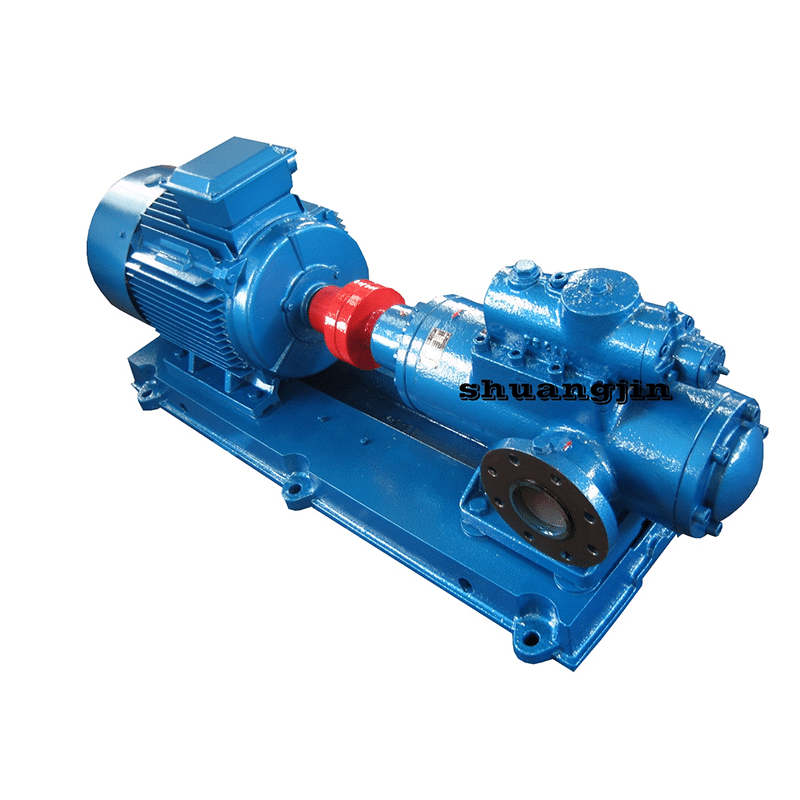

Worm Screw Pump: A Reliable and Efficient Solution for Industrial Applications

By:Admin

Introduction:

In the world of industrial pumping, technological advancements play a crucial role in improving efficiency, reducing costs, and enhancing productivity. Enter the innovative Worm Screw Pump, created by [Company Name], an industry-leading pump manufacturer.

[Company Name] is a renowned global company specializing in the development and production of high-performance pumping solutions. With years of experience and expertise, the company has successfully revolutionized the industry by introducing the state-of-the-art Worm Screw Pump.

Body:

1. Understanding the Worm Screw Pump:

The Worm Screw Pump, developed by [Company Name], is a groundbreaking solution specifically designed to address the challenges faced by various industries, including oil and gas, food and beverage, pharmaceuticals, and wastewater treatment, to name a few.

This highly efficient pump operates on the principle of positive displacement, utilizing a combination of a worm and screw to displace fluid. As fluid enters the pump, the rotating worm acts as a conveyor, propelling the fluid towards the discharge port with minimal pulsation.

2. Unparalleled Efficiency and Reliability:

One of the most remarkable features of the Worm Screw Pump is its unparalleled efficiency and reliability. By leveraging its unique design and advanced manufacturing techniques, [Company Name] has achieved a pump that offers outstanding performance levels and guarantees minimal maintenance requirements.

The worm and screw configuration ensures a smooth and continuous flow, preventing clogging and providing reliable operation even in challenging conditions. The pump's high precision and tight clearances contribute to excellent suction capabilities, making it an ideal choice for handling viscous, abrasive, and shear-sensitive fluids.

3. Wide Range of Applications:

The versatility of the Worm Screw Pump makes it suitable for a wide range of industrial applications.

In the oil and gas industry, the pump's ability to handle highly viscous materials, such as crude oil, asphalt, and drilling mud, ensures consistent and reliable extraction processes. Furthermore, its self-priming capabilities make it an indispensable component in offshore drilling platforms.

The food and beverage industry benefits from the Worm Screw Pump's gentle handling of delicate fluids, including creams, sauces, and syrups. Its hygienic design and easy-to-clean features are crucial in meeting strict industry regulations.

The pharmaceutical sector relies on the pump's accurate and precise flow control for the transportation of various pharmaceutical ingredients, such as creams, gels, and ointments. The pump's low-shear operation ensures the integrity of sensitive ingredients throughout the processes.

Moreover, in wastewater treatment plants, the Worm Screw Pump effectively handles sludge, rendering it an optimal choice for dewatering, thickening, and solid-liquid separation operations.

