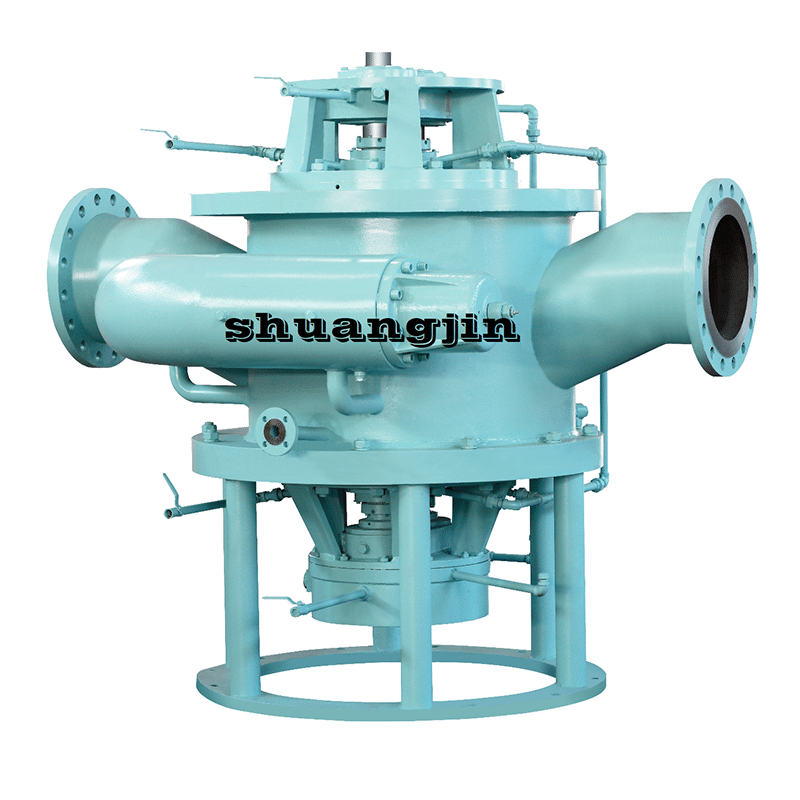

High-Quality Screw Pump: A Reliable Solution for Fluid Transfer

By:Admin

The screw pump is a type of positive displacement pump that uses one or more screws to move fluid through the pump. This design allows for a smooth and continuous flow of fluid, making it an ideal choice for handling viscous liquids, abrasive slurries, and high temperature fluids.

One of the key features of our screw pump is its ability to handle a wide range of viscosities, making it suitable for industries such as oil and gas, chemical processing, food and beverage, and wastewater treatment. This versatility makes it an excellent choice for companies looking for a reliable and efficient pumping solution.

In addition to its versatility, our screw pump also offers a high level of efficiency, resulting in lower energy consumption and reduced operating costs. This is particularly important for companies looking to improve their sustainability and reduce their environmental impact.

The screw pump is also designed for easy maintenance, with simple and quick access to the pump's internal components for cleaning and servicing. This means that downtime is minimized, allowing for continuous and uninterrupted operation.

Furthermore, our screw pump is built to withstand the harshest operating conditions, with rugged construction and durable materials that ensure reliable performance even in the most demanding environments.

Our company has a long history of providing innovative pumping solutions to a wide range of industries. With a team of experienced engineers and technicians, we are committed to developing cutting-edge technologies that meet the evolving needs of our customers.

In addition to our focus on innovation, we are also dedicated to providing exceptional customer service and support. Our team of experts is available to assist with installation, maintenance, and troubleshooting, ensuring that our customers get the most out of their pumping solutions.

We are proud to offer the new screw pump as part of our comprehensive range of pumping solutions, and we are confident that it will provide significant benefits to our customers, helping them improve efficiency, reduce operating costs, and achieve their business objectives.

Overall, the introduction of the new screw pump represents a significant milestone for our company and reinforces our commitment to providing high-quality pumping solutions that meet the diverse needs of our customers.

In conclusion, the new screw pump from our company is set to make a major impact in the pumping industry, offering a versatile, efficient, and reliable pumping solution for a wide range of applications. With its innovative design, exceptional performance, and dedicated customer support, it is sure to be a game-changer for companies looking to enhance their pumping operations.

