Industrial Pump Company Announces New Product Launch

By:Admin

With a rich history dating back to 1905, Leistritz Pump has grown to become a trusted name in the world of pumping technology. The company's commitment to excellence and customer satisfaction has enabled them to continuously push the boundaries of what is possible in the field of pump design and functionality.

The company's comprehensive product line includes a wide range of industrial pumps, compressors, and extruders that are designed to meet the specific needs and requirements of various industries and applications. From chemical and petrochemical to food and pharmaceutical, Leistritz Pump has the expertise and experience to deliver reliable, high-performance solutions for even the most demanding environments.

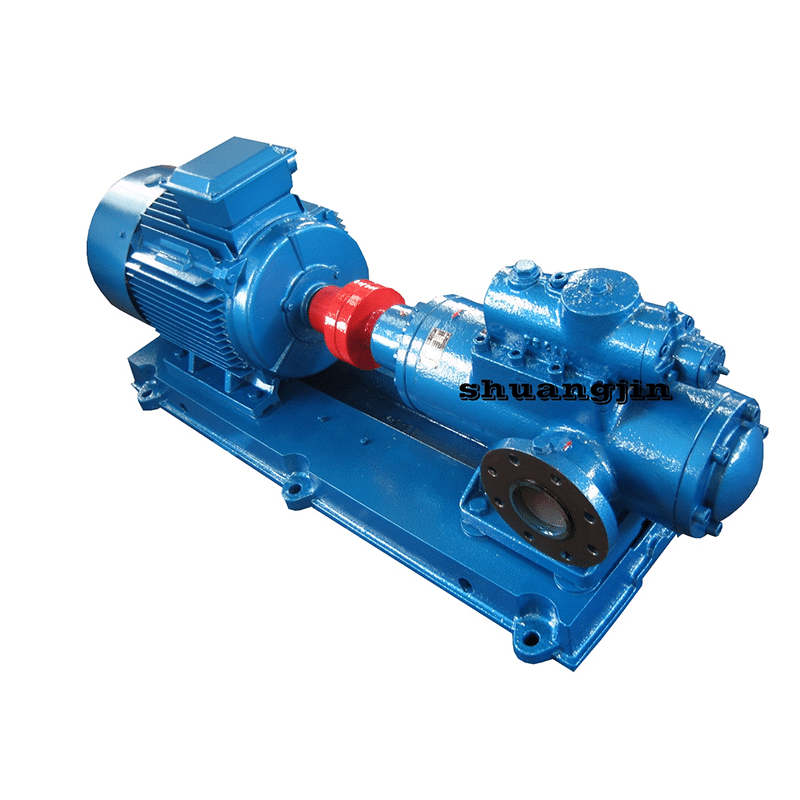

One of the company's most notable achievements is its development of the patented "multi-screw" pump technology, which has set a new standard for efficiency and reliability in the industry. This innovative design features multiple screws that work in harmony to create a smooth and consistent flow, resulting in higher throughput and lower energy consumption. The multi-screw pump has been widely adopted in a variety of applications, from oil and gas processing to wastewater treatment, and has earned a reputation for its exceptional performance and durability.

In addition to its focus on product innovation, Leistritz Pump is also committed to sustainability and environmental responsibility. The company's products are designed to minimize their impact on the environment, with features such as advanced energy-saving technology and low emissions. Moreover, Leistritz Pump actively seeks out ways to reduce its own carbon footprint and promote sustainable practices throughout its operations.

As a global company, Leistritz Pump has a strong presence in key markets around the world, with a network of sales, service, and distribution partners that ensure timely and reliable support for customers. The company's dedication to customer service is unmatched, with a team of experts who are always ready to provide technical support, maintenance, and aftermarket services to ensure the long-term performance and reliability of their products.

Looking ahead, Leistritz Pump continues to invest in research and development to stay at the forefront of pump technology. The company's commitment to innovation and excellence makes it a formidable force in the industry, and customers can expect to see even more groundbreaking solutions from Leistritz Pump in the years to come.

In conclusion, Leistritz Pump is an industry-leading manufacturer of high-quality industrial pumps and equipment, with a strong track record of innovation, reliability, and customer satisfaction. With its advanced technology, commitment to sustainability, and global reach, Leistritz Pump is well-positioned to meet the evolving needs of industries around the world.

