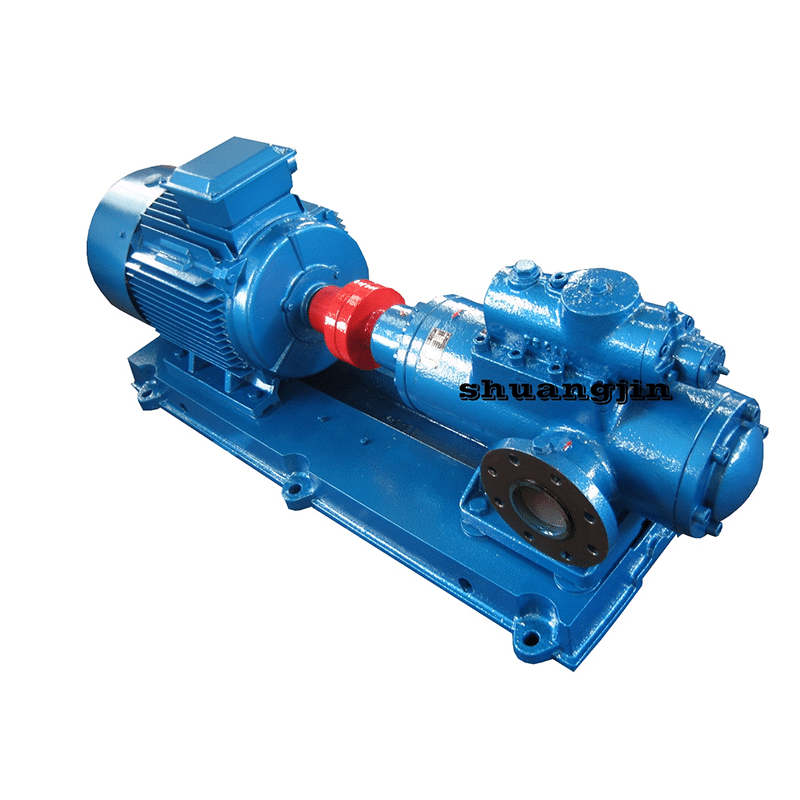

Highly Efficient Twin Screw Pump for Industrial Applications

By:Admin

[City, State] - In a generous move to support the local community, a leading industrial equipment manufacturer has donated a state-of-the-art Twin Screw Pump to the [City] municipality. The [Company], known for its innovative and high-quality pumping solutions, has made this donation to aid in the efficient distribution of water to the residents of the city.

The Twin Screw Pump, a highly advanced and reliable piece of equipment, is designed to handle a wide variety of fluids with ease. Its unique design allows for gentle pumping action, low pulsation, and a smooth flow, making it an ideal choice for the distribution of water in a municipal setting. With its robust construction and advanced technology, the pump is expected to significantly improve the efficiency and reliability of the city's water distribution system.

The donation of the Twin Screw Pump comes as part of [Company]'s ongoing commitment to corporate social responsibility and giving back to the communities in which it operates. The company, which has a long history of supporting various charitable causes and initiatives, saw an opportunity to contribute to the well-being of the residents of [City] by providing them with a cutting-edge piece of equipment that will directly impact their daily lives.

"We are thrilled to be able to donate this Twin Screw Pump to the [City] municipality," said [Company spokesperson]. "Water distribution is a crucial aspect of urban life, and we are confident that our pump will help the city to improve the efficiency of its water infrastructure. It is our hope that this donation will not only benefit the city and its residents but also serve as a symbol of our commitment to being a responsible corporate citizen."

The [City] municipality, which has been facing challenges with its aging water distribution system, has expressed its gratitude for the generous donation. The Twin Screw Pump will be installed at a key location within the city's water infrastructure, where it will be used to ensure the smooth and reliable distribution of water to homes and businesses.

"We are incredibly thankful to [Company] for their generous donation of the Twin Screw Pump," said [City official]. "This state-of-the-art equipment will undoubtedly make a positive impact on our water distribution system, allowing us to provide better service to our residents. We are truly grateful for [Company]'s support and commitment to our community."

The installation of the Twin Screw Pump is expected to take place in the coming weeks, and the city's water department is already making preparations to integrate the new equipment into its existing infrastructure. Once operational, the pump is expected to deliver immediate improvements in the efficiency and reliability of the water distribution system, ultimately benefiting thousands of residents and businesses in the city.

