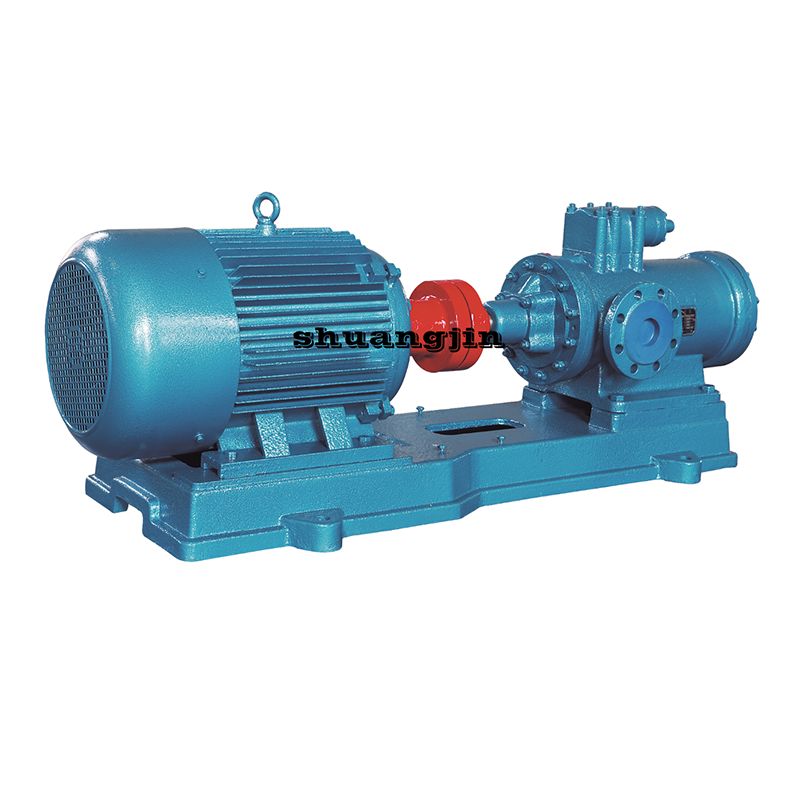

Highly Efficient Screw Pump for Various Industrial Applications

By:Admin

[Company Name], a leading provider of innovative solutions for the oil and gas industry, is making waves with its strategic use of screw pumps to enhance production efficiency. The company's commitment to incorporating cutting-edge technology into its operations has led to a significant increase in output and a reduction in downtime, positioning [Company Name] as an industry leader in the field of oil and gas production.

Screw pumps are a type of positive displacement pump that is commonly used in industrial applications to move fluid or semi-fluid materials. Their unique design and functionality make them well-suited for handling viscous liquids, making them an ideal choice for use in the oil and gas industry. By harnessing the power of screw pumps, [Company Name] has been able to optimize its production processes and streamline operations, ultimately leading to improved performance and increased profitability.

One of the key advantages of screw pumps is their ability to handle a wide range of materials, including those with high viscosity or solid content. This versatility makes them an invaluable asset for companies operating in the oil and gas sector, where the ability to effectively transport and process various types of fluids is essential. By integrating screw pumps into its production facilities, [Company Name] has been able to overcome many of the challenges associated with handling difficult-to-manage materials, thus improving overall operational efficiency and output.

In addition to their versatility, screw pumps also offer a high level of precision and reliability, allowing for consistent performance and minimal downtime. This is particularly important in the oil and gas industry, where any disruption to production can have significant financial repercussions. By investing in state-of-the-art screw pump technology, [Company Name] has been able to minimize the risk of equipment failure and ensure the continuous and reliable operation of its production facilities, resulting in a more stable and profitable business.

Furthermore, screw pumps are known for their energy efficiency, making them a sustainable and cost-effective choice for companies looking to improve their environmental footprint and reduce operating expenses. By utilizing screw pumps in its production processes, [Company Name] has been able to minimize energy consumption and reduce its overall carbon footprint, demonstrating a commitment to responsible and sustainable business practices.

Through its innovative use of screw pumps, [Company Name] has been able to achieve notable improvements in production efficiency, output capacity, and overall operational performance. The company's strategic investment in this technology has not only positioned it as a leader in the oil and gas industry but has also set a new standard for excellence and innovation within the sector.