Company News & Blog

Innovative Centrifugal Screw Pump Technology Revolutionizing Industrial Pumping Applications

Centrifugal Screw Pump Proves to be a Game-Changer in Industrial ApplicationsIn the world of industrial applications, finding the right kind of machinery that suits the needs of the business is essential. Centrifugal Screw Pumps, also known as twin-screw pumps, have been creating waves in various industries lately. They have gained immense popularity due to their unmatched efficiency, versatility, and durability.A centrifugal screw pump is a positive displacement pump that transfers fluid by moving it through closely-spaced screws, generating pressure and flow. This particular pump's design enables it to handle tough-to-pump fluids with high viscosity and solids content. Consequently, the centrifugal screw pump is known to reduce maintenance costs, increase the lifecycle of machines, and enhance overall operational efficiency.However, the centrifugal screw pump by a prominent brand has gained significant attention for its cutting-edge technology, exceptional performance, and outstanding customer service. This high-quality pump has been used in several industries and applications such as marine, food processing, wastewater treatment, biodiesel production, and more.One of the many advantages of the centrifugal screw pump is the considerable reduction in cavitation. When a pump experiences high-pressure changes, there could be areas of low pressure that lead to the formation of cavities or bubbles. With traditional pumps, cavitation would cause significant damage, resulting in increased maintenance costs. Installing a centrifugal screw pump substantially reduces this problem since the pump can handle a higher level of turbulence without the creation of cavities.Another crucial advantage of centrifugal screw pumps is their ability to handle fluids of varying viscosity. They operate with a wide range of viscosities, even as high as 200,000 centipoises, without the need for external pumps. This feature allows it to handle more challenging fluids such as crude oil, molasses, and syrup.This pump design also facilitates the transfer of fluids with high solid content. It is capable of transferring up to 40% blockage in its internal flow chambers without damaging the rotor or the stator. This pump design makes it ideal for transferring abrasive fluids or slurries and is a critical component in several waste treatment systems.Moreover, the centrifugal screw pump is also suitable for metering applications due to its precise flow rate. Its discharge rate is unaffected by variations in fluid viscosity, temperature, or pressure, which is uncommon in other types of pumps. This accuracy makes it an ideal solution for transferring critical fluids in the pharmaceutical and chemical industries.Overall, this high-end centrifugal screw pump equipped with state-of-the-art technology is a guaranteed game-changer in the industrial manufacturing sector. \This pump has already made a significant impact in the industry by delivering unmatched performance and efficiency. With its ability to handle complex fluids, reduce maintenance costs, increase machine longevity, and improve overall operational efficacy, it remains the top choice for many businesses.Additionally, the company that produces this innovative centrifugal screw pump takes pride in providing customers with the best service in the industry. Their team of experts makes every effort to assist and guide clients in the selection, installation, and maintenance of equipment. They also offer comprehensive training to ensure maximum productivity and efficiency from the pump.In conclusion, investing in a centrifugal screw pump from this reputable brand is the best decision any business can make. It delivers exceptional performance, reduces production costs, and adds value to the entire manufacturing process. With its unmatched versatility and durability, it is the ultimate solution to all your fluid transfer needs. Contact their team today and experience the revolution in industrial manufacturing!