4. Advantages and Benefits:

The Worm Screw Pump offers numerous advantages and benefits:

a) High efficiency and low life-cycle costs: The pump's minimal maintenance requirements and long lifespan significantly reduce operational costs.

b) Versatile and adaptable: The pump can handle a wide range of fluids and viscosities, making it suitable for diverse industrial applications.

c) Improved safety and performance: The pump's robust construction and high precision guarantee safe and reliable operation even in harsh environments.

d) Compact and space-saving design: The Worm Screw Pump's compact footprint allows for easy installation, saving valuable floor space.

e) Enhanced environmental sustainability: The pump's efficient fluid displacement and low energy consumption contribute to a reduced carbon footprint.

Conclusion:

The innovative Worm Screw Pump, developed by [Company Name], represents a significant advancement in industrial pumping solutions. Its versatile capabilities, unparalleled efficiency, and reliability make it a game-changer in various industries, including oil and gas, food and beverage, pharmaceuticals, and wastewater treatment.

With its outstanding performance, low maintenance requirements, and ability to handle a wide range of fluid types, the Worm Screw Pump is poised to revolutionize the way industries approach fluid transportation systems.

Company News & Blog

Screw Pump Construction and Working: An In-Depth Guide to Understanding the Process

Screw Pump Construction And Working[Company Introduction][Company Name], a leader in the pump manufacturing industry, has recently introduced its latest innovation - a screw pump designed to revolutionize the fluid transportation industry. With decades of experience and expertise, [Company Name] takes pride in developing innovative solutions that cater to the specific needs of its clients across various sectors. [Company Name] has established itself as a reliable and trusted partner for industries such as oil and gas, chemical, power generation, and wastewater management. With a focus on quality, efficiency, and sustainability, the company strives to provide cutting-edge solutions that enhance productivity while minimizing environmental impact.[News Content]In line with [Company Name]'s commitment to innovation, the company has recently unveiled its latest screw pump, which promises to transform fluid transportation systems in various industries. Screw pumps are widely used in applications where the precise handling of liquids is critical, and [Company Name]'s new innovation represents a major advancement in this field.The construction of the screw pump plays a vital role in its efficient operation. The pump consists of a screw rotor and a closely fitting stator. The rotor consists of one or more helical screws, while the stator is typically made up of a rubber-lined metal shell with a helical profile. This design creates a series of enclosed cavities that progressively move the fluid from the suction end to the discharge end of the pump.What sets [Company Name]'s screw pump apart from its competitors is its meticulous attention to detail in the construction process. The screws and stator are manufactured with precision to ensure a tight fit that eliminates any potential leakage. This minimizes product loss, enhances efficiency, and reduces maintenance requirements. Furthermore, the use of high-quality materials guarantees the pump's durability and longevity even in the harshest operating conditions.The working principle of [Company Name]'s screw pump revolves around the rotational motion of the helical screws. As the rotor turns, the cavities formed between the screw threads progress along the stator, trapping the fluid and pushing it forward. This positive displacement ensures an efficient and consistent flow rate, even when handling viscous or abrasive fluids.The screw pump's unique design enables it to handle a wide range of fluids, including shear-sensitive substances and those containing solids. Its gentle pumping action prevents product deterioration or damage, making it ideal for delicate procedures in industries such as food and beverage, pharmaceuticals, and cosmetics.In addition to its versatility, [Company Name]'s screw pump also offers significant energy savings. With its efficient design and minimal internal losses, the pump requires lower power consumption compared to conventional solutions. This not only reduces operational costs but also contributes to a sustainable future by conserving energy resources.Furthermore, the screw pump is designed with ease of maintenance in mind. Its simple yet robust construction allows for easy disassembly and access to internal components, facilitating quick repairs and servicing. This reduces downtime and ensures that operations can resume promptly, minimizing any potential financial losses for businesses.With its commitment to continuous improvement and innovation, [Company Name] is setting new standards in the pump manufacturing industry. The recently introduced screw pump showcases the company's dedication to providing high-quality, efficient, and sustainable solutions for fluid transportation in various industries. With its superior construction and working principle, this innovative pump promises to revolutionize the way liquids are handled and transported, offering unprecedented reliability and performance.As [Company Name] continues to push the boundaries of pump technology, its customers can look forward to further advancements that will drive efficiency, productivity, and sustainability in fluid transportation systems worldwide.

