discharge piping system. This makes them ideal for applications that require the transfer of high viscosity fluids, such as oils, grease, and slurries.The company's Single Screw Pumps are designed with efficiency and durability in mind. They are made from high-quality materials and manufactured to the highest standards of accuracy, ensuring that they perform well in even the most demanding applications. These pumps are also easy to operate and maintain, making them a popular choice among businesses that value reliability and ease of use.One of the key features of Single Screw Pumps is their ability to handle a wide range of fluids. This makes them ideal for use in a variety of industries, including the food and beverage, pharmaceutical, and chemical industries. They are also used in the construction and mining industries, where they are used to transfer fluids such as cement, grout, and sewage.The company's Single Screw Pumps are also available in a range of sizes and configurations, allowing businesses to choose a pump that best meets their needs. They can be customized with different materials and coatings, ensuring that they are suitable for use with corrosive or abrasive fluids.Another advantage of Single Screw Pumps is their low maintenance and operational costs. They are designed to operate with minimal downtime and require only basic maintenance, which helps to reduce costs and improve efficiency.In addition to producing high-quality Single Screw Pumps, the company is also committed to providing excellent customer service. They offer a range of support services, including technical support and maintenance services, to ensure that their customers get the most out of their pumps.Overall, Single Screw Pumps are an excellent choice for businesses that require a reliable, efficient, and low-maintenance pumping solution. They represent a sound investment for any business that values quality and performance. With their wide range of applications and customizable configurations, they are sure to meet the needs of businesses in a variety of industries.