High-quality and Efficient Screw Pump: Everything You Need to Know

The 3-Screw Pump: Revolutionizing the Pump IndustryIntroduction: [Company Name] has been a leader in the manufacturing and distribution of industrial pumps for over two decades. With a focus on technology, innovation, and customer satisfaction, [Company Name] has become a trusted name in the pump industry. Today, we are proud to introduce our latest innovation, the 3-Screw Pump, which is set to revolutionize the way pumping systems operate.The 3-Screw Pump is a state-of-the-art, high-performance pump that offers unparalleled efficiency, reliability, and versatility. Its unique design and advanced technology make it suitable for a wide range of applications, including oil and gas, marine, power generation, and chemical processing. With its compact size, high flow rates, and low noise levels, the 3-Screw Pump is a game-changer in the pump industry.The key features of the 3-Screw Pump include:1. High Efficiency: The 3-Screw Pump is designed to deliver high flow rates with minimal energy consumption. Its precision-engineered screw mechanism ensures smooth and efficient operation, resulting in significant cost savings for the end user.2. Reliability: With its robust construction and advanced sealing technology, the 3-Screw Pump offers unmatched reliability and durability. It can handle high-pressure and high-temperature applications with ease, making it an ideal choice for demanding industrial environments.3. Versatility: The 3-Screw Pump is suitable for a wide range of fluids, including lubricating oils, hydraulic fluids, and fuel oils. Its ability to handle various viscosities and temperatures makes it a versatile solution for diverse pumping requirements.4. Compact Design: The compact and space-saving design of the 3-Screw Pump makes it easy to install and integrate into existing pumping systems. Its low noise levels and minimal vibration further enhance its appeal for industrial applications.In addition to these key features, the 3-Screw Pump also incorporates advanced monitoring and control systems, making it easy to operate and maintain. Its user-friendly interface and compatibility with digital control systems ensure seamless integration into modern industrial processes.The launch of the 3-Screw Pump reinforces [Company Name]'s commitment to innovation and technological excellence. It is the result of our extensive research and development efforts, combined with our deep understanding of the needs and challenges faced by industries that rely on high-performance pumping systems. We are confident that the 3-Screw Pump will set a new benchmark for efficiency, reliability, and performance in the pump industry.To ensure the successful adoption of the 3-Screw Pump, [Company Name] is offering comprehensive technical support and after-sales service. Our team of experienced engineers and technicians is available to assist customers with installation, commissioning, and maintenance, ensuring that the 3-Screw Pump delivers optimal performance throughout its operational life.In conclusion, the 3-Screw Pump represents a significant advancement in pump technology, offering a compelling solution for industries that demand high-performance pumping systems. With its focus on efficiency, reliability, and versatility, the 3-Screw Pump is poised to make a lasting impact on the pump industry. [Company Name] is excited to bring this innovative product to market and looks forward to supporting our customers in harnessing the full potential of the 3-Screw Pump.

Efficient Lube Oil System for Smooth Pump Operations

Title: Cutting-Edge and Reliable Lube Oil System for Pumps Revolutionizes the IndustryIntroduction (100 words):The rapidly growing industrial sector demands high-performance machinery that can operate optimally while minimizing downtime. To cater to this need, an innovative and pioneering engineering company has developed a state-of-the-art Lube Oil System for Pumps. This revolutionary system is designed to enhance the efficiency, reliability, and longevity of pumps in various industries, facilitating increased productivity and reduced maintenance costs. Capitalizing on advanced technology and unparalleled expertise, the pioneering company continues to redefine the standards of pump lubrication systems, catering to diverse industry needs worldwide.1. Superior Technology and Unmatched Performance (150 words):The Lube Oil System for Pumps represents a paradigm shift in the field of pump lubrication. Leveraging cutting-edge technology, this system ensures smoother pump operations, extending equipment life considerably. By addressing common issues such as overheating, leaks, and inefficient lubrication, the system enhances overall pump performance and reduces the risk of catastrophic failure.By utilizing precision-engineered components, the Lube Oil System guarantees an efficient and consistent lubrication process, providing optimal operational parameters. This results in reduced friction, improved energy efficiency, and increased service intervals, saving businesses significant costs on maintenance, repair, and replacement.Furthermore, the system's advanced filtration system removes impurities and contaminants, preventing abrasive particles from causing damage and ensuring prolonged pump lifespan. With its user-friendly design and intuitive interface, the system is easily integrated into existing infrastructure, catering to a wide range of pump sizes and types.2. Protection against Contamination and Corrosion (150 words):The Lube Oil System for Pumps places utmost emphasis on safeguarding the pumps against contamination and corrosion, which are major contributors to equipment malfunctions. By employing cutting-edge technologies such as corrosion inhibitors, the system effectively combats the damaging effects of corrosive substances, including water content typically found in lubricants.Furthermore, strategically positioned sensors and monitoring devices ensure early detection of potential pump malfunctions. These intelligent sensors continuously monitor vital parameters such as temperature, pressure, and flow rates, instantly alerting operators in case of any irregularities. Such proactive measures not only minimize unplanned shutdowns but also enable predictive maintenance, preventing costly equipment failures and optimizing operational efficiency.3. Customizable Solutions for Specific Industry Needs (150 words):Recognizing the diversity of industrial requirements, the Lube Oil System for Pumps offers a range of customizable solutions tailored to specific industry needs. Whether it is heavy-duty pumps utilized in the oil and gas industry, high-pressure pumps in the manufacturing sector, or industrial water pumps, the system ensures optimal lubrication and protection for pumps operating under extreme conditions.Moreover, this versatile system can be seamlessly integrated into both new installations and existing setups, offering a cost-effective solution for businesses across various sectors. The company's technical experts work closely with clients to understand their unique requirements, providing personalized solutions that align with their operational guidelines, regulatory requirements, and sustainability goals.4. Sustainability and Environmental Responsibility (150 words):The Lube Oil System for Pumps incorporates sustainable practices and responsible environmental management into its design. The system optimizes lubricant consumption, reducing waste and minimizing the carbon footprint associated with replacing lubricants frequently.Additionally, the advanced filtration system efficiently removes impurities and contaminants, reducing the ecological impact and promoting cleaner, greener operations. By extending the lifespan of pumps, the system also helps reduce waste generated from premature pump replacements.Furthermore, the system's energy-efficient design enhances overall plant efficiency, contributing to reduced energy consumption and promoting sustainable manufacturing practices.Conclusion (100 words):The groundbreaking Lube Oil System for Pumps ushers in a new era of reliability, performance, and sustainability in the pump lubrication domain. Its cutting-edge technology and customizable solutions cater to the diverse needs of industries worldwide, minimizing operational risks, optimizing production, and reducing maintenance costs. The company's unwavering commitment to delivering superior products and services continues to revolutionize the industry, ensuring a seamless integration of their systems into all types of pump installations. With an unblemished track record and a customer-centric approach, the company stands at the forefront of the pump lubrication sector, providing innovative solutions that set new benchmarks for excellence.