In addition to its use of screw pumps, [Company Name] is dedicated to staying at the forefront of technological advancements in the industry. The company continuously seeks out new opportunities to improve its operations and enhance its capabilities, with a focus on delivering the highest quality products and services to its clients. By leveraging the latest advancements in engineering and technology, [Company Name] is well-positioned to continue its trajectory of growth and success in the oil and gas sector.

As the industry continues to evolve, [Company Name] remains committed to driving innovation and pushing the boundaries of what is possible in oil and gas production. With its strategic use of screw pumps and its unwavering dedication to excellence, [Company Name] is poised to achieve even greater success in the years to come, solidifying its position as a leading force in the industry.

Company News & Blog

Boost Your Efficiency with the Power of Multiphase Pumps

Multiphase Pump Technology Revolutionizes the Oil and Gas IndustryThe oil and gas industry is one of the most important sectors in the world today. It provides the energy and resources needed for transportation, heating, and electricity generation. However, the extraction of oil and gas from the earth is not always an easy task. It requires specialized equipment and techniques to effectively extract and transport the valuable resources. Multiphase pump technology has emerged as one of the most promising and game-changing technologies in the industry.The development of Multiphase Pumps has been revolutionary for the Oil and Gas industry. These pumps have the capability to handle a mixture of oil, gas, and water in a single flow pipeline. They have the potential to dramatically reduce costs and improve efficiency in oil and gas production by eliminating the need for expensive and complex infrastructure, such as separation facilities and pipelines. Multiphase pumps also have a small environmental footprint and are ideal for offshore production.One of the key players in the Multiphase Pump industry is a company that has been at the forefront of developing this technology. This company, founded in 1990 in Norway, is dedicated to creating innovative solutions for the oil and gas industry. It has established itself as a global leader in Multiphase Pump technology with over 2800 pump installations worldwide.The company’s flagship product is a multiphase pump that can handle up to 100% gas, 100% oil, or any combination in-between. The pump is extremely efficient and can operate in harsh environments, such as the North Sea, where conventional pumps cannot operate. Its unique design allows for efficient transport of oil and gas from wells in remote locations, minimizing the use of expensive infrastructure.Multiphase pump technology has numerous advantages over traditional methods. It can significantly reduce the cost of infrastructure, reduce downtime, and improve the overall efficiency of production. In addition, multiphase pumps can be used in a variety of applications, including oil production, gas production, and transportation. They can also be used in the development of unconventional resources such as shale gas and oil sands.The company’s multiphase pumps have been successfully used in a variety of projects worldwide. These include offshore platforms in the North Sea, deepwater subsea installations in the Gulf of Mexico, and onshore operations in the Middle East. The pumps have helped clients achieve cost savings of up to 50% and have significantly reduced emissions and carbon footprints.In addition to its successful pump installations, the company offers a range of services to support its clients. These services include custom design and engineering, installation and commissioning, training, maintenance, and upgrades. The company’s expert engineers and technicians provide comprehensive support to ensure that clients’ pumps perform at their best.The company’s dedication to innovation and customer satisfaction has earned it recognition from customers and the industry. It has won multiple awards for its innovative products and services. In 2020, the company received the Norwegian Export Award for its successful export of multiphase pumps to international markets.Multiphase pump technology has the potential to revolutionize the oil and gas industry by improving efficiency, reducing costs, and minimizing environmental impact. The company’s innovative approach to pump technology and excellent customer service has made it a leader in the industry. Its pumps and services have helped clients all over the world to extract oil and gas more efficiently and effectively. As the demand for cleaner energy sources increases, multiphase pump technology will play an even more important role in the energy transition. The company’s dedication to innovation and customer satisfaction will continue to drive its success and position it at the forefront of the industry.

