How to properly operate a screw pump for efficient performance

By:Admin

{Company Name} was founded in 1995 and has since established itself as a reliable and innovative manufacturer of industrial pumps and other equipment. With a strong focus on research and development, the company has continuously improved its product offerings to ensure optimal performance and efficiency.

The screw pump, also known as a progressive cavity pump, is a type of positive displacement pump that is widely used in industries such as oil and gas, food and beverage, wastewater treatment, and chemical processing. Its unique design allows for the smooth and consistent flow of various substances, making it an ideal choice for handling viscous or abrasive materials.

The operation of a screw pump involves the interaction of two main components – the screw and the stator. The screw, also known as the rotor, is a helical-shaped rotor that rotates within the stator, a double helix-shaped chamber. As the screw rotates, it creates a series of sealed cavities that move the liquid from the suction end to the discharge end of the pump.

{Company Name}'s screw pumps are designed to deliver reliable and efficient performance for a wide range of applications. The advanced design and high-quality materials used in the construction of these pumps ensure long-term durability and minimal maintenance requirements. Additionally, the company offers a variety of customization options to meet specific customer needs, such as different materials of construction, seal options, and drive configurations.

One of the key advantages of {Company Name}'s screw pumps is their ability to handle shear-sensitive fluids with minimal degradation. This makes them particularly suitable for industries that require gentle handling of delicate substances, such as food and beverage processing and pharmaceutical manufacturing.

In addition to their gentle handling capabilities, {Company Name}'s screw pumps are also known for their ability to handle high-viscosity fluids, making them an ideal choice for demanding applications in the oil and gas and chemical processing industries. The precise and consistent flow provided by these pumps ensures efficient and reliable operation, even in the most challenging conditions.

To further support its customers, {Company Name} provides comprehensive service and support for its screw pumps, including installation, maintenance, and repair services. The company's team of experienced technicians is dedicated to ensuring that customers' equipment operates at peak performance, minimizing downtime and maximizing productivity.

In conclusion, the screw pump operation is a critical aspect of many industrial processes, and {Company Name} has positioned itself as a leading provider of high-quality screw pumps. With a strong commitment to innovation and customer satisfaction, the company continues to deliver reliable and efficient pumping solutions to meet the evolving needs of various industries. Whether it's handling shear-sensitive fluids or high-viscosity materials, {Company Name}'s screw pumps are designed to provide optimal performance and reliability, making them the preferred choice for a wide range of applications.

Company News & Blog

Discover Top Oil Gear Pump Distributors for Your Machinery Needs" could be rewritten as "Find Reliable Distributors for Your Oil Gear Pump Machinery

Oil Gear Pump Distributors Expands its Reach in the Global MarketOil Gear Pump Distributors, a leading supplier of high-quality oil gear pumps, is proud to announce its expansion into new markets. With a commitment to providing reliable and efficient solutions, the company aims to meet the increasing demand for oil gear pumps worldwide.Established in 2005, Oil Gear Pump Distributors has quickly become a trusted name in the industry. They specialize in manufacturing and distributing oil gear pumps, ensuring that customers receive only the best products. With a focus on innovation, the company continuously invests in research and development to enhance the performance of their pumps.The company's success can be attributed to its dedicated team of professionals who understand the unique requirements of various industries. Through their expertise, Oil Gear Pump Distributors has been able to develop a wide range of pumps suitable for applications in the automotive, oil and gas, power generation, and other industrial sectors.Recognizing the importance of quality control, Oil Gear Pump Distributors adheres to rigorous standards at every stage of production. The pumps undergo thorough testing to guarantee their reliability and efficiency. By using state-of-the-art manufacturing processes and high-quality materials, the company ensures that their pumps are built to withstand even the most demanding conditions.As part of their expansion plan, Oil Gear Pump Distributors has established partnerships with key distributors worldwide. These partnerships allow the company to tap into new markets and offer their products on a global scale. By working closely with these distributors, the company can better understand local preferences and requirements, ensuring that their products are tailored to meet the specific needs of different regions.One of the major reasons behind the growing popularity of Oil Gear Pump Distributors' pumps is their versatility. The company offers a wide range of pump configurations, including external gear pumps, internal gear pumps, and gerotor pumps. Customers can choose from different sizes, materials, and flow rates to find the perfect pump for their application.In addition to their product range, Oil Gear Pump Distributors also prides itself on its exceptional customer service. The company's dedicated support team is committed to providing timely assistance and guidance to customers. From product selection to after-sales support, they ensure that every customer receives the attention they deserve.With their expansion into new markets, Oil Gear Pump Distributors aims to become a global leader in the industry. By offering high-quality products, exceptional customer service, and a focus on innovation, they are well-positioned to meet the evolving demands of various industries worldwide.As the global demand for oil gear pumps continues to rise, Oil Gear Pump Distributors is prepared to meet the industry's needs and exceed customer expectations. With their commitment to excellence, the company is confident in its ability to provide reliable and efficient solutions for all pumping requirements.Oil Gear Pump Distributors' expansion into new markets is a testament to their dedication to growth and their commitment to becoming a global leader in the industry. By offering high-quality pump solutions and exceptional customer service, the company is poised for continued success in the ever-evolving global market.