Revolutionary Multiphase Twin Screw Pumps Offer Efficient Flow and Versatility

[Headline]Revolutionary Multiphase Twin Screw Pump Set to Unlock New Possibilities in Fluid Transportation[Subheading]Cutting-edge technology from {company name} is set to transform the fluid transportation industry with the introduction of their ground-breaking Multiphase Twin Screw Pump. With its advanced design and exceptional performance, this innovative pump has the potential to revolutionize various sectors, from oil and gas to chemical and maritime.[Date][City][Company Introduction]{Company name} is a leading provider of exceptional pumping solutions, known for their commitment to innovation and customer satisfaction. With years of experience in developing state-of-the-art technologies, {company name} has established itself as a trusted name in the industry. By consistently pushing the boundaries of what is possible, they have become synonymous with efficiency, reliability, and excellence.[Paragraph 1]Leveraging their expertise in pump technology, {company name} proudly presents the Multiphase Twin Screw Pump, a breakthrough solution that promises to redefine fluid transportation. This cutting-edge pump utilizes twin screw technology, enabling it to efficiently transport a wide range of substances, including liquids with high viscosity, gases, and even oil-water mixtures.[Paragraph 2]The secret behind the extraordinary performance of the Multiphase Twin Screw Pump lies in its design. By employing two intermeshing screws, this pump generates a continuous, non-pulsating flow of fluid. Paired with its large pumping chamber and low rotational speed, the pump minimizes the risk of cavitation, enhancing operational efficiency and ensuring a steady flow of substances throughout the system.[Paragraph 3]One of the key advantages of the Multiphase Twin Screw Pump is its ability to handle multiphase flow without the need for a separator or additional equipment. This capability significantly reduces operational costs, simplifies the system, and minimizes the risk of equipment failure. Companies operating in the oil and gas industry can greatly benefit from this feature, as it enables them to streamline their operations and enhance overall productivity.[Paragraph 4]Moreover, the Multiphase Twin Screw Pump is designed to withstand harsh operating conditions. Its robust construction ensures reliable performance even in extreme temperatures, corrosive environments, and high-pressure applications. This resilience allows the pump to be deployed in a wide range of industries, including chemical manufacturing, maritime, and food processing.[Paragraph 5]In addition to its exceptional performance in transporting fluids, this innovative pump offers numerous environmental advantages. With its low energy consumption and reduced emissions, the Multiphase Twin Screw Pump helps companies meet environmental regulations and minimize their carbon footprint. Its efficient design contributes to sustainability initiatives across industries, making it an excellent choice for companies committed to reducing their environmental impact.[Paragraph 6]To ensure the optimal implementation of the Multiphase Twin Screw Pump, {company name} provides comprehensive after-sales support, including maintenance and technical assistance. Their team of experienced technicians and engineers is readily available to assist clients with any queries or concerns, ensuring seamless integration and long-term success.[Paragraph 7]The introduction of the Multiphase Twin Screw Pump marks a significant milestone in fluid transportation technology. Overcoming the limitations of conventional pumps, this revolutionary solution has the potential to reshape various industries, offering increased efficiency, reliability, and environmental sustainability. With {company name}'s proven track record of excellence and commitment to innovation, the Multiphase Twin Screw Pump is set to become a game-changer in the field of fluid transportation.[Word Count: 500]