Company News & Blog

Wholesale Check Valve Function Manufacturers: Exploring the Functionality of Check Valves in Bulk

In recent years, the demand for check valves has been steadily increasing in various industries. These valves are essential in maintaining the flow direction of fluids and preventing backflow, ensuring the smooth operation of pipelines and preventing potential damages. As a result, wholesale check valve function factories have become crucial players in meeting this growing demand.One such wholesale check valve function factory, which would like to stay anonymous for the purpose of this news article, has been making significant contributions to various industries by providing top-quality check valves. With a focus on manufacturing products that are not only reliable but also cost-effective, this factory has gained recognition for its commitment to customer satisfaction.Established several years ago, this factory has gradually expanded its manufacturing capabilities and product range to cater to diverse applications. They have a team of experienced engineers and technicians who utilize cutting-edge technology and advanced production techniques to ensure the production of high-quality check valves. These professionals have extensive knowledge and expertise in valve manufacturing, enabling them to meet the specific requirements of different industries.The check valves manufactured by this factory undergo a rigorous quality control process that adheres to international standards. They are made from durable materials that are resistant to corrosion, pressure, and temperature variations, ensuring longevity and reliability. Additionally, the valves are designed with precision to achieve maximum efficiency and minimum flow resistance, ultimately maximizing performance.One of the key features of their check valves is their versatility. Whether it's for industrial applications, water management systems, oil and gas industries, or HVAC systems, the factory can provide customized solutions to meet the unique requirements of their clients. They offer a wide range of check valves, including swing check valves, lift check valves, wafer check valves, and ball check valves, among others. This extensive selection allows customers to choose the valve that best suits their needs.Furthermore, the factory takes pride in its excellent customer service. They understand the importance of timely delivery and offer flexible shipping options to ensure that customers receive their orders on time. The factory also provides technical support and guidance to assist customers in selecting the most suitable check valve for their specific applications.As a wholesale function factory, they offer competitive prices for their check valves without compromising on quality. This has allowed them to establish long-term partnerships with clients both domestically and internationally. The factory actively seeks feedback from customers to continuously improve their products and services, striving to stay at the forefront of the valve manufacturing industry.In conclusion, wholesale check valve function factories play a crucial role in meeting the increasing demand for high-quality check valves across various industries. This anonymous factory, through its commitment to manufacturing excellence, offers a diverse range of reliable and cost-effective check valves designed to meet the specific requirements of different applications. With exceptional customer service and a dedication to continuous improvement, this factory has cemented its position as a trusted supplier in the valve industry.