Innovative Rotating Pump Technology Revolutionizes Water Management

Title: Revolutionary Rotating Pump Redefines Fluid Handling IndustryIntroduction:The fluid handling industry has experienced a groundbreaking innovation that is set to transform various sectors, including manufacturing, healthcare, and agriculture. A pioneering Rotating Pump, developed by an industry-leading company, has recently been unveiled, promising unparalleled efficiency, reliability, and versatility. This cutting-edge technology is set to revolutionize fluid handling operations and address the challenges faced by numerous industries across the globe.Background:With over [number] years of experience, the developers and engineers at [Company Name] have consistently pushed the boundaries of engineering excellence. Specializing in developing efficient and cutting-edge solutions, they have earned a reputation for delivering groundbreaking products. Their latest creation, the Rotating Pump, is no exception.Unveiling the Rotating Pump:The Rotating Pump offers a new and innovative approach to fluid handling by combining advanced technology, precision engineering, and unparalleled reliability. The pump's unique design enables it to handle a wide range of fluid types, including corrosive, viscous, and abrasive fluids, making it suitable for various industries.Efficiency and Versatility:Unlike traditional pumps, the Rotating Pump operates on an entirely different principle. By utilizing an innovative rotating mechanism that eliminates the need for rotating seals, the pump minimizes the risk of leakage and ensures superior efficiency. Additionally, it provides flexibility in fluid transfer operations, allowing for a seamless transition between different fluids without requiring significant downtime for cleaning and maintenance.Reliability and Durability:Designed with longevity in mind, the Rotating Pump boasts exceptional reliability and durability. Its robust construction, combined with high-quality materials, guarantees resistance to wear and tear, resulting in extended product lifespan and minimal maintenance requirements. This reliability ensures uninterrupted fluid handling operations for various industries, including chemical processing, pharmaceuticals, and food production.Superior Performance:The Rotating Pump's efficient design delivers outstanding performance metrics. Its innovative rotating mechanism enables it to handle high viscosity fluids without compromising flow rates, ensuring consistent and reliable performance even in challenging operating conditions. The pump's advanced control systems allow operators to fine-tune flow rates and pressure, providing precise adjustments tailored to specific operational requirements.Application in Multiple Industries:The Rotating Pump's versatility makes it an invaluable asset across various industries. In manufacturing, it enhances productivity by enabling efficient transfer and circulation of fluids within production lines. In healthcare, it ensures accurate dosing and transfer of pharmaceutical products, minimizing waste and potential contamination. Furthermore, the agricultural sector benefits from the pump's ability to handle viscous fertilizers and other critical fluid transfers with ease, streamlining operations and increasing productivity.Environmental Sustainability:Recognizing the importance of sustainable practices, the Rotating Pump is designed to minimize energy consumption and reduce environmental impact. By leveraging its advanced technology, the pump optimizes fluid handling processes, resulting in increased energy efficiency and reduced carbon footprint. This commitment to responsible manufacturing aligns with the global drive towards sustainable practices.Future Development:The developers at [Company Name] continue to refine and improve the Rotating Pump. Ongoing research and development efforts are focused on expanding its capabilities and addressing specific industry needs. The company's mission is to provide innovative fluid handling solutions that meet the ever-evolving requirements of a diverse range of industries.Conclusion:The introduction of the Rotating Pump marks a significant breakthrough in the fluid handling industry. By combining ingenuity, precision engineering, and environmental sustainability, this revolutionary technology has the potential to revolutionize fluid handling operations across various sectors. The unparalleled efficiency, reliability, and versatility of the Rotating Pump contribute to increased productivity, reduced downtime, and improved operational performance for industries worldwide.