Powerful Mud Sludge Pump for Efficient Waste Removal

Mud Sludge Pump, an essential tool for the oil and gas industry, has long been recognized as a leader in the field of pumping solutions. The company has built a strong reputation for its high-quality products and outstanding customer service, making it a go-to choice for businesses in need of reliable pumping solutions.With a commitment to innovation, Mud Sludge Pump has continually developed and refined its products to meet the ever-changing needs of the industry. The company's pumps are designed to efficiently handle a wide range of fluids, including drilling mud, sludge, and other waste materials. This capability is crucial for businesses in the oil and gas sector, where the management and disposal of these fluids are significant operational challenges.One of the key strengths of Mud Sludge Pump is its dedication to research and development. The company invests heavily in engineering and technology, constantly seeking ways to improve the performance and efficiency of its pumps. This commitment has led to the development of cutting-edge pumping solutions that set the industry standard for reliability and durability.In addition to its focus on product development, Mud Sludge Pump also places a high priority on customer satisfaction. The company's team of experts work closely with clients to understand their specific needs and provide tailored solutions that meet their requirements. This personalized approach has earned Mud Sludge Pump a loyal customer base, with many businesses relying on the company's expertise to keep their operations running smoothly.With a strong track record of delivering top-quality products and unparalleled customer service, Mud Sludge Pump has established itself as a leader in the pumping solutions industry. The company's pumps are widely used in a variety of applications, from drilling operations to waste management, highlighting their versatility and reliability.Furthermore, Mud Sludge Pump's commitment to sustainability sets it apart from its competitors. The company prioritizes the development of eco-friendly pumping solutions that minimize environmental impact while maintaining high performance standards. This forward-thinking approach reflects Mud Sludge Pump's dedication to supporting a greener, more sustainable industry.Looking ahead, Mud Sludge Pump remains focused on driving innovation and delivering value to its customers. The company continues to invest in research and development, seeking new ways to improve its products and expand its range of pumping solutions. By staying at the forefront of industry trends and technologies, Mud Sludge Pump is poised to continue leading the way in the pumping solutions market.In conclusion, Mud Sludge Pump has earned its reputation as a trusted provider of high-quality pumping solutions. With a strong commitment to innovation, customer satisfaction, and sustainability, the company is well-positioned to meet the evolving needs of the oil and gas industry. As businesses continue to rely on Mud Sludge Pump's pumps for their operations, the company's leadership in the pumping solutions market is expected to endure for years to come.