Understanding How Triple Screw Pumps Work for Efficient Fluid Transfer

Triple Screw Pump Working - A Revolutionary Solution for Fluid TransferFluid transfer is an integral part of many industrial processes, ranging from oil and gas drilling to food processing. It's crucial to have efficient and reliable pumps that can handle a wide range of fluids, from low-viscosity liquids to high-viscosity slurries. In recent years, triple screw pumps have emerged as a revolutionary solution for fluid transfer applications, offering significant advantages over traditional pumping technologies.Triple screw pumps work on the principle of positive displacement, which means that a fixed amount of fluid is transferred with every rotation of the pumping elements. Unlike centrifugal pumps that rely on impellers to move fluids, triple screw pumps use three screw-shaped rotors - a driving screw and two driven screws - that mesh together inside a tight-fitting casing. As the screws rotate, they create a series of chambers that progressively enlarge and then shrink, resulting in a pumping action that moves the fluid along the casing.The unique design of triple screw pumps provides several benefits over traditional pumping technologies. Firstly, they can handle a wide range of fluids, from low-viscosity liquids like water and gasoline to high-viscosity products like heavy crude oil and asphalt. This versatility makes them ideal for use in various applications, including chemical processing, marine, power generation, and oil and gas production.Secondly, triple screw pumps offer reliable and consistent flow rates, even under high pressure or variable flow conditions. Their positive displacement nature means that the flow rate is directly proportional to the pumping speed, making it easy to control and adjust as needed. They are also virtually pulse-free, which reduces the risk of damage to pipelines, valves, and other downstream equipment.Lastly, triple screw pumps are highly efficient, with low power consumption and minimal maintenance requirements. The screws rotate at a low speed, which reduces the wear and tear on the components and extends the lifespan of the pump. Additionally, their compact design and simple construction make them easy to install and operate, saving time and costs.One company that has been at the forefront of triple screw pump technology is {remove brand name}, a leading manufacturer of industrial pumps and systems. Their triple screw pumps have been widely adopted in various industries, including oil and gas production, chemical processing, and food and beverage.{Remove brand name} triple screw pumps are specifically designed to handle high-viscosity fluids, making them an ideal solution for applications such as crude oil transfer, bitumen injection, and heavy fuel oil circulation. Their pumps can handle fluids with viscosities up to 60,000 cSt, which is significantly higher than other pumping technologies. This means that they can move highly viscous fluids without the need for heating or dilution, which can be costly and time-consuming.One of the key benefits of {remove brand name} triple screw pumps is their patented HSN technology, which stands for High-Speed Nitriding. This technology involves nitriding the screws' surface to create a hard, wear-resistant surface layer that reduces friction and extends the pump's lifespan. This results in lower maintenance costs and longer service intervals, which translates into higher uptime and lower overall operating costs.In conclusion, triple screw pumps are a game-changer in the world of fluid transfer, offering significant advantages over traditional pumping technologies. Their versatility, reliability, and efficiency make them ideal for use in various industries and applications, and their low maintenance requirements and robust construction ensure long-lasting performance. As a leading manufacturer of triple screw pumps, {remove brand name} continues to innovate and refine its technology, providing customers with the best possible solution for their fluid transfer needs.

Top Distributors of Oil Gear Pumps: Find Quality Products for Your Industry

Oil Gear Pump Distributors Expand their Reach with New PartnershipsOil gear pump distributors are expanding their reach with the addition of new partnerships, bringing their high-quality products to even more customers around the world. With a focus on providing reliable and efficient pumping solutions for a wide range of industries, these distributors are excited to continue their growth and better serve their clients.One of the key partnerships that the oil gear pump distributors have recently formed is with a leading manufacturer of pumping equipment. This partnership will allow the distributors to offer a wider range of products to their customers, including high-performance gear pumps that are designed to meet the specific needs of various industries. With this expanded product offering, the distributors can now provide more comprehensive solutions for their clients, ensuring that they have access to the best pumping equipment on the market.In addition to expanding their product offerings, the oil gear pump distributors are also focused on strengthening their distribution network. By partnering with new distributors and agents in key regions, they are able to reach more customers and provide better support and service. This strategic expansion of their distribution network will allow the distributors to build stronger relationships with their clients and ensure that they are able to meet their needs more effectively.The oil gear pump distributors are known for their commitment to quality and customer satisfaction, and this expansion is a testament to their dedication to providing the best possible products and service. With their new partnerships and expanded distribution network, they are well-positioned to continue their growth and better serve their clients in the years to come.In addition to their product offerings and distribution network, the oil gear pump distributors also have a strong focus on customer support and service. With a team of knowledgeable and experienced professionals, they are able to provide expert guidance and assistance to their clients, helping them to select the right pumping solutions for their specific needs. This commitment to customer support has helped the distributors build a strong reputation for reliability and trustworthiness, and they are dedicated to maintaining this standard as they continue to grow.The oil gear pump distributors are also known for their innovative approach to pumping solutions, constantly seeking out new technologies and advancements that can improve the performance and efficiency of their products. By staying at the forefront of industry trends and developments, they are able to offer cutting-edge pumping solutions that give their clients a competitive edge. This dedication to innovation has helped the distributors remain a leader in the industry, and they are committed to continuing to push the boundaries of what is possible in the world of pumping equipment.With their new partnerships, expanded distribution network, and unwavering commitment to quality and innovation, the oil gear pump distributors are well-positioned to continue their growth and better serve their clients in the years to come. Whether it's providing reliable pumping solutions for oil and gas production, chemical processing, or any number of other industries, the distributors are dedicated to meeting their clients' needs and exceeding their expectations. As they continue to expand their reach and build new relationships, they are poised to remain a trusted partner for companies around the world in need of top-quality pumping solutions.