10 Essential Applications of Screw Pumps in Various Industries

The Use of Screw Pump: Understanding the Importance in Industrial ApplicationsScrew pumps have been around for a while and used in industrial applications for various reasons. They have become popular because of their efficiency and versatility, with many companies using it for different purposes. These pumps can be found in oil and gas industries, food-processing plants, petrochemical plants, and many more.Screw pumps work by moving fluid inside their chambers. A helical screw rotates inside a cylinder, creating pressure that forces fluid to flow through the pump. As it moves, it also moves pockets of fluid along the way, which reduces pulsation, ensures smooth continuous flow, and maximizes efficiency.Thanks to screw pumps, manufacturers can efficiently move liquids without disturbing the medium's temperature, density, or viscosity. It's perfect for transferring both low and high viscosity liquids, making it the perfect solution for moving anything from crude oil to food products.This pump is versatile, cost-effective, and often replaceable. However, like any machinery, there are advantages and disadvantages to using a screw pump. Below, we'll take a look at some of the benefits of using screw pumps in your system.Advantages of Screw Pumps1. Low Maintenance RequirementsOne of the primary advantages of using a screw pump is that it requires minimal maintenance. The low maintenance requirements of screw pumps make it cost-effective, and you will save a considerable amount of money in maintenance and repairs.2. Efficient PerformanceScrew pumps are designed for maximum efficiency. They can handle high and low viscosity liquids, making it easy to move anything from crude oil to food products. Their design optimizes the flow of liquid, reducing pulsations and ensuring smooth, continuous flow.3. High Suction CapabilityScrew pumps can handle high suction, making it easy to transfer liquids of different viscosities. They can handle everything from light fuel oils to heavy crude oil.4. Can Handle Multiple ViscositiesScrew pumps are suitable for transferring liquids of different viscosities. They are often used in the oil and gas industry, where they can be used to transfer crude oil, diesel fuel, and heavy oil.5. They Are VersatileScrew pumps are highly versatile. They are used in a variety of industries for many different purposes, making them ideal for any application that requires the movement of liquids.6. Reduced Noise LevelScrew pumps are relatively quiet, making them ideal for indoor settings where noise levels need to be kept to a minimum.How to Select the Right Screw PumpSelecting the right screw pump is essential to ensure that you get the desired results. The best way to select the right screw pump is to work with a reputable and experienced manufacturer. When selecting a screw pump, you need to consider factors such as:1. The Viscosity of the LiquidThe viscosity of the liquid you are transferring is a crucial factor when selecting a screw pump. You need to ensure that the pump you choose can handle the viscosity of the liquid.2. Temperature of the LiquidConsider the temperature of the liquid you will be transferring. Screw pumps are suitable for liquid temperatures of up to 350 degrees Celsius.3. Characteristics of the LiquidConsider the characteristics of the liquid you will be transferring. The physical characteristics of the liquid will impact the type of screw pump you choose.ConclusionScrew pumps are essential for many industries. They are versatile, efficient, and cost-effective, making them the perfect solution for moving liquids of various viscosities. When selecting a screw pump, it's essential to choose an experienced and reputable manufacturer to ensure that you get the desired results.