Screw Pump vs Gear Pump: Understanding the Key Differences

Title: Understanding the Differences Between Screw Pumps and Gear Pumps: A Closer Look at Pumping TechnologiesIntroduction:In the world of fluid transfer and pumping technologies, two commonly used pump types are screw pumps and gear pumps. Both these pumps play a crucial role in various industries, including oil and gas, chemical, food processing, and many others. However, understanding the differences between screw pumps and gear pumps is vital in order to determine the most suitable option for specific applications. This article aims to shed light on these differences, highlighting the unique features and advantages of each pumping technology.Screw Pumps:Screw pumps, also known as progressive cavity pumps, operate based on the principle of displacement. They consist of two main components – a helical rotor and a stator. The rotor, often in the shape of a screw, rotates within the stator, resulting in the transfer of fluids from the suction side to the discharge side.Screw pumps are recognized for their ability to handle highly viscous fluids, including heavy oils, sludge, and slurries. Their design features enable them to generate a smooth, non-pulsating flow, making them suitable for applications requiring precise control over fluid transfer. Furthermore, screw pumps exhibit low shear rates, making them ideal for handling shear-sensitive materials without damaging their integrity.One key advantage of screw pumps is their self-priming capability. They can effectively handle fluids with entrained air or gas, eliminating the need for additional priming mechanisms. Screw pumps also showcase excellent suction lift capability, enabling efficient pumping even when the fluid source is located below the pump.Gear Pumps:Gear pumps, on the other hand, utilize rotating gears to transfer fluids. They consist of two meshing gears – a drive gear and a driven gear. As the gears rotate, liquid is drawn into the pump and pushed through the outlet. Gear pumps are widely used in various industries due to their simplicity, compact size, and high efficiency.Gear pumps excel in applications requiring high flow rates and moderate pressures. Their smooth operation allows for noiseless performance, making them suitable for applications where noise reduction is essential. Additionally, gear pumps can handle clean fluids, as well as fluids containing small particulate matter without clogging or damage to the gears.One of the key advantages of gear pumps is their ability to provide consistent flow, even under varying pressures. This makes them ideal for applications where stable pressure levels are critical. Another noteworthy feature is their ability to operate efficiently over a wide range of viscosities, allowing flexibility in fluid transfer applications.Conclusion:In conclusion, understanding the differences between screw pumps and gear pumps is pivotal in selecting the appropriate pumping technology for specific industrial applications. Screw pumps are best suited for handling highly viscous fluids and shear-sensitive materials, offering self-priming capability and low shear rates. On the other hand, gear pumps excel in high flow rate applications, offering consistent flow even under varying pressures and versatility across a wide range of viscosities.As industries continue to advance, the demand for efficient fluid transfer technologies will persist. Both screw pumps and gear pumps provide reliable solutions, each with their unique set of advantages. It is crucial for industries to evaluate their specific requirements and consult with experts to make informed decisions regarding the selection of the most suitable pumping technology for enhanced productivity and operational success.

A Guide to Choosing the Best Gear Pump for Industrial Applications

article regarding the features and benefits of an Oil Gear Pump for industrial applications.Oil Gear Pump: The Reliable Choice for Industrial ApplicationsAn oil gear pump is an industrial pump that is commonly used to transfer fluids such as oil, glycol, and water in a variety of industrial applications. The pump is designed to deliver a steady and continuous flow of fluid in a range of pressures and temperatures.One of the significant benefits of an oil gear pump is its high efficiency in transferring fluids. The pump has a positive displacement mechanism that eliminates wasteful fluid transfer, ensuring that fluids are transferred efficiently with minimal energy loss. This makes the oil gear pump an ideal solution for industries that require high levels of precision and accuracy in fluid transfer.Another benefit of the oil gear pump is its versatility. The pump can be used in a range of applications, including power generation, oil and gas, chemical processing, pulp and paper, and many others. The ability of the pump to handle different types of fluids and varying pressure levels makes it a reliable choice for many industries.Oil gear pumps are also known for their durability and reliability. The pump is made of robust materials that can withstand harsh industrial environments. The design of the pump allows for minimal maintenance, providing a long-lasting and reliable solution for fluid transfer applications.In addition to its durability, the oil gear pump is designed with safety in mind. The pump’s design eliminates the risk of leaks, ensuring that fluid transfer is safe and reliable. This is especially important in industries where safety is a top priority such as in the oil and gas industry, chemical processing, and pharmaceuticals.One of the leading companies that provide oil gear pumps is ATEX Pumps. The company specializes in providing pumps for industrial applications and has a range of oil gear pumps that are designed to meet the specific requirements of different industries.ATEX Pumps oil gear pumps are designed with high-quality materials, making them reliable and long-lasting. The pumps have a compact design that allows for easy installation and minimal maintenance. ATEX Pumps oil gear pumps are also customizable, allowing for pumps that meet specific flow rates, pressure requirements, and fluid types.Apart from oil gear pumps, ATEX Pumps provides a range of other pumps that are suitable for various industrial applications. These include centrifugal pumps, magnetic drive pumps, diaphragm pumps, and many others. ATEX Pumps also provides customized solutions that meet the unique requirements of different industries.In conclusion, an oil gear pump is a reliable and efficient solution for fluid transfer applications in various industries. Its high efficiency, versatility, durability, and safety features make it a popular choice for many industries. If you are looking for an oil gear pump for your industrial application, ATEX Pumps is an excellent choice for quality and reliability.