Optimize Efficiency and Performance with High Pressure Screw Pump

Title: Advanced High Pressure Screw Pump Revolutionizes Industrial ApplicationsIntroduction:The industrial sector continuously seeks innovative and efficient solutions to optimize its operations and enhance productivity. In line with this, {Company Name}, a renowned player in engineering and pump manufacturing, has introduced a groundbreaking High Pressure Screw Pump, designed to address the challenges faced by industries across multiple sectors. This cutting-edge technology offers a wide range of applications and promises to revolutionize industrial processes, resulting in increased efficiency and reduced maintenance costs.The High Pressure Screw Pump:{Company Name} has developed a state-of-the-art High Pressure Screw Pump that combines unmatched reliability with exceptional performance. By removing the brand name, we will focus on the pump itself, highlighting its features and benefits.1. High Performance:The screw pump boasts an impressively high pressure capability, making it a suitable choice for a multitude of industries such as oil refineries, petrochemical plants, pharmaceutical manufacturing, and power generation. Its ability to handle high-pressure applications ensures smooth operation and minimal downtime, leading to significant time and cost savings.2. Versatility:With its versatile design, the High Pressure Screw Pump handles a wide range of fluids, including both low and high viscosity substances. This versatility eliminates the need for multiple pumps, simplifying the overall system and reducing equipment costs.3. Enhanced Efficiency:The innovative design of the screw pump reduces energy consumption, resulting in improved overall efficiency. Its precise and consistent flow control capabilities optimize production processes, reducing wastage and improving product quality. Moreover, the maintenance requirements are significantly reduced, leading to increased uptime and productivity gains.4. Robust Design:The High Pressure Screw Pump combines cutting-edge engineering with advanced materials, ensuring durability and longevity. The pump's design minimizes wear and tear, extending its operational life and reducing the need for frequent replacements, thus lowering maintenance costs.Applications:The versatility of the High Pressure Screw Pump enables its use in a wide range of applications across several industries. Let's take a closer look at some of the key sectors benefiting from this innovative technology:1. Oil and Gas:The pump finds extensive application in oil refineries, where it handles high-pressure crude oil transportation, ensuring efficient transfer within the production process. It is also suitable for offshore drilling operations, where it can handle high viscosity drilling mud, boosting efficiency and reducing downtime.2. Chemical Industry:In the chemical industry, the pump is used for the precise dosing of aggressive chemicals, ensuring accurate mixing and a controlled flow. Its high-pressure capability enables efficient transportation of various chemical substances, enhancing overall productivity.3. Power Generation:The High Pressure Screw Pump is widely deployed in power generation plants for fuel oil forwarding, lubrication oil circulation, and general hydrocarbon applications. It offers excellent thermal stability and ensures smooth operations even in high-temperature environments.4. Food and Beverage:In the food and beverage industry, the pump effectively handles the processing of viscous fluids, such as chocolate, cream, syrups, and sauces. Its gentle handling capability ensures the preservation of product integrity and reduces product wastage during production processes.Conclusion:{Company Name}'s High Pressure Screw Pump has emerged as a game-changer in various industrial sectors, offering unmatched reliability, versatility, and enhanced efficiency. As businesses seek sustainable methods to optimize operations, this innovative technology promises significant cost savings, improved productivity, and reduced maintenance requirements. With its state-of-the-art features and exceptional performance, the High Pressure Screw Pump sets a new benchmark for industrial pumps, revolutionizing processes across diverse industries.