In addition to the donation of the pump, [Company] has also committed to providing training and technical support to the city's water department to ensure the proper operation and maintenance of the equipment. This ongoing support is expected to further enhance the long-term impact of the donation and help to maximize the benefits of the Twin Screw Pump for the city and its residents.

The donation of the Twin Screw Pump by [Company] serves as a shining example of the positive impact that corporate generosity can have on local communities. By providing the city of [City] with a cutting-edge piece of equipment to improve its water distribution system, [Company] has demonstrated its dedication to being a responsible corporate citizen and making a meaningful difference in the lives of those it serves.

Company News & Blog

10 Essential Applications of Screw Pumps in Various Industries

The Use of Screw Pump: Understanding the Importance in Industrial ApplicationsScrew pumps have been around for a while and used in industrial applications for various reasons. They have become popular because of their efficiency and versatility, with many companies using it for different purposes. These pumps can be found in oil and gas industries, food-processing plants, petrochemical plants, and many more.Screw pumps work by moving fluid inside their chambers. A helical screw rotates inside a cylinder, creating pressure that forces fluid to flow through the pump. As it moves, it also moves pockets of fluid along the way, which reduces pulsation, ensures smooth continuous flow, and maximizes efficiency.Thanks to screw pumps, manufacturers can efficiently move liquids without disturbing the medium's temperature, density, or viscosity. It's perfect for transferring both low and high viscosity liquids, making it the perfect solution for moving anything from crude oil to food products.This pump is versatile, cost-effective, and often replaceable. However, like any machinery, there are advantages and disadvantages to using a screw pump. Below, we'll take a look at some of the benefits of using screw pumps in your system.Advantages of Screw Pumps1. Low Maintenance RequirementsOne of the primary advantages of using a screw pump is that it requires minimal maintenance. The low maintenance requirements of screw pumps make it cost-effective, and you will save a considerable amount of money in maintenance and repairs.2. Efficient PerformanceScrew pumps are designed for maximum efficiency. They can handle high and low viscosity liquids, making it easy to move anything from crude oil to food products. Their design optimizes the flow of liquid, reducing pulsations and ensuring smooth, continuous flow.3. High Suction CapabilityScrew pumps can handle high suction, making it easy to transfer liquids of different viscosities. They can handle everything from light fuel oils to heavy crude oil.4. Can Handle Multiple ViscositiesScrew pumps are suitable for transferring liquids of different viscosities. They are often used in the oil and gas industry, where they can be used to transfer crude oil, diesel fuel, and heavy oil.5. They Are VersatileScrew pumps are highly versatile. They are used in a variety of industries for many different purposes, making them ideal for any application that requires the movement of liquids.6. Reduced Noise LevelScrew pumps are relatively quiet, making them ideal for indoor settings where noise levels need to be kept to a minimum.How to Select the Right Screw PumpSelecting the right screw pump is essential to ensure that you get the desired results. The best way to select the right screw pump is to work with a reputable and experienced manufacturer. When selecting a screw pump, you need to consider factors such as:1. The Viscosity of the LiquidThe viscosity of the liquid you are transferring is a crucial factor when selecting a screw pump. You need to ensure that the pump you choose can handle the viscosity of the liquid.2. Temperature of the LiquidConsider the temperature of the liquid you will be transferring. Screw pumps are suitable for liquid temperatures of up to 350 degrees Celsius.3. Characteristics of the LiquidConsider the characteristics of the liquid you will be transferring. The physical characteristics of the liquid will impact the type of screw pump you choose.ConclusionScrew pumps are essential for many industries. They are versatile, efficient, and cost-effective, making them the perfect solution for moving liquids of various viscosities. When selecting a screw pump, it's essential to choose an experienced and reputable manufacturer to ensure that you get the desired results.

