Top Pump Manufacturer Announces New Product Line

By:Admin

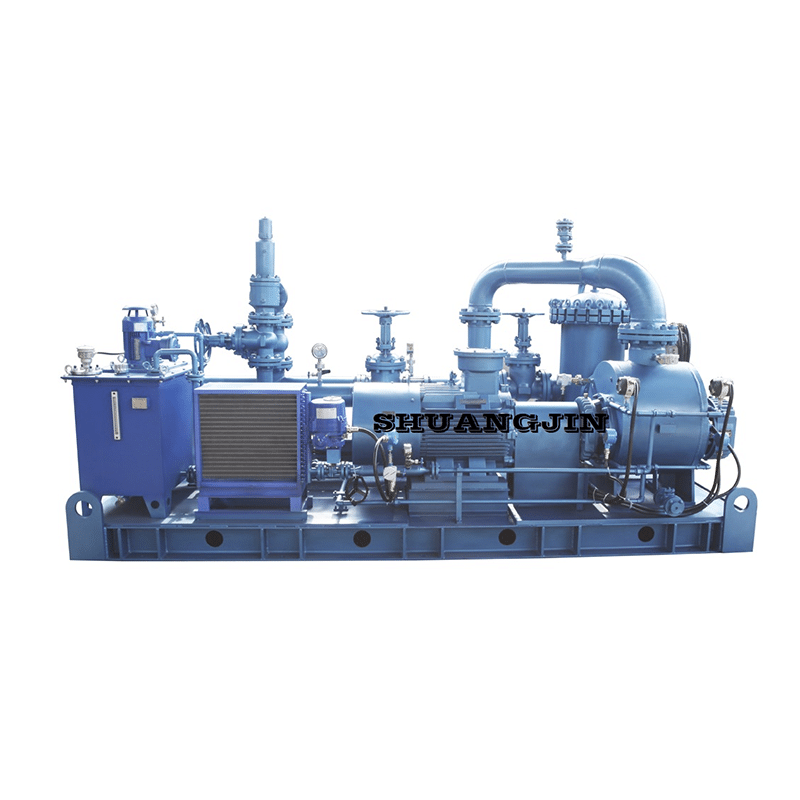

The company, with a history dating back to [year of establishment], has gained a strong reputation for its high-quality products and exceptional customer service. [Company Name] offers a wide range of industrial pumps, including centrifugal pumps, screw pumps, and gear pumps, catering to various industries such as oil and gas, chemical, maritime, and power generation.

One of the highlights of [Company Name]'s product portfolio is its innovative screw pumps, which are designed to handle challenging fluid handling applications with ease. These screw pumps are known for their reliability, efficiency, and low maintenance requirements, making them a popular choice among industrial operators.

In addition to its impressive product line, [Company Name] also prides itself on its commitment to sustainability and environmental responsibility. The company has been investing in research and development to create energy-efficient pump solutions that minimize environmental impact while maximizing performance.

Furthermore, [Company Name] has been focusing on digitalization and smart technologies to enhance the capabilities of its pumps. By integrating advanced monitoring and control systems, the company's pumps are able to provide real-time data and insights, enabling operators to optimize their processes and reduce downtime.

It's within this context of innovation and commitment to excellence that [Company Name] introduces its latest addition to the market – the new generation of screw pumps, which is set to revolutionize fluid handling operations. Developed in response to the increasing demand for reliable and efficient pumps, these new screw pumps are designed to deliver superior performance while reducing operational costs.

One of the key features of the new generation of screw pumps is their advanced design, which includes optimized screw profiles, improved sealing systems, and enhanced bearing arrangements. These design elements work together to minimize internal leakage, reduce wear and tear, and increase overall pump efficiency.

Furthermore, the new screw pumps are equipped with state-of-the-art control and monitoring systems, allowing for remote monitoring, predictive maintenance, and real-time performance optimization. This level of connectivity and intelligence enables operators to stay ahead of potential issues and make informed decisions to improve their processes.