Affordable and Efficient Air Conditioning for Heating Options

As the cold weather approaches, it’s time to start thinking about getting your heating system ready for the winter. One option that many homeowners are considering is using air conditioning units for heating. This innovative approach can provide an energy-efficient and cost-effective solution for keeping your home warm during the winter months.One of the leading companies in this field is {}. With over 20 years of experience in the HVAC industry, {} has become a trusted name in providing heating and cooling solutions for residential and commercial properties. The company has earned a reputation for delivering high-quality products and exceptional customer service, making them a go-to choice for homeowners looking for innovative heating solutions.Using air conditioning units for heating has become increasingly popular in recent years, and for good reason. These systems, known as heat pumps, work by transferring heat from the outside air into your home, providing an efficient and eco-friendly way to warm up your living space. This process is highly efficient and can significantly reduce energy consumption, leading to lower utility bills and a smaller carbon footprint.One of the key benefits of using air conditioning units for heating is their versatility. In addition to providing warmth during the winter, these systems can also be used for cooling during the summer months, making them a year-round solution for maintaining a comfortable indoor environment. This dual functionality can save homeowners the hassle and expense of having separate heating and cooling systems, making it a convenient and cost-effective choice.Another advantage of using air conditioning units for heating is their ability to provide consistent warmth throughout your home. Traditional heating systems, such as furnaces, can often result in uneven heating, with some areas of the house feeling much colder than others. Heat pumps, on the other hand, distribute heat evenly, creating a more comfortable and consistent temperature throughout your living space.When it comes to choosing the right air conditioning unit for heating, {} offers a wide range of options to suit different needs and preferences. From ductless mini-split systems to high-efficiency heat pumps, the company provides a variety of solutions designed to meet the unique requirements of each customer. With energy-saving features and advanced technology, their products are designed to deliver maximum performance and reliability.In addition to providing top-quality heating systems, {} also offers professional installation and maintenance services to ensure that your new unit functions at its best. Their team of experienced technicians can help you select the right system for your home and provide expert installation to ensure optimal performance. Furthermore, they offer regular maintenance services to keep your heating system in top condition, extending its lifespan and reducing the risk of breakdowns.As the demand for energy-efficient and eco-friendly heating solutions continues to grow, the use of air conditioning units for heating is expected to become even more popular in the coming years. With their proven track record in delivering high-quality products and excellent customer service, {} is well-positioned to meet this increasing demand and continue to be a leader in the HVAC industry.For homeowners looking for a reliable and innovative heating solution, {} provides a range of air conditioning units designed to deliver efficient, consistent, and cost-effective warmth throughout the winter months. With their expertise and commitment to customer satisfaction, {} is a name you can trust for all your heating and cooling needs.

Optimize Your Home's Cooling System with a Heat Pump

Heat Pump Cooling Systems have become increasingly popular in recent years due to their energy efficiency and ability to provide both heating and cooling in one system. One company at the forefront of this technology is {company name}, a leading provider of heating, ventilation, and air conditioning (HVAC) solutions.{Company name} has been pioneering the development and implementation of heat pump cooling systems for residential and commercial applications. Their innovative designs and high-quality products have made them a trusted name in the HVAC industry.Heat pump cooling systems work by transferring heat from one location to another using a refrigerant. In the summer, the system extracts heat from inside the building and releases it outside, providing cooling. In the winter, the process is reversed, and heat is extracted from the outdoor air and brought inside to warm the building. This dual functionality makes heat pump cooling systems highly efficient and environmentally friendly.{Company name} offers a range of heat pump cooling systems designed to meet the specific needs of their customers. Whether it's a small residential unit or a large commercial installation, {company name} has the expertise and technology to deliver reliable and efficient solutions.One of the key advantages of {company name}'s heat pump cooling systems is their energy efficiency. By using the natural heat in the air or ground, these systems can provide significant cost savings compared to traditional heating and cooling systems. This not only benefits the customer's bottom line but also contributes to a reduced carbon footprint, making them a sustainable choice for environmentally conscious consumers.In addition to their energy efficiency, {company name}'s heat pump cooling systems are also known for their reliability and longevity. With a commitment to quality and performance, {company name} ensures that their products are built to last, providing peace of mind for their customers.Another important aspect of {company name}'s heat pump cooling systems is their ease of installation and maintenance. Their experienced technicians are well-equipped to handle the installation of these systems, ensuring a smooth and efficient process. Additionally, {company name} offers maintenance and support services to ensure that their customers' systems continue to operate at peak performance for years to come.{Company name} is also dedicated to innovation and continuous improvement in their heat pump cooling systems. They invest in research and development to stay ahead of the curve, incorporating the latest technological advances to enhance the performance and efficiency of their products.With a focus on customer satisfaction, {company name} is known for providing excellent service and support. Their team of knowledgeable professionals is always available to answer any questions and provide assistance, ensuring a positive experience for their customers.In conclusion, {company name} is a leading provider of heat pump cooling systems, offering reliable, energy-efficient, and cost-effective solutions for residential and commercial applications. With a commitment to quality, performance, and customer satisfaction, {company name} is a trusted name in the HVAC industry, and their heat pump cooling systems continue to set the standard for excellence in the field.