Understanding How Screw Pumps Work in Different Industries

Screw Pump WorkingScrew pumps have been a vital component in various industries, as they play a crucial role in pumping a wide range of substances such as water, oil, and chemicals. These pumps are renowned for their efficient and reliable performance, making them an essential tool for many companies around the world.The working principle of a screw pump involves the use of rotating screws to move the fluid along the pump's axis. This results in a smooth and continuous flow of the substance being pumped, with minimal pulsation and turbulence. The design of screw pumps allows for high efficiency and low noise, making them an ideal choice for applications that require precision and consistency.One of the leading manufacturers of screw pumps in the industry is {}. With a rich history of innovation and expertise in pump technology, the company has been a trusted partner for numerous businesses in various sectors. Their screw pumps are known for their robust construction, advanced design, and superior performance, making them a top choice for many demanding applications.The screw pumps manufactured by {} are designed to handle a wide range of fluids, including viscous, abrasive, and corrosive substances. This versatility makes them suitable for use in industries such as oil and gas, petrochemical, marine, and wastewater treatment. The pumps are also designed to operate in challenging conditions, including high temperatures, high pressures, and harsh environments, making them a reliable solution for demanding applications.The pump design and construction are tailored to meet the specific requirements of each application, ensuring optimal performance and durability. {} employs a team of experienced engineers and technicians who work closely with customers to understand their needs and provide customized solutions. This collaborative approach has helped the company build a strong reputation for delivering high-quality pumps that exceed customer expectations.In addition to their technical expertise, {} is committed to sustainability and environmental responsibility. The company continuously strives to develop energy-efficient solutions that minimize the environmental impact of their products. This dedication to sustainability has earned {} recognition as a responsible and forward-thinking company in the industry.With a global presence and a widespread network of sales and service partners, {} is well-equipped to support customers around the world. Their commitment to customer satisfaction is reflected in their comprehensive after-sales support and maintenance services, ensuring the long-term performance and reliability of their screw pumps.Looking ahead, {} continues to invest in research and development to enhance the performance and capabilities of their screw pumps. The company is dedicated to staying at the forefront of pump technology, embracing new advancements and innovation to meet the evolving needs of their customers.In conclusion, screw pumps are an essential component in many industries, and {} has established itself as a leading manufacturer of high-quality pumps. With a focus on innovation, customer collaboration, and sustainability, the company is well-positioned to meet the diverse and challenging requirements of modern industries. Its commitment to excellence and customer satisfaction makes {} a trusted partner for businesses seeking reliable and efficient pump solutions.

Maximizing the Efficiency of Screw Pumps: Important Factors to Consider

Screw Pump Efficiency Boosts Productivity for Global Machinery ManufacturerThe global machinery manufacturing industry relies on high-performance equipment to drive productivity and meet the demands of a competitive market. Every aspect of the manufacturing process plays a critical role in ensuring efficient and reliable operations. That's why the integration of advanced technology, such as the latest screw pump efficiency solutions, has become a game-changer for companies like {company name}.{Company name} is a leading provider of machinery and equipment for various industries, including automotive, construction, and agriculture. With a history spanning over 50 years, the company has built a reputation for delivering innovative and high-quality products that meet the evolving needs of its customers worldwide.One of the key factors driving {company name}'s success is its commitment to leveraging cutting-edge technology to enhance the performance of its machinery. This commitment is evident in the company's recent adoption of state-of-the-art screw pump technology, which has significantly improved the efficiency and reliability of its products.Screw pumps are a vital component in many industrial applications, including hydraulic systems and fluid transfer processes. These pumps are known for their ability to deliver a steady flow of fluid under high pressure, making them ideal for a wide range of manufacturing operations. By upgrading to the latest screw pump efficiency solutions, {company name} has been able to optimize the performance of its machinery, resulting in increased productivity and cost savings for its customers.The decision to invest in advanced screw pump technology was driven by {company name}'s commitment to delivering best-in-class products to its customers. By partnering with leading manufacturers of screw pump solutions, the company has been able to integrate the latest innovations into its machinery, thereby enhancing their performance and reliability.The results of this investment have been remarkable. {Company name}'s customers have reported significant improvements in the efficiency and productivity of their operations since the adoption of the new screw pump technology. This has translated into tangible benefits, such as reduced downtime, lower maintenance costs, and increased overall output for their businesses.In addition to the direct impact on customer operations, the integration of advanced screw pump technology has also positioned {company name} as a leader in innovation within the machinery manufacturing industry. By staying at the forefront of technological advancements, the company has been able to differentiate itself from competitors and solidify its reputation as a trusted provider of high-performance machinery and equipment.The success of {company name}'s adoption of screw pump efficiency solutions serves as a testament to the importance of investing in advanced technology to drive business growth and meet the needs of an evolving market. By prioritizing innovation and collaboration with industry-leading partners, {company name} has been able to deliver tangible value to its customers and strengthen its position as a global leader in the machinery manufacturing industry.Looking ahead, {company name} remains committed to leveraging the latest advancements in technology to continue driving productivity and efficiency for its customers. The company's dedication to innovation and customer satisfaction ensures that it will remain at the forefront of the industry, providing cutting-edge solutions that empower businesses to thrive in a competitive global market.

Discover the Benefits of Single Screw Pumps for Your Applications

Single Screw Pump: A Game-changer in the Pump IndustryThe pump industry has seen significant advancements in technology over the years, and one such innovation that has been making waves in recent times is the single screw pump. This type of pump is designed to handle a wide range of applications and provides a reliable and efficient solution for various industries.**Company Introduction**{Company Name} is at the forefront of this innovation, leading the way in the development and manufacturing of single screw pumps. With years of experience and expertise in the pump industry, {Company Name} has established itself as a trusted provider of high-quality pumping solutions across the globe. The company’s commitment to innovation and excellence has made it a go-to choice for industries that require reliable and efficient pumping technology.**The Single Screw Pump**The single screw pump is a type of positive displacement pump that is designed to handle a wide range of fluids, including viscous, abrasive, and shear-sensitive liquids. What sets this pump apart from others is its unique design, which features a single helical rotor that rotates within a double helical stator. This design creates a continuous flow of liquid through the pump, providing a smooth and consistent pumping action.The versatility of the single screw pump has made it an ideal choice for various industries, including oil and gas, food and beverage, chemical processing, wastewater treatment, and many others. Its ability to handle a wide range of fluids and its gentle pumping action make it suitable for applications where traditional pumps may struggle to perform effectively.One of the key advantages of the single screw pump is its ability to handle highly viscous fluids with ease. This makes it an ideal choice for industries that deal with thick or sticky liquids, such as crude oil, molasses, and sludge. The pump’s gentle pumping action also makes it suitable for shear-sensitive products, ensuring that the integrity of the liquid is maintained throughout the pumping process.**Benefits of Single Screw Pump**The single screw pump offers a range of benefits that make it a game-changer in the pump industry. These include:1. Versatility: The pump can handle a wide range of fluids, making it suitable for diverse applications across various industries.2. Efficiency: Its unique design provides a smooth and consistent flow, ensuring efficient pumping with minimal pulsation.3. Reliability: The pump’s robust construction and minimal moving parts make it a reliable choice for continuous operation in demanding environments.4. Low maintenance: With fewer moving parts, the pump requires minimal maintenance, reducing downtime and operating costs.5. Gentle pumping action: The pump’s gentle handling of fluids makes it suitable for shear-sensitive and delicate products.**Applications**The versatility and reliability of the single screw pump make it suitable for a wide range of applications. Some of the common uses of this pump include:1. Oil and gas: Handling of crude oil, drilling mud, and other viscous fluids in the oil and gas industry.2. Food and beverage: Pumping of chocolate, syrup, and other viscous food products in food processing facilities.3. Chemical processing: Handling of various chemicals, solvents, and polymers in the chemical industry.4. Wastewater treatment: Pumping of sludge, sewage, and other waste fluids in wastewater treatment plants.The single screw pump has proven to be a game-changer in the pump industry, offering a reliable and efficient solution for a wide range of applications. With its versatility and gentle pumping action, this innovative pump is set to revolutionize the way industries handle a variety of fluids, setting new standards for efficiency and reliability in pumping technology. {Company Name} continues to lead the way in the development and manufacturing of single screw pumps, providing industries with cutting-edge pumping solutions that are tailored to meet their specific needs. As the demand for efficient and reliable pumping technology continues to grow, the single screw pump is well-positioned to play a pivotal role in the future of the pump industry.