Innovative Impeller Pump Design Revolutionizes Industrial Fluid Transfer

New Screw Impeller Pump Revolutionizes Industrial PumpingIndustrial processes require highly efficient and reliable pumping systems that can handle large volumes of liquids and solids. And, I am pleased to announce that the Screw Impeller Pump, produced by a leading manufacturer in the industry, delivers exactly that. The pump represents a technological revolution in the world of industrial pumping systems, and it has proved to be a game changer in harsh industrial environments across the globe.The Screw Impeller Pump, also known as the twin-screw pump, is a highly advanced pump that works on a unique screw impeller technology. The pump produces a smooth fluid flow while handling fluids with high viscosity, which is important in a variety of industrial applications. This is achieved by the co-rotating screws with a helical rotation that move precisely together and trap the fluid within the pump's cavity, moving it along steadily and continuously.The pump has been designed after decades of research and development on screw impeller technology. The pump manufacturer has implemented a patented technology that ensures that the Screw Impeller Pump performs exceptionally well in handling abrasive materials and viscous liquids that other pumps would typically struggle with. The technology involves an improved screw profile that helps to produce a more consistent flow rate, higher efficiency, and lower noise levels.To ensure that the Screw Impeller Pump meets the rigorous requirements of different industrial applications worldwide, the manufacturer has put a lot of effort into its construction. The pump features sturdy construction materials that resist wear, corrosion, and high-pressure surges. This makes it ideal for pumping fluids such as petroleum products, chemicals, paint, lubricants, and food products. The hard-wearing construction also ensures that the pump operates for longer periods without incurring downtime.The Screw Impeller Pump also comes with a highly advanced sealing system that prevents leaks, ensures that the pump's operation is smooth and stable, and reduces maintenance costs. This has been achieved by using a specially designed shaft seal that coats the shaft's surface with a low-friction coating that reduces friction. This feature significantly reduces the need for frequent maintenance and replacements.Another notable feature of the Screw Impeller Pump is its versatility. The pump can handle different types of fluids and materials and works well even in harsh industrial environments. It is also energy-efficient, which translates to reduced energy costs and lower carbon emissions. The pump consumes less energy to produce the same fluid volume as compared to conventional pumps, making it a great environmentally friendly alternative to traditional pumps.In addition to its excellent features, the Screw Impeller Pump delivers consistently high performance, thanks to its advanced monitoring and control systems. The manufacturer has incorporated advanced sensors and control systems that help to monitor the pump's performance in real-time. This ensures that the pump operates at its optimal level while preventing downtime and costly machine breakdowns.In summary, the Screw Impeller Pump is a high-performance industrial pump that has been designed to deliver exceptional performance in handling different types of fluids with various viscosities and solids. The pump's robust construction, advanced sealing system, and energy-efficient design make it a great addition to industrial process lines. Its versatility, consistency, and low maintenance costs make it a cost-effective solution to many industrial pumping challenges.As a renowned pump distributor, we are proud to offer this innovative pump to our clients across various industrial sectors. Get in touch with our experts today to learn more about the Screw Impeller Pump and how you can incorporate it into your industrial processes.

Maximizing Efficiency of Screw Pumps: Tips and Techniques

Screw Pump Efficiency Revolutionizes the Pumping IndustryIn the world of industrial pumping, efficiency is everything. And one company has been leading the charge in revolutionizing pump efficiency with their innovative screw pump technology.For decades, the pumping industry has relied on traditional centrifugal pumps to move liquids and gases in various industrial applications. While these pumps have served their purpose, they often come with inefficiencies and limitations that can affect their performance and productivity. This is where the screw pump, a game-changing alternative, comes into play.With its unique design and capabilities, the screw pump has proven to be a more efficient and reliable option for a wide range of industrial pumping tasks. Unlike traditional centrifugal pumps, screw pumps are able to handle high viscosity liquids, solids, and abrasive materials with ease. This makes them ideal for demanding applications such as oil and gas, chemical processing, wastewater treatment, and marine industries.One company at the forefront of this screw pump revolution is [Company Name]. With a history dating back to [year], [Company Name] has been a leading manufacturer and supplier of screw pumps and other pumping solutions for a diverse range of industries. Their commitment to innovation and customer satisfaction has earned them a reputation for excellence in the pumping industry.[Company Name]’s screw pumps are designed with efficiency and performance in mind. Their unique helical rotor design allows for smooth and continuous pumping of a wide variety of fluids, resulting in higher flow rates and lower energy consumption. This not only saves on operational costs but also reduces downtime and maintenance requirements, making their screw pumps a cost-effective and reliable choice for industrial pumping needs.Furthermore, [Company Name] offers a range of customizable options and accessories for their screw pumps, allowing customers to tailor their pumping solutions to their specific requirements. Whether it’s different materials of construction, sizes, or configurations, [Company Name] ensures that their screw pumps meet the unique needs of each customer and application.In addition to their innovative products, [Company Name] is committed to providing exceptional customer service and support. Their team of experts works closely with customers to understand their pumping challenges and provide tailored solutions that maximize efficiency and performance. From initial consultation to installation and ongoing maintenance, [Company Name] is dedicated to being a trusted partner for all of their customers’ pumping needs.With a strong focus on research and development, [Company Name] continues to push the boundaries of screw pump technology. Their investment in cutting-edge design and engineering ensures that their products remain at the forefront of pump efficiency and reliability, setting new standards in the industry.The success of [Company Name] and their screw pump technology has not gone unnoticed. They have garnered a loyal customer base and earned numerous accolades and certifications for their commitment to quality and innovation. Their dedication to sustainable and environmentally friendly pumping solutions has also positioned them as a leader in the industry.As the industrial pumping industry continues to evolve, efficiency and reliability will remain key factors in determining the success of pumping solutions. With their innovative screw pump technology and commitment to customer satisfaction, [Company Name] is well-positioned to lead the way in revolutionizing the pumping industry for years to come.