How Screw Pumps Increase Pressure in Industrial Applications

Title: Innovative Screw Pump Pressure System Reimagines Fluid Conveyance in Industrial ApplicationsIntroduction (124 words):With rapid advancements in industrial technology, the demand for efficient fluid conveyance systems has become more crucial than ever. Recognizing this need, innovative engineering company [Company Name] has unveiled their latest solution—an advanced Screw Pump Pressure System. Boasting remarkable reliability, versatility, and industry-leading performance, this cutting-edge system is set to revolutionize fluid conveyance across various industries. Designed with state-of-the-art technologies and engineering expertise, the [Company Name]'s Screw Pump Pressure System is a game-changer in terms of operational cost-efficiency, maintenance, and overall productivity. Let us delve into the remarkable features and benefits of this groundbreaking solution.Title: Enhanced Reliability and Durability(136 words)The Screw Pump Pressure System, developed by [Company Name], is engineered to deliver enhanced reliability and durability in industrial fluid conveyance operations. Through thorough research and rigorous testing, this revolutionary system has proven itself capable of withstanding high-pressure and high-viscosity fluid transportation. Utilizing advanced materials and cutting-edge engineering techniques, the system is built to withstand demanding industrial environments, minimizing downtime and increasing overall productivity.Designed with precision components and assembled with meticulous attention to detail, the Screw Pump Pressure System offers unparalleled performance and durability. From challenging offshore oil drilling operations to intricate chemical processing, this system can handle a wide range of demanding tasks, ensuring smooth fluid conveyance even in the harshest conditions. Its robust design ensures long service life, reducing maintenance costs and maximizing uptime for businesses in need of reliable and high-performance fluid conveyance solutions.Title: Versatile Fluid Handling Capabilities(140 words)One of the key highlights of the Screw Pump Pressure System developed by [Company Name] is its remarkable versatility in handling various types of fluids. Whether it is crude oil, lubricants, chemicals, or other viscous substances, this system guarantees efficient and reliable conveyance. With its ability to maintain a consistent flow, the Screw Pump Pressure System ensures minimal pulsation, ensuring smooth operations in critical applications.Furthermore, this innovative solution offers adjustable speeds and pressure capabilities, allowing for increased flexibility in meeting diverse industrial requirements. By adapting to a wide range of fluid viscosities, the system can seamlessly integrate into various production processes, significantly improving overall operational efficiency. This adaptability extends to both horizontal and vertical fluid conveyance applications, making it a versatile choice for a wide range of industries, including oil and gas, chemical processing, wastewater treatment, and more.Title: Unrivaled Performance and Cost Efficiency(140 words)The Screw Pump Pressure System developed by [Company Name] has set new benchmarks in terms of performance and cost efficiency. Equipped with precision-engineered screw rotors and advanced sealing technologies, this system ensures consistent flow rates, minimal leakage, reduced energy consumption, and optimal operational efficiency.Thanks to its exceptional performance, the Screw Pump Pressure System boasts significant cost-saving advantages for businesses in the long run. Reduced energy consumption translates to lower operational costs, while the system's low-maintenance design minimizes downtime, boosts overall productivity, and improves return on investment. Moreover, the enhanced performance capabilities of this system enable businesses to optimize their manufacturing processes, achieve faster turnaround times, and meet increasing production demands.Conclusion (112 words):In conclusion, the Screw Pump Pressure System developed by [Company Name] presents a transformative solution to fluid conveyance challenges in various industries. Its remarkable reliability, versatile fluid handling capabilities, and unrivaled performance and cost efficiency set it apart from traditional systems. With its ability to withstand demanding environments and handle diverse fluid viscosities, this system is poised to revolutionize fluid conveyance operations, driving industrial productivity and profitability. [Company Name]'s commitment to innovation and advanced engineering exemplifies their dedication to providing cutting-edge solutions that cater to the evolving needs of modern industries.