How Screw Pumps Increase Pressure in Industrial Applications

Title: Innovative Screw Pump Pressure System Reimagines Fluid Conveyance in Industrial ApplicationsIntroduction (124 words):With rapid advancements in industrial technology, the demand for efficient fluid conveyance systems has become more crucial than ever. Recognizing this need, innovative engineering company [Company Name] has unveiled their latest solution—an advanced Screw Pump Pressure System. Boasting remarkable reliability, versatility, and industry-leading performance, this cutting-edge system is set to revolutionize fluid conveyance across various industries. Designed with state-of-the-art technologies and engineering expertise, the [Company Name]'s Screw Pump Pressure System is a game-changer in terms of operational cost-efficiency, maintenance, and overall productivity. Let us delve into the remarkable features and benefits of this groundbreaking solution.Title: Enhanced Reliability and Durability(136 words)The Screw Pump Pressure System, developed by [Company Name], is engineered to deliver enhanced reliability and durability in industrial fluid conveyance operations. Through thorough research and rigorous testing, this revolutionary system has proven itself capable of withstanding high-pressure and high-viscosity fluid transportation. Utilizing advanced materials and cutting-edge engineering techniques, the system is built to withstand demanding industrial environments, minimizing downtime and increasing overall productivity.Designed with precision components and assembled with meticulous attention to detail, the Screw Pump Pressure System offers unparalleled performance and durability. From challenging offshore oil drilling operations to intricate chemical processing, this system can handle a wide range of demanding tasks, ensuring smooth fluid conveyance even in the harshest conditions. Its robust design ensures long service life, reducing maintenance costs and maximizing uptime for businesses in need of reliable and high-performance fluid conveyance solutions.Title: Versatile Fluid Handling Capabilities(140 words)One of the key highlights of the Screw Pump Pressure System developed by [Company Name] is its remarkable versatility in handling various types of fluids. Whether it is crude oil, lubricants, chemicals, or other viscous substances, this system guarantees efficient and reliable conveyance. With its ability to maintain a consistent flow, the Screw Pump Pressure System ensures minimal pulsation, ensuring smooth operations in critical applications.Furthermore, this innovative solution offers adjustable speeds and pressure capabilities, allowing for increased flexibility in meeting diverse industrial requirements. By adapting to a wide range of fluid viscosities, the system can seamlessly integrate into various production processes, significantly improving overall operational efficiency. This adaptability extends to both horizontal and vertical fluid conveyance applications, making it a versatile choice for a wide range of industries, including oil and gas, chemical processing, wastewater treatment, and more.Title: Unrivaled Performance and Cost Efficiency(140 words)The Screw Pump Pressure System developed by [Company Name] has set new benchmarks in terms of performance and cost efficiency. Equipped with precision-engineered screw rotors and advanced sealing technologies, this system ensures consistent flow rates, minimal leakage, reduced energy consumption, and optimal operational efficiency.Thanks to its exceptional performance, the Screw Pump Pressure System boasts significant cost-saving advantages for businesses in the long run. Reduced energy consumption translates to lower operational costs, while the system's low-maintenance design minimizes downtime, boosts overall productivity, and improves return on investment. Moreover, the enhanced performance capabilities of this system enable businesses to optimize their manufacturing processes, achieve faster turnaround times, and meet increasing production demands.Conclusion (112 words):In conclusion, the Screw Pump Pressure System developed by [Company Name] presents a transformative solution to fluid conveyance challenges in various industries. Its remarkable reliability, versatile fluid handling capabilities, and unrivaled performance and cost efficiency set it apart from traditional systems. With its ability to withstand demanding environments and handle diverse fluid viscosities, this system is poised to revolutionize fluid conveyance operations, driving industrial productivity and profitability. [Company Name]'s commitment to innovation and advanced engineering exemplifies their dedication to providing cutting-edge solutions that cater to the evolving needs of modern industries.