The launch of the new generation of screw pumps underscores [Company Name]'s ongoing commitment to providing cutting-edge solutions that address the evolving needs of the industrial pump market. By leveraging its expertise in pump technology and its dedication to innovation, the company aims to set new standards for performance, reliability, and sustainability in fluid handling operations.

In addition to the new screw pumps, [Company Name] is also ramping up its efforts in aftermarket services, including maintenance, spares, and technical support. With a global network of service centers and highly trained professionals, the company is well-positioned to provide comprehensive support to its customers, ensuring maximum uptime and operational efficiency.

As the industrial pump market continues to grow, [Company Name] remains a key player at the forefront of industry trends and technological advancements. With its commitment to excellence, sustainability, and customer satisfaction, the company is poised to make significant contributions to the future of fluid handling operations worldwide.

Company News & Blog

Durable and Efficient Twin Screw Pump for Various Industrial Applications

Fristam Twin Screw Pump has recently introduced a new and innovative solution to meet the growing demand for efficient pumping systems in various industries. With a focus on reliability, performance, and ease of maintenance, this new pump is set to revolutionize the way companies handle their fluid transfer needs.The Fristam Twin Screw Pump is designed to handle a wide range of applications, including food and beverage, pharmaceutical, chemical, and personal care, among others. Its unique design allows for gentle product handling, making it suitable for delicate or shear-sensitive products. With its high efficiency and low pulsation characteristics, this pump is ideal for applications where product integrity is crucial.One of the key features of the Fristam Twin Screw Pump is its ability to handle both low and high viscosity products with ease. This versatility makes it a valuable asset for companies dealing with a variety of different substances. Additionally, its hygienic design and ease of cleaning make it compliant with the strict regulations and standards of the food and pharmaceutical industries.In addition to its impressive performance capabilities, the Fristam Twin Screw Pump is also designed with maintenance in mind. The pump is easy to disassemble and reassemble, reducing downtime and lowering the overall cost of ownership. This feature is especially important for companies looking to maximize their operational efficiency and minimize unnecessary expenses.Furthermore, the Fristam Twin Screw Pump is built to last, with a durable construction that can withstand the demands of continuous use. Its robust design and high-quality materials ensure that it can operate reliably for extended periods, providing companies with peace of mind and confidence in their pumping capabilities.With the introduction of the Fristam Twin Screw Pump, the company continues to solidify its position as a leading provider of pumping solutions for various industries. The pump is a testament to the company's commitment to innovation and excellence, and it is expected to make a significant impact in the market.In summary, the launch of the Fristam Twin Screw Pump represents a major milestone for the company and its customers. With its impressive performance, versatile capabilities, and ease of maintenance, this pump is set to become a valuable asset for companies across a wide range of industries. As the demand for efficient and reliable pumping systems continues to grow, the Fristam Twin Screw Pump is well-positioned to meet and exceed the expectations of its users.

