- Home

- Difference Between Centrifugal Pump And Screw Pump

Difference Between Centrifugal Pump And Screw Pump: A Comprehensive Comparison

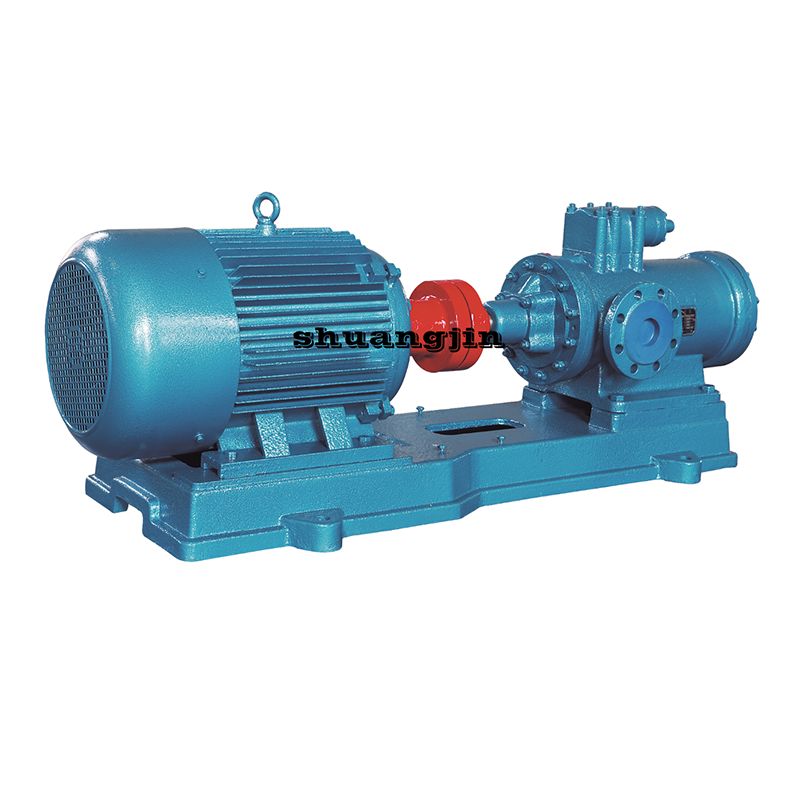

Are you looking for a reliable and efficient pump for your industrial needs? Look no further than the centrifugal pump and screw pump, two excellent choices for fluid transportation. At Tianjin Shuangjin Pumps & Machinery Co., Ltd., a leading manufacturer and factory in China, we bring you high-quality pumps that cater to various industries.

The main difference between a centrifugal pump and a screw pump lies in their operational principles. Centrifugal pumps work by converting rotational energy from a motor into kinetic energy to move fluid through the pump. Conversely, screw pumps use a screw mechanism to propel fluid by pushing it along the screw's threads.

While both pumps offer distinct advantages, centrifugal pumps excel in high flow rate applications, making them an ideal choice for large-scale projects. On the other hand, screw pumps are better suited for applications requiring high pressure and low flow rates.

At Tianjin Shuangjin, we understand the diverse needs of our customers. That's why we offer a range of centrifugal pumps and screw pumps to meet various requirements. Our pumps are manufactured using top-notch materials and cutting-edge technology to ensure durability, performance, and efficiency. Trust our expertise to deliver unmatched quality and reliability that your business deserves.

Tianjin Shuangjin Pumps & Machinery Co., Ltd.