Screw Pump vs Gear Pump: Understanding the Key Differences

Title: Understanding the Differences Between Screw Pumps and Gear Pumps: A Closer Look at Pumping TechnologiesIntroduction:In the world of fluid transfer and pumping technologies, two commonly used pump types are screw pumps and gear pumps. Both these pumps play a crucial role in various industries, including oil and gas, chemical, food processing, and many others. However, understanding the differences between screw pumps and gear pumps is vital in order to determine the most suitable option for specific applications. This article aims to shed light on these differences, highlighting the unique features and advantages of each pumping technology.Screw Pumps:Screw pumps, also known as progressive cavity pumps, operate based on the principle of displacement. They consist of two main components – a helical rotor and a stator. The rotor, often in the shape of a screw, rotates within the stator, resulting in the transfer of fluids from the suction side to the discharge side.Screw pumps are recognized for their ability to handle highly viscous fluids, including heavy oils, sludge, and slurries. Their design features enable them to generate a smooth, non-pulsating flow, making them suitable for applications requiring precise control over fluid transfer. Furthermore, screw pumps exhibit low shear rates, making them ideal for handling shear-sensitive materials without damaging their integrity.One key advantage of screw pumps is their self-priming capability. They can effectively handle fluids with entrained air or gas, eliminating the need for additional priming mechanisms. Screw pumps also showcase excellent suction lift capability, enabling efficient pumping even when the fluid source is located below the pump.Gear Pumps:Gear pumps, on the other hand, utilize rotating gears to transfer fluids. They consist of two meshing gears – a drive gear and a driven gear. As the gears rotate, liquid is drawn into the pump and pushed through the outlet. Gear pumps are widely used in various industries due to their simplicity, compact size, and high efficiency.Gear pumps excel in applications requiring high flow rates and moderate pressures. Their smooth operation allows for noiseless performance, making them suitable for applications where noise reduction is essential. Additionally, gear pumps can handle clean fluids, as well as fluids containing small particulate matter without clogging or damage to the gears.One of the key advantages of gear pumps is their ability to provide consistent flow, even under varying pressures. This makes them ideal for applications where stable pressure levels are critical. Another noteworthy feature is their ability to operate efficiently over a wide range of viscosities, allowing flexibility in fluid transfer applications.Conclusion:In conclusion, understanding the differences between screw pumps and gear pumps is pivotal in selecting the appropriate pumping technology for specific industrial applications. Screw pumps are best suited for handling highly viscous fluids and shear-sensitive materials, offering self-priming capability and low shear rates. On the other hand, gear pumps excel in high flow rate applications, offering consistent flow even under varying pressures and versatility across a wide range of viscosities.As industries continue to advance, the demand for efficient fluid transfer technologies will persist. Both screw pumps and gear pumps provide reliable solutions, each with their unique set of advantages. It is crucial for industries to evaluate their specific requirements and consult with experts to make informed decisions regarding the selection of the most suitable pumping technology for enhanced productivity and operational success.

Leading Pump Manufacturer in Tianjin Unveils New Product Line

Tianjin Pump is a leading company in the field of industrial pump manufacturing and has been a key player in the industry for over three decades. The company is known for its high-quality products, innovative technologies, and commitment to customer satisfaction. With a strong focus on research and development, Tianjin Pump has consistently pushed the boundaries of what is possible in the world of pump technology.Recently, Tianjin Pump announced the launch of a new series of industrial pumps that are set to revolutionize the way various industries approach their pumping needs. The company's latest offering promises to deliver unmatched performance, reliability, and efficiency, setting a new standard for the industry as a whole.Founded in 1986, Tianjin Pump has grown to become a global leader in the design and manufacture of industrial pumps. The company's products are widely used in sectors such as oil and gas, power generation, water treatment, and chemical processing. With a strong emphasis on quality and precision engineering, Tianjin Pump has earned a reputation for delivering pumps that are durable, dependable, and capable of meeting the most demanding application requirements.At the core of Tianjin Pump's success is its ongoing commitment to innovation. The company invests heavily in research and development, constantly seeking new ways to improve its products and stay ahead of the competition. This dedication to pushing the boundaries of what is possible has resulted in a steady stream of groundbreaking products that have redefined the industry's expectations.One of the key features of Tianjin Pump's new series of industrial pumps is its advanced design, which incorporates the latest technologies to deliver superior performance and efficiency. These pumps are engineered to operate at peak efficiency, reducing energy consumption and minimizing operating costs for the end user. By leveraging cutting-edge materials and manufacturing techniques, Tianjin Pump has been able to develop pumps that offer unmatched durability and reliability, even in the most challenging operating conditions.In addition to their technical prowess, Tianjin Pump's new series of industrial pumps are also designed with ease of maintenance and serviceability in mind. This ensures that customers can rely on their pumps to deliver consistent performance over the long term, with minimal downtime and maintenance requirements. This focus on customer satisfaction is a testament to Tianjin Pump's commitment to delivering value beyond just the initial purchase of its products.With the launch of its new series of industrial pumps, Tianjin Pump is poised to further solidify its position as a global leader in the pump manufacturing industry. The company's unwavering dedication to innovation, quality, and customer satisfaction has set it apart from its competitors, and the latest offering is a testament to its ongoing commitment to pushing the boundaries of what is possible in the world of pump technology.As industries continue to evolve and demand for more efficient and reliable pumping solutions grows, Tianjin Pump is well-positioned to meet these challenges head-on. The company's new series of industrial pumps represents a significant leap forward in pump technology and is set to raise the bar for the industry as a whole. With its long history of excellence and a track record of delivering innovative, high-quality products, Tianjin Pump is set to continue leading the way in the world of industrial pump manufacturing for years to come.

Top-quality Oil & Gas Pumps: Your Guide to Efficient Industry Solutions

Oil and Gas Pumps Revolutionize the Energy IndustryIn today's rapidly evolving technological landscape, the demand for efficient and reliable equipment in the oil and gas industry is higher than ever. To meet these increasing demands, Oil and Gas Pumps (name removed) has emerged as a leading provider of cutting-edge pumping solutions. With their acclaimed company history of innovation and commitment to customer satisfaction, Oil and Gas Pumps has revolutionized the energy industry.With a diverse range of offerings, Oil and Gas Pumps provides pumping solutions that cater to various applications within the oil and gas sector. Their pumps play a crucial role in exploration, production, refining, and distribution processes, ensuring a smooth and continuous flow of oil and gas.One of the key factors that sets Oil and Gas Pumps apart from its competitors is its relentless pursuit of innovation. The company invests heavily in research and development, constantly striving to develop pumps that are more efficient, durable, and environmentally friendly. By pushing the boundaries of engineering, Oil and Gas Pumps has been able to enhance productivity while reducing the carbon footprint of its operations.Furthermore, Oil and Gas Pumps' commitment to customer satisfaction is second to none. The company takes immense pride in its ability to provide tailored solutions that meet the specific needs of its clients. By working closely with customers, Oil and Gas Pumps ensures that its pumps are perfectly suited to the varied challenges faced in the oil and gas industry, whether it be offshore drilling in extreme environments or onshore refining in remote locations.Oil and Gas Pumps owes its success, in large part, to its team of highly skilled professionals. With expertise in mechanical engineering, fluid dynamics, and industrial design, the company's engineers are at the forefront of technological advancements in pumping solutions. Through continuous training and development programs, Oil and Gas Pumps ensures that its workforce remains knowledgeable and equipped to handle even the most complex projects.Moreover, the company's dedication to quality control is unfaltering. Each pump undergoes rigorous testing and inspection to ensure it meets the highest industry standards. This commitment to quality has earned Oil and Gas Pumps a stellar reputation for reliability and durability, resulting in long-lasting relationships with customers worldwide.In addition to its technological prowess and commitment to excellence, Oil and Gas Pumps is also deeply aware of the need to minimize its environmental impact. The company strives to create sustainable solutions and reduce energy consumption in its pumps. By implementing energy-efficient designs and utilizing eco-friendly materials, Oil and Gas Pumps aims to contribute to the global effort of transitioning to a greener and more sustainable future.Through its continued investment in research and development, its customer-centric approach, and its unwavering commitment to innovation and quality, Oil and Gas Pumps has established itself as a trusted leader in the pumping solutions industry. With each new product, the company continues to drive advancements in the oil and gas sector, facilitating greater efficiency, productivity, and sustainability.As the global demand for oil and gas continues to rise, it is companies like Oil and Gas Pumps that will play a vital role in meeting these ever-increasing demands. With their state-of-the-art pumping solutions, the company is helping to shape the future of the energy industry, ensuring a smooth and reliable supply of oil and gas for years to come.