Top Industrial Valves for Your Business Needs

Industrial Valves Celebrates 50 Years of Excellence in the Manufacturing IndustryIndustrial Valves is proud to announce that it is celebrating its 50th anniversary in the manufacturing industry. The company, which was established in 1971, has spent the last five decades providing high-quality valves and other industrial products to a wide range of customers across the globe.From its humble beginnings as a small workshop, Industrial Valves has grown to become a leading manufacturer in the industry, thanks to its dedication to quality, innovation, and customer satisfaction. The company's success can be attributed to its experienced team of engineers, technicians, and support staff, who work tirelessly to ensure that every product meets the highest standards of performance and reliability.Industrial Valves specializes in the design, manufacturing, and distribution of a wide range of industrial valves, including ball valves, gate valves, globe valves, check valves, and butterfly valves. These valves are used in various industries, such as oil and gas, petrochemical, power generation, water treatment, and many others. The company also offers customized solutions to meet the specific needs of its customers, ensuring that they receive the best possible products for their applications.One of the key factors that set Industrial Valves apart from its competitors is its commitment to innovation. The company invests heavily in research and development, constantly seeking new ways to improve its products and processes. This has led to the development of cutting-edge technologies that have helped the company stay ahead of the curve in an increasingly competitive market.In addition to its dedication to quality and innovation, Industrial Valves also places a strong emphasis on customer satisfaction. The company understands the importance of building strong relationships with its clients, and it works closely with them to ensure that their needs are met in a timely and efficient manner. This approach has earned Industrial Valves a reputation for reliability and trustworthiness, making it a preferred supplier for many companies around the world.As Industrial Valves celebrates its 50th anniversary, the company is looking towards the future with optimism. It plans to continue its legacy of excellence by expanding its product range, entering new markets, and embracing the latest technologies. The company also aims to strengthen its position as a global leader in the manufacturing industry, while maintaining its core values of quality, innovation, and customer satisfaction.To commemorate this milestone, Industrial Valves is planning a series of events and initiatives throughout the year. These include special promotions, industry conferences, and charity events, all aimed at celebrating the company's achievements and expressing gratitude to its customers, employees, and partners for their continued support over the years."We are incredibly proud to reach this significant milestone in our company's history," said [company representative]. "It is a testament to the hard work and dedication of our team, as well as the trust and support of our customers. As we look to the future, we are excited about the opportunities that lie ahead and are committed to maintaining our position as a leader in the manufacturing industry."With 50 years of experience behind it, Industrial Valves is well-positioned to continue its success for many years to come. The company's dedication to quality, innovation, and customer satisfaction has set it apart in the industry, and it will undoubtedly continue to be a trusted partner for businesses around the world.

Effective Maintenance Tips for Screw Pumps

Title: Expert Tips for Screw Pump MaintenanceIntroduction:Screw pumps are vital components in a wide range of industries, including oil and gas, petrochemicals, wastewater treatment, and food processing, among others. These pumps play a crucial role in ensuring the smooth flow of liquids or semi-solid materials in various industrial processes. However, like any other mechanical equipment, regular maintenance is essential to keep screw pumps operating at optimal efficiency.In this article, we will discuss expert tips for screw pump maintenance, utilizing our industry knowledge and experience to provide valuable insights. Our aim is to help businesses maximize their operational efficiency, reduce downtime, and extend the lifespan of screw pumps, ultimately saving costs in the long run.Understanding Screw Pump Components:Before delving into maintenance procedures, it is essential to have a basic understanding of screw pump components. Screw pumps typically consist of three main parts:1. Rotors: These are the primary moving components responsible for transferring fluid. Two or more rotors with intermeshing threads create a sealed cavity that moves fluid from the pump's inlet to its outlet.2. Stator: The fixed component surrounding the rotors, the stator provides a tight seal to prevent leakage and assists in fluid movement.3. Housing: The casing that encloses the rotors and stators, ensuring a secure and stable operation.Expert Tips for Screw Pump Maintenance:1. Regular Inspection and Cleaning: - Schedule routine inspections to identify signs of wear, damage, or leakage in the pump and its parts. - Clean the pump regularly by flushing it with an appropriate cleaning agent to remove any accumulated debris or contaminants.2. Lubrication: - Ensure the rotor and stator are adequately lubricated to reduce friction, heat, and wear. - Use compatible lubricants recommended by the pump manufacturer for optimal performance.3. Shaft Alignment: - Misalignment can cause undue stress on the pump's components, leading to premature failure. - Regularly check and correct any misalignment issues to maintain smooth operation.4. Sealing System: - Inspect and replace worn or damaged seals regularly to prevent fluid leakage, ensuring efficient pump performance. - Utilize high-quality, chemical-resistant seals suitable for the specific fluid being pumped.5. Temperature and Vibration Monitoring: - Monitor the pump's operating temperature and vibrations using appropriate sensors. - Abnormal readings can indicate potential issues, such as overheating or mechanical imbalance, requiring immediate attention.6. Regular Bearing Maintenance: - Lubricate bearings as per the manufacturer's guidelines to minimize friction and prevent premature wear. - Monitor bearing condition and replace if signs of damage or deterioration are evident.7. Overload Protection: - Install overload protection devices to safeguard the pump against excessive loads, preventing potential damage.8. Spare Parts Inventory: - Maintain a stock of essential spare parts to minimize downtime in the event of failure or breakdown. - Consult with product experts to identify critical components that require immediate replacement availability.By following these expert tips, businesses can optimize the performance and longevity of their screw pumps, ensuring uninterrupted operation and maximizing efficiency.Company Introduction: {Insert company introduction here}Conclusion:Proactive maintenance of screw pumps is crucial for businesses relying on these mechanical systems to achieve smooth operations in various industries. Regular inspection, cleaning, lubrication, and addressing misalignment are just a few essential maintenance practices to keep screw pumps in optimal condition. Following these expert tips and leveraging the knowledge and experience of the company would assist businesses in reducing downtime, minimizing repairs, and extending the lifespan of their screw pumps, ultimately leading to increased operational and cost efficiencies.

Efficiently Regulate Heat Pumps with Advanced Control Systems

Heat Pump Control: Transforming the Heating IndustryThe heating industry is transforming, and Heat Pump Control is at the forefront of this change. They are a leading manufacturer and supplier of high-quality heat pumps and controllers that are widely used in domestic, industrial, and commercial heating applications. Heat Pump Control is dedicated to producing innovative products that help homeowners and businesses improve their energy efficiency while reducing their carbon footprint.Heat Pump Control has been serving the heating industry for over a decade and has gained a reputation as a reliable and trustworthy supplier of heat pumps and controllers. Their products are designed to meet the needs of a wide range of clients, including homeowners, businesses, and industrial facilities. They also have a team of skilled technicians who are on hand to offer installation, repair, and maintenance services.One of the key features of Heat Pump Control's products is their energy efficiency. Heat pumps are known for being highly efficient, but the controllers developed by Heat Pump Control take this to the next level. Their controllers are designed to optimize the performance of their heat pumps, reducing energy consumption and enhancing overall efficiency. This means that clients can save money on their energy bills while still enjoying a comfortable living or working environment.Another important feature of Heat Pump Control's products is their versatility. They offer a range of heat pumps and controllers that cater to different applications, from small domestic installations to large industrial facilities. Their products are designed to be highly adaptable and can be customized to meet the specific needs of each client. This means that Heat Pump Control can provide solutions for a wide range of heating requirements, from single-family homes to large commercial buildings.One area where Heat Pump Control is particularly innovative is in their use of smart technology. Their controllers are designed to be fully integrated with smart home and smart building systems, allowing clients to control their heating remotely and make adjustments based on their individual preferences. This not only improves convenience but also allows for greater energy savings since clients can adjust their heating settings to suit their needs.Heat Pump Control is also committed to sustainability and reducing the carbon footprint of its products. They are constantly exploring ways to minimize the environmental impact of their products and manufacturing processes. Their heat pumps are designed to use renewable energy sources such as air and ground, which reduces the amount of non-renewable energy needed to heat homes and businesses. This approach helps clients reduce their carbon footprint and contribute to a more sustainable future.In conclusion, Heat Pump Control is a forward-thinking manufacturer and supplier of heat pumps and controllers that are transforming the heating industry. Their products are highly efficient, versatile, and adaptable, making them suitable for a wide range of applications. They also prioritize sustainability and the use of smart technology to deliver the latest innovations in the heating industry. With Heat Pump Control, clients can enjoy quality heating solutions that are designed to improve energy efficiency and reduce their carbon footprint.

High-Quality Pumps for Efficient Fluid Transfer: What You Need to Know

Mono Pump, a leading manufacturer of industrial pumps, has recently announced the launch of their latest innovation in pump technology. The new pump is designed to revolutionize the industry with its advanced features and state-of-the-art design.With over 80 years of experience in the pump manufacturing industry, Mono Pump has established itself as a trusted and reliable provider of high-quality pumps for a wide range of industrial applications. The company’s commitment to innovation and excellence has made them a preferred choice for customers worldwide.The new pump, which has been in development for several years, represents a significant advancement in pump technology. It features a unique design that allows for increased efficiency and reliability, making it an ideal solution for demanding industrial applications.One of the key features of the new pump is its improved performance capabilities. With a higher flow rate and increased pressure capabilities, the pump is able to handle even the most challenging pumping tasks with ease. This will significantly improve productivity and efficiency for businesses that rely on industrial pumps for their operations.In addition to its performance capabilities, the new pump also boasts a number of advanced features that set it apart from other pumps on the market. These include enhanced durability, reduced maintenance requirements, and improved energy efficiency. These features make the pump a cost-effective and sustainable solution for businesses looking to optimize their pumping operations.Another notable aspect of the new pump is its versatility. It is designed to handle a wide range of fluids, including abrasive and viscous materials, making it suitable for a variety of industrial applications. This flexibility makes the pump a valuable asset for businesses operating in diverse industries.The launch of the new pump is a reflection of Mono Pump’s ongoing commitment to innovation and customer satisfaction. The company has invested heavily in research and development to create a product that meets the evolving needs of the industry. By listening to customer feedback and staying abreast of the latest technological advancements, Mono Pump has been able to stay at the forefront of the pump manufacturing industry.In addition to their cutting-edge products, Mono Pump also offers a range of services to support their customers. This includes pump installation, maintenance, and repair services, as well as technical support and training. This comprehensive approach to customer service has helped the company build strong and lasting relationships with their clients.As the demand for efficient and reliable industrial pumps continues to grow, Mono Pump remains committed to meeting this need. Their latest innovation is set to raise the bar for pump technology, offering a solution that delivers on performance, durability, and sustainability. With a solid reputation and a track record of success, Mono Pump is well positioned to lead the way in the industry for years to come.

High-Performance Pump System Innovates Water Management Solutions

Pcm Pump, a renowned global leader in providing pumping solutions, has come up with an innovative product to meet the ever-growing demands of the industry. The company has introduced a state-of-the-art pump that promises to revolutionize the pumping industry by delivering superior performance, reliability, and efficiency.Pcm Pump has been a trusted name in the pumping industry for over several decades. The company has a rich heritage of providing cutting-edge pumping solutions to a wide range of industries including oil and gas, food and beverage, mining, wastewater, and many others. With a strong focus on innovation and customer satisfaction, Pcm Pump has established itself as a market leader in the pumping industry.The latest product from Pcm Pump is a result of extensive research, development, and engineering expertise of the company. The new pump is designed to address the key challenges faced by the industry such as increasing demand for higher flow rates, improved energy efficiency, and reduced maintenance downtime. The pump features advanced technology and robust construction, making it suitable for a wide range of applications in diverse industries.One of the key highlights of the new pump is its superior performance. The pump is designed to deliver high flow rates and exceptional efficiency, making it an ideal choice for critical pumping applications. With its advanced design and engineering, the pump ensures reliable and consistent performance, even in the most demanding operating conditions. This ensures that the customers can rely on the pump for uninterrupted operations and maximum productivity.In addition to performance, the new pump also offers unmatched reliability. Pcm Pump understands the importance of reliability in critical pumping applications, and hence, the new pump is built to withstand the toughest operating conditions. The pump is constructed using high-quality materials and precision engineering, making it highly durable and dependable. This means that the customers can count on the pump to deliver consistent performance, day in and day out.Energy efficiency is another key focus area for Pcm Pump, and the new pump is designed with this in mind. The pump is equipped with advanced technology to minimize energy consumption while maximizing pumping efficiency. This not only helps in reducing operating costs but also contributes to environmental sustainability. With the new pump, customers can expect to achieve significant energy savings without compromising on performance.Furthermore, the new pump is designed for ease of maintenance, reducing downtime and operational costs for the customers. Pcm Pump has incorporated innovative features in the pump to facilitate easy maintenance and servicing, ensuring that the pump remains in top condition and delivers optimal performance throughout its service life.The introduction of this innovative pump further cements Pcm Pump's position as a leading provider of pumping solutions. The company's commitment to innovation, quality, and customer satisfaction is evident in the new product, which is set to raise the bar in the pumping industry.With its superior performance, reliability, efficiency, and ease of maintenance, the new pump from Pcm Pump is poised to make a significant impact in the industry. The company is confident that the new product will meet the evolving needs of the industry and set new benchmarks for pumping solutions.As Pcm Pump continues to push the boundaries of pumping technology, the new pump is a testament to the company's dedication to excellence and innovation. With its rich legacy and expertise in the pumping industry, Pcm Pump is well positioned to lead the way in delivering advanced pumping solutions to its customers around the world.

