Maximizing Efficiency of Screw Pumps: Tips and Techniques

By:Admin

In the world of industrial pumping, efficiency is everything. And one company has been leading the charge in revolutionizing pump efficiency with their innovative screw pump technology.

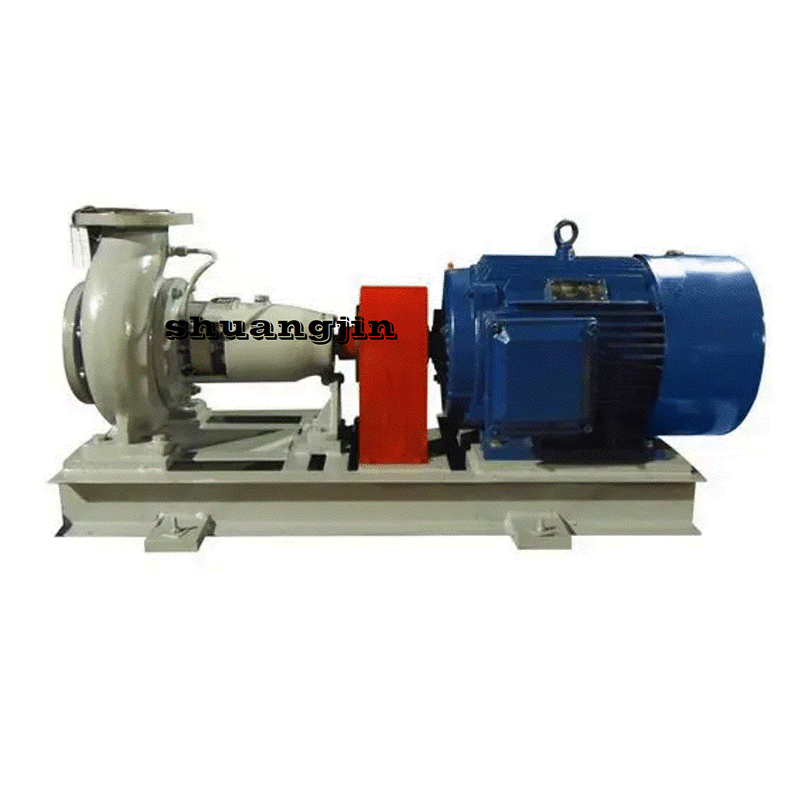

For decades, the pumping industry has relied on traditional centrifugal pumps to move liquids and gases in various industrial applications. While these pumps have served their purpose, they often come with inefficiencies and limitations that can affect their performance and productivity. This is where the screw pump, a game-changing alternative, comes into play.

With its unique design and capabilities, the screw pump has proven to be a more efficient and reliable option for a wide range of industrial pumping tasks. Unlike traditional centrifugal pumps, screw pumps are able to handle high viscosity liquids, solids, and abrasive materials with ease. This makes them ideal for demanding applications such as oil and gas, chemical processing, wastewater treatment, and marine industries.

One company at the forefront of this screw pump revolution is [Company Name]. With a history dating back to [year], [Company Name] has been a leading manufacturer and supplier of screw pumps and other pumping solutions for a diverse range of industries. Their commitment to innovation and customer satisfaction has earned them a reputation for excellence in the pumping industry.

[Company Name]’s screw pumps are designed with efficiency and performance in mind. Their unique helical rotor design allows for smooth and continuous pumping of a wide variety of fluids, resulting in higher flow rates and lower energy consumption. This not only saves on operational costs but also reduces downtime and maintenance requirements, making their screw pumps a cost-effective and reliable choice for industrial pumping needs.

Furthermore, [Company Name] offers a range of customizable options and accessories for their screw pumps, allowing customers to tailor their pumping solutions to their specific requirements. Whether it’s different materials of construction, sizes, or configurations, [Company Name] ensures that their screw pumps meet the unique needs of each customer and application.

In addition to their innovative products, [Company Name] is committed to providing exceptional customer service and support. Their team of experts works closely with customers to understand their pumping challenges and provide tailored solutions that maximize efficiency and performance. From initial consultation to installation and ongoing maintenance, [Company Name] is dedicated to being a trusted partner for all of their customers’ pumping needs.

With a strong focus on research and development, [Company Name] continues to push the boundaries of screw pump technology. Their investment in cutting-edge design and engineering ensures that their products remain at the forefront of pump efficiency and reliability, setting new standards in the industry.