The Essential Guide to Lubricating Oil Pumps for Better Performance

Title: Leading Manufacturer Unveils Innovative Lubricating Oil Pumps for Enhanced Efficiency in Industrial ApplicationsIntroduction:In an era where industries are constantly seeking ways to optimize efficiency and productivity, renowned manufacturer [Company Name] has developed a ground-breaking range of lubricating oil pumps poised to revolutionize the realm of industrial equipment. These state-of-the-art pumps, devoid of any specific brand name, promise to enhance operational performance, reliability, and maintenance procedures for a range of applications across industries globally.[Company Name]:[Company Name] is a leading force in the manufacturing sector, recognized for its commitment to delivering cutting-edge solutions that cater to the evolving needs of various industries. With a rich history of innovation spanning several decades, the company has established itself as a trusted industry partner, successfully meeting and surpassing customer expectations.Lubricating Oil Pumps - Enhanced Efficiency and Performance:With a strong focus on research and development, [Company Name] leverages advanced technologies to engineer lubricating oil pumps that offer unmatched operational efficiency. These pumps are designed to effectively lubricate and protect essential equipment components, extending their lifespan and preventing premature wear and tear.Efficient Design:The lubricating oil pumps showcase an innovative design that optimizes flow rate and pressure, ensuring a steady supply of oil to machinery at all times. By maintaining consistent lubrication, the pumps ensure smooth operation, reducing friction and minimizing energy consumption. Industries, ranging from automotive and manufacturing to mining and agriculture, can benefit significantly from these new developments.Reliability and Maintenance:[Company Name] places great emphasis on improving the reliability and maintenance procedures of their lubricating oil pumps. By employing cutting-edge materials and technologies, these pumps minimize the risk of untimely breakdowns and the subsequent need for costly repairs. This reduction in downtime allows businesses to operate seamlessly, boosting productivity and profitability.Customizable Solutions:Understanding the unique requirements of each industry, [Company Name] offers a range of customizable solutions. Clients can choose from a variety of pump sizes, designs, and specifications, enabling them to tailor the lubrication process to their specific operational needs. Whether a large manufacturing plant or a small-scale agricultural unit, these lubrication pumps cater to diverse applications flawlessly.Sustainable Solutions:Environmental sustainability is a critical consideration in today's industrial landscape, and [Company Name] acknowledges this by integrating eco-friendly features into their lubricating oil pumps. These pumps not only improve operational efficiency but also reduce waste and emissions, aligning with global efforts towards a greener future.Global Reach:With an extensive distribution network and international presence, [Company Name] ensures that their innovative lubricating oil pumps reach clients across the globe promptly. Their commitment to exceptional customer service extends beyond the sale, as the company provides comprehensive after-sales support, including maintenance assistance and spare parts availability.Conclusion:[Company Name]'s groundbreaking lubricating oil pumps represent a significant breakthrough in industrial equipment. With enhanced efficiency, reliability, and customizable features, these pumps cater to diverse operational needs across industries. As environmental consciousness continues to grow, [Company Name]'s commitment to sustainable solutions sets them apart as an industry leader. By choosing these high-performance lubricating oil pumps, businesses can streamline operations and achieve unparalleled productivity, surpassing their operational targets in an ever-competitive landscape.

Discover the Benefits of Using Industrial Screw Pumps for Pumping Applications

Title: Revolutionary Screw Pumps Set to Transform Industrial ProcessesIntroduction:In the ever-evolving world of industrial processes, one company is making headlines for its groundbreaking product: Screw Pumps. Designed to be efficient, reliable, and customizable, these pumps are set to revolutionize various sectors, from oil and gas to wastewater treatment. With their innovative features and advanced technology, Screw Pumps are quickly gaining recognition as the go-to solution for numerous industrial applications.Company Background and Vision:Established in {year of establishment}, {Company Name} has been at the forefront of innovation and engineering excellence for several decades. With a strong focus on research and development, the company has successfully introduced cutting-edge products and solutions to the market. Drawing on their extensive expertise, {Company Name} recognized the need for a more reliable and efficient pumping solution, leading to the development of Screw Pumps.The Revolutionary Design:The standout feature of Screw Pumps lies in their innovative screw technology. Unlike conventional pumps, Screw Pumps utilize a pair of intermeshing screws that rotate within a tightly sealed enclosure. This design not only eliminates the need for valves, pistons, and other moving parts but also drastically reduces energy consumption and maintenance requirements. The screws themselves are precision-engineered from high-quality materials, ensuring a longer lifespan and enhanced durability.Unparalleled Versatility:The versatility of Screw Pumps makes them suitable for a wide range of industrial applications. From oil refineries and petrochemical plants to food processing facilities and manufacturing plants, these pumps offer unparalleled performance and efficiency. They excel in handling both abrasive and non-abrasive fluids, such as crude oil, slurries, sewage, chemicals, and even high-viscosity liquids. The ability to handle such diverse applications makes Screw Pumps an ideal choice for industries worldwide.Energy Efficiency for Sustainability:One of the key advantages of Screw Pumps is their energy-efficient operation. By utilizing a low-shear process, these pumps greatly reduce energy consumption and contribute to a more sustainable future. Additionally, the absence of valves and pistons eliminates energy loss due to friction, resulting in substantial cost savings for industries. With environmental concerns becoming increasingly prominent, Screw Pumps offer an eco-friendly solution without compromising on performance.Enhanced Reliability and Lower Maintenance:Reliability is of utmost importance in any industrial process, and Screw Pumps deliver on that front. Thanks to their simple design and robust construction, these pumps require minimal maintenance and provide extended service life. The absence of valves and pistons translates to fewer components that can fail, reducing the risk of unplanned downtime and costly repairs. This reliability ensures uninterrupted operation, ultimately boosting the productivity and profitability of businesses.Customizable Solutions:Recognizing that different industries and processes require specific solutions, {Company Name} offers customized Screw Pump configurations tailored to meet individual requirements. This customization may include various material options, screw profiles, and pump sizes to optimize performance. By working closely with clients, {Company Name} ensures that the Screw Pumps not only meet but exceed their expectations, providing solutions that enhance efficiency and productivity.Conclusion:As industries continue to demand more efficient and sustainable solutions, Screw Pumps stand out as a game-changer. Combining their innovative design, energy efficiency, and reliability, these pumps have the potential to transform industrial processes across various sectors. With {Company Name} leading the way, businesses can now benefit from a cutting-edge pumping solution that boosts productivity, reduces environmental impacts, and ensures long-term success in the years to come.