Screw Pump Diagram: A Detailed Guide to Understanding How Screw Pumps Work

Screw Pump DiagramScrew pumps are a crucial component in a variety of industries, including oil and gas, water treatment, and food and beverage. They are used to move liquids or slurries and are known for their reliability and efficiency. One company at the forefront of screw pump technology is {}. Their innovative designs and high-quality products have made them a leading supplier in the industry.Screw pumps, also known as progressive cavity pumps, work by using a screw-shaped rotor to move fluid through the pump. As the rotor turns, it creates a series of small chambers between the screw and the pump housing. These chambers trap the fluid and move it along the length of the screw before releasing it at the outlet. This design allows for a smooth and consistent flow of fluid, making screw pumps ideal for applications where precise and continuous pumping is necessary.{} has been a key player in the screw pump industry for over 30 years. The company prides itself on its commitment to innovation and customer satisfaction. Their team of engineers and technical experts are constantly working to improve their products and develop new technologies to meet the evolving needs of their clients. With a focus on quality and reliability, {} has built a reputation for excellence in the industry.One of the key features of {}'s screw pump design is its ability to handle a wide range of viscosities and fluid types. Whether it's thick sludge in a wastewater treatment plant or high-viscosity crude oil in a refinery, their pumps are designed to deliver consistent performance and efficiency. This versatility makes {}'s screw pumps an attractive choice for a variety of industries and applications.In addition to their standard product line, {} also offers customized solutions to meet the specific needs of their clients. They work closely with customers to understand their requirements and develop tailored pump systems that deliver optimal performance and reliability. This dedication to customer service has helped {} build long-lasting relationships with clients around the world.Another important aspect of {}'s screw pump technology is its focus on energy efficiency. By optimizing their pump designs and utilizing advanced materials, they have been able to reduce energy consumption and operational costs for their clients. This commitment to sustainability and cost-effectiveness has made {} a trusted partner in the industry.As the demand for screw pumps continues to grow, {} remains at the forefront of the industry. Their ongoing investment in research and development and dedication to quality and customer satisfaction set them apart in the market. With a global network of sales and service partners, {} is well-positioned to meet the needs of their clients wherever they may be.In conclusion, screw pumps play a critical role in a wide range of industries, and {} has established itself as a leading supplier in the industry. With a focus on innovation, quality, and customer satisfaction, they have earned a reputation for excellence in the market. As the demand for screw pumps continues to grow, {} is well-positioned to meet the needs of their clients and drive the industry forward with their advanced technology and superior products.

New Sanitary Screw Pump Introduced for Efficient and Hygienic Operations" Rewritten Title: "Efficient and Hygienic Sanitary Screw Pump Now Available for Purchase