Screw Pump Definition: A Comprehensive Guide to Understanding This Essential Hydraulic Device

Screw Pump Definition: In-Depth Understanding of This Versatile MachineryIn the world of industrial processing, various types of pumps play a vital role in ensuring the smooth functioning of operations. One such indispensable piece of equipment is the screw pump. Known for its efficient and reliable performance, the screw pump is widely utilized across multiple industries. This article presents an in-depth exploration of screw pumps, their definition, and their applications.Before delving into the details of screw pumps, let us provide a brief overview of the company. {} is a renowned manufacturer of industrial machinery, specializing in the production of high-quality pumps. With a rich history dating back several decades, the company has built a solid reputation for delivering cutting-edge solutions to its global clientele. Committed to innovation and customer satisfaction, {} continues to revolutionize the industry with its reliable and robust products.A screw pump, also known as an Archimedean screw pump, is a positive displacement pump that operates by using one or more screws or rotors. The design of the screw pump enables it to move fluids by trapping and pushing them along the screw's threads. As the screw rotates, the fluid is continuously displaced, creating a steady flow.The versatility of screw pumps is highlighted by their ability to handle a wide range of liquids, from viscous fluids to abrasive slurries. Their self-priming capability makes them particularly suitable for applications where the liquid needs to be drawn from a lower level. In industries such as oil and gas, wastewater treatment, food and beverage, and pharmaceuticals, screw pumps are extensively employed due to their robust construction and reliability.One significant advantage of screw pumps is their ability to handle fluids containing solid particles without clogging or damaging the pump. This unique feature renders screw pumps ideal for applications involving the transfer of sludge, slurry, or sewage. By withstanding the challenges posed by abrasive and corrosive materials, screw pumps ensure uninterrupted operations and minimize downtime.The design of a screw pump generally consists of two or more intermeshing screws, enclosed within a cylindrical housing. As the screws rotate, their continuous movement propels the fluid through the pump. The close tolerances between the screws and the housing minimize slippage, resulting in efficient and precise fluid transfer. To further enhance performance, some screw pumps incorporate additional features like variable speed drives or multiple stages to meet specific application requirements.With their ability to generate high pressures, screw pumps find widespread use in hydraulic systems. These pumps have the capability to deliver a constant flow of fluid, making them ideal for applications requiring precise control. Screw pumps are commonly utilized in industries such as agriculture, construction, and manufacturing, where they power various equipment and provide hydraulic force for operational tasks.In conclusion, screw pumps offer a reliable and versatile solution for fluid transfer across multiple industries. Their unique design allows them to handle a wide range of fluids, including viscous, abrasive, and solid-laden substances. By ensuring continuous and efficient operation, screw pumps have become an indispensable component of industrial processes worldwide.ABOUT {}: For several decades, {} has been a leading manufacturer of industrial machinery, catering to diverse industries globally. With a customer-centric approach and a commitment to excellence, the company delivers cutting-edge solutions to meet the unique needs of their clients. Through continuous innovation and a focus on quality, {} sets industry standards and drives technological advancements. With a worldwide presence, the company continues to expand its global footprint, establishing itself as a benchmark for reliability and performance in the industrial machinery sector.

Understanding the Basics of Displacement Pumps: A Guide

Displacement Pumps: A Versatile Solution for a Range of IndustriesDisplacement Pumps, a leading manufacturer of industrial pumps, has been serving various industries with its high-quality and reliable pumping solutions for over three decades. The company takes pride in its commitment to innovation, quality, and customer satisfaction, and has emerged as a trusted name in the world of fluid handling equipment.Displacement Pumps offers a wide range of displacement pumps, including diaphragm pumps, gear pumps, piston pumps, and rotary vane pumps, that cater to the diverse needs of industries such as oil and gas, chemical processing, pharmaceutical, food and beverage, water and wastewater, and many others. These pumps are designed to handle a variety of fluids, including corrosive chemicals, viscous liquids, abrasive slurries, and high-temperature substances, making them a versatile solution for a range of applications.One of the key advantages of displacement pumps is their ability to deliver a steady and consistent flow of fluid, regardless of changes in pressure or viscosity. This makes them ideal for processes that require precise and accurate dosing, metering, or transferring of liquids. Whether it's in a refinery for pumping crude oil, in a food processing plant for handling viscous sauces, or in a pharmaceutical facility for transferring sensitive chemicals, displacement pumps offer the reliability and performance that industries depend on.Moreover, Displacement Pumps is dedicated to staying at the forefront of pump technology, constantly improving and innovating its product line to meet the evolving needs of its customers. The company invests heavily in research and development to develop cutting-edge pumping solutions that are energy-efficient, environmentally friendly, and easy to maintain. This commitment to innovation has enabled Displacement Pumps to stay ahead of the competition and provide its customers with state-of-the-art pumping technology.In addition to its product excellence, Displacement Pumps is also known for its exceptional customer service and support. The company has a team of experienced engineers and technical experts who work closely with customers to understand their specific requirements and provide customized pumping solutions that best suit their needs. From initial consultation and pump selection to installation, maintenance, and after-sales support, Displacement Pumps ensures that its customers receive the highest level of service and satisfaction.With a global presence and a network of distributors and service centers in key locations around the world, Displacement Pumps is able to serve customers in diverse industries and geographies. The company's commitment to quality, reliability, and customer satisfaction has earned it a strong reputation and a loyal customer base, making it a preferred choice for industrial pumping solutions.As the demand for efficient and dependable fluid handling equipment continues to grow, Displacement Pumps remains dedicated to meeting the challenges of the industry and exceeding the expectations of its customers. With its superior pumping technology, unwavering commitment to innovation, and exceptional customer service, Displacement Pumps is poised to maintain its position as a leading provider of displacement pumps for a wide range of industries.In conclusion, Displacement Pumps has established itself as a trusted and reliable manufacturer of displacement pumps, offering innovative and high-quality pumping solutions for various industries. With a focus on product excellence, customer satisfaction, and continuous improvement, the company continues to set the standard for industrial pumping technology and remains a preferred choice for businesses worldwide.