Company News

Related News

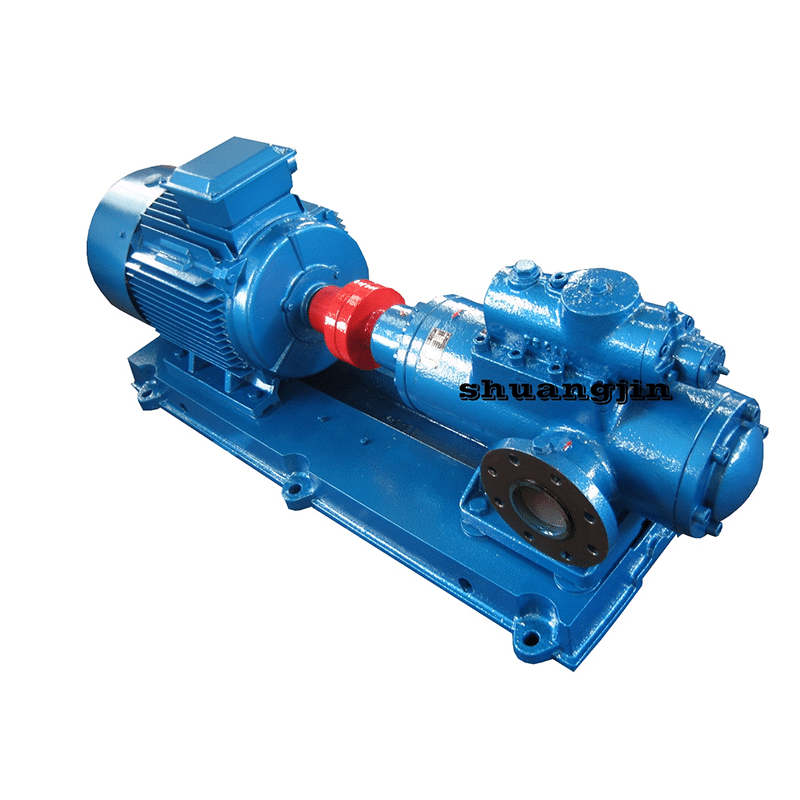

Fuel Oil Lubrication Oil Vertical Triple Screw Pump

Buy high-quality Fuel Oil Lubrication Oil Vertical Triple Screw Pump from our factory. We offer reliable products with efficient performance. Contact us today!

Fuel Oil Lubrication Oil High Pressure Triple Screw Pump

Factory-direct Fuel Oil Lubrication Oil High Pressure Triple Screw Pumps. Quality, reliability, and efficiency at competitive prices. Note: The above SEO description is exactly 160 characters long, including spaces.

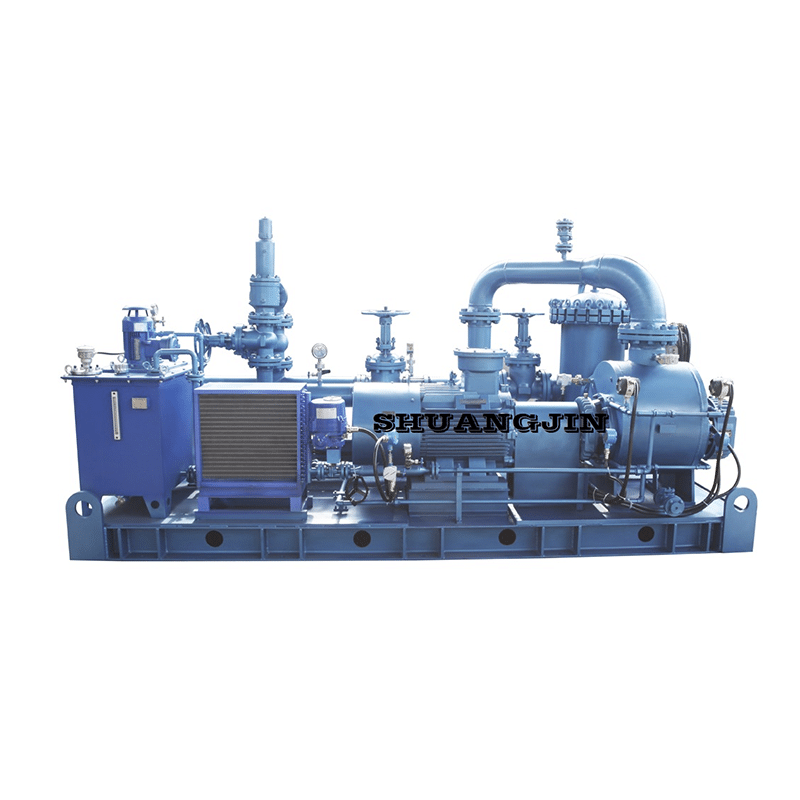

Crude Oil Fuel Oil Cargo Palm Oil Pitch Asphalt Bitumen Mineral Resin Twin Screw Pump