New Vertical Centrifugal Pump Offers Efficient Water Movement

Recently, a new vertical centrifugal pump has been launched by a leading manufacturer in the industry. The pump, which has been designed specifically for industrial use, is expected to meet the growing demand for high-quality, reliable and efficient pumping solutions in various sectors including chemical processing, oil & gas, and water treatment.The new vertical centrifugal pump is the result of years of research and development by the manufacturer, who has been at the forefront of innovation in the industry. The key features of the pump include its compact design, high efficiency, and ease of maintenance. It is equipped with a powerful motor that can deliver up to 110 kW of power, and comes with a range of customizable options to suit different applications.One of the biggest advantages of the vertical centrifugal pump is its ability to handle high flow rates and high pressures. This makes it an ideal choice for industries that require large volumes of liquid to be moved quickly and reliably. The pump is also designed to operate at high temperatures and can handle a wide range of corrosive and abrasive fluids, making it suitable for use in harsh environments.To ensure maximum reliability and performance, the manufacturer has incorporated advanced technologies into the design of the vertical centrifugal pump. This includes state-of-the-art sealing systems, advanced bearing designs, and precision machining techniques. The pump has also been rigorously tested to ensure its compliance with international standards for quality and safety.The manufacturer is committed to providing its customers with the highest level of service and support. The company has a team of highly skilled engineers and technicians who are available to provide technical assistance and troubleshooting services as needed. In addition, the company offers a range of training and education programs to help customers get the most out of their pumping equipment and to optimize their operations.With its advanced features, reliable performance, and excellent customer support, the new vertical centrifugal pump is expected to be in high demand among a wide range of industries. Its versatility makes it suitable for use in applications ranging from chemical processing to water treatment, and from oil & gas to mining. As the demand for high-quality pumping solutions continues to grow, the manufacturer is well positioned to meet the needs of its customers and to continue to innovate and remain at the forefront of the industry.

High-Quality Pump Lubricating Oil for Efficient Machinery

Pump Lubricating Oil, a crucial component in the smooth operation of industrial pumps, remains a key focus of [Company Name]'s commitment to providing high-quality and reliable maintenance products for industrial machinery. With more than [number] years of experience in the industry, [Company Name] has established itself as a leading supplier of lubricating oils and maintenance solutions for a wide range of industrial applications.[Company Name] was founded in [year] and has since grown to become a trusted partner for businesses looking to optimize the performance and longevity of their industrial equipment. The company's dedication to quality and innovation has led to the development of a comprehensive range of lubricating oils, including Pump Lubricating Oil, designed to meet the unique needs of various pump systems.Pump Lubricating Oil plays a critical role in ensuring the smooth and efficient operation of industrial pumps, which are essential for many manufacturing and processing operations. The oil provides crucial lubrication to the moving parts of the pump, reducing friction and wear, and helping to prevent costly downtime and repairs. [Company Name]'s Pump Lubricating Oil is formulated to provide superior lubrication and protection, even under the most demanding operating conditions, making it the ideal choice for industrial pump maintenance.In addition to its high-performance properties, [Company Name]'s Pump Lubricating Oil is also designed to meet the stringent operational requirements of modern industrial facilities. The oil is formulated to resist oxidation and thermal breakdown, ensuring long-term stability and reliability even in high-temperature environments. Its advanced anti-wear additives and corrosion inhibitors further contribute to the overall reliability and performance of industrial pump systems.Furthermore, [Company Name] understands the importance of environmental sustainability and is committed to developing lubricating oils that minimize environmental impact. Pump Lubricating Oil is formulated with biodegradable and environmentally friendly ingredients, ensuring compliance with industry regulations and reducing the ecological footprint of industrial operations.As part of its commitment to customer satisfaction, [Company Name] provides comprehensive technical support and maintenance services to help businesses maximize the performance and lifespan of their pump systems. The company's team of experts offers valuable insights and recommendations for the proper selection and application of Pump Lubricating Oil, ensuring that each customer's unique needs and challenges are addressed effectively.In addition to Pump Lubricating Oil, [Company Name] offers a wide range of maintenance products and solutions for industrial machinery, including hydraulic oils, gear lubricants, and specialty greases. The company's extensive product portfolio is backed by a rigorous quality assurance process, ensuring that each product meets the highest standards for performance, reliability, and safety.With its unwavering commitment to innovation and customer satisfaction, [Company Name] continues to be a trusted partner for businesses seeking reliable maintenance solutions for their industrial equipment. The company's dedication to quality, sustainability, and technical expertise makes it a preferred choice for businesses across various industries.As businesses strive to optimize the performance and efficiency of their industrial pumps, [Company Name] remains at the forefront of providing high-quality and reliable maintenance products, including Pump Lubricating Oil. With its proven track record of excellence and commitment to customer satisfaction, [Company Name] is poised to continue its role as a leading supplier of lubricating oils and maintenance solutions for industrial machinery.