Exploring the Distinctions Between Screw Pumps and Gear Pumps – A Comprehensive Guide

Title: Decoding the Distinctions Between Screw Pumps and Gear PumpsIntroduction:In the world of fluid processing and transportation, pumps play a pivotal role in powering various industries such as oil and gas, pharmaceuticals, food processing, and many others. Screw pumps and gear pumps are two popular types of pumps used for handling different liquid mediums. Understanding the differences between these pumps is crucial in determining the most suitable choice for specific applications. This article aims to shed light on the dissimilarities between screw pumps and gear pumps, exploring their operating principles, advantages, and drawbacks.Section 1: The Operating Principles of Screw Pumps and Gear PumpsScrew pumps, also known as progressive cavity pumps, operate based on the principle of positive displacement. They consist of a rotating helical rotor that moves within a stationary double helical stator. As the rotor turns, cavities are formed and progress along the axis, pushing the liquid from the inlet to the outlet.On the other hand, gear pumps operate using the principle of positive displacement as well. They consist of two meshing gears, known as the driving gear and the driven gear, enclosed within a closely fitted housing. As the gears rotate, the liquid is trapped in the cavities between the teeth, creating a seal and forcing the liquid to move from the inlet to the outlet.Section 2: Advantages and Drawbacks of Screw Pumps and Gear Pumps2.1 Screw Pumps:Screw pumps offer several advantages, making them suitable for a wide range of applications. Firstly, they excel at handling high viscosity liquids and fluids with solid content. Thanks to their gentle pumping action, screw pumps are capable of handling shear-sensitive and abrasive fluids without compromising their integrity. Moreover, screw pumps provide a steady flow rate with minimal pulsation, ensuring smooth and consistent delivery. However, one drawback to consider is their relatively lower efficiency compared to gear pumps, resulting in higher energy consumption.2.2 Gear Pumps:Gear pumps offer their own set of advantages and drawbacks. One significant advantage of gear pumps is their ability to generate high pressures, especially in applications requiring high delivery heads. Additionally, gear pumps exhibit excellent self-priming capabilities, making them suitable for applications where a reliable suction source may be limited. However, gear pumps may struggle with handling highly viscous fluids and those containing solids. Their operation can also produce pulsations and pressure fluctuations, which can be detrimental to certain sensitive processes.Section 3: Applications and Industries3.1 Screw Pumps:Screw pumps find applications in numerous industries, such as oil and gas, wastewater treatment, and chemical processing. Their ability to handle high-viscosity fluids, combined with their gentle pumping action, makes them ideal for applications involving crude oil, sludge, and abrasive chemicals.3.2 Gear Pumps:Gear pumps find widespread use in industries such as automotive, pharmaceuticals, and food processing. The ability of gear pumps to generate high pressures and their self-priming capabilities make them suitable for applications involving lubricating oils, hydraulic fluids, and metering precise volumes of liquid.Conclusion:In conclusion, both screw pumps and gear pumps serve essential roles in fluid processing and transfer applications. Choosing the appropriate pump type depends on factors such as the viscosity of the liquid, presence of solids, required pressure, and the level of pulsation tolerance. Understanding the distinct operating principles, advantages, and drawbacks of screw pumps and gear pumps is crucial in selecting the right pump for specific industrial needs.