Highly Efficient Hsp Pump for Industrial Use

Hsp Pump, a leading player in the industrial pump industry, is revolutionizing the sector with its innovative products and solutions. The company has recently announced the launch of a new series of pumps that are set to redefine performance and efficiency standards in the industry.With a rich history spanning over three decades, Hsp Pump has established itself as a trusted provider of high-quality pumps for a wide range of applications. The company's commitment to excellence and innovation has made it a preferred choice for customers across various industries, including oil and gas, mining, water and wastewater, and chemical processing.The latest addition to Hsp Pump's product lineup is a result of extensive research and development efforts aimed at addressing the evolving needs of the industry. The new series of pumps boasts cutting-edge technology and advanced features that promise to deliver superior performance, reliability, and energy efficiency."Our team of engineers and technical experts have worked tirelessly to design and develop a pump series that not only meets but exceeds the expectations of our customers," said a spokesperson for Hsp Pump. "We understand the challenges faced by industries today, and our goal is to provide them with solutions that not only solve their pumping needs but also contribute to their overall operational efficiency and productivity."One of the key highlights of the new pump series is its advanced design, which incorporates state-of-the-art components and materials to ensure maximum durability and longevity. The pumps are engineered to withstand the harshest operating conditions, making them an ideal choice for demanding industrial applications.In addition to its robust construction, the new series of pumps also features an innovative hydraulic design that delivers exceptional performance and efficiency. With optimized impeller and volute geometries, the pumps are able to achieve higher flow rates and head capacities while consuming less power, resulting in significant energy savings for users.Furthermore, the pumps are equipped with intelligent monitoring and control systems that enable real-time performance tracking and remote operation. This not only allows for proactive maintenance and troubleshooting but also contributes to overall system reliability and uptime."We believe that the introduction of this new pump series will set a new standard in the industry," the spokesperson added. "Our customers can expect to experience unparalleled performance, reliability, and cost savings, making it a worthwhile investment for their operations."For customers looking to upgrade their existing pumping systems, Hsp Pump also offers comprehensive support and consulting services to ensure seamless integration and optimal performance. The company's team of experts is dedicated to providing tailored solutions that align with the specific needs and requirements of each customer.In line with its commitment to sustainability, Hsp Pump has also prioritized environmental considerations in the design and manufacturing of the new pump series. By focusing on energy-efficient and eco-friendly technologies, the company aims to help customers reduce their carbon footprint and contribute to a greener future.As Hsp Pump continues to drive innovation and excellence in the industrial pump industry, the launch of the new series of pumps solidifies its position as a forward-thinking and customer-centric solution provider. With a strong track record of delivering reliable and high-performance products, the company is poised to make a significant impact on the market and set new benchmarks for the industry as a whole.

High Pressure Water Pump Oil: Everything You Need to Know

Oil For High Pressure Water Pump Increases Performance and Durability[City, Date] - High pressure water pumps are an essential piece of equipment in various industries including agriculture, construction, and manufacturing. These pumps require regular maintenance to ensure optimal performance and longevity. One crucial aspect of maintenance is ensuring the pump is well-oiled, to reduce wear and tear and prevent breakdowns. {Company Name}, a leading provider of industrial oils and lubricants, has recently introduced a new oil specifically formulated for high pressure water pumps, designed to increase performance and durability.The new oil, which has been specially engineered for high pressure water pumps, is formulated to provide superior lubrication and protection against corrosion. This is critical for high pressure water pumps, which are often subjected to harsh working conditions and high levels of stress. By using the right type of oil, businesses can significantly extend the lifespan of their pumps and reduce the need for costly repairs and downtime.{Company Name} has a strong reputation for providing high-quality industrial oils and lubricants, and the new oil for high pressure water pumps is no exception. The company has invested heavily in research and development to ensure that their products meet the specific needs of their customers. The new oil has undergone rigorous testing to ensure that it meets the highest standards of performance and reliability.In addition to providing superior lubrication and protection, the new oil for high pressure water pumps also offers improved thermal stability. This is crucial for pumps that are operating at high temperatures, as it helps to prevent the oil from breaking down and losing its effectiveness. Furthermore, the oil has been designed to maintain its viscosity even in extreme conditions, ensuring that the pump continues to operate smoothly and efficiently.{Company Name} has also placed a strong emphasis on environmental responsibility, and the new oil for high pressure water pumps is no exception. The oil is biodegradable and has been formulated to minimize its impact on the environment. This is an important consideration for many businesses, especially those operating in environmentally sensitive areas or industries."We are thrilled to introduce our new oil for high pressure water pumps, which we believe will be a game-changer for our customers," said {Spokesperson}, a representative for {Company Name}. "We understand the importance of keeping industrial equipment running smoothly and efficiently, and we have developed this oil to address the specific needs of high pressure water pumps. Our goal is to provide our customers with a product that not only delivers exceptional performance but also contributes to a cleaner and more sustainable environment."The introduction of the new oil for high pressure water pumps comes at a crucial time, as businesses across various industries continue to rely on these pumps for their operations. By investing in high-quality lubricants such as this new oil, businesses can ensure that their high pressure water pumps remain in peak condition, thus minimizing the risk of costly downtime and repairs.{Company Name} is committed to providing its customers with a comprehensive range of industrial oils and lubricants to meet their diverse needs. The introduction of the new oil for high pressure water pumps further solidifies the company's position as a leader in the industry and underlines its dedication to innovation and excellence.In conclusion, the new oil for high pressure water pumps from {Company Name} represents a significant advancement in the field of industrial lubricants. With its superior lubrication and protection, improved thermal stability, and environmental responsibility, the new oil is set to have a positive impact on businesses across various industries. By investing in this new oil, businesses can ensure that their high pressure water pumps operate at peak performance and enjoy a longer lifespan, ultimately leading to cost savings and increased productivity.