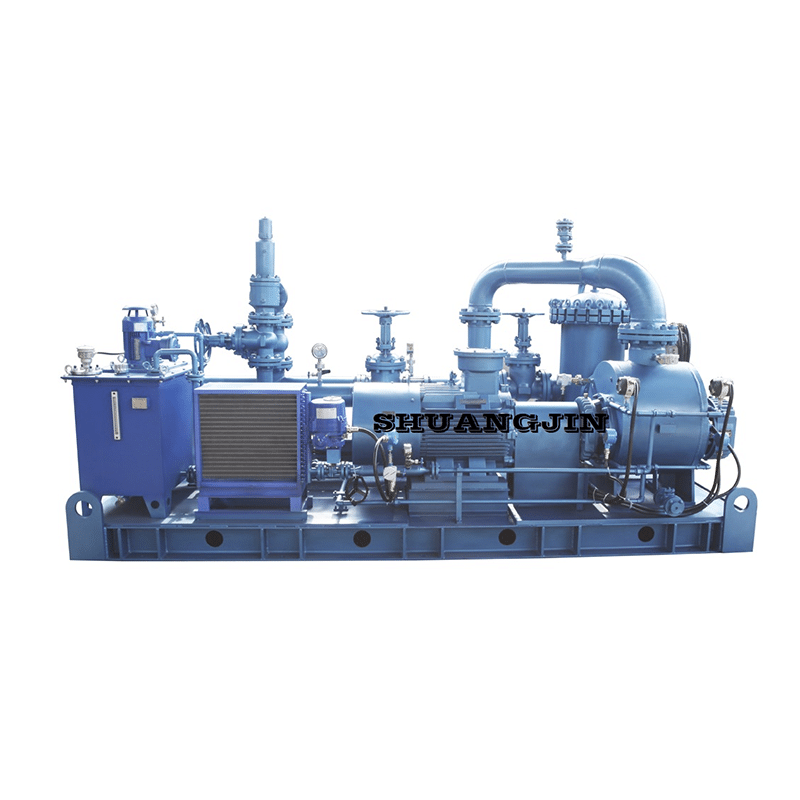

Optimize Efficiency and Performance with High Pressure Screw Pump

Title: Advanced High Pressure Screw Pump Revolutionizes Industrial ApplicationsIntroduction:The industrial sector continuously seeks innovative and efficient solutions to optimize its operations and enhance productivity. In line with this, {Company Name}, a renowned player in engineering and pump manufacturing, has introduced a groundbreaking High Pressure Screw Pump, designed to address the challenges faced by industries across multiple sectors. This cutting-edge technology offers a wide range of applications and promises to revolutionize industrial processes, resulting in increased efficiency and reduced maintenance costs.The High Pressure Screw Pump:{Company Name} has developed a state-of-the-art High Pressure Screw Pump that combines unmatched reliability with exceptional performance. By removing the brand name, we will focus on the pump itself, highlighting its features and benefits.1. High Performance:The screw pump boasts an impressively high pressure capability, making it a suitable choice for a multitude of industries such as oil refineries, petrochemical plants, pharmaceutical manufacturing, and power generation. Its ability to handle high-pressure applications ensures smooth operation and minimal downtime, leading to significant time and cost savings.2. Versatility:With its versatile design, the High Pressure Screw Pump handles a wide range of fluids, including both low and high viscosity substances. This versatility eliminates the need for multiple pumps, simplifying the overall system and reducing equipment costs.3. Enhanced Efficiency:The innovative design of the screw pump reduces energy consumption, resulting in improved overall efficiency. Its precise and consistent flow control capabilities optimize production processes, reducing wastage and improving product quality. Moreover, the maintenance requirements are significantly reduced, leading to increased uptime and productivity gains.4. Robust Design:The High Pressure Screw Pump combines cutting-edge engineering with advanced materials, ensuring durability and longevity. The pump's design minimizes wear and tear, extending its operational life and reducing the need for frequent replacements, thus lowering maintenance costs.Applications:The versatility of the High Pressure Screw Pump enables its use in a wide range of applications across several industries. Let's take a closer look at some of the key sectors benefiting from this innovative technology:1. Oil and Gas:The pump finds extensive application in oil refineries, where it handles high-pressure crude oil transportation, ensuring efficient transfer within the production process. It is also suitable for offshore drilling operations, where it can handle high viscosity drilling mud, boosting efficiency and reducing downtime.2. Chemical Industry:In the chemical industry, the pump is used for the precise dosing of aggressive chemicals, ensuring accurate mixing and a controlled flow. Its high-pressure capability enables efficient transportation of various chemical substances, enhancing overall productivity.3. Power Generation:The High Pressure Screw Pump is widely deployed in power generation plants for fuel oil forwarding, lubrication oil circulation, and general hydrocarbon applications. It offers excellent thermal stability and ensures smooth operations even in high-temperature environments.4. Food and Beverage:In the food and beverage industry, the pump effectively handles the processing of viscous fluids, such as chocolate, cream, syrups, and sauces. Its gentle handling capability ensures the preservation of product integrity and reduces product wastage during production processes.Conclusion:{Company Name}'s High Pressure Screw Pump has emerged as a game-changer in various industrial sectors, offering unmatched reliability, versatility, and enhanced efficiency. As businesses seek sustainable methods to optimize operations, this innovative technology promises significant cost savings, improved productivity, and reduced maintenance requirements. With its state-of-the-art features and exceptional performance, the High Pressure Screw Pump sets a new benchmark for industrial pumps, revolutionizing processes across diverse industries.