Essential Check Valve for Well Pump: A Key Component for Smooth Pump Operation

Title: Advanced Check Valve for Well Pump Revolutionizing Water Management SystemsIntroduction:The use of reliable and efficient check valves in well pumps is crucial for the effective management of water resources. Among the leading pioneers in this domain, a renowned company has emerged with its groundbreaking check valve technology, poised to revolutionize water management systems. With stringent quality standards and a commitment to innovation, this company aims to improve the reliability and performance of well pumps, ensuring a sustainable water supply for communities around the globe.(Company Name), A Driving Force in Water Management Solutions:With years of expertise in the field, (Company Name) has garnered a reputation as a leading manufacturer of high-quality check valves and related water management solutions. From residential to industrial applications, their product range caters to the diverse needs of customers worldwide. Equipped with state-of-the-art facilities and an experienced team of engineers, the company is driven by a mission to deliver robust, sustainable, and innovative solutions to enhance water management practices.Check Valve for Well Pump: A Game-Changing Technology:The latest breakthrough from (Company Name) is their cutting-edge check valve, designed specifically for well pumps. Engineered with advanced features, this device offers unparalleled reliability, efficiency, and longevity. The check valve's unique design and construction make it highly resistant to corrosion, ensuring consistent performance even in the harshest environments. Its superior sealing capability prevents backflow, reducing the risk of water contamination and promoting healthier water resources.Key Features and Benefits:1. Durability: Constructed from high-quality materials, the check valve guarantees exceptional durability, extending the lifespan of well pumps and reducing maintenance costs.2. Corrosion Resistance: The use of corrosion-resistant materials ensures the longevity of the valve, protecting it from harmful elements and maintaining optimal performance.3. Flawless Operation: The advanced design promotes smooth and stable water flow, preventing water hammer and reducing the risk of system failures.4. Easy Installation: The valve's user-friendly design simplifies installation, minimizing downtime and ensuring hassle-free integration with existing well pump systems.5. Energy Efficiency: With its streamlined design, the check valve optimizes energy consumption by reducing unnecessary pressure fluctuations, contributing to energy savings and lower operating costs.Environmental Sustainability and Social Responsibility:Addressing the global need for sustainable water management, (Company Name) adheres to environmentally friendly practices throughout their manufacturing processes. They prioritize the use of eco-friendly materials, minimizing the impact on natural resources. Furthermore, their dedication to social responsibility extends to leveraging innovative technologies that support water conservation efforts and improving the overall well-being of communities worldwide.Partnership with Global Water Organizations:Recognizing the importance of collaboration in water resource management, (Company Name) actively partners with global water organizations to promote knowledge-sharing, research, and innovation. By actively participating in industry conferences, workshops, and seminars, they contribute to shaping the future of sustainable water management practices.Conclusion:The check valve from (Company Name) represents a significant advancement in the field of well pump technology, offering enhanced performance, durability, and sustainability. By incorporating this state-of-the-art valve into water management systems, communities can achieve improved efficiency, reduced energy consumption, and increased reliability. (Company Name)'s commitment to innovation and social responsibility is set to reshape the landscape of water management, facilitating a sustainable future for generations to come.

Understanding the Working Principle of a Single Screw Pump

Title: Revolutionary Single Screw Pump Sets New Benchmark in Efficiency and ReliabilityIntroduction:Innovation has always been at the core of the industrial sector, and the introduction of the revolutionary Single Screw Pump has set a new benchmark in terms of efficiency and reliability. This groundbreaking solution is poised to revolutionize various industries, such as oil and gas, food processing, wastewater treatment, and chemical manufacturing, by providing enhanced performance, reduced maintenance requirements, and improved operational safety.Working Principle of the Single Screw Pump:The Single Screw Pump, developed by an innovative company committed to providing cutting-edge industrial solutions, operates on a simple yet highly effective principle. This pump consists of a single threaded screw rotor rotating within a rubber stator. As the rotor moves, it entrains the liquid from the inlet side and pushes it towards the outlet side of the pump. This unique design ensures a smooth and continuous flow, minimizing pressure fluctuations and reducing the risk of cavitation.The precision engineering of the Single Screw Pump results in numerous advantages that set it apart from traditional pump systems. Firstly, it can handle a wide range of liquids, including highly viscous, abrasive, and even shear-sensitive fluids. This versatility ensures that industries can efficiently process various substances without compromising performance or safety.Moreover, the pump's design minimizes pulsation and turbulence during operation, resulting in a steady and consistent flow. This feature not only ensures product quality continuity in sensitive industries like food processing but also reduces the wear and tear on the pump, prolonging its lifespan and significantly reducing maintenance requirements.Furthermore, the Single Screw Pump's ability to handle high suction and discharge pressures makes it ideal for oil and gas applications, where long-distance transportation is often required. Its reliability and efficiency in such demanding environments have been proven time and again, positioning it as an indispensable component in the industry.Company Introduction:The development and success of the Single Screw Pump can be attributed to the company's unwavering commitment to research and development, technological advancements, and dedication to customer satisfaction. Established over two decades ago, this pioneering company has become a global leader in providing innovative industrial solutions tailored to the unique needs of its customers.This company possesses state-of-the-art facilities and a highly skilled team of engineers who work tirelessly to conceptualize and manufacture cutting-edge equipment that pushes the boundaries of industrial efficiency. By fostering a culture of continuous learning and improvement, the company ensures that its solutions stay ahead of the rapidly evolving technological landscape.Investing heavily in research and development, the company has explored novel materials, advanced design techniques, and optimized manufacturing processes to create products that maximize performance and reliability. These efforts have resulted in the groundbreaking Single Screw Pump, which is poised to redefine pumping technology around the world.The company's commitment to customer satisfaction extends beyond the quality of its products. It provides exceptional after-sales support, technical assistance, and regular maintenance services to ensure that its customers receive uninterrupted operation and maximum return on investment. This dedication to customer service has helped forge long-standing partnerships and a global network of satisfied clients.Conclusion:The advent of the Single Screw Pump marks a significant milestone in the industrial sector. Its superior efficiency, reliability, and versatility set it apart from traditional pumping solutions, making it an invaluable asset for a wide range of industries. With its innovative design and the commitment of the company behind it, this revolutionary pump is set to transform pumping systems, paving the way for enhanced performance and productivity in various industrial applications.

How to Choose the Best Oil Pumps on the Market

[Title]: Global Pumps for Oil Market Witnesses Steady Growth as Demand Increases[Introduction]:The global pumps for oil market has been witnessing a steady growth trajectory in recent years, primarily fueled by increasing oil extraction activities across the globe. With rising energy needs and growing exploration and production activities in both conventional and unconventional oilfields, the demand for efficient and reliable pumps for oil has been on the rise. These pumps play a crucial role in facilitating the extraction, transportation, and refining processes of oil, making them an essential component of the oil and gas industry.[Paragraph 1]:The market for pumps for oil is expected to expand at a substantial CAGR over the forecast period of [period]. This growth can be attributed to several factors, such as the increasing number of oil and gas exploration projects, the rising adoption of advanced pumping technologies, and the continuous investment in the development of new oilfields. Additionally, the growth of offshore oil exploration activities has further fueled the demand for pumps that can withstand harsh marine environments.[Paragraph 2]:One of the key players operating in the global pumps for oil market is [company name]. With over [number] years of experience, the company has established itself as a trusted manufacturer and supplier of high-quality pumps designed specifically for oil applications. The pumps are known for their efficiency, durability, and reliability, making them a preferred choice among oil industry operators worldwide.[Paragraph 3]:[Company name] offers a wide range of pumps for oil, including centrifugal pumps, reciprocating pumps, and rotary pumps. These pumps are engineered to meet the unique requirements of different stages of oil extraction and processing, ensuring optimal performance and productivity. The company's cutting-edge technology and innovative designs enable the pumps to handle various viscosities of oil while maintaining high efficiency levels.[Paragraph 4]:One of the standout features of [company name]'s pumps for oil is their robust construction, which enables them to withstand the harsh operating conditions often encountered in oilfields. The pumps are designed to handle corrosive fluids, high temperatures, and abrasive materials, ensuring long service life and minimizing downtime. Moreover, the company's commitment to quality and adherence to international standards ensure that their pumps deliver consistent results even in the most challenging environments.[Paragraph 5]:In addition to their superior performance, [company name]'s pumps for oil also prioritize sustainability and environmental considerations. The company has made significant investments in research and development to enhance energy efficiency and reduce carbon emissions associated with oil pumping operations. These initiatives have garnered praise from industry experts, positioning [company name] as a responsible and eco-friendly solution provider.[Paragraph 6]:Geographically, [company name] has a well-established presence in major oil-producing regions, including North America, the Middle East, and Asia. The company's extensive distribution network and strategic partnerships ensure timely delivery and support to customers, regardless of their location. This widespread reach allows [company name] to cater to the diverse needs of oil industry operators globally, adding to its market dominance.[Paragraph 7]:Looking ahead, the global pumps for oil market is poised for significant growth as oil extraction activities expand and become more technologically advanced. With the increasing focus on renewable energy sources and the transition toward a greener future, the development of more efficient and sustainable pumps for oil will play a pivotal role in meeting the world's energy needs. As a leading player in the industry, [company name] remains committed to continuous innovation and delivering cutting-edge solutions that help shape the future of oil pumping technology.[Conclusion]:As the global demand for oil continues to rise, the pumps for oil market is expected to witness steady growth. With [company name] at the forefront of pump manufacturing, oil industry operators can rely on their expertise to provide reliable and efficient solutions. By combining advanced technology, durable construction, and environmental consciousness, [company name] stands as a key player in the global pumps for oil market, poised to meet the evolving needs of the oil and gas industry.