Sanitary Screw Pump Solution Enhances Efficiency and Quality in Food and Beverage IndustryThe food and beverage industry is one of the largest and fastest-growing industries in the world. With increasing demand for high-quality products, efficient production processes, and food safety, manufacturers are under intense pressure to deliver products that meet the needs of consumers and regulators. In this context, sanitation, hygiene, and process efficiency are essential components of any food and beverage production process.One of the key components of a modern food and beverage processing system is the sanitary screw pump. Designed to handle delicate, viscous, and shear-sensitive products, these pumps are used to move food and beverage products from one place to another in a hygienic manner. They are also used to transfer industrial fluids, such as water, chemicals, and pharmaceuticals, in an efficient and safe manner.Sanitary screw pumps are designed to meet the strictest hygiene and safety standards in the food and beverage industry. They are made of FDA-approved materials such as stainless steel, and they have no seals, which reduces the risk of contamination and ensures that the purity of the product is maintained. Also, they are designed to be CIP (clean-in-place) and SIP (sterilize-in-place) compatible, which makes them easy to clean and sterilize.One of the leading companies that provide sanitary screw pumps and solutions for the food and beverage industry is {remove brand name}. Their expertise in design, engineering, and manufacturing of sanitary screw pumps has made them a trusted partner for many food and beverage processors around the world.At {remove brand name}, they offer a wide range of sanitary screw pumps that cater to the needs of different food and beverage manufacturers. They provide advanced solutions that enhance process efficiency, product quality, and safety. Some of the products they offer include Twin Screw Pumps, Hygienic Self Priming Pumps, and Centrifugal Pumps.Their Twin Screw Pumps are designed to handle a wide range of products, including chocolate, cream, fruit and vegetable purees, and sauces. Their compact design, low pulsation, and high flow rate make them an ideal solution for manufacturers that require fast and efficient product transfer.The Hygienic Self Priming Pumps offered by {remove brand name} are ideal for applications that require a high level of hygiene and safety. They are designed with a self-priming feature, which eliminates the need for a separate priming system. Also, they are easy to clean and maintain, which reduces downtime and improves productivity.In addition to their range of pumps, {remove brand name} provides comprehensive solutions that include engineering, installation, and maintenance services. Their team of experts works closely with clients to understand their needs and design solutions that meet their specific requirements. Also, they provide training, technical support, and after-sales services to ensure that clients get the most out of their products.Recently, {remove brand name} provided a sanitary screw pump solution for a leading food and beverage manufacturer in Asia. The manufacturer was facing challenges in transferring a delicate cream-based product from one tank to another without causing any damages to the product. They also needed a solution that could work efficiently and reduce downtime.After a thorough analysis of the manufacturer's needs and requirements, {remove brand name} designed and installed a Twin Screw Pump system that met their specific needs. The system was designed to handle the delicate cream-based product without causing any damages. Also, the system was easy to maintain, which reduced downtime and improved productivity.One of the key benefits of the solution provided by {remove brand name} was its ability to maintain the quality and integrity of the product. The Twin Screw Pump system ensured that the product was transferred in a hygienic and safe manner without any contamination. Also, the system was efficient and reduced energy consumption, which helped the manufacturer to reduce their operating costs.At {remove brand name}, they are committed to providing high-quality sanitary screw pumps and solutions that meet the needs of the food and beverage industry. Their expertise, experience, and dedication to customer service have made them a trusted partner for many food and beverage manufacturers around the world.