The success of [Company Name] and their screw pump technology has not gone unnoticed. They have garnered a loyal customer base and earned numerous accolades and certifications for their commitment to quality and innovation. Their dedication to sustainable and environmentally friendly pumping solutions has also positioned them as a leader in the industry.

As the industrial pumping industry continues to evolve, efficiency and reliability will remain key factors in determining the success of pumping solutions. With their innovative screw pump technology and commitment to customer satisfaction, [Company Name] is well-positioned to lead the way in revolutionizing the pumping industry for years to come.

Company News & Blog

Screw Pump Diagram: A Detailed Guide to Understanding How Screw Pumps Work

Screw Pump DiagramScrew pumps are a crucial component in a variety of industries, including oil and gas, water treatment, and food and beverage. They are used to move liquids or slurries and are known for their reliability and efficiency. One company at the forefront of screw pump technology is {}. Their innovative designs and high-quality products have made them a leading supplier in the industry.Screw pumps, also known as progressive cavity pumps, work by using a screw-shaped rotor to move fluid through the pump. As the rotor turns, it creates a series of small chambers between the screw and the pump housing. These chambers trap the fluid and move it along the length of the screw before releasing it at the outlet. This design allows for a smooth and consistent flow of fluid, making screw pumps ideal for applications where precise and continuous pumping is necessary.{} has been a key player in the screw pump industry for over 30 years. The company prides itself on its commitment to innovation and customer satisfaction. Their team of engineers and technical experts are constantly working to improve their products and develop new technologies to meet the evolving needs of their clients. With a focus on quality and reliability, {} has built a reputation for excellence in the industry.One of the key features of {}'s screw pump design is its ability to handle a wide range of viscosities and fluid types. Whether it's thick sludge in a wastewater treatment plant or high-viscosity crude oil in a refinery, their pumps are designed to deliver consistent performance and efficiency. This versatility makes {}'s screw pumps an attractive choice for a variety of industries and applications.In addition to their standard product line, {} also offers customized solutions to meet the specific needs of their clients. They work closely with customers to understand their requirements and develop tailored pump systems that deliver optimal performance and reliability. This dedication to customer service has helped {} build long-lasting relationships with clients around the world.Another important aspect of {}'s screw pump technology is its focus on energy efficiency. By optimizing their pump designs and utilizing advanced materials, they have been able to reduce energy consumption and operational costs for their clients. This commitment to sustainability and cost-effectiveness has made {} a trusted partner in the industry.As the demand for screw pumps continues to grow, {} remains at the forefront of the industry. Their ongoing investment in research and development and dedication to quality and customer satisfaction set them apart in the market. With a global network of sales and service partners, {} is well-positioned to meet the needs of their clients wherever they may be.In conclusion, screw pumps play a critical role in a wide range of industries, and {} has established itself as a leading supplier in the industry. With a focus on innovation, quality, and customer satisfaction, they have earned a reputation for excellence in the market. As the demand for screw pumps continues to grow, {} is well-positioned to meet the needs of their clients and drive the industry forward with their advanced technology and superior products.

High-Quality Marine Water Pressure Pump for Your Boat

Marine Water Pressure Pump: The Perfect Solution for Marine Water SystemsAs the leading provider of marine equipment, [Company Name] is proud to introduce a revolutionary Marine Water Pressure Pump to improve the water systems on various marine vessels. This new and innovative product is designed to provide an efficient and reliable solution for maintaining water pressure on boats, yachts, and other marine vessels.With years of experience in the marine industry, [Company Name] understands the unique challenges that boat owners and marine enthusiasts face when it comes to water systems. The Marine Water Pressure Pump is the result of extensive research and development, aimed at creating a product that not only meets, but exceeds the expectations of marine enthusiasts.The Marine Water Pressure Pump is designed to deliver a consistent and reliable water flow, ensuring that boat owners have access to clean and fresh water at all times. Whether it's for showering, washing dishes, or any other water-related activities, this pump is the perfect solution for maintaining water pressure on marine vessels.One of the key features of the Marine Water Pressure Pump is its durability and resilience. Designed to withstand the harsh marine environment, this pump is built to last, ensuring that boat owners can rely on it for years to come. Additionally, the pump is easy to install and operate, making it a hassle-free solution for marine water systems."We are thrilled to introduce the Marine Water Pressure Pump to the market," said [Spokesperson's Name], [Company Name]'s spokesperson. "We understand the importance of having a reliable water system on marine vessels, and our new pump is designed to provide exactly that. We believe that this product will make a significant impact on the marine industry and greatly improve the overall experience for boat owners and enthusiasts."In addition to its functionality and durability, the Marine Water Pressure Pump is also designed with energy efficiency in mind. By minimizing energy consumption, this pump is not only environmentally friendly, but also helps boat owners save on operating costs in the long run.The Marine Water Pressure Pump is just one of the many high-quality marine products offered by [Company Name]. With a commitment to excellence and customer satisfaction, the company is dedicated to providing innovative solutions that meet the evolving needs of the marine industry.In conclusion, the Marine Water Pressure Pump is a game-changing product that is set to revolutionize the way water systems are managed on marine vessels. With its reliability, durability, and energy efficiency, this pump offers the perfect solution for maintaining water pressure on boats, yachts, and other marine vessels. Backed by the expertise and reputation of [Company Name], boat owners and marine enthusiasts can trust that they are investing in a top-of-the-line product that will enhance their overall experience on the water.

Advanced Technology in Oil Pump Systems Increases Efficiency in the Energy Industry

Oil Pump System Revolutionizes the Oil and Gas IndustryThe oil and gas industry is one of the most important sectors of the global economy. The energy resources generated by this industry enable everything from transportation to heating, and without oil and gas, modern society could not function. It is therefore critical that oil and gas companies have access to reliable, efficient, and cost-effective technologies that help them extract and process hydrocarbons safely and reliably. That is where the Oil Pump System (OPS), a revolutionary technology that is changing the landscape of the oil and gas industry, comes in.The OPS is an innovative, electric-powered pump system that is designed to improve the efficiency and reliability of oil and gas extraction. Unlike conventional pump systems, which rely on mechanical methods for extraction and rely on fossil fuels for power, the OPS is powered by electricity. This removes the need for on-site fuel storage and transportation, making operations safer and greener. Furthermore, the OPS is up to 50% more efficient than traditional pump systems because it constantly adapts to the well's changing conditions. The result is less down time, improved yields, and lower costs.The OPS is also designed for use in harsh, remote environments, making it ideal for oil and gas companies that operate in challenging areas. The pump's durable construction and sealed, watertight design make it resistant to wear and tear, corrosion, and other factors that can damage traditional pumps. Additionally, the OPS's electric motor is designed to operate in extreme heat and cold, enabling it to work reliably even in environments where temperatures can vary widely.Another key advantage of the OPS is its advanced control system, which enables operators to remotely monitor and adjust the pump's performance in real-time. This allows for quicker response times to changes in well conditions, reducing the risk of downtime or damage to the well. Furthermore, the OPS's intuitive interface is easy to use, making it accessible to operators with a wide range of technical knowledge and experience.The OPS was developed by an engineering firm that has been working in the oil and gas industry for more than 20 years. With a commitment to innovation and quality, the company has a proven track record of developing cutting-edge technologies that help oil and gas companies improve their efficiency, reduce their environmental impact, and increase their profitability. The OPS is the latest example of this commitment, and it has quickly become a favorite of oil and gas companies both large and small.According to the company, the OPS has been tested extensively in real-world conditions and has consistently performed well. In one recent case study, an oil and gas company that had been using a conventional pump system switched to the OPS and saw a 30% increase in efficiency and a 25% reduction in maintenance costs. The company also reported that the OPS helped them achieve higher production rates and that it was easier to operate and maintain than their previous system.For oil and gas companies, the benefits of the OPS are clear. It is a reliable, efficient, and cost-effective pump system that can help them extract hydrocarbons more easily and with less environmental impact. It is also a durable and safe solution that can be used in even the harshest of environments. With all of these advantages, it is no wonder that the OPS is quickly becoming a must-have technology for oil and gas companies around the world.In conclusion, the Oil Pump System is a revolutionary technology that is changing the oil and gas industry. Its superior efficiency, reliability, and cost-effectiveness make it an attractive option for companies looking to improve their bottom line, while its durability and safety features make it ideal for use in harsh, remote environments. With the Oil Pump System, oil and gas companies can extract hydrocarbons more easily and with less environmental impact, ensuring that the world has access to the energy resources it needs to function.

Boost Your Efficiency with the Power of Multiphase Pumps

Multiphase Pump Technology Revolutionizes the Oil and Gas IndustryThe oil and gas industry is one of the most important sectors in the world today. It provides the energy and resources needed for transportation, heating, and electricity generation. However, the extraction of oil and gas from the earth is not always an easy task. It requires specialized equipment and techniques to effectively extract and transport the valuable resources. Multiphase pump technology has emerged as one of the most promising and game-changing technologies in the industry.The development of Multiphase Pumps has been revolutionary for the Oil and Gas industry. These pumps have the capability to handle a mixture of oil, gas, and water in a single flow pipeline. They have the potential to dramatically reduce costs and improve efficiency in oil and gas production by eliminating the need for expensive and complex infrastructure, such as separation facilities and pipelines. Multiphase pumps also have a small environmental footprint and are ideal for offshore production.One of the key players in the Multiphase Pump industry is a company that has been at the forefront of developing this technology. This company, founded in 1990 in Norway, is dedicated to creating innovative solutions for the oil and gas industry. It has established itself as a global leader in Multiphase Pump technology with over 2800 pump installations worldwide.The company’s flagship product is a multiphase pump that can handle up to 100% gas, 100% oil, or any combination in-between. The pump is extremely efficient and can operate in harsh environments, such as the North Sea, where conventional pumps cannot operate. Its unique design allows for efficient transport of oil and gas from wells in remote locations, minimizing the use of expensive infrastructure.Multiphase pump technology has numerous advantages over traditional methods. It can significantly reduce the cost of infrastructure, reduce downtime, and improve the overall efficiency of production. In addition, multiphase pumps can be used in a variety of applications, including oil production, gas production, and transportation. They can also be used in the development of unconventional resources such as shale gas and oil sands.The company’s multiphase pumps have been successfully used in a variety of projects worldwide. These include offshore platforms in the North Sea, deepwater subsea installations in the Gulf of Mexico, and onshore operations in the Middle East. The pumps have helped clients achieve cost savings of up to 50% and have significantly reduced emissions and carbon footprints.In addition to its successful pump installations, the company offers a range of services to support its clients. These services include custom design and engineering, installation and commissioning, training, maintenance, and upgrades. The company’s expert engineers and technicians provide comprehensive support to ensure that clients’ pumps perform at their best.The company’s dedication to innovation and customer satisfaction has earned it recognition from customers and the industry. It has won multiple awards for its innovative products and services. In 2020, the company received the Norwegian Export Award for its successful export of multiphase pumps to international markets.Multiphase pump technology has the potential to revolutionize the oil and gas industry by improving efficiency, reducing costs, and minimizing environmental impact. The company’s innovative approach to pump technology and excellent customer service has made it a leader in the industry. Its pumps and services have helped clients all over the world to extract oil and gas more efficiently and effectively. As the demand for cleaner energy sources increases, multiphase pump technology will play an even more important role in the energy transition. The company’s dedication to innovation and customer satisfaction will continue to drive its success and position it at the forefront of the industry.

Lubricating Oil Pumps: Power Your Machinery with Reliable Performance

Lubricating Oil Pumps Revolutionize the Industrial SectorIn an era of rapid technological advancements, industries across the globe are constantly searching for innovative solutions to enhance their operational efficiency. One such revolutionary development in the field of industrial machinery is the introduction of high-performance lubricating oil pumps. These pumps, designed to remove friction and reduce wear and tear in various industrial applications, have quickly garnered attention for their unparalleled functionality and contribution to the optimization of the manufacturing process.The leading provider in this cutting-edge technology, Company X, has garnered significant recognition for their advanced lubricating oil pumps. Founded in 1980, Company X has consistently focused on the development and production of lubricating systems that deliver outstanding performance, reliability, and cost efficiency.Company X’s lubricating oil pumps are hailed as game-changers as they address critical issues faced by industries globally. One of the main challenges encountered in industrial operations is machinery breakdown, often caused by excessive friction and inadequate lubrication. These issues lead to increased maintenance costs and downtime, greatly hampering productivity. However, with the advent of Company X’s high-performance lubricating oil pumps, industries are witnessing increased reliability, reduced downtime, and significant cost savings.Company X has dedicated substantial efforts towards research and development, allowing them to create an extensive range of lubricating oil pumps that cater to diverse industrial requirements. These pumps are specifically engineered to ensure a constant supply of oil, maintaining optimum lubrication levels even under severe working conditions. By utilizing innovative technology, the pumps achieve efficient oil distribution, resulting in reduced wear and tear, increased operational reliability, and extended machinery lifespan.Furthermore, Company X’s lubricating oil pumps are designed with versatility in mind. Irrespective of the industry or application, these pumps can be seamlessly integrated into various systems, including hydraulic machines, turbines, compressors, and injection molding machines, among others. The pumps’ compatibility with different equipment types showcases their adaptability and underscores their value across a spectrum of industrial sectors.One of the standout features of Company X’s lubricating oil pumps is their advanced control systems. These systems ensure precise lubricant distribution, eliminating the risk of over-lubrication or insufficient lubrication. With integrated sensors and monitoring capabilities, the pumps can measure and regulate oil flow in real-time, guaranteeing optimal lubrication at all times. Such advanced control mechanisms have proven to be groundbreaking, as they prevent unnecessary wear and tear, minimize energy consumption, and reduce oil wastage.As the leading player in the lubricating oil pump industry, Company X places great emphasis on environmental sustainability. The incorporation of eco-friendly materials, such as recyclable components and energy-efficient motors, reflects the company’s commitment to reducing its ecological footprint. By investing in Company X’s lubricating oil pumps, industries can not only enhance their productivity and profitability, but also contribute to environmental conservation.The widespread adoption of these lubricating oil pumps is a testament to their impact on the industrial sector. Companies across a range of industries, including manufacturing, automotive, aerospace, and energy, have experienced transformative results by integrating these pumps into their operations. Reduced maintenance costs, increased machinery lifespan, enhanced productivity, and improved environmental sustainability are just a few of the benefits that have positioned Company X’s lubricating oil pumps as the preferred choice for industrial lubrication needs.In conclusion, Company X’s lubricating oil pumps have revolutionized the industrial sector. Their unmatched functionality, versatility, and advanced control systems have positioned them at the forefront of lubrication technology. With these pumps, companies enjoy enhanced operational efficiency, reduced maintenance costs, and increased profitability. The revolutionary impact of Company X’s lubricating oil pumps has solidified their role as catalysts for progress, ushering in a new era of optimized industrial machinery.

Ultimate Guide to Industrial Marine Pumps: Uncovering the Top Solutions for Efficient Operations

[Assistant]Title: Leading Industrial Pump Manufacturer Expands Product Line to Meet Growing DemandSubtitle: Company showcases advanced solutions aimed at revolutionizing industrial marine applications [Introduction]In today’s rapidly evolving industrial landscape, the demand for efficient and reliable industrial marine pumps has reached unprecedented heights. Recognizing this, one of the industry's leading manufacturers has recently expanded its product line to cater to the needs of this niche market. This move aims to revolutionize the way industries approach marine applications, promising enhanced performance, reduced downtime, and improved sustainability.[Company Background]With decades of experience in pump manufacturing, the company has established itself as a trusted global leader in the industry. Known for its commitment to innovation and cutting-edge technology, the company has garnered a robust reputation within various sectors, including marine, oil and gas, power generation, and chemical processing.Driven by a passion for continuous improvement, the company invests heavily in research and development to ensure the highest quality products are offered to its customers. As a result, they boast an extensive portfolio of efficient, durable, and cost-effective solutions that have become synonymous with excellence.[Diverse Product Range]Expanding on their range of industrial pumps, the company has launched an array of advanced marine pumps, specifically designed to withstand the harsh operating conditions encountered in marine environments. These pumps offer a wide range of applications, including ballast water management, cargo handling, bilge pumping, cooling systems, and more. The company's commitment to meeting the unique demands of the marine industry is evident through the latest product offerings.1. Cutting-edge Ballast Water Management Systems: Recognizing the significance of environmental conservation, the company has developed highly efficient ballast water management systems that comply with international guidelines. With advanced filtration and disinfection technologies, these systems ensure the prevention of invasive species transfer without compromising vessel performance.2. Cargo and Bilge Pumps: Engineered to handle the demanding requirements of cargo handling and bilge pumping, the company's pumps deliver exceptional reliability and operational efficiency. With features like high flow rates, corrosion resistance, and low maintenance requirements, these pumps stand as a testament to the company's commitment to delivering long-lasting and highly effective solutions.3. Cooling Systems: Marine vessels mandate reliable cooling systems to maintain optimal operating temperatures. Understanding this critical need, the company offers an extensive range of cooling pumps designed to withstand the unpredictable conditions encountered at sea. Notable features include compatibility with both fresh and seawater, efficient heat transfer capabilities, and high corrosion resistance.[Innovation and Sustainability]Priding itself on being an industry pioneer, the company continuously strives to develop sustainable solutions to minimize environmental impact. The introduction of eco-friendly materials, energy-efficient systems, and technologies that reduce carbon emissions further reinforces their commitment to sustainability.To enhance operational efficiency, the company has incorporated smart monitoring technologies into their marine pumps. Real-time data monitoring and predictive maintenance capabilities ensure optimal performance, reduced downtime, and cost-effective operations.[Future Prospects]With their expanded marine pumps portfolio, the company is well-positioned to cater to the rapidly growing industrial marine sector. As the demand for efficient water management, cargo handling, and cooling systems continue to rise, the company's advanced solutions are set to play a pivotal role in transforming the industry.To further support their customers, the company has bolstered its after-sales services, ensuring timely maintenance, spare parts availability, and a dedicated support team to cater to any queries or concerns. These customer-centric initiatives reinforce the company's commitment to delivering holistic and reliable solutions to clients worldwide.In conclusion, the recent expansion of industrial marine pumps by the leading pump manufacturer demonstrates their dedication to meeting the requirements of this rapidly expanding market. With innovative technologies, sustainable practices, and a commitment to customer satisfaction, the company aims to revolutionize the industrial marine industry, setting new benchmarks for efficiency, reliability, and environmental responsibility.

10 Essential Factors to Consider When Choosing a Pump

article.Allweiler Pump Rebrands as ACI FluidsLeading global pump manufacturer, Allweiler Pump, has officially rebranded as ACI Fluids, following the acquisition by the American industrial conglomerate, Cameron Corporation. The exciting new development will see ACI Fluids bolster their state-of-the-art product portfolio, expand their global network, and continue to offer world-class services to customers across multiple industries.ACI Fluids has a rich history of innovation, with over 150 years of experience in the pump industry. Over the years, the company has established itself as a name to be reckoned with and has become synonymous with reliability and quality. As the company takes on a new identity, it seeks to build on its legacy and scale new heights of success.ACI Fluids offers an extensive range of pumps that cater to a variety of industrial applications. Its portfolio includes centrifugal, positive displacement, and gear pumps, among others. The company has a reputation for manufacturing pumps that are durable, efficient, and operate at peak performance even under challenging conditions. ACI Fluids' product range serves industries such as oil and gas, marine, chemical, food and beverage, and water and wastewater.The acquisition of Allweiler Pump by Cameron Corporation presents numerous opportunities for ACI Fluids to expand its presence in different markets. The synergy created by the acquisition will allow the company to leverage the technological expertise and operational efficiency of both organizations. This development will translate to more significant investments in research and development, enhancing engineering capabilities, expanding product lines, and exploring new avenues of growth.ACI Fluids' mission is to be a reliable partner to its customers by offering exceptional customer service and technical support. Its team of experienced engineers and technicians work closely with customers to provide customized solutions that meet their unique requirements. The company's commitment to customer satisfaction is evident from the testimonials of its satisfied customers, who have attested to the quality of its products and services.The appointment of Kevin Snee as President of ACI Fluids marks a significant milestone in the company's growth. Kevin joins the company with a wealth of industry experience, having previously served as Senior Vice President of Global Sales and Marketing at Blackmer. In his new role, Kevin will be responsible for driving the company's strategic vision, leading its growth initiatives, and developing strong customer relationships.Kevin's appointment comes at a time when ACI Fluids is looking to strengthen its presence in emerging markets such as Asia and the Middle East. He sees these regions as critical to the company's growth and is committed to investing resources to expand the company's footprint. Kevin also plans to continue building on the company's primary focus of delivering exceptional products and services to its customers.In conclusion, the rebranding of Allweiler Pump to ACI Fluids is a significant development in the pump industry. With a history rooted in innovation and a reputation for quality, ACI Fluids is poised for growth under the leadership of Kevin Snee. As it expands its product portfolio, leverages new technologies, and explores new markets, ACI Fluids remains committed to its core values of reliability, quality, and superior customer service.

Why the Latest Innovation in Pump Technology is Revolutionizing the Oil Industry

[Suggested Introduction]In a groundbreaking development, a renowned company is set to revolutionize the industrial world with its latest offering, the Screw Oil Pump. This cutting-edge innovation is poised to transform oil extraction processes by improving efficiency and reducing environmental impact. With an unwavering commitment to sustainable practices, the company aims to set new benchmarks in the oil industry. In this article, we will delve deeper into the features and benefits of this state-of-the-art Screw Oil Pump, shedding light on its potential to reshape the entire sector.[Body]The Screw Oil Pump, developed by a trailblazing company with decades of experience in the oil industry, is a paradigm shift in oil extraction technologies. Leveraging their expertise, the company has designed and engineered this pump to enhance efficiency and sustainability. By seamlessly combining robust engineering principles with advanced technological innovations, they have created a product that addresses key challenges faced in the oil extraction process.At the heart of this innovation lies the unique design of the Screw Oil Pump, which optimizes the pumping mechanism for oil extraction. Unlike conventional pumps, this cutting-edge solution significantly reduces energy consumption, leading to substantial cost savings for oil producers. The pump's remarkable efficiency is achieved through a combination of precise engineering and the utilization of state-of-the-art materials, ensuring maximum output while minimizing energy wastage.Furthermore, the Screw Oil Pump is equipped with an intelligent control system that allows it to adapt to varying extraction conditions. Built-in sensors and proprietary algorithms enable the pump to continuously monitor and adjust operating parameters, ensuring optimal performance even in challenging environments. This not only improves productivity but also significantly reduces downtime and maintenance requirements, resulting in further cost savings for oil producers.In addition to its economic benefits, the Screw Oil Pump prioritizes environmental sustainability. Industry-related carbon emissions and their impact on the environment have long been a concerning issue. However, this revolutionary pump incorporates advanced technologies to minimize its carbon footprint. By employing efficient motors and leveraging smart controls to optimize energy consumption, the pump enables oil producers to contribute to a greener future while maintaining their operational efficiency.Moreover, the Screw Oil Pump is designed with longevity in mind. Recognizing the importance of durability in the industrial sector, the company has used only the highest-quality materials and components to ensure product reliability and extended lifespan. By doing so, they reduce the need for frequent replacements and repairs, further contributing to cost-effectiveness and sustainable operations.Another distinctive feature of the Screw Oil Pump is its versatility. The pump can be seamlessly integrated into existing oil extraction systems, ensuring a smooth transition and ease of implementation for oil producers. This compatibility eliminates the need for extensive modifications, saving both time and resources for companies adopting this innovative solution.As the world continues to shift towards renewable energy sources, the sustainability and efficiency of traditional energy industries, such as oil extraction, become increasingly crucial. The Screw Oil Pump presents an opportunity for oil producers to keep pace with the evolving energy landscape and simultaneously address concerns related to cost, efficiency, and environmental impact.The combination of cutting-edge technology, energy efficiency, sustainability, and ease of integration positions the Screw Oil Pump as a game-changer in the oil extraction industry. With its potential to revolutionize operations and secure a more sustainable future, the pump has garnered immense interest from industry experts and professionals alike.[Conclusion]As the global demand for oil and energy continues to rise, it is imperative for the industry to embrace innovative solutions that propel us towards a more sustainable future. The Screw Oil Pump, with its remarkable efficiency, environmental consciousness, and adaptability, presents an exciting opportunity for oil producers worldwide. By reducing energy consumption, optimizing performance, and prioritizing sustainability, this groundbreaking pump is poised to redefine the way oil extraction is carried out. Embracing this ingenious solution can not only benefit individual companies but also contribute to the larger goal of achieving a greener and more sustainable energy sector.