High-Quality Screw Pump Catalogue for Industrial Applications

Screw Pump Catalogue Released by Leading Industrial Company{} is proud to announce the release of their highly anticipated Screw Pump Catalogue, showcasing a wide range of innovative and efficient screw pump solutions for industrial applications. The company, known for its expertise in providing high-quality industrial equipment, continues to set the standard for reliable and cutting-edge solutions in the industry.The newly released Screw Pump Catalogue features a comprehensive lineup of screw pump products designed to meet the diverse needs of various industrial sectors. From oil and gas to chemical processing, marine, and power generation, {} offers a wide range of screw pump options to cater to the specific requirements of different applications.One of the standout features of the screw pumps showcased in the catalogue is their exceptional performance and reliability. With a focus on precision engineering and advanced technology, {} ensures that each screw pump meets the highest standards for efficiency, durability, and long-term performance. This commitment to quality has earned {} a reputation as a trusted partner for industrial businesses seeking top-of-the-line pump solutions.The catalogue also highlights the company's dedication to innovation and customization. Customers can choose from a range of options, including different materials, sizes, flow rates, and pressure capabilities to tailor the screw pumps to their unique operational needs. With {}’s in-depth knowledge and experience in the industry, customers can rely on the company to provide expert guidance in selecting the most suitable screw pump for their specific requirements.In addition to the wide array of standard screw pump offerings, {} also provides custom engineering and design services for specialized applications. This customization capability sets {} apart as a versatile and adaptable partner for businesses with unique pump requirements. The company's team of engineers and technical experts work closely with customers to develop tailored solutions that address specific challenges and deliver optimal performance.Furthermore, {} takes pride in its commitment to customer satisfaction and support. With a global network of service centers and technical professionals, the company offers comprehensive after-sales support, including maintenance, repairs, and spare parts supply. Customers can have peace of mind knowing that {} is dedicated to ensuring the ongoing reliability and longevity of their screw pump investments.The release of the Screw Pump Catalogue solidifies {}’s position as a leading provider of industrial pump solutions. With a strong focus on quality, innovation, and customer-centric approach, {} continues to empower businesses across diverse industries with reliable and high-performing screw pump technologies.About {}:{} is a renowned industrial company specializing in the design, manufacturing, and supply of high-quality pump solutions for a wide range of industrial applications. With a strong commitment to excellence and innovation, the company has established itself as a trusted partner for businesses seeking reliable and efficient pump technologies. Through its comprehensive product offerings, customization capabilities, and dedicated customer support, {} continues to lead the way in delivering cutting-edge pump solutions to meet the evolving needs of industrial sectors worldwide.In conclusion, the release of the Screw Pump Catalogue by {} represents a significant milestone for the company and the industrial sector as a whole. With its extensive range of high-quality screw pump solutions and unwavering commitment to customer satisfaction, {} sets a new standard for excellence and reliability in the industry. Businesses looking for best-in-class pump technologies can rely on {} to deliver top-notch products and support for their operational success.