Discover the Distinctions Between Screw Pumps and Gear Pumps

Screw Pump and Gear Pump: Understanding the Differences in Pumping TechnologyPumping technology plays a crucial role in various industries, from manufacturing and oil and gas to wastewater treatment and food processing. For efficient and reliable pumping, two types of pumps that are often utilized are screw pumps and gear pumps. While both serve the purpose of moving fluids from one place to another, they differ in design and application. In this article, we will explore the differences between screw pumps and gear pumps.A screw pump, as the name suggests, operates by using rotating screws to move fluids from the inlet to the outlet. It consists of two or more intermeshing screws contained within a cylindrical or semi-cylindrical housing. The screws rotate in opposite directions, trapping the fluid between them and forcing it to move along the length of the screws. This type of pump is known for its gentle and smooth operation, making it ideal for handling shear-sensitive fluids or those containing small solids.On the other hand, a gear pump works by using two or more intermeshing gears to create a pumping action. The gears rotate in opposite directions, creating a partial vacuum at the inlet, which draws the fluid in, and then forces it out through the outlet. Gear pumps are characterized by their simplicity, compactness, and high-speed operation. They are commonly used for high-pressure applications, such as hydraulic systems, and for handling clean fluids with low viscosity.The key difference between these two types of pumps lies in their design and how they move fluids. Screw pumps use the rotating action of the screws to transport the fluid, while gear pumps rely on the intermeshing gears to create the necessary pumping action. This fundamental distinction affects the overall performance, efficiency, and suitability of each pump for specific applications.In terms of performance, screw pumps are known for their ability to handle viscous fluids and those with solids content. The continuous and smooth motion of the screws ensures minimal pulsations and provides a steady flow, making it suitable for applications where a consistent output is required. On the other hand, gear pumps excel in generating high-pressure output, making them ideal for applications that require pressurized fluid delivery. Their precise metering capabilities also make them suitable for applications that demand accurate flow control.When it comes to efficiency, screw pumps offer higher volumetric efficiencies compared to gear pumps. Due to their progressive cavity design, screw pumps can handle variable flow rates with minimal slip, ensuring a higher percentage of fluid is efficiently moved from the inlet to the outlet. Gear pumps, while generally less efficient, compensate with their compact size and ability to generate high pressure, making them suitable for space-constrained environments or applications with specific pressure requirements.In terms of application, screw pumps find extensive use in industries such as wastewater treatment, oil and gas, chemical processing, and food manufacturing. Their ability to handle high viscosity fluids, such as sludge, oil, and syrup, makes them suitable for these demanding environments. Gear pumps, on the other hand, are commonly employed in hydraulic systems, fuel transfer, lubrication systems, and various industrial processes that require high pressure and precise flow control.In conclusion, screw pumps and gear pumps are two distinct types of pumping technology, each with its own benefits and applications. Screw pumps offer gentle and steady fluid movement, making them well-suited for shear-sensitive fluids and those with solids content. Gear pumps, on the other hand, excel in generating high pressures and precise flow control, making them ideal for applications with specific pressure requirements. Understanding the differences between these two types of pumps can help industries make informed decisions when it comes to selecting the most suitable pumping technology for their specific needs.

Highly efficient centrifugal pumps revolutionizing industry operations

Centrifugal Pump Technology Boosts Efficiency and ProductivityIn today’s highly competitive world, businesses are clamoring for ways to improve their efficiency and productivity. One of the most often overlooked areas of improvement is in the realm of industrial pumps. Companies like [BRAND NAME REMOVED] are harnessing centrifugal pump technology to give businesses a powerful edge in their quest for increased output and profitability.Centrifugal pumps are well-known for their ability to transfer fluids from one location to another across different types of systems. They accomplish this through the use of a rotating impeller that is surrounded by a casing. As the impeller spins, it creates a force that pulls fluid in through the center of the pump, accelerates it, and then creates a high-pressure discharge at the outer circumference of the pump.This technology is incredibly versatile, utilized in a wide range of industries such as agriculture, mining, oil & gas, and water treatment. The reason centrifugal pumps are so popular is that they are reliable, efficient, energy-saving, and require minimal maintenance.[BRAND NAME REMOVED] understands the importance of this technology and has created a range of centrifugal pumps that are tailor-made for all kinds of industrial applications. Their pumps are manufactured using the highest-quality materials and the most advanced engineering techniques to provide optimal performance and durability.One of the company’s most successful products is the (REMOVED) Series Centrifugal Pump, which is designed to handle a wide range of fluids, including highly abrasive and corrosive liquids. The pump is also equipped with a sturdy bearing assembly and seals that are fully interchangeable with other leading brands, making it easy to integrate into existing systems.As a result of its highly efficient design, this centrifugal pump consumes less energy, which translates to significant cost savings for the user. Additionally, its compact size means it can be installed in tight spaces, a valuable feature for businesses looking to maximize their facility’s layout.Another innovative feature of the (REMOVED) Series Centrifugal Pump is its suction and discharge ports, which can be adjusted to eight different directions, making it ideal for tight installation spaces and versatile enough to be adapted to various system configurations.In summary, centrifugal pump technology is an indispensable tool for businesses that value reliability, efficiency, energy savings, and durability. [BRAND NAME REMOVED] understands this and has developed a line of pumps that can be tailored to any industrial application. With their commitment to quality and innovation, [BRAND NAME REMOVED] is an excellent choice for businesses looking for a competitive edge.