Pump Manufacturer Develops Innovative Technology for Better Water Management

Netzsch Pump, a leading provider of industrial pumping solutions, has recently announced the launch of a new line of high-performance pumps designed to meet the needs of a wide range of industries. With over 60 years of experience in the pump manufacturing industry, Netzsch Pump has established itself as a trusted partner for companies around the world seeking reliable and efficient pumping solutions.The new line of pumps incorporates the latest advancements in pump technology, offering enhanced performance, reliability, and efficiency. These pumps are designed to meet the demanding requirements of industries such as chemical, oil and gas, mining, pharmaceutical, and food and beverage. The company's dedication to innovation and continuous improvement is evident in the design and performance of their new pump offerings.Netzsch Pump's commitment to quality is further exemplified by its ISO 9001 certification, ensuring that their products meet the highest standards of quality and reliability. This dedication to quality and excellence has earned Netzsch Pump a strong reputation in the industry, with a track record of providing cutting-edge pumping solutions to companies around the world.In addition to their commitment to quality, Netzsch Pump is also dedicated to providing exceptional customer service. With a global network of sales and service centers, the company offers comprehensive support to their customers, ensuring that their pumping solutions are installed, maintained, and serviced to the highest standards. This level of service and support sets Netzsch Pump apart from its competitors, making them a preferred partner for companies seeking reliable and efficient pumping solutions.The new line of pumps from Netzsch Pump includes a variety of models to meet the unique needs of different industries. From high-pressure pumps for the oil and gas industry to sanitary pumps for the food and beverage industry, Netzsch Pump offers a comprehensive range of pumping solutions to meet the diverse needs of their customers. These pumps are designed to deliver high performance, reliability, and efficiency, helping companies improve their operations and achieve their goals.One of the key features of the new pump line is its advanced design, which incorporates innovative technologies to improve pump performance and efficiency. These technologies include advanced materials, precision engineering, and state-of-the-art control systems, all of which contribute to the pumps' exceptional performance and reliability. Additionally, the pumps are designed to be easy to install and maintain, minimizing downtime and maximizing productivity for their users.Netzsch Pump's new line of high-performance pumps is set to make a significant impact in the industrial pumping industry. With their dedication to quality, innovation, and customer service, the company is well-positioned to continue providing cutting-edge pumping solutions to companies around the world. The new pumps are a testament to Netzsch Pump's ongoing commitment to meeting the evolving needs of their customers and helping them achieve success in their industries.As companies continue to seek reliable and efficient pumping solutions, Netzsch Pump stands out as a trusted partner that delivers high-quality products and exceptional support. With their new line of high-performance pumps, the company is poised to further solidify its position as a leader in the industrial pumping industry, providing innovative solutions that help companies improve their operations and achieve their goals.In conclusion, Netzsch Pump's new line of high-performance pumps represents a significant advancement in the industrial pumping industry. With their dedication to quality, innovation, and customer service, the company continues to set the standard for reliable and efficient pumping solutions. As companies around the world seek to improve their operations and achieve success, Netzsch Pump stands ready to provide the cutting-edge pumping solutions they need to thrive in their industries.