Discover the Versatility and Benefits of Single Screw Pumps

Title: Leading Pump Manufacturer Introduces New Innovative Single Screw PumpIntroduction (50 words):[Company Name], a global leader in pump manufacturing, is proud to announce the launch of its latest cutting-edge product, the highly efficient Single Screw Pump. This innovative solution promises to revolutionize various industries by delivering unparalleled performance, reliability, and cost-effectiveness.Body:1. Overview of Single Screw Pump (100 words):The Single Screw Pump, developed by [Company Name], is a remarkable advancement in pumping technology. It is designed to handle a wide range of challenging applications across industries, including oil and gas, wastewater treatment, food and beverage, pharmaceuticals, and more. This pump ensures smooth and efficient operations, significantly reducing downtime and maintenance costs. With a compact design and intelligent features, the Single Screw Pump demonstrates the company's commitment to providing high-quality solutions that meet the evolving needs of its global customer base.2. Unmatched Performance and Reliable Operation (150 words):The Single Screw Pump from [Company Name] incorporates an advanced single screw mechanism that enables it to handle highly viscous fluids, abrasive materials, and even delicate substances with exceptional precision and efficiency. The pump's unique design minimizes pulsation and ensures consistent flow, delivering unmatched performance and reliable operation.The combination of optimized tolerance, smooth chamber geometry, and precision-crafted rotors ensures minimal wear and tear on internal components, resulting in extended service life and reduced downtime. This reliability and durability make the pump an ideal choice for critical applications where consistent performance is essential.3. Cost-effective and Energy-efficient Solution (150 words):In addition to its outstanding performance, the Single Screw Pump offers significant cost savings and enhanced energy efficiency. By minimizing internal leakage, the pump reduces power consumption, resulting in lower energy bills and a reduced environmental footprint. Its robust construction and minimal maintenance requirements further contribute to overall cost-effectiveness.Furthermore, the Single Screw Pump's compact design allows for easy installation and maintenance, saving valuable space and resources. The pump's adaptability to a broad range of applications eliminates the need for multiple pumps, reducing capital costs and simplifying inventory management.4. Cutting-edge Technological Features (150 words):[Company Name]'s Single Screw Pump features several state-of-the-art technological advancements. The pump is equipped with an innovative self-compensation system that automatically adjusts the screw position, eliminating the risk of wear and improving overall performance. This self-compensation technology ensures consistent operational efficiency, even in demanding conditions.Additionally, the pump's intelligent control system provides real-time monitoring and feedback, allowing operators to make informed decisions and optimize performance. The integration of smart technology enhances reliability, reduces maintenance costs, and improves overall system efficiency.Conclusion (50 words):With the introduction of their latest Single Screw Pump, [Company Name] reaffirms its commitment to innovation and excellence. The pump's exceptional performance, reliability, and cost-effectiveness make it an invaluable asset across various industries, addressing the evolving needs of businesses worldwide. [Company Name] continues to push boundaries, providing cutting-edge solutions to meet the challenges of the future.

Major Development in Tianjin: Shuangjin Makes Headlines in Latest News

Tianjin Shuangjin, a leading Chinese manufacturing and technology company, recently announced a strategic partnership with a global leader in the consumer electronics industry. This partnership is aimed at leveraging the strengths of both companies to drive innovation and efficiency in the rapidly evolving consumer electronics market.Tianjin Shuangjin, with its state-of-the-art manufacturing facilities and cutting-edge technology, has established itself as a key player in the consumer electronics industry. The company's commitment to quality and innovation has earned it a reputation for excellence and reliability. By partnering with a global leader in consumer electronics, Tianjin Shuangjin aims to further enhance its capabilities and expand its reach in the international market.The partnership will focus on the development and production of a range of consumer electronics products, including smartphones, tablets, and wearable devices. By combining their expertise and resources, the two companies aim to bring to market innovative and high-quality consumer electronics that meet the needs and preferences of consumers worldwide.In addition to product development and manufacturing, the partnership will also explore opportunities for collaboration in areas such as research and development, supply chain management, and marketing. By working together, the companies aim to optimize their operations and deliver greater value to their customers."We are thrilled to announce this strategic partnership with [Global leader in consumer electronics]," said a spokesperson for Tianjin Shuangjin. "This collaboration represents a significant milestone for our company and reflects our commitment to driving innovation and growth in the consumer electronics market. By leveraging our complementary strengths and resources, we are confident that we can deliver truly exceptional products and experiences to consumers around the world."The partnership with Tianjin Shuangjin is also expected to benefit the global leader in consumer electronics. By tapping into Tianjin Shuangjin's manufacturing expertise and technological capabilities, the company aims to strengthen its position in the highly competitive consumer electronics market and meet the growing demand for innovative and high-quality products."We are excited to partner with Tianjin Shuangjin to drive innovation and excellence in the consumer electronics industry," said a spokesperson for the global leader in consumer electronics. "Tianjin Shuangjin's commitment to quality and innovation aligns with our own values, and we believe that together, we can create compelling and differentiated products that resonate with consumers around the world."The strategic partnership between Tianjin Shuangjin and the global leader in consumer electronics comes at a time of significant transformation and opportunity in the consumer electronics market. With the increasing convergence of technology and lifestyle, consumers are demanding products that not only offer cutting-edge features and performance but also reflect their personal style and values.By working together, Tianjin Shuangjin and its partner aim to address these evolving consumer needs and deliver products that exceed expectations. The companies are confident that their collaboration will result in a new generation of consumer electronics products that are designed to inspire and empower people in their daily lives.As the partnership between Tianjin Shuangjin and the global leader in consumer electronics continues to take shape, both companies are optimistic about the opportunities and possibilities that lie ahead. With their shared commitment to innovation, excellence, and customer satisfaction, they are well-positioned to make a meaningful impact in the consumer electronics market and set new standards for quality and performance.The strategic partnership between Tianjin Shuangjin and the global leader in consumer electronics represents a powerful combination of expertise, resources, and vision. As they work together to create and deliver innovative consumer electronics products, they are poised to shape the future of the industry and create value for customers and stakeholders alike.

