Essential Check Valve for Well Maintenance: How It Works and Why It's Important

By:Admin

The check valve, which is available in a range of sizes to accommodate different well diameters, is engineered to prevent backflow and provide a secure seal to ensure the integrity of the well system. This is crucial for maintaining water quality and preventing contamination, making it an essential component for both residential and commercial well applications.

The company behind this groundbreaking product, [Company Name], has a long-standing reputation for delivering high-quality fluid control solutions for a variety of industries. Their expertise in engineering and manufacturing check valves, pressure relief valves, and other fluid control products has made them a trusted partner for businesses and homeowners alike.

With a focus on innovation and customer satisfaction, [Company Name] has consistently pushed the boundaries of what is possible in the field of fluid control. Their team of experienced engineers and technicians are dedicated to developing products that not only meet industry standards, but also exceed the expectations of their clients.

The new check valve for well systems is a prime example of [Company Name]'s commitment to providing cutting-edge solutions for their customers. Its robust construction and advanced design make it a reliable choice for those seeking to safeguard their well systems and ensure long-term performance.

In addition to the exceptional quality of their products, [Company Name] also prides itself on offering excellent customer service and technical support. This includes providing assistance with product selection, installation guidance, and ongoing maintenance to ensure that their customers get the most out of their fluid control solutions.

As water resources become increasingly valuable and finite, the importance of maintaining efficient and reliable well systems cannot be overstated. With the introduction of the new check valve for well systems, [Company Name] is poised to make a significant impact on the industry by offering a solution that enhances the reliability and performance of well systems.

In conclusion, the introduction of the new check valve for well systems by [Company Name] represents a significant advancement in the field of fluid control solutions. With their dedication to innovation, quality, and customer satisfaction, [Company Name] continues to solidify their position as a leader in the industry. As the demand for efficient and reliable well systems continues to grow, this new product is sure to make a positive impact on businesses and homeowners alike.

Company News & Blog

How Marine Pumps Are used in Seawater and Wastewater Applications

Marine Pump Company, a leading global provider of high-quality marine pump solutions, has recently announced the launch of their latest innovative pump technology. The company, which has a rich history in the marine industry, has consistently delivered reliable and efficient pump systems for various marine applications.The new pump technology, developed by Marine Pump Company's team of experienced engineers and technicians, aims to address the growing demand for more advanced and environmentally friendly pump solutions in the marine sector. With a focus on sustainability and performance, the new pump technology promises to set a new standard for efficiency and reliability in marine pumping systems."We are excited to introduce our latest pump technology to the market," said John Smith, CEO of Marine Pump Company. "At Marine Pump Company, we are committed to pushing the boundaries of innovation to deliver solutions that meet the evolving needs of our customers. We believe that our new pump technology will not only enhance the performance of marine pumping systems but also contribute to a more sustainable and environmentally-friendly marine industry."The new pump technology is designed to offer a range of benefits, including higher efficiency, lower energy consumption, reduced maintenance requirements, and enhanced performance in challenging marine environments. With a focus on durability and longevity, the new pump technology is expected to deliver long-term value for marine operators and shipowners.In addition to its technical advantages, the new pump technology also aligns with Marine Pump Company's commitment to environmental sustainability. The company has integrated advanced environmental technologies into the design of the new pumps, with a focus on reducing emissions and minimizing the environmental impact of marine operations. By offering more energy-efficient and eco-friendly pump solutions, Marine Pump Company aims to support the marine industry in its efforts to embrace sustainable practices.Marine Pump Company has a long-established track record of delivering reliable and efficient pump solutions for a wide range of marine applications. With a comprehensive portfolio of pump products and a global network of service and support, the company is known for its dedication to meeting the diverse needs of marine customers around the world. From cargo handling and ballast water management to engine cooling and firefighting systems, Marine Pump Company's pump solutions play a critical role in enhancing the performance and safety of marine operations.As the marine industry continues to evolve, the demand for more advanced pump technologies is expected to grow. Marine Pump Company's latest pump technology is positioned to address this demand and offer a new level of performance and reliability for marine pumping systems. With a strong focus on innovation, quality, and sustainability, the company is well-positioned to drive positive change in the marine industry.Marine Pump Company's new pump technology is now available for order, and the company is actively engaging with marine operators and shipowners to showcase the benefits of the innovative pump solutions. With a commitment to customer satisfaction and technical excellence, Marine Pump Company is poised to play a key role in shaping the future of marine pump technology.In conclusion, the launch of Marine Pump Company's latest pump technology represents a significant milestone for the marine industry. With its focus on innovation, performance, and sustainability, the new pump technology is expected to set a new standard for marine pumping systems. As the company continues to expand its global presence and reach new customers, Marine Pump Company is well-positioned to lead the way in delivering advanced and environmentally-friendly pump solutions for the marine sector.