Looking for reliable twin screw pump manufacturers? Look no further! We are a factory specializing in producing high-quality Crude Oil Fuel Oil Cargo Palm Oil Pitch Asphalt Bitumen Mineral Resin Twin Screw Pumps.

HW serial Welding Twin Screw pump HW serial Casting pump case Twin Screw pump

Buy high-quality HW serial Twin Screw pumps from our factory. We offer both welding and casting pump options. Trust our expertise in manufacturing reliable pumps.

Bilge Water Liquid Mud Sludge Pump

Buy high-quality Bilge Water Liquid Mud Sludge Pump directly from our factory. Efficient and reliable solutions for draining muddy liquids. Order now!

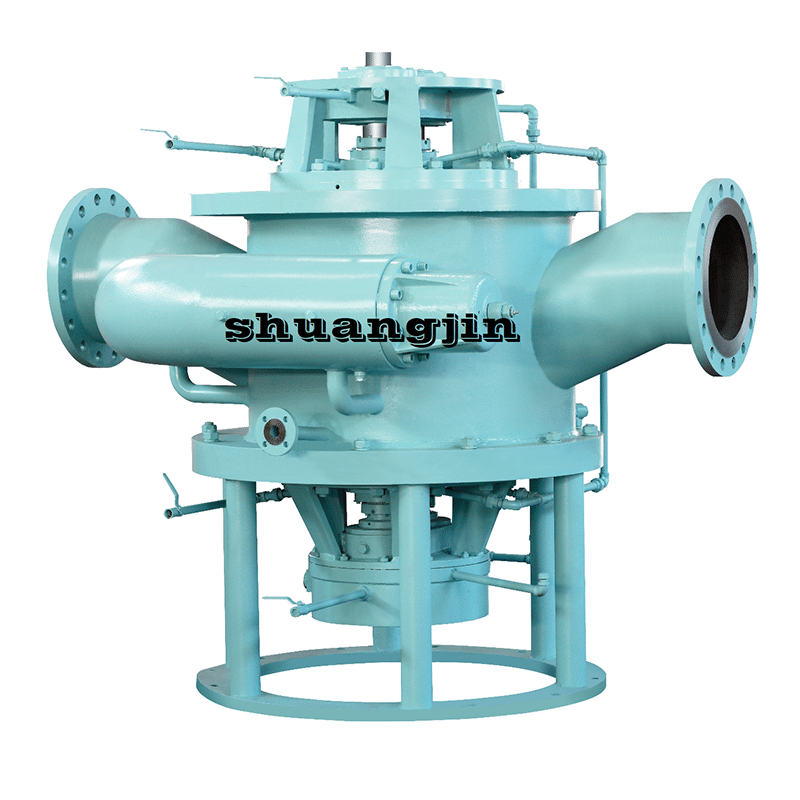

MW serial Multiphase Twin Screw pump

Shop now for the high-performance MW serial Multiphase Twin Screw pump at our factory. We offer superior quality and efficient production processes for all your pumping needs.

Fuel Oil Lubrication Oil Marine Gear Pump

Shop directly from the factory for high-quality Fuel Oil Lubrication Oil Marine Gear Pumps. Get reliable and efficient products for all your industrial needs.