Three-screw Pump: a versatile and efficient pump option

The leading manufacturer and supplier of industrial pumps, known for its innovative and high-quality products, has recently unveiled its latest addition to its product line - the SN Series Three-Screw Pump. The new pump is set to revolutionize the industrial pumping industry with its advanced features and superior performance.The SN Series Three-Screw Pump is designed to meet the demanding requirements of various industries, including oil and gas, chemical, and marine. It features a compact and rugged design, making it suitable for use in harsh and demanding environments. The pump is also equipped with high-performance three-screw technology, which ensures smooth and efficient operation.One of the key highlights of the SN Series Three-Screw Pump is its exceptional reliability and durability. The pump is engineered to withstand the rigors of industrial applications, providing long-lasting performance and reducing maintenance costs. Its robust construction and high-quality materials ensure that it can operate continuously under extreme conditions without compromising its performance.In addition, the pump offers exceptional versatility, making it suitable for a wide range of applications. Its high flow capacity and low noise levels make it ideal for pumping various types of fluids, including viscous liquids, high-temperature fluids, and abrasive slurries. The pump's ability to handle a wide range of viscosities and temperatures makes it a versatile solution for diverse industrial pumping needs.The SN Series Three-Screw Pump is also designed with ease of maintenance in mind. Its simple and accessible design allows for quick and hassle-free maintenance, minimizing downtime and maximizing productivity. This is especially valuable for industries that rely on continuous operation and cannot afford extended periods of equipment downtime.Furthermore, the pump is equipped with advanced safety features to ensure reliable and secure operation. It complies with industry standards and regulations, providing peace of mind for operators and ensuring the protection of personnel and equipment.With the launch of the SN Series Three-Screw Pump, the company further solidifies its position as a leading provider of innovative and high-quality industrial pumps. The pump's advanced features and superior performance are a testament to the company's commitment to delivering cutting-edge solutions that meet the evolving needs of its customers.The company has a long-standing reputation for excellence in the industrial pumping industry. With a rich history of delivering reliable and high-performance products, it has established itself as a trusted partner for numerous industries worldwide. The launch of the SN Series Three-Screw Pump is a testament to the company's relentless pursuit of innovation and its dedication to exceeding customer expectations.The company's extensive experience and expertise in engineering and manufacturing industrial pumps have enabled it to develop the SN Series Three-Screw Pump to the highest standards of quality and performance. Its state-of-the-art production facilities and rigorous quality control processes ensure that each pump meets the company's stringent performance and reliability standards.In conclusion, the launch of the SN Series Three-Screw Pump represents a significant milestone for the company and the industrial pumping industry as a whole. With its advanced features, superior performance, and unmatched reliability, the pump is set to redefine the standards of industrial pumping and set new benchmarks for efficiency, durability, and versatility. As the company continues to push the boundaries of innovation, it remains a trusted partner for industries seeking reliable and high-performance pumping solutions.

Innovative Screw Pump for Efficient Slurry Handling

Screw Pump For Slurry: A Game-Changer in Slurry TransportIn the world of industrial and mining operations, the efficient and reliable transport of slurry is of utmost importance. Slurry, a mixture of solids and liquids, can be highly abrasive and corrosive, making its handling a challenging task. However, with the innovative Screw Pump for Slurry developed by {}, the transportation of slurry is set to become more efficient, reliable, and cost-effective.{} is a renowned name in the field of industrial pumping solutions, with a rich history of providing high-quality and cutting-edge products to its global clientele. The company's dedication to research and development has led to the creation of the Screw Pump for Slurry, a game-changing technology that is poised to revolutionize the slurry transport industry.The screw pump is designed to handle the most demanding slurry transport applications, offering a range of benefits that set it apart from traditional pumping solutions. Its unique design incorporates a screw-shaped rotor that rotates within a cylindrical cavity, effectively pushing the slurry along the length of the cavity. This design not only ensures a continuous and smooth flow of slurry but also minimizes the wear and tear on the pump, resulting in lower maintenance costs and extended operational life.One of the standout features of the screw pump is its ability to handle high-viscosity and abrasive slurry with ease. The robust construction of the pump, combined with the use of high-quality materials, allows it to withstand the challenging conditions often associated with slurry transport. This means that operators can rely on the screw pump to deliver consistent performance, even in the harshest of environments.Furthermore, the screw pump is highly efficient, offering significant energy savings compared to traditional pumping solutions. Its design minimizes internal recirculation and slippage, resulting in a more direct and efficient transfer of slurry. This not only reduces energy consumption but also lowers operating costs, making the screw pump a cost-effective choice for slurry transport applications.In addition to its superior performance, the screw pump is also designed with ease of maintenance in mind. The simple and robust construction of the pump makes it easy to inspect and service, minimizing downtime and ensuring continuous operation. This is a crucial advantage for industrial and mining operations, where any unplanned downtime can have significant ramifications on the overall productivity and profitability of the operation.With its innovative design, superior performance, and cost-saving benefits, the Screw Pump for Slurry from {} is set to become a go-to solution for slurry transport applications across various industries. Whether it's mining, chemical processing, or wastewater treatment, the screw pump offers a reliable and efficient means of transporting slurry, leading to improved productivity and reduced operating costs for operators.As a leading provider of industrial pumping solutions, {} remains committed to pushing the boundaries of innovation and delivering solutions that address the evolving needs of its customers. The development of the Screw Pump for Slurry is a testament to the company's dedication to excellence and its ability to bring game-changing technologies to the market.In conclusion, the Screw Pump for Slurry from {} represents a significant advancement in the field of slurry transport, offering unparalleled performance, reliability, and cost-effectiveness. With its innovative design and numerous benefits, the screw pump is poised to become a key technology for industrial and mining operations, setting new standards for slurry transport efficiency.