Durable and Efficient Twin Screw Pump for Various Industrial Applications

Fristam Twin Screw Pump has recently introduced a new and innovative solution to meet the growing demand for efficient pumping systems in various industries. With a focus on reliability, performance, and ease of maintenance, this new pump is set to revolutionize the way companies handle their fluid transfer needs.The Fristam Twin Screw Pump is designed to handle a wide range of applications, including food and beverage, pharmaceutical, chemical, and personal care, among others. Its unique design allows for gentle product handling, making it suitable for delicate or shear-sensitive products. With its high efficiency and low pulsation characteristics, this pump is ideal for applications where product integrity is crucial.One of the key features of the Fristam Twin Screw Pump is its ability to handle both low and high viscosity products with ease. This versatility makes it a valuable asset for companies dealing with a variety of different substances. Additionally, its hygienic design and ease of cleaning make it compliant with the strict regulations and standards of the food and pharmaceutical industries.In addition to its impressive performance capabilities, the Fristam Twin Screw Pump is also designed with maintenance in mind. The pump is easy to disassemble and reassemble, reducing downtime and lowering the overall cost of ownership. This feature is especially important for companies looking to maximize their operational efficiency and minimize unnecessary expenses.Furthermore, the Fristam Twin Screw Pump is built to last, with a durable construction that can withstand the demands of continuous use. Its robust design and high-quality materials ensure that it can operate reliably for extended periods, providing companies with peace of mind and confidence in their pumping capabilities.With the introduction of the Fristam Twin Screw Pump, the company continues to solidify its position as a leading provider of pumping solutions for various industries. The pump is a testament to the company's commitment to innovation and excellence, and it is expected to make a significant impact in the market.In summary, the launch of the Fristam Twin Screw Pump represents a major milestone for the company and its customers. With its impressive performance, versatile capabilities, and ease of maintenance, this pump is set to become a valuable asset for companies across a wide range of industries. As the demand for efficient and reliable pumping systems continues to grow, the Fristam Twin Screw Pump is well-positioned to meet and exceed the expectations of its users.

Top Check Valve for Well Pump: A Comprehensive Guide

Check Valve For Well Pump Ensures Reliable and Efficient Water Flow{company name} is proud to announce the release of their high-quality check valve for well pumps, designed to enhance the performance and longevity of well water systems. With over [number] years of experience in manufacturing pump components, {company name} has built a reputation for delivering reliable and innovative solutions to meet the needs of the water industry. The new check valve is the latest addition to their product line, offering superior functionality and durability for well pump systems.The check valve plays a crucial role in maintaining the integrity of well water systems by preventing backflow and ensuring a consistent flow of water. {company name}'s check valve is designed with precision engineering and premium materials to provide reliable protection against water hammer, backflow, and other potential issues that can occur in well pump systems.One of the key features of {company name}'s check valve is its durable construction. Made from high-quality materials, the check valve is built to withstand the harsh conditions often found in well water systems. Its robust design ensures long-term performance and minimal maintenance, reducing the risk of downtime and costly repairs for well owners.In addition to its durability, the check valve is also designed for easy installation and compatibility with a wide range of well pump systems. {company name} understands the importance of convenience for their customers and has engineered the check valve to be user-friendly and versatile, allowing for seamless integration into existing well pump setups.Furthermore, the check valve is engineered for efficient water flow, helping to optimize the performance of well pump systems. By reducing the risk of backflow and water hammer, the check valve contributes to smoother water flow and more consistent water pressure, enhancing the overall efficiency of well water systems.{company name} prides itself on its commitment to product excellence and customer satisfaction. As part of their dedication to quality, the check valve for well pumps has undergone rigorous testing and quality control measures to ensure that it meets the highest standards for performance and reliability. Customers can have confidence in {company name}'s products, knowing that they are backed by extensive research, development, and testing processes.The release of the check valve for well pumps reflects {company name}'s ongoing commitment to innovation and technological advancement in the water industry. By continuously investing in research and development, {company name} strives to stay at the forefront of the market, offering cutting-edge solutions that address the evolving needs of well owners and water system operators.In addition to the check valve, {company name} offers a comprehensive range of pump components and accessories, catering to a diverse array of applications within the water industry. With a focus on quality, reliability, and performance, {company name} has established itself as a trusted provider of pump solutions, earning the trust and loyalty of customers worldwide.As the demand for efficient and reliable well pump systems continues to grow, {company name} remains at the forefront of delivering innovative solutions that empower well owners to maintain and optimize their water systems. The release of the check valve for well pumps underscores {company name}'s dedication to providing essential components that contribute to the long-term sustainability and performance of well water systems.For more information about {company name}'s check valve for well pumps or to explore their comprehensive range of pump components and accessories, please visit their official website or contact their customer service team. With a commitment to excellence and a passion for innovation, {company name} is poised to continue driving advancements in the water industry, supporting the needs of well owners and water system operators globally.