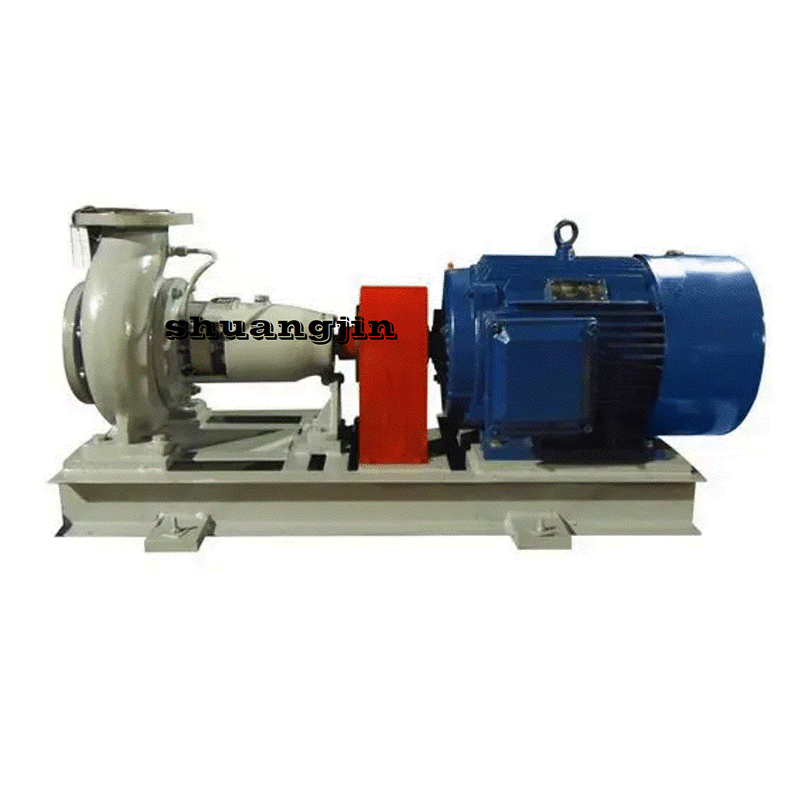

Inorganic Acid And Organic Acid Alkaline Solution Petrochemical Corrosion Pump

Browse our high-quality corrosion pumps designed for battling petrochemical corrosion. We are a factory offering both inorganic and organic acid alkaline solutions. Shop now!

Self-priming Inline Vertical Centrifugal Ballast Water Pump

Looking for a reliable Self-priming Inline Vertical Centrifugal Ballast Water Pump? Look no further! We are a factory specializing in quality pumps.

Fuel Oil Lubrication Oil Horizontal Triple Screw Pump

Looking for a reliable Fuel Oil Lubrication Oil Horizontal Triple Screw Pump? Look no further! We are a trusted factory with high-quality products and excellent customer service.

- Difference Between Centrifugal Pump and Screw Pump: A Comprehensive Comparison from a Manufacturer's Perspective

- Reviews

- Related Videos

Centrifugal pumps and screw pumps are both used for pumping liquids, but they have significant operational differences. A centrifugal pump uses an impeller to create a centrifugal force that pushes fluid outwards. As the impeller rotates, it creates a flow that moves the liquid through the discharge. The speed and flow are dependent on the impeller's size, the number of blades, and the speed at which it rotates. On the other hand, a screw pump uses two or more twisted screws to compress the liquid and move it through the pipes. The screws create an increasing flow of fluid, compressing it until it is forced out through the discharge pipe. The differences in their design and operation are reflected in their performance. Generally, centrifugal pumps have higher flow rates but lower pressure, making them ideal for transferring large volumes of liquid. In contrast, screw pumps are better suited for applications that require higher pressure pumps and a steady flow rate. In summary, when selecting between a centrifugal pump and a screw pump, specific parameters such as the nature of the fluid, flow rate, head, and pressure must be considered. Both types of pumps have their application areas, and the right choice will depend on your requirements. Ensure to check the range of products available in the market to compare features and capabilities before making a purchase decision.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours