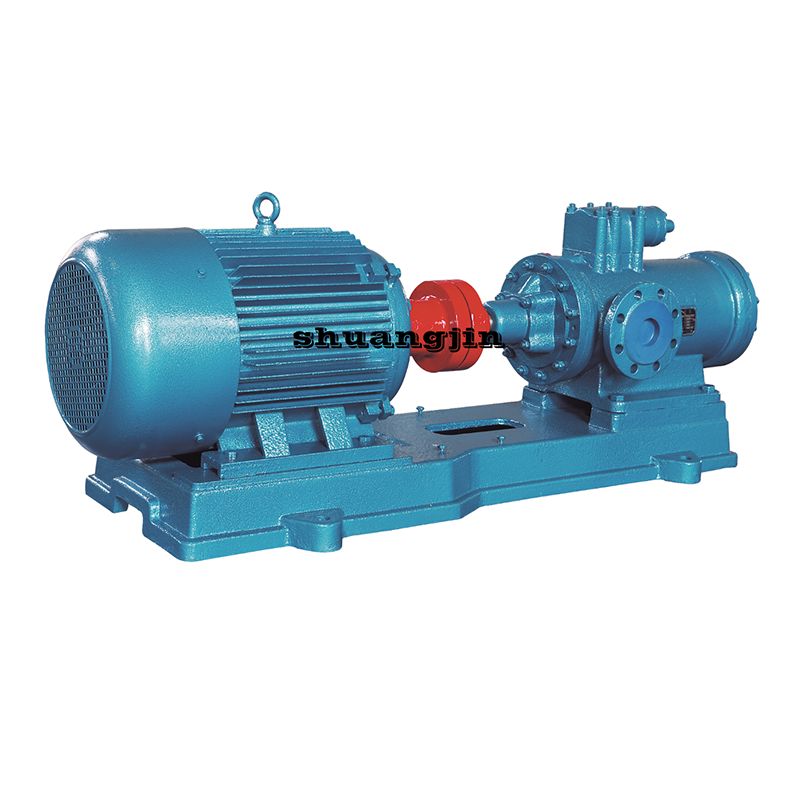

Screw Pump: A Reliable Solution for Fluid Transfer

By:Admin

The new screw pumps from Pompa are specifically designed to meet the demands of various industries including oil and gas, petrochemical, food and beverage, and water treatment. The pumps are built to handle a wide range of viscosities and temperatures, making them versatile and suitable for a variety of applications.

One of the key features of the new screw pumps is their high efficiency and low maintenance requirements. The pumps are constructed with precision-engineered components that ensure smooth and reliable operation, while also minimizing the need for frequent maintenance. This not only translates to cost savings for the end users but also minimizes downtime and maximizes productivity.

In addition to their superior performance, the new screw pumps from Pompa are also designed with a focus on durability and longevity. The company has utilized advanced materials and manufacturing techniques to ensure that the pumps can withstand the harshest operating conditions and continue to perform consistently over an extended period of time.

Furthermore, Pompa has incorporated the latest technology and design principles into the new line of screw pumps to ensure that they meet the highest industry standards for safety and environmental responsibility. The company is committed to providing its customers with pumps that not only deliver exceptional performance but also adhere to the strictest regulations and guidelines for workplace and environmental safety.

The introduction of the new line of screw pumps is a testament to Pompa's ongoing dedication to research and development. The company has invested significant resources into the design and testing of these pumps to ensure that they exceed the expectations of their customers and deliver unmatched value.

"We are excited to launch our new line of screw pumps, which we believe will set a new standard for performance and reliability in the industry," said a spokesperson for Pompa. "We have leveraged our expertise and experience to develop pumps that not only meet the current needs of our customers but also anticipate their future requirements. We are confident that these pumps will prove to be a game-changer for many industries and further solidify our position as a leader in the pump manufacturing sector."

Pompa has also emphasized its commitment to providing comprehensive support and service for its new line of screw pumps. The company has a team of skilled engineers and technicians who are trained to assist customers with installation, operation, and maintenance of the pumps. This ensures that customers can derive maximum benefit from their investment and continue to rely on Pompa for their pumping needs.