New Vertical Centrifugal Pump Offers Efficient Water Movement

Recently, a new vertical centrifugal pump has been launched by a leading manufacturer in the industry. The pump, which has been designed specifically for industrial use, is expected to meet the growing demand for high-quality, reliable and efficient pumping solutions in various sectors including chemical processing, oil & gas, and water treatment.The new vertical centrifugal pump is the result of years of research and development by the manufacturer, who has been at the forefront of innovation in the industry. The key features of the pump include its compact design, high efficiency, and ease of maintenance. It is equipped with a powerful motor that can deliver up to 110 kW of power, and comes with a range of customizable options to suit different applications.One of the biggest advantages of the vertical centrifugal pump is its ability to handle high flow rates and high pressures. This makes it an ideal choice for industries that require large volumes of liquid to be moved quickly and reliably. The pump is also designed to operate at high temperatures and can handle a wide range of corrosive and abrasive fluids, making it suitable for use in harsh environments.To ensure maximum reliability and performance, the manufacturer has incorporated advanced technologies into the design of the vertical centrifugal pump. This includes state-of-the-art sealing systems, advanced bearing designs, and precision machining techniques. The pump has also been rigorously tested to ensure its compliance with international standards for quality and safety.The manufacturer is committed to providing its customers with the highest level of service and support. The company has a team of highly skilled engineers and technicians who are available to provide technical assistance and troubleshooting services as needed. In addition, the company offers a range of training and education programs to help customers get the most out of their pumping equipment and to optimize their operations.With its advanced features, reliable performance, and excellent customer support, the new vertical centrifugal pump is expected to be in high demand among a wide range of industries. Its versatility makes it suitable for use in applications ranging from chemical processing to water treatment, and from oil & gas to mining. As the demand for high-quality pumping solutions continues to grow, the manufacturer is well positioned to meet the needs of its customers and to continue to innovate and remain at the forefront of the industry.

Fueling Innovation: Ctp Pump Offers Cutting-Edge Solutions for Gas Stations

Introducing the Next Generation of Fuel Efficiency: CTP Pump Revolutionizes the IndustryIn today’s fast-paced world, the demand for fuel-efficient vehicles and machinery is higher than ever. As climate concerns continue to grow, individuals and businesses alike are searching for ways to reduce their carbon footprint and make more environmentally conscious choices. This is where CTP Pump, a pioneering company in the field of fuel-saving technology, comes into play. With their innovative and cutting-edge fuel pump technology, CTP Pump is revolutionizing the industry and changing the way we think about fuel efficiency.Founded in [year], CTP Pump has quickly emerged as a leader in the development and implementation of fuel-saving solutions for a wide range of industries. Their groundbreaking technology has been proven to significantly reduce fuel consumption and carbon emissions, ultimately saving businesses and individuals money while also contributing to a greener and more sustainable future.One of the key aspects of CTP Pump’s technology is its adaptability to a wide range of fuel-driven systems. Whether it’s a commercial truck, an industrial generator, or a construction vehicle, CTP Pump’s innovative technology can be seamlessly integrated to optimize performance and reduce fuel consumption. This versatility is one of the reasons why CTP Pump has garnered such widespread attention and acclaim in the industry.The core principle behind CTP Pump’s technology lies in its ability to deliver the precise amount of fuel needed for optimal combustion. By accurately measuring and dispensing the right amount of fuel at the right time, CTP Pump’s system ensures that every drop of fuel is utilized to its maximum potential. This not only results in significant cost savings for businesses, but also reduces harmful emissions that contribute to environmental pollution.Furthermore, CTP Pump’s technology is designed to be user-friendly and easily adaptable to existing fuel systems. This means that businesses can seamlessly integrate CTP Pump’s technology into their operations without having to undergo extensive modifications or disruptions. This user-centric approach has made CTP Pump’s technology highly sought after by businesses looking to make a meaningful impact on their fuel efficiency and environmental footprint.In addition to its technological advancements, CTP Pump is also committed to providing exceptional customer support and service. Their team of experts is dedicated to working closely with clients to understand their specific needs and provide customized solutions that deliver tangible results. From initial consultation to ongoing support, CTP Pump’s customer service is second to none, ensuring that their clients experience a seamless and successful transition to their innovative technology.As the demand for fuel-efficient solutions continues to grow, CTP Pump is poised to play a pivotal role in shaping the future of the industry. With their unwavering commitment to innovation, sustainability, and customer satisfaction, CTP Pump is well-positioned to lead the way in revolutionizing fuel efficiency and driving positive change across various sectors.Looking ahead, CTP Pump plans to continue pushing the boundaries of fuel-saving technology, with a focus on developing even more advanced and efficient solutions. By staying at the forefront of technological advancements and industry trends, CTP Pump is determined to cement its status as the go-to provider for cutting-edge fuel efficiency solutions.In conclusion, CTP Pump’s game-changing technology is setting a new standard for fuel efficiency and environmental responsibility. With their innovative approach, commitment to excellence, and unwavering dedication to customer satisfaction, CTP Pump is driving positive change and reshaping the future of fuel-saving technology. As businesses and individuals seek to make smarter, more sustainable choices, CTP Pump is undoubtedly at the forefront of this transformative movement, and their impact will undoubtedly be felt for years to come.