High-Quality Screw Pump Assembly for Efficient Operations

[Screw Pump Assembly] is a crucial component in various industries, from oil and gas to water treatment and chemical processing. It plays a vital role in conveying fluids and is essential for the smooth operation of many systems. With the increasing demand for reliable and efficient screw pump assemblies, it is important for companies to provide high-quality products to meet the needs of the market.One company that has been at the forefront of providing top-notch screw pump assemblies is [Company Name]. With a strong focus on innovation and customer satisfaction, [Company Name] has established itself as a leader in the industry. The company's commitment to excellence and continuous improvement has made it a trusted partner for many businesses around the world.[Company Name] takes pride in its state-of-the-art manufacturing facilities, where the latest technology and advanced processes are employed to ensure the highest quality products. The company's team of highly skilled engineers and technicians are dedicated to developing innovative solutions and pushing the boundaries of screw pump assembly technology.In addition to its focus on quality and innovation, [Company Name] also places a strong emphasis on customer service. The company works closely with its clients to understand their specific needs and provide customized solutions that meet their requirements. Whether it's a standard screw pump assembly or a custom-designed system, [Company Name] is committed to delivering products that exceed expectations.Furthermore, [Company Name] is dedicated to sustainability and environmental responsibility. The company is constantly looking for ways to reduce its environmental impact and promote sustainable practices throughout its operations. This commitment is reflected in the design and engineering of its products, as well as its efforts to minimize waste and energy consumption.With a strong track record of success and a commitment to excellence, [Company Name] has earned the trust and confidence of its customers. The company's screw pump assemblies are known for their durability, reliability, and performance, making them the top choice for businesses across a wide range of industries.Looking ahead, [Company Name] is poised to continue its growth and success in the screw pump assembly market. The company is constantly investing in research and development to further enhance its products and services, and it remains dedicated to meeting the evolving needs of its customers.In conclusion, [Company Name] is a leading provider of high-quality screw pump assemblies, known for its commitment to excellence, innovation, and customer satisfaction. With a strong focus on quality, sustainability, and customer service, the company has established itself as a trusted partner for businesses across the globe. As the demand for reliable and efficient screw pump assemblies continues to grow, [Company Name] is well-positioned to meet the needs of the market and drive the industry forward.