With the launch of the new line of screw pumps, Pompa has once again demonstrated why it is regarded as a pioneering force in the pump industry. The company's focus on innovation, quality, and customer satisfaction continues to set it apart from its competitors and solidify its reputation as a trusted and reliable partner for industrial pump solutions. As industries continue to evolve and demand more advanced pumping technologies, Pompa is well-positioned to meet these challenges and deliver cutting-edge solutions that exceed expectations.

Company News & Blog

Top 10 Efficient Pumps for the Oil and Gas Sector

Title: Advancements in Pumping Technology Revolutionize the Oil and Gas IndustryIntroduction:The oil and gas industry is witnessing a remarkable transformation with the introduction of advanced pumping technology, leading to increased efficiency and productivity. Cutting-edge pumps, such as those offered by renowned manufacturers, are revolutionizing the sector by providing innovative solutions and improved performance. This article will delve into the recent advancements in pumping technology and how these developments are reshaping the oil and gas industry.1. Importance of Pumps in the Oil and Gas Industry:Pumps play a vital role in the oil and gas industry, facilitating the extraction, transportation, and processing of hydrocarbons. They are used to transfer crude oil, refined products, and natural gas through vast pipelines spanning great distances. In addition, pumps are crucial for artificial lift systems, enhancing production from oil wells by efficiently extracting the oil or gas from reservoirs. In this context, the continuous evolution of pumps is instrumental in maximizing the industry's productivity.2. Integration of Advanced Technologies in Pump Design: Recent advancements in technology have revolutionized pump design, resulting in more efficient and reliable operations. Companies, such as {}, have incorporated state-of-the-art technologies into their pumps, offering enhanced performance and durability. These advancements include:a. Sensor-based Monitoring Systems: Pumps are now equipped with sensor-based monitoring systems that provide real-time data to operators. This allows for seamless monitoring of pump performance, early detection of abnormalities, and timely maintenance, thereby minimizing downtime and reducing maintenance costs.b. Predictive Maintenance: With the implementation of machine learning algorithms, pumps can now predict potential failures and schedule maintenance before breakdowns occur. This proactive approach reduces unplanned downtime, ensuring uninterrupted operations and enhancing productivity.c. Energy Efficiency: Pumps are being designed with energy-efficient features, such as variable frequency drives, which regulate the pump speed based on demand. This prevents unnecessary energy consumption and reduces operational costs, contributing to a more sustainable and eco-friendly oil and gas industry.3. Increased Reliability and Performance:The integration of advanced technologies in pump design has significantly improved reliability and performance. Modern pumps can handle harsh operating conditions, such as extreme temperatures and corrosive environments, without compromising efficiency. Additionally, these pumps have increased flow rates, allowing for faster and more efficient transportation of oil and gas across pipelines.The durability of these pumps is further enhanced by the utilization of robust materials and advanced coatings that prevent corrosion and erosion. As a result, maintenance requirements are reduced, while the lifespan of the pumps is extended, ensuring uninterrupted operations in critical installations.4. Remote Monitoring and Control:The digitalization of the oil and gas industry has paved the way for remote monitoring and control of pumping systems. Operators can now remotely manage and monitor multiple pumps, reducing the need for on-site personnel. This not only enhances safety but also improves operational efficiency, as real-time data analytics enable optimized decision-making for improved productivity.5. Environmental Considerations:As sustainability gains prominence, pumps designed for the oil and gas industry now focus on reducing environmental impact. Advanced technologies, such as smart sensors and energy efficiency features, play a vital role in minimizing carbon footprint and optimizing resource consumption. By choosing pumps that prioritize eco-friendly operations, companies can contribute to the reduction of environmental pollution and the conservation of natural resources.Conclusion:The integration of advanced pumping technology in the oil and gas industry has resulted in significant improvements in efficiency, reliability, and sustainability. Companies like {} are leading the way in reshaping the sector, offering cutting-edge pump solutions designed to meet the evolving needs of the industry. These advancements not only increase productivity but also contribute to a more environmentally conscious and efficient oil and gas sector.