Highly Efficient Twin Screw Pump for Industrial Applications

Twin Screw Pump Generously Donated to Local Municipality to Support Water Distribution[City, State] - In a generous move to support the local community, a leading industrial equipment manufacturer has donated a state-of-the-art Twin Screw Pump to the [City] municipality. The [Company], known for its innovative and high-quality pumping solutions, has made this donation to aid in the efficient distribution of water to the residents of the city.The Twin Screw Pump, a highly advanced and reliable piece of equipment, is designed to handle a wide variety of fluids with ease. Its unique design allows for gentle pumping action, low pulsation, and a smooth flow, making it an ideal choice for the distribution of water in a municipal setting. With its robust construction and advanced technology, the pump is expected to significantly improve the efficiency and reliability of the city's water distribution system.The donation of the Twin Screw Pump comes as part of [Company]'s ongoing commitment to corporate social responsibility and giving back to the communities in which it operates. The company, which has a long history of supporting various charitable causes and initiatives, saw an opportunity to contribute to the well-being of the residents of [City] by providing them with a cutting-edge piece of equipment that will directly impact their daily lives."We are thrilled to be able to donate this Twin Screw Pump to the [City] municipality," said [Company spokesperson]. "Water distribution is a crucial aspect of urban life, and we are confident that our pump will help the city to improve the efficiency of its water infrastructure. It is our hope that this donation will not only benefit the city and its residents but also serve as a symbol of our commitment to being a responsible corporate citizen."The [City] municipality, which has been facing challenges with its aging water distribution system, has expressed its gratitude for the generous donation. The Twin Screw Pump will be installed at a key location within the city's water infrastructure, where it will be used to ensure the smooth and reliable distribution of water to homes and businesses."We are incredibly thankful to [Company] for their generous donation of the Twin Screw Pump," said [City official]. "This state-of-the-art equipment will undoubtedly make a positive impact on our water distribution system, allowing us to provide better service to our residents. We are truly grateful for [Company]'s support and commitment to our community."The installation of the Twin Screw Pump is expected to take place in the coming weeks, and the city's water department is already making preparations to integrate the new equipment into its existing infrastructure. Once operational, the pump is expected to deliver immediate improvements in the efficiency and reliability of the water distribution system, ultimately benefiting thousands of residents and businesses in the city.In addition to the donation of the pump, [Company] has also committed to providing training and technical support to the city's water department to ensure the proper operation and maintenance of the equipment. This ongoing support is expected to further enhance the long-term impact of the donation and help to maximize the benefits of the Twin Screw Pump for the city and its residents.The donation of the Twin Screw Pump by [Company] serves as a shining example of the positive impact that corporate generosity can have on local communities. By providing the city of [City] with a cutting-edge piece of equipment to improve its water distribution system, [Company] has demonstrated its dedication to being a responsible corporate citizen and making a meaningful difference in the lives of those it serves.