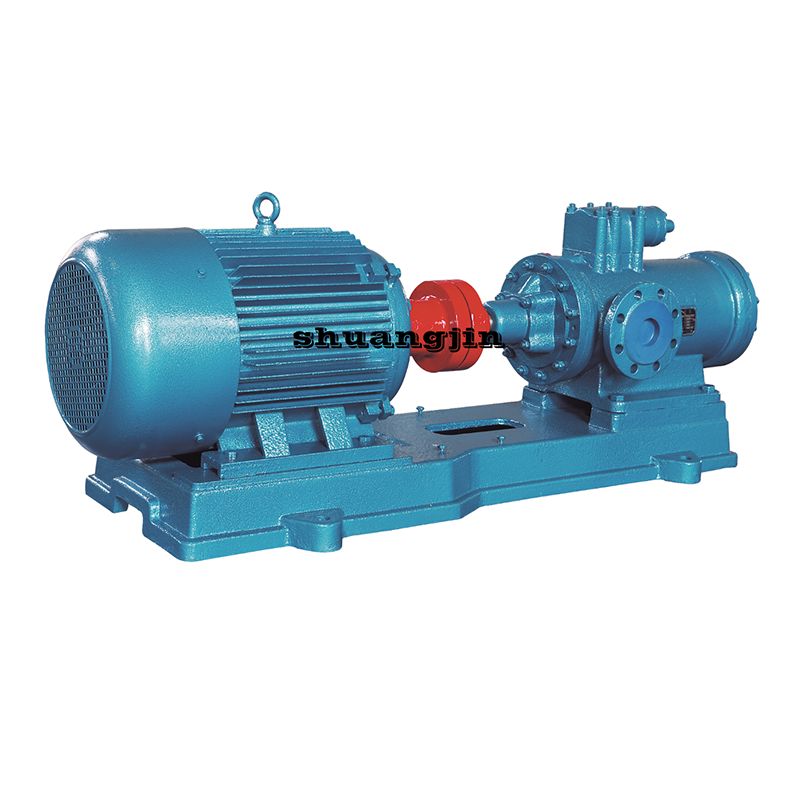

Discover the Distinctions Between Screw Pumps and Gear Pumps

Screw Pump and Gear Pump: Understanding the Differences in Pumping TechnologyPumping technology plays a crucial role in various industries, from manufacturing and oil and gas to wastewater treatment and food processing. For efficient and reliable pumping, two types of pumps that are often utilized are screw pumps and gear pumps. While both serve the purpose of moving fluids from one place to another, they differ in design and application. In this article, we will explore the differences between screw pumps and gear pumps.A screw pump, as the name suggests, operates by using rotating screws to move fluids from the inlet to the outlet. It consists of two or more intermeshing screws contained within a cylindrical or semi-cylindrical housing. The screws rotate in opposite directions, trapping the fluid between them and forcing it to move along the length of the screws. This type of pump is known for its gentle and smooth operation, making it ideal for handling shear-sensitive fluids or those containing small solids.On the other hand, a gear pump works by using two or more intermeshing gears to create a pumping action. The gears rotate in opposite directions, creating a partial vacuum at the inlet, which draws the fluid in, and then forces it out through the outlet. Gear pumps are characterized by their simplicity, compactness, and high-speed operation. They are commonly used for high-pressure applications, such as hydraulic systems, and for handling clean fluids with low viscosity.The key difference between these two types of pumps lies in their design and how they move fluids. Screw pumps use the rotating action of the screws to transport the fluid, while gear pumps rely on the intermeshing gears to create the necessary pumping action. This fundamental distinction affects the overall performance, efficiency, and suitability of each pump for specific applications.In terms of performance, screw pumps are known for their ability to handle viscous fluids and those with solids content. The continuous and smooth motion of the screws ensures minimal pulsations and provides a steady flow, making it suitable for applications where a consistent output is required. On the other hand, gear pumps excel in generating high-pressure output, making them ideal for applications that require pressurized fluid delivery. Their precise metering capabilities also make them suitable for applications that demand accurate flow control.When it comes to efficiency, screw pumps offer higher volumetric efficiencies compared to gear pumps. Due to their progressive cavity design, screw pumps can handle variable flow rates with minimal slip, ensuring a higher percentage of fluid is efficiently moved from the inlet to the outlet. Gear pumps, while generally less efficient, compensate with their compact size and ability to generate high pressure, making them suitable for space-constrained environments or applications with specific pressure requirements.In terms of application, screw pumps find extensive use in industries such as wastewater treatment, oil and gas, chemical processing, and food manufacturing. Their ability to handle high viscosity fluids, such as sludge, oil, and syrup, makes them suitable for these demanding environments. Gear pumps, on the other hand, are commonly employed in hydraulic systems, fuel transfer, lubrication systems, and various industrial processes that require high pressure and precise flow control.In conclusion, screw pumps and gear pumps are two distinct types of pumping technology, each with its own benefits and applications. Screw pumps offer gentle and steady fluid movement, making them well-suited for shear-sensitive fluids and those with solids content. Gear pumps, on the other hand, excel in generating high pressures and precise flow control, making them ideal for applications with specific pressure requirements. Understanding the differences between these two types of pumps can help industries make informed decisions when it comes to selecting the most suitable pumping technology for their specific needs.