Industry Leading Pump Manufacturer Introduces Innovative Technology in Latest News Release

Leistritz Pump, a global leader in the design and manufacturing of high-performance pumps and systems, has recently announced a significant milestone in their business expansion strategy. The company has successfully completed a merger with a leading engineering firm, [company name], to further strengthen their position in the market and expand their product offerings.With a history dating back to [year], [company name] has built a reputation for delivering innovative solutions to complex engineering challenges. The company's portfolio includes a wide range of products and services, including custom-designed pump systems, fluid handling equipment, and engineering services for various industries such as oil and gas, chemical processing, power generation, and marine applications.The merged entity will leverage the strengths of both companies to drive growth and innovation in the global pump and systems market. The synergy of [company name]'s engineering expertise and Leistritz Pump's industry-leading pump technologies will enable the combined company to offer a broader range of solutions to meet the evolving needs of customers worldwide."This merger represents a significant step forward in our mission to provide comprehensive and cutting-edge pump and system solutions to our customers," said [spokesperson], CEO of Leistritz Pump. "By combining our technical capabilities and market knowledge with [company name]'s engineering excellence, we are poised to deliver unmatched value to our customers and partners."The newly merged company will operate under the [company name] brand, leveraging the established reputation and customer base of both organizations. The integration of the two companies' resources and expertise is expected to result in a stronger, more agile organization that can better serve the needs of customers in diverse industries.In addition to broadening its product portfolio, the merger is also expected to bring about operational synergies that will enhance the company's manufacturing, distribution, and service capabilities. With a more comprehensive and efficient operational footprint, the combined entity will be better positioned to meet the growing demand for high-performance pump and system solutions around the world."We are excited about the opportunities this merger presents for our employees, customers, and partners," said [spokesperson]. "The combined strengths of our organizations will enable us to better anticipate and respond to market trends, and to provide innovative solutions that address the most complex engineering challenges."The merger is a testament to the commitment of both companies to drive sustainable growth and to reinforce their positions as leading providers of engineered pump and system solutions. With a strong focus on innovation, quality, and customer satisfaction, the merged company is well-equipped to deliver superior value to its customers and to drive continued success in the global pump and systems market.As the newly merged company embarks on this exciting new chapter, it remains dedicated to pursuing excellence in all aspects of its business. By leveraging the expertise and resources of both organizations, the combined entity is poised to set new standards for performance, reliability, and customer satisfaction in the pump and systems industry.In conclusion, the merger between Leistritz Pump and [company name] marks a significant milestone in the evolution of both companies, and it represents a compelling opportunity for customers, employees, and partners. The combined strengths of these organizations will enable the newly merged company to deliver unparalleled value and innovation, further solidifying its position as a global leader in the pump and system solutions market.