High-Quality Pump Lubricating Oil for Efficient Machinery

Pump Lubricating Oil, a crucial component in the smooth operation of industrial pumps, remains a key focus of [Company Name]'s commitment to providing high-quality and reliable maintenance products for industrial machinery. With more than [number] years of experience in the industry, [Company Name] has established itself as a leading supplier of lubricating oils and maintenance solutions for a wide range of industrial applications.[Company Name] was founded in [year] and has since grown to become a trusted partner for businesses looking to optimize the performance and longevity of their industrial equipment. The company's dedication to quality and innovation has led to the development of a comprehensive range of lubricating oils, including Pump Lubricating Oil, designed to meet the unique needs of various pump systems.Pump Lubricating Oil plays a critical role in ensuring the smooth and efficient operation of industrial pumps, which are essential for many manufacturing and processing operations. The oil provides crucial lubrication to the moving parts of the pump, reducing friction and wear, and helping to prevent costly downtime and repairs. [Company Name]'s Pump Lubricating Oil is formulated to provide superior lubrication and protection, even under the most demanding operating conditions, making it the ideal choice for industrial pump maintenance.In addition to its high-performance properties, [Company Name]'s Pump Lubricating Oil is also designed to meet the stringent operational requirements of modern industrial facilities. The oil is formulated to resist oxidation and thermal breakdown, ensuring long-term stability and reliability even in high-temperature environments. Its advanced anti-wear additives and corrosion inhibitors further contribute to the overall reliability and performance of industrial pump systems.Furthermore, [Company Name] understands the importance of environmental sustainability and is committed to developing lubricating oils that minimize environmental impact. Pump Lubricating Oil is formulated with biodegradable and environmentally friendly ingredients, ensuring compliance with industry regulations and reducing the ecological footprint of industrial operations.As part of its commitment to customer satisfaction, [Company Name] provides comprehensive technical support and maintenance services to help businesses maximize the performance and lifespan of their pump systems. The company's team of experts offers valuable insights and recommendations for the proper selection and application of Pump Lubricating Oil, ensuring that each customer's unique needs and challenges are addressed effectively.In addition to Pump Lubricating Oil, [Company Name] offers a wide range of maintenance products and solutions for industrial machinery, including hydraulic oils, gear lubricants, and specialty greases. The company's extensive product portfolio is backed by a rigorous quality assurance process, ensuring that each product meets the highest standards for performance, reliability, and safety.With its unwavering commitment to innovation and customer satisfaction, [Company Name] continues to be a trusted partner for businesses seeking reliable maintenance solutions for their industrial equipment. The company's dedication to quality, sustainability, and technical expertise makes it a preferred choice for businesses across various industries.As businesses strive to optimize the performance and efficiency of their industrial pumps, [Company Name] remains at the forefront of providing high-quality and reliable maintenance products, including Pump Lubricating Oil. With its proven track record of excellence and commitment to customer satisfaction, [Company Name] is poised to continue its role as a leading supplier of lubricating oils and maintenance solutions for industrial machinery.

Screw Pump vs Centrifugal Pump: What's the Difference?