Efficient and Reliable Screw Pump Technology Unveiled for Various Industrial Applications

Title: Innovative Screw Pump Reinvents Water Management SolutionsSubtitle: Cutting-edge Technology Increases Efficiency and Reduces Environmental ImpactDate: [Current Date][City, State] – In a remarkable leap forward for water management technology, industry-leading company [Remove Brand Name], renowned for its expertise in fluid handling solutions, has introduced its groundbreaking Screw Pump. This state-of-the-art device promises to revolutionize water management systems, providing highly efficient and environmentally friendly solutions for various industries.With an impressive reputation for delivering superior quality products, [Remove Brand Name] has once again demonstrated its commitment to innovation and sustainability. The Screw Pump, a flagship offering in its ever-expanding portfolio, represents a significant milestone in the company's journey toward providing cutting-edge solutions that meet the growing demands of a rapidly changing world.The Screw Pump, designed to maximize efficiency and minimize energy consumption, introduces a unique approach to water management. By utilizing advanced screw technology, this groundbreaking device offers a host of benefits that go beyond traditional pumping systems. It brings unparalleled reliability, enhanced performance, and reduced maintenance costs to a range of industries including agriculture, water treatment, utilities, and oil and gas.One of the key advantages of the Screw Pump is its ability to handle various types of fluids, including viscous, abrasive, and corrosive substances. This versatility ensures that it can be employed across a wide range of applications, making it an ideal choice for industries with diverse fluid handling requirements.Furthermore, the Screw Pump's robust construction and advanced design deliver unrivaled operational efficiency. By employing precision engineering techniques, this device minimizes energy consumption, resulting in significant cost savings for businesses. With its innovative screw mechanism, the pump achieves optimal flow rates and pressure, allowing industries to streamline their operations while conserving energy resources.Moreover, the Screw Pump is engineered to excel in harsh environments. Its durable design and materials ensure exceptional reliability, reducing downtime and enhancing productivity. By withstanding extreme temperatures and corrosive elements, this pump provides long-term performance without compromising its efficiency.As a company known for its commitment to sustainability, [Remove Brand Name] has prioritized minimizing the environmental impact of its products in the Screw Pump's development. By optimizing energy usage and minimizing waste, this cutting-edge solution aligns perfectly with industry demands for eco-friendly water management systems. The Screw Pump's reduced energy consumption not only benefits businesses but also contributes to a greener future by limiting carbon emissions and overall ecological footprint.The Screw Pump's versatility extends beyond its design and capabilities. Backed by [Remove Brand Name]'s unwavering commitment to customer satisfaction, the device comes with an extensive support network. The company's highly skilled technicians and engineers ensure seamless installation, reliable operation, and regular maintenance to guarantee uninterrupted and efficient performance of the Screw Pump throughout its lifespan.In addition, [Remove Brand Name] leverages its industry-leading expertise and commitment to research and development to continuously improve the Screw Pump's design and explore innovative applications. By collaborating with renowned research institutions and industry experts, the company remains at the forefront of water management technology advancements, driving the industry forward.With its introduction of the Screw Pump, [Remove Brand Name] has set a new industry benchmark for water management solutions. This breakthrough device offers unmatched efficiency, versatility, and reliability, empowering various sectors to optimize their fluid handling processes while minimizing environmental impact. As [Remove Brand Name] continues to push boundaries and redefine industry standards, its commitment to sustainable innovation inspires confidence in a better, greener future.About [Remove Brand Name]:[Remove Brand Name] is an internationally recognized leader in fluid handling solutions. With a focus on innovation, sustainability, and customer satisfaction, the company has established itself as a key player across numerous industries. By utilizing cutting-edge technology and collaborating with industry experts, [Remove Brand Name] consistently provides superior products that meet the evolving needs of their customers.