The Key Principles of Pump Operation Explained

Pump Principle, a leading provider of industrial pump solutions, has recently introduced its latest line of innovative pumps designed to meet the diverse needs of the industrial sector. With a strong focus on efficiency, reliability, and sustainability, Pump Principle has quickly become a trusted partner for industries ranging from manufacturing and agriculture to oil and gas.Founded in 1995, Pump Principle has established itself as a pioneer in the field of pump technology. The company's commitment to research and development has resulted in a range of cutting-edge pump solutions that have set new standards in the industry. With a customer-centric approach, Pump Principle has built a strong reputation for delivering high-quality products and personalized service to its clients.One of the key principles that sets Pump Principle apart is its dedication to innovation. The company is constantly seeking out new technologies and methodologies to enhance the performance of its pumps. This commitment to innovation has led to the development of a range of pumps that are not only more efficient and reliable but also more environmentally friendly. Pump Principle's pumps are designed to minimize energy consumption and reduce waste, helping companies to lower their carbon footprint and contribute to a more sustainable future.One of the highlights of Pump Principle's latest line of pumps is its focus on versatility. The company understands that different industries have different needs when it comes to pump solutions, and therefore it has developed a range of pumps that can be customized to meet specific requirements. Whether it's a high-pressure pump for the oil and gas industry or a heavy-duty pump for the mining sector, Pump Principle has the expertise to tailor its products to suit a wide variety of applications.Furthermore, Pump Principle places a strong emphasis on durability and reliability. The company knows that industrial processes can be demanding, and therefore its pumps are built to withstand harsh operating conditions and deliver consistent performance over time. By using high-quality materials and rigorous testing processes, Pump Principle ensures that its pumps meet the highest standards of reliability, reducing downtime and maintenance costs for its clients.In addition to its focus on product excellence, Pump Principle is also committed to providing exceptional customer service. The company takes pride in its team of dedicated professionals who are always ready to assist clients with their pump needs. From initial consultation and product selection to installation and ongoing support, Pump Principle's experts work closely with clients to ensure that they receive the best possible pump solutions for their specific requirements.With a strong track record of success and a growing list of satisfied clients, Pump Principle continues to expand its presence in the industrial pump market. The company's unwavering commitment to quality, innovation, and customer service has positioned it as a preferred partner for companies looking for reliable and efficient pump solutions.As industries continue to evolve and demand more advanced technologies, Pump Principle is poised to remain at the forefront of the industry, driving innovation and setting new benchmarks for pump performance and sustainability. With its latest line of pumps, the company is well-positioned to meet the evolving needs of industrial clients, helping them to achieve greater efficiency, productivity, and environmental responsibility.In conclusion, Pump Principle's dedication to excellence and innovation has made it a trusted name in the industrial pump sector. With its latest line of versatile, reliable, and sustainable pumps, the company is well-equipped to address the diverse needs of industries and provide them with the cutting-edge pump solutions they require for their operations. As Pump Principle continues to grow and expand its reach, it remains committed to delivering high-quality products and exceptional service to its clients, solidifying its position as a leader in the industrial pump market.

Expert Industrial Pump Repair Services for Your Business

Industrial Pump Repair, a leading provider of pump repair services, has established itself as a reliable and efficient solution for pump maintenance and repair needs. With over 20 years of experience in the industry, Industrial Pump Repair prides itself on delivering top-notch service to a wide range of industrial clients.The company specializes in the repair and maintenance of various types of industrial pumps, including centrifugal pumps, positive displacement pumps, and multi-stage pumps. Their team of skilled technicians is equipped with the necessary expertise and tools to diagnose and repair pump issues efficiently, minimizing downtime and maximizing operational efficiency for their clients.Industrial Pump Repair understands the critical role that pumps play in industrial operations, and the impact that pump failures can have on production and overall business performance. As such, the company is committed to providing prompt and reliable repair services to ensure that their clients’ pumps are functioning at optimal levels at all times.One of the key advantages of choosing Industrial Pump Repair for pump maintenance and repair needs is their dedication to quality and customer satisfaction. The company employs a rigorous quality control process to ensure that all repairs are carried out to the highest standards, and that clients receive the best possible service.In addition to their repair services, Industrial Pump Repair also offers preventative maintenance programs to help clients proactively address potential pump issues and extend the lifespan of their equipment. By conducting regular inspections and maintenance checks, the company can help identify and address potential problems before they escalate into major issues, saving clients time and money in the long run.Furthermore, Industrial Pump Repair prides itself on its responsive and client-focused approach to doing business. The company understands that pump failures can occur at any time, often causing significant disruptions to operations. As such, they offer emergency repair services to address urgent pump issues promptly, minimizing the impact of downtime on their clients’ businesses.Industrial Pump Repair’s commitment to excellence and customer satisfaction has earned them a solid reputation in the industry, with many clients relying on their services for their pump repair needs. The company has worked with a wide range of industrial clients, including those in the manufacturing, chemical, food and beverage, and oil and gas industries, among others.Moreover, Industrial Pump Repair is known for its competitive pricing and transparent approach to doing business. The company provides clients with detailed quotes and explanations of the repair process, ensuring that they are fully informed and confident in the services being provided.As part of their dedication to continuous improvement, Industrial Pump Repair invests in ongoing training for their technicians and stays abreast of the latest technologies and techniques in the pump repair industry. This commitment to staying ahead of the curve allows the company to deliver innovative and effective solutions to their clients’ pump repair needs.In conclusion, Industrial Pump Repair stands out as a reliable and efficient partner for industrial clients in need of pump maintenance and repair services. With their extensive experience, dedication to quality, and commitment to customer satisfaction, the company has solidified its position as a trusted name in the industry. Industrial Pump Repair continues to be a go-to solution for businesses looking to keep their pumps in peak operating condition.