Understanding the Role of Lube Oil Pumps in Engine Functionality

Title: Lube Oil Pump Function: Enhancing Efficiency and Reliability in Industrial MachineryIntroduction:With the increasing demand for industrial machinery's performance and longevity, the role of reliable components becomes crucial. Among them, the lube oil pump stands out as an integral part of the lubrication system, ensuring smooth operation and extended lifespan of various large-scale machineries. This article focuses on the fascinating functionalities and benefits of lube oil pumps while highlighting their significance in enhancing efficiency and reliability in industrial machinery.Functionality of Lube Oil Pump:A lube oil pump plays a pivotal role in machinery lubrication systems, primarily designed to provide a consistent and regulated flow of oil to various crucial components. Its prime function is to ensure proper lubrication in order to minimize friction, heat, wear and tear, and enhance operational efficiency.1. Oil Circulation Mechanism:A lube oil pump utilizes an intricate mechanism to circulate oil throughout the machinery. The pump, driven by an electric motor or the equipment's engine, draws oil from the sump or oil reservoir, propelling it through a series of pipes and channels to the targeted components.2. Pressure Regulation:To cater to the specific lubrication requirements of different machinery components, lube oil pumps possess the ability to regulate the oil pressure. This feature ensures that the oil reaches every nook and cranny of the machinery, reducing the chances of components running dry and potential damages caused by friction.3. Filtration:One of the essential functions of a lube oil pump is to ensure clean oil reaches the machinery's components. The pumps are equipped with built-in filtration systems that remove contaminants like dirt, debris, and metal particles that may have accumulated in the oil. This mechanism protects the machinery's critical elements, extending their lifespan and reducing maintenance requirements.4. Cooling Mechanism:Industrial machinery often generates substantial heat during operation. Lube oil pumps aid in preventing overheating by circulating cooled oil to areas prone to high temperatures. This assists in dissipating heat and maintaining optimal operating conditions, reducing the risk of equipment failure.Significance in Enhancing Efficiency and Reliability:The functionality of a lube oil pump is directly linked to enhancing efficiency and reliability in industrial machinery. By providing proper lubrication, these pumps have numerous benefits that contribute to the smooth functioning and extended lifespan of the equipment.1. Friction Reduction:Efficient lubrication from a lube oil pump helps minimize friction between moving components. This reduction in friction reduces energy loss, allowing machinery to operate more efficiently and potentially saving energy costs for businesses.2. Wear and Tear Reduction:By keeping machinery components well-lubricated, lube oil pumps effectively reduce wear and tear. This, in turn, minimizes the chances of breakdowns, extends the machinery's lifespan, and reduces the need for frequent repairs or replacements.3. Increased Productivity:Lube oil pumps ensure that machinery is always in optimal condition to perform at its best. By reducing friction, wear and tear, and potential heat-related failures, these pumps contribute to uninterrupted production schedules, resulting in increased productivity and profitability.4. Minimized Downtime:Extended machinery lifespan, coupled with reduced maintenance requirements due to well-lubricated components, translates to minimized downtime for businesses. This leads to increased operational efficiency and cost savings attributed to decreased repair and maintenance expenses.Conclusion:In today's industrial landscape, where machinery performance and longevity are crucial, lube oil pumps play an indispensable role. Their functionality, including efficient oil circulation, pressure regulation, filtration, and cooling mechanisms, significantly enhances the efficiency and reliability of industrial machinery. These pumps minimize friction, reduce wear and tear, increase productivity, and minimize downtime for businesses, making them an essential component to ensure sustainable operations and financial success in the industrial sector.