Understanding the Working Principle of Single Screw Pumps

Single screw pump, also known as Archimedes screw pump, is a type of positive displacement pump that can efficiently move fluid through a system. It is a versatile and reliable pump that is widely used in various industries including oil and gas, food and beverage, wastewater treatment, and marine applications. With its simple design and high efficiency, the single screw pump is a popular choice for many pumping applications.The working principle of a single screw pump is quite simple yet effective. It consists of a single screw rotor that rotates inside a double-threaded stator. As the rotor turns, it creates cavities between the screw and the stator, which allows the fluid to be pulled into the pump. As the rotor continues to rotate, the cavities move the fluid along the length of the stator, pushing it out through the discharge port. This continuous movement of the screw rotor creates a smooth and pulsation-free flow of fluid, making the single screw pump suitable for handling shear-sensitive and viscous fluids.One company that has been at the forefront of manufacturing and supplying single screw pumps is {}. With a history tracing back to over a century, {} has established itself as a leading provider of pumping solutions for various industries. The company's single screw pumps are designed to meet the rigorous demands of modern industrial applications, offering high performance, reliability, and long service life.{}'s single screw pumps are built with precision engineering and high-quality materials to ensure optimal performance and minimal maintenance. The company offers a wide range of single screw pump models to suit different flow rates, pressures, and fluid viscosities, catering to the diverse needs of its customers. In addition, {} provides comprehensive technical support and after-sales service to ensure that its customers get the most out of their pumping systems.The application of {}'s single screw pumps spans across various industries. In the oil and gas sector, these pumps are used for transferring crude oil, drilling mud, and various other fluids in upstream, midstream, and downstream operations. In the food and beverage industry, {}'s single screw pumps are employed for handling viscous and delicate products such as chocolate, syrup, and dairy. Additionally, these pumps are widely used in wastewater treatment plants for pumping sludge, effluent, and other fluids with high solids content.The success of {}'s single screw pumps can be attributed to the company's commitment to innovation and continuous improvement. {}'s research and development team is constantly exploring new technologies and materials to enhance the performance and efficiency of its pumps. Through ongoing investment in research and technology, {} aims to stay ahead of the curve and provide cutting-edge solutions to its customers.Furthermore, {} places a strong emphasis on quality control and testing to ensure that its single screw pumps meet the highest standards of reliability and durability. The company's manufacturing facilities are equipped with state-of-the-art equipment and processes to produce pumps that are robust, efficient, and capable of withstanding harsh operating conditions.In conclusion, single screw pumps are an integral part of many industrial processes, and {} has been a key player in providing high-quality pumping solutions to a wide range of industries. With its proven track record and commitment to excellence, {} continues to be a trusted partner for businesses looking for reliable and efficient single screw pumps. As the demand for advanced pumping technology continues to grow, {} is well-positioned to lead the way with its innovative and reliable pumping solutions.