Screw Pump and Centrifugal Pump are two common types of pumps used in various industrial and commercial applications. While both pumps are designed to move fluid from one place to another, they have distinct differences in terms of design, operation, and performance. Understanding the difference between these two types of pumps can help businesses make informed decisions when selecting the most suitable pump for their specific needs.The primary difference between a screw pump and a centrifugal pump lies in their mechanism of fluid displacement. Screw pumps, as the name suggests, use a rotating screw to move the fluid along the axis of the screw. This results in a smooth and continuous flow of fluid, making screw pumps ideal for handling viscous fluids, slurries, and abrasive materials. On the other hand, centrifugal pumps use a rotating impeller to create centrifugal force, which then moves the fluid outwards from the center of the pump, creating a high-velocity flow. This makes centrifugal pumps well-suited for applications that require high flow rates and low viscosity fluids.In terms of operational efficiency, screw pumps are generally more efficient in handling viscous fluids and maintaining a steady flow rate, even when working against high pressure. This makes them suitable for applications such as oil and gas processing, wastewater treatment, and food processing. Centrifugal pumps, on the other hand, excel in applications that require high flow rates and a continuous supply of fluid, such as water distribution, HVAC systems, and chemical processing.Another key difference between screw pumps and centrifugal pumps is their ability to handle solids. Screw pumps are well-equipped to handle solids and abrasive materials without clogging, making them a popular choice for pumping slurries and wastewater with solid particles. Centrifugal pumps, while capable of handling some solids, are generally less efficient in managing abrasive materials and may require additional equipment for solids handling.Additionally, screw pumps are known for their quiet operation and low pulsation, making them suitable for applications that require a smooth and consistent flow of fluid. In contrast, centrifugal pumps may produce more noise and pulsation, particularly at high flow rates and pressures.{Company} is a leading manufacturer of industrial pumps, offering a wide range of solutions for various fluid handling applications. With a focus on innovation and reliability, {Company} has developed a diverse portfolio of screw pumps and centrifugal pumps to meet the diverse needs of its customers. The company's screw pumps are designed to provide efficient and reliable performance in handling viscous fluids, abrasive materials, and high-pressure applications. With a strong emphasis on durability and minimal maintenance, {Company}'s screw pumps are built to withstand the most demanding industrial environments.On the other hand, {Company}'s centrifugal pumps are engineered to deliver high flow rates, smooth operation, and exceptional performance in fluid transportation and distribution. With advanced design features and a focus on energy efficiency, {Company}'s centrifugal pumps are well-suited for applications in water management, HVAC systems, and general industrial processes.In conclusion, while both screw pumps and centrifugal pumps are essential for fluid handling in various industries, they have distinct differences in terms of design, operation, and performance. Understanding these differences is crucial for businesses to select the most suitable pump for their specific needs. With a strong reputation for quality and innovation, {Company} continues to be a leading provider of both screw pumps and centrifugal pumps, offering reliable solutions for a wide range of fluid handling applications.

New Vertical Centrifugal Pump Offers Efficient Water Movement

Recently, a new vertical centrifugal pump has been launched by a leading manufacturer in the industry. The pump, which has been designed specifically for industrial use, is expected to meet the growing demand for high-quality, reliable and efficient pumping solutions in various sectors including chemical processing, oil & gas, and water treatment.The new vertical centrifugal pump is the result of years of research and development by the manufacturer, who has been at the forefront of innovation in the industry. The key features of the pump include its compact design, high efficiency, and ease of maintenance. It is equipped with a powerful motor that can deliver up to 110 kW of power, and comes with a range of customizable options to suit different applications.One of the biggest advantages of the vertical centrifugal pump is its ability to handle high flow rates and high pressures. This makes it an ideal choice for industries that require large volumes of liquid to be moved quickly and reliably. The pump is also designed to operate at high temperatures and can handle a wide range of corrosive and abrasive fluids, making it suitable for use in harsh environments.To ensure maximum reliability and performance, the manufacturer has incorporated advanced technologies into the design of the vertical centrifugal pump. This includes state-of-the-art sealing systems, advanced bearing designs, and precision machining techniques. The pump has also been rigorously tested to ensure its compliance with international standards for quality and safety.The manufacturer is committed to providing its customers with the highest level of service and support. The company has a team of highly skilled engineers and technicians who are available to provide technical assistance and troubleshooting services as needed. In addition, the company offers a range of training and education programs to help customers get the most out of their pumping equipment and to optimize their operations.With its advanced features, reliable performance, and excellent customer support, the new vertical centrifugal pump is expected to be in high demand among a wide range of industries. Its versatility makes it suitable for use in applications ranging from chemical processing to water treatment, and from oil & gas to mining. As the demand for high-quality pumping solutions continues to grow, the manufacturer is well positioned to meet the needs of its customers and to continue to innovate and remain at the forefront of the industry.

Exploring the Versatility of Screw Pumps - Unraveling the Inner Workings of Centrifugal Designs

Centrifugal Screw Pump Revolutionizes Fluid Transfer: Introducing a Game-Changing Device by Leading Pump Manufacturer[Company Name], a renowned manufacturer in the fluid transfer industry, has recently unveiled their latest innovation – the Centrifugal Screw Pump. This groundbreaking device promises to revolutionize fluid transfer processes across various sectors, offering improved efficiency, reliability, and ease of use.The Centrifugal Screw Pump is a result of meticulous research and development by [Company Name], a company with a longstanding reputation for delivering high-quality fluid transfer solutions. With a rich history spanning several decades, [Company Name] has continuously strived to push the boundaries of innovation in the pump manufacturing field.The Centrifugal Screw Pump is designed to address the challenges faced by industries dependent on smooth fluid transfer operations. Its cutting-edge technology combines the benefits of centrifugal force and screw pumping mechanisms, resulting in a device that boasts excellence in both performance and versatility.One of the key features of the Centrifugal Screw Pump is its ability to handle a wide range of fluids, including those with high viscosity and entrained solids. This adaptability makes it ideal for applications across a multitude of industries, such as oil and gas, chemical processing, power generation, and wastewater treatment.The unique design of the Centrifugal Screw Pump allows for enhanced operational efficiency. Its innovative screw impeller ensures a smooth and consistent flow rate, minimizing the risk of pulsation and cavitation. This feature not only increases productivity but also prolongs the lifespan of the pump, reducing maintenance costs for businesses.Moreover, the Centrifugal Screw Pump offers significant energy savings compared to traditional fluid transfer devices. Its advanced motor design, combined with a robust impeller structure, reduces power consumption while delivering optimal performance. This translates into reduced operational costs and a smaller environmental footprint, aligning with the global push towards sustainability.Furthermore, the Centrifugal Screw Pump is engineered for easy installation and maintenance. Its compact and modular design simplifies on-site assembly, minimizing downtime during installation. Additionally, the pump's user-friendly interface provides operators with real-time performance metrics and alerts, facilitating proactive troubleshooting and ensuring consistent operation.Safety is also prioritized with the Centrifugal Screw Pump, as it incorporates various features to mitigate risks. Equipped with advanced sensors, the pump actively monitors temperature, pressure, and other parameters, automatically shutting down in case of system anomalies. This proactive approach not only protects valuable assets but also prevents accidents and ensures operator well-being.The Centrifugal Screw Pump comes backed by [Company Name]'s extensive customer support and service network. With a global footprint and a commitment to customer satisfaction, the company offers comprehensive technical assistance, spare parts availability, and prompt maintenance services. This ensures that businesses using the Centrifugal Screw Pump can rely on uninterrupted operations and optimal performance.As [Company Name] continues to advance the boundaries of pump manufacturing and revolutionize the fluid transfer industry, they solidify their position as a pioneer in the field. The Centrifugal Screw Pump stands as a testament to their dedication to innovation, efficiency, and customer-centricity, offering businesses a game-changing solution for their fluid transfer needs.In conclusion, the introduction of the Centrifugal Screw Pump by [Company Name] is set to transform fluid transfer processes across industries. With its exceptional performance, versatility, energy efficiency, and user-friendly features, this revolutionary pump device promises to enhance productivity, reduce operational costs, and contribute to a more sustainable future.

Discover the Latest Advancements in Pump Technology

Title: Advanced Pump Technologies Revolutionizing Industrial and Municipal Application IndustriesIntroduction:In the world of industrial and municipal applications, where efficiency, durability, and reliability are paramount, every element of the system has to be perfectly aligned to ensure seamless operations. One company that has been at the forefront of developing cutting-edge pumping solutions is Bornemann Pump (brand name removed), a global leader in pump technology. With a rich history spanning several decades, the company has been revolutionizing various industries with its advanced pump technologies. In this article, we will explore the contributions of Bornemann Pump and how it continues to enhance the performance and productivity of industrial and municipal sectors worldwide.1. A Legacy of Excellence:Bornemann Pump, with its headquarters in Germany, has emerged as a trusted name in the global pumping industry since its establishment in 1853. With over 150 years of expertise, the company has perfected the art of engineering precision pumping solutions, gaining international recognition for their exceptional quality, reliability, and longevity. Bornemann Pump's commitment to innovation has resulted in numerous patents and industry accolades, positioning them as a preferred choice among industry professionals.2. Application Diversity:The comprehensive range of Bornemann Pump's products caters to various industries, including chemical, oil and gas, food and beverage, pharmaceutical, shipbuilding, and wastewater management. From transferring aggressive fluids to handling cryogenics, Bornemann Pump's pumps are designed to meet the diverse requirements of these industries. The company's pumps ensure seamless handling of fluids, reduce downtime, and optimize energy consumption, thus enhancing overall operational efficiency.3. Twin Screw Pump Technology:One of the key innovations introduced by Bornemann Pump is the twin screw pump technology, which has revolutionized fluid transfer applications across industries. The company's twin screw pumps are capable of handling a wide range of fluid viscosities, making them ideal for transferring both low and high-viscosity liquids. This versatile pump technology ensures gentle product handling while delivering consistent and accurate flow rates.4. Hygienic Solutions for Food and Beverage Industry:Bornemann Pump's expertise in the food and beverage industry has resulted in the development of hygienic pump solutions. These pumps comply with stringent sanitary regulations and are designed to handle delicate fluids, ensuring the preservation of product quality, taste, and integrity. The company's hygienic pumps are widely used for transferring beverages, dairy products, sauces, and other food items without compromising on safety and cleanliness.5. Eco-Friendly Solutions for Wastewater Management:With the growing focus on environmental sustainability, Bornemann Pump has ventured into providing eco-friendly solutions for wastewater management. The company's progressive cavity pumps are designed to efficiently handle sewage and sludge, reducing energy consumption and minimizing environmental impact. Bornemann Pump's wastewater management solutions offer reliable performance, enhanced longevity, and reduced maintenance, making them ideal for both municipal and industrial applications.6. Continuous Research and Development:Bornemann Pump prides itself on its continued investment in research and development to meet the evolving demands of the industry. The company's dedicated team of engineers and technicians collaborate with leading scientific institutions to explore new avenues for pump technology. By incorporating state-of-the-art materials and advanced manufacturing techniques, Bornemann Pump ensures that its products remain at the forefront of innovation and deliver exceptional performance.Conclusion:Bornemann Pump's relentless pursuit of excellence has positioned the company as a frontrunner in the global pumping industry. With its advanced pump technologies and commitment to customer satisfaction, the company has successfully catered to the diverse needs of various industries, enabling seamless operations and improved productivity. As Bornemann Pump continues to innovate and refine its products, it will undoubtedly play an instrumental role in shaping the future of industrial and municipal applications worldwide.

High-quality and Efficient Screw Pump: Everything You Need to Know

The 3-Screw Pump: Revolutionizing the Pump IndustryIntroduction: [Company Name] has been a leader in the manufacturing and distribution of industrial pumps for over two decades. With a focus on technology, innovation, and customer satisfaction, [Company Name] has become a trusted name in the pump industry. Today, we are proud to introduce our latest innovation, the 3-Screw Pump, which is set to revolutionize the way pumping systems operate.The 3-Screw Pump is a state-of-the-art, high-performance pump that offers unparalleled efficiency, reliability, and versatility. Its unique design and advanced technology make it suitable for a wide range of applications, including oil and gas, marine, power generation, and chemical processing. With its compact size, high flow rates, and low noise levels, the 3-Screw Pump is a game-changer in the pump industry.The key features of the 3-Screw Pump include:1. High Efficiency: The 3-Screw Pump is designed to deliver high flow rates with minimal energy consumption. Its precision-engineered screw mechanism ensures smooth and efficient operation, resulting in significant cost savings for the end user.2. Reliability: With its robust construction and advanced sealing technology, the 3-Screw Pump offers unmatched reliability and durability. It can handle high-pressure and high-temperature applications with ease, making it an ideal choice for demanding industrial environments.3. Versatility: The 3-Screw Pump is suitable for a wide range of fluids, including lubricating oils, hydraulic fluids, and fuel oils. Its ability to handle various viscosities and temperatures makes it a versatile solution for diverse pumping requirements.4. Compact Design: The compact and space-saving design of the 3-Screw Pump makes it easy to install and integrate into existing pumping systems. Its low noise levels and minimal vibration further enhance its appeal for industrial applications.In addition to these key features, the 3-Screw Pump also incorporates advanced monitoring and control systems, making it easy to operate and maintain. Its user-friendly interface and compatibility with digital control systems ensure seamless integration into modern industrial processes.The launch of the 3-Screw Pump reinforces [Company Name]'s commitment to innovation and technological excellence. It is the result of our extensive research and development efforts, combined with our deep understanding of the needs and challenges faced by industries that rely on high-performance pumping systems. We are confident that the 3-Screw Pump will set a new benchmark for efficiency, reliability, and performance in the pump industry.To ensure the successful adoption of the 3-Screw Pump, [Company Name] is offering comprehensive technical support and after-sales service. Our team of experienced engineers and technicians is available to assist customers with installation, commissioning, and maintenance, ensuring that the 3-Screw Pump delivers optimal performance throughout its operational life.In conclusion, the 3-Screw Pump represents a significant advancement in pump technology, offering a compelling solution for industries that demand high-performance pumping systems. With its focus on efficiency, reliability, and versatility, the 3-Screw Pump is poised to make a lasting impact on the pump industry. [Company Name] is excited to bring this innovative product to market and looks forward to supporting our customers in harnessing the full potential of the 3-Screw Pump.

Professional Heat Pump Repair Services for Your Home

Heat Pump Repairs - Keeping Your Home Comfortable All Year RoundAs the seasons change and temperatures fluctuate, it's essential to ensure that your home's heating and cooling systems are in prime condition. One of the most popular and efficient methods for maintaining a comfortable temperature in your home is through the use of heat pumps. These devices are designed to transfer heat from one area to another, providing warmth during the winter months and cooling during the summer.For homeowners who rely on heat pumps to maintain a comfortable indoor climate, it's essential to have a trusted and reliable repair service on hand. That's where we come in. With years of experience and a team of highly skilled technicians, we are dedicated to providing top-notch heat pump repair services.Our company, with its strong commitment to customer satisfaction and quality workmanship, has earned a reputation for being a leader in the heating and cooling industry. We understand the importance of having a functioning heat pump, and we strive to deliver prompt and efficient repairs to keep our customers' homes comfortable all year round.When it comes to heat pump repairs, our technicians are trained to handle a wide range of issues, from minor malfunctions to major system failures. We take pride in our ability to diagnose problems quickly and accurately, providing our customers with effective solutions that are tailored to their specific needs.In addition to our repair services, we also offer maintenance and tune-up packages to help prevent costly breakdowns and keep heat pumps operating at peak performance. By scheduling regular maintenance appointments with our team, homeowners can extend the lifespan of their heat pumps and ensure that they are always running efficiently.Furthermore, we understand that emergencies can happen at any time, which is why we offer 24/7 emergency repair services. Our customers can rest easy knowing that we are always just a phone call away, ready to provide swift and reliable assistance whenever they need it.We take great pride in being a trusted partner for homeowners in need of heat pump repairs. Our commitment to excellence, combined with our extensive knowledge and expertise, sets us apart as a top choice for heating and cooling services. Whether it's a minor repair or a major system overhaul, our team is dedicated to delivering exceptional results that exceed our customers' expectations.In conclusion, when it comes to keeping your home comfortable all year round, having a reliable heat pump repair service is essential. Our company, with its dedication to customer satisfaction and top-notch workmanship, is proud to be a leading provider of heating and cooling services. With our team of skilled technicians and commitment to excellence, homeowners can trust us to keep their heat pumps running smoothly and efficiently. Contact us today for all of your heat pump repair needs, and experience the difference that our expertise and dedication can make in keeping your home comfortable.

New Gas Pump Technology Promises More Fuel Efficiency and Faster Refueling

CTP Pump, leading supplier of industrial pumps and equipment, has announced an expansion of their product line to meet the growing demand for innovative and efficient pumping solutions in the manufacturing and processing industries.With a focus on providing high-quality and reliable products, CTP Pump has been a trusted supplier to a wide range of industries for over 30 years. The company offers a comprehensive range of pumping solutions, including centrifugal pumps, diaphragm pumps, and gear pumps, as well as a variety of accessories and components to meet the specific needs of their customers.In response to the increasing demand for advanced pumping technology, CTP Pump has introduced a new line of innovative and efficient pumps that are designed to improve performance, reduce energy consumption, and lower operating costs. These new products have been developed in collaboration with leading industry experts and are backed by extensive research and development to ensure they meet the highest standards of quality and reliability.The new product line includes a range of high-efficiency centrifugal pumps that are designed to deliver superior performance and energy savings. These pumps are equipped with state-of-the-art technology, such as advanced impeller designs and precision-engineered components, to provide optimal flow rates and pressure levels while minimizing maintenance requirements and downtime.In addition to centrifugal pumps, CTP Pump has also expanded their portfolio to include a new series of diaphragm pumps that are specifically designed to handle a wide range of fluids, including corrosive and abrasive materials. These pumps feature a rugged and durable construction, as well as innovative diaphragm designs that ensure reliable and consistent performance in the most demanding applications.Furthermore, CTP Pump has introduced a new line of gear pumps that are engineered for efficient and reliable operation in a variety of industrial and commercial settings. These pumps are designed to deliver precise and consistent flow rates, as well as high levels of durability and longevity to meet the needs of their customers.As a leading supplier of industrial pumps and equipment, CTP Pump is committed to providing comprehensive solutions to help their customers improve their operational efficiency and productivity. The company's team of experienced engineers and technicians are available to support their customers throughout every step of the pump selection, installation, and maintenance process.In addition to their extensive product line, CTP Pump offers a variety of services, including technical support, maintenance and repair, and customized pumping solutions to meet the specific needs of their customers.With the introduction of their new product line, CTP Pump is poised to further strengthen their position as a trusted provider of innovative and efficient pumping solutions for the manufacturing and processing industries. The company's commitment to quality, reliability, and customer satisfaction makes them the preferred choice for businesses looking to enhance their pumping operations.For more information about CTP Pump and their range of industrial pumping solutions, visit their website or contact their sales team to discuss specific requirements and learn more about the benefits of their new product line.

High-quality industrial pumps: What you need to know

Bornemann Pump, a leading provider of high-quality industrial pumps, recently announced the launch of a new line of cutting-edge pumps designed to meet the unique needs of various industries. With a focus on innovation and customer satisfaction, Bornemann Pump has established itself as a trusted partner for companies seeking reliable and efficient pumping solutions.The new pump series, which includes models for a wide range of applications, incorporates the latest technological advancements to deliver superior performance and durability. Built with precision engineering and high-quality materials, these pumps are designed to withstand the most demanding operating conditions while maintaining optimal efficiency.Bornemann Pump has a long history of developing innovative pumping solutions for industries such as oil and gas, chemical processing, food and beverage, and pharmaceuticals. The company's commitment to understanding the specific requirements of each industry has enabled it to develop pumps that not only meet but exceed the expectations of its customers.In addition to its cutting-edge product line, Bornemann Pump offers a comprehensive range of services to support its customers throughout the entire lifecycle of their pumping systems. From initial consultation and design to installation, maintenance, and technical support, the company provides a full suite of solutions to ensure the seamless operation of its pumps.Bornemann Pump's customer-centric approach is underscored by its dedication to providing personalized support and expertise. Its team of highly skilled engineers and technicians work closely with customers to understand their unique challenges and develop customized pumping solutions that address their specific needs.The company's industry-leading expertise and commitment to quality have earned it a reputation for excellence in the pumping industry. Its pumps are renowned for their reliability, efficiency, and longevity, making them the preferred choice for businesses looking to enhance their operational efficiency and minimize downtime.With a global network of sales and service centers, Bornemann Pump is well-positioned to serve a diverse range of industries around the world. Its extensive reach enables the company to provide timely and efficient support to its customers, ensuring that their pumping systems operate at peak performance at all times.As Bornemann Pump continues to push the boundaries of pumping technology, it remains dedicated to delivering innovative solutions that empower its customers to achieve their business objectives. The company's ongoing investment in research and development reaffirms its commitment to staying at the forefront of the industry and delivering state-of-the-art pumping solutions that redefine industry standards.In conclusion, Bornemann Pump's latest line of cutting-edge pumps is a testament to the company's unwavering commitment to innovation and excellence. With a focus on meeting the unique needs of its customers and delivering superior pumping solutions, Bornemann Pump continues to set the bar for quality and reliability in the industry. Whether it's in oil and gas, chemical processing, food and beverage, or pharmaceuticals, businesses can trust Bornemann Pump to provide the most advanced pumping solutions to meet their needs.