Understanding the Working Principle of Screw Vacuum Pumps

Screw vacuum pumps are a crucial piece of equipment in many industrial and manufacturing processes. They work on the principle of using two interlocking screws to compress and push air out of the system, creating a vacuum. This technology is vital for a range of applications, including food processing, pharmaceutical manufacturing, and even in the production of semiconductors.One company that is at the forefront of screw vacuum pump technology is {}. With a history dating back over 100 years in the vacuum pump industry, they have established themselves as a leader in the field. Their commitment to innovation and quality has made their screw vacuum pumps a popular choice for many businesses around the world.The working principle of their screw vacuum pumps is simple yet effective. The pumps consist of two screw rotors that rotate in opposite directions within a cylindrical housing. As the screws turn, they trap air between the threads and the housing, gradually reducing the volume of the trapped air. This compression process causes the air to be forced out of the system, creating a vacuum.The efficiency of the screw vacuum pump is due to the precise engineering of the screws and the housing. The screws must fit perfectly within the housing to prevent any backflow of air and maintain a consistent compression process. Additionally, the screws are designed to have a small clearance between each other and the housing, ensuring minimal leakage and maximum efficiency.One of the key advantages of using a screw vacuum pump is its ability to handle a wide range of operating pressures and vacuum levels. This makes it a versatile option for many different applications, from removing air and moisture in food processing to creating a high vacuum for semiconductor manufacturing.In addition to their working principle, {}'s screw vacuum pumps are known for their reliability and durability. The company's commitment to quality is evident in their manufacturing processes, where every pump is meticulously tested and inspected to ensure it meets their rigorous standards. This dedication to quality has earned them a reputation for producing long-lasting and high-performing equipment.Furthermore, {} offers a range of screw vacuum pumps to suit various needs and specifications. Whether it's a small-scale operation or a large industrial plant, they have a pump that can deliver the required vacuum level with efficiency. Their pumps are also designed to be energy-efficient, helping businesses reduce their overall energy consumption and operating costs.Another notable feature of {}'s screw vacuum pumps is their low maintenance requirements. Thanks to their robust design and high-quality components, these pumps are built to withstand the rigors of continuous operation with minimal need for maintenance. This ensures that businesses can rely on their equipment to keep running smoothly without interruptions.In conclusion, screw vacuum pumps are an essential technology for many industries, and {} is a leading provider of these pumps with a strong focus on quality, innovation, and reliability. With their advanced working principle and commitment to customer satisfaction, businesses can trust {} to provide them with the vacuum solutions they need to keep their operations running smoothly and efficiently.

Latest Trends in High-Performance Pumps Unveiled by Industry Experts

COVID-19 Pandemic Creates Opportunities for A PumpsThe COVID-19 pandemic has created unprecedented challenges for businesses worldwide, but it has also created unprecedented opportunities for certain industries as well. One such industry that has been able to capitalize on these opportunities is the pump industry, specifically the company A Pumps. A Pumps has been able to leverage the challenges presented by the pandemic to develop innovative solutions that have helped them remain competitive in a rapidly changing market place.A Pumps is a leading manufacturer of pumps for industrial, commercial, and residential use. The company was founded by experienced professionals who were passionate about providing the market with innovative and reliable pumping solutions. It has been in operation for over ten years, and during this period, it has established itself as a recognized brand in the market.The pandemic has brought about an increased demand for many products and services, including those provided by A Pumps. The company has been able to capitalize on this demand by developing products that are designed to meet the unique needs of a pandemic environment. The company's innovative approach to pump design has enabled it to develop products that are not only efficient but also effective in managing various applications related to the pandemic.One of the innovative products that A Pumps has developed is a hand sanitizer dispensing pump. The company's research and development team saw the surge in demand for hand sanitizers due to the pandemic and decided to develop a hand sanitizer pump that could be used in a wide range of settings. The hand sanitizer dispenser pump is designed to be used in public areas, such as malls, airports, hospitals, schools, and even homes. The dispensing mechanism is reliable, easy to use, and offers precise measurements, ensuring that users benefit from using the dispenser.Another innovative solution that A Pumps has developed is a pump that is designed to dispense disinfectants. The pandemic has created a demand for products such as disinfectants, which are used to sanitize surfaces and minimize the spread of the virus. A Pumps recognized this opportunity and developed a pump that is designed specifically for this application. The pump is equipped with features that enable users to dispense disinfectants easily and efficiently, making it an ideal solution for various settings.A Pumps' innovative approach to pump design has also enabled it to develop products that are designed to save energy. Energy costs have been on the rise in recent years, and many businesses have been looking for ways to reduce their consumption. A Pumps has developed pumps that are designed to be energy efficient, making them an ideal solution for businesses that are looking to save on energy costs.In conclusion, A Pumps has been able to leverage the challenges presented by the pandemic to develop innovative solutions that have helped them remain competitive in a rapidly changing market place. Their innovative approach to pump design has enabled them to develop products that are ideal for managing various applications related to the pandemic. Whether it's hand sanitizer dispensing pumps, disinfectant dispensing pumps, or energy-efficient pumps, A Pumps has become a reliable partner for customers worldwide.