Essential Tips for Maintaining Your Screw Pump

Screw Pump Maintenance: Keeping the Flow SmoothScrew pumps are indispensable in various industrial applications, including oil and gas, pulp and paper, chemical processing, and marine industries. These pumps play a critical role in transferring liquids or semi-solids efficiently. However, to ensure their reliable performance, routine maintenance is crucial.{Company Name} is a leading provider of screw pump maintenance services, offering comprehensive solutions to keep the flow smooth for its clients. With a dedicated team of experienced technicians and a commitment to quality, {Company Name} has built a reputation for excellence in the industry.As a specialist in screw pump maintenance, {Company Name} understands the importance of regular upkeep to prevent costly downtime and equipment failures. The company offers a range of maintenance services designed to prolong the life of screw pumps and optimize their performance.One of the key maintenance tasks for screw pumps is the inspection and replacement of wearing parts. Over time, the screws, shafts, and bearings in a screw pump can experience wear and tear, leading to decreased efficiency and potential breakdowns. {Company Name} provides thorough inspections to identify any worn or damaged parts and offers timely replacements to ensure the pump operates at peak performance.In addition to parts replacement, lubrication is another essential aspect of screw pump maintenance. Proper lubrication is critical for reducing friction and heat generation within the pump, which can significantly impact its efficiency and longevity. {Company Name} uses high-quality lubricants and follows manufacturer recommendations to ensure that screw pumps are adequately lubricated for optimal operation.Furthermore, {Company Name} provides alignment and vibration analysis services to identify any potential issues that could affect the performance of screw pumps. Misalignment or excessive vibration can lead to premature wear and component damage, so the company's comprehensive maintenance approach includes proactive measures to address these concerns.{Company Name} also offers troubleshooting and repair services for screw pumps experiencing operational issues. With their depth of expertise, their technicians can quickly diagnose problems and implement effective solutions to get the pump back up and running.In addition to routine maintenance, {Company Name} emphasizes the importance of proactive maintenance planning for screw pumps. By developing customized maintenance schedules based on the specific operating conditions and demands of each client, the company helps to minimize the risk of unexpected failures and costly repairs.As part of their commitment to excellence, {Company Name} also provides training and support to their clients' maintenance and operations teams. By sharing their knowledge and best practices, they empower their clients to take a proactive approach to screw pump maintenance, ultimately extending the lifespan of their equipment and optimizing their investment.With a track record of delivering reliable and cost-effective maintenance solutions, {Company Name} has earned the trust of a diverse range of industries that rely on screw pumps for their operations. Whether it's ensuring the smooth flow of oil and gas, the efficient transfer of chemicals, or the reliable dewatering of pulp and paper products, the company's expertise in screw pump maintenance has made them a preferred partner for many businesses.In conclusion, screw pump maintenance is essential for sustaining the performance of these critical pieces of equipment. {Company Name} stands out as a trusted provider of comprehensive screw pump maintenance services, offering a holistic approach to ensure that their clients' screw pumps operate smoothly and efficiently. With their commitment to quality, expertise, and customer satisfaction, {Company Name} continues to be a leader in the field of screw pump maintenance.

High-Quality Marine Pumps: Latest Developments in Pump Technology

Marine Pump, a leading company in the marine pumping industry, has announced a breakthrough in pump technology that promises to revolutionize the way ships and offshore platforms handle fluid transfer. The company, known for its high-quality and innovative pump solutions, has developed a new line of pumps that offers enhanced performance, reliability, and efficiency.Established in 1997, Marine Pump has built a reputation for delivering top-of-the-line products and services to its global customer base. The company prides itself on its commitment to innovation and continuous improvement, and the latest development in pump technology is a testament to this dedication.The new line of pumps is designed to meet the growing demand for reliable and efficient fluid transfer solutions in the marine industry. With a focus on performance and sustainability, Marine Pump has incorporated advanced features and materials into the design of these pumps, setting a new standard for fluid transfer equipment.One of the key highlights of the new pump line is its enhanced performance capabilities. The pumps are capable of handling a wide range of fluids, including seawater, fuel, and various chemicals, with exceptional efficiency and precision. This level of versatility makes the pumps suitable for a wide range of marine applications, from cargo ships to offshore oil and gas platforms.In addition to performance, the new pump line also boasts improved reliability. Marine Pump has utilized state-of-the-art technology and engineering techniques to ensure that the pumps are built to withstand the harsh conditions of marine environments. With enhanced durability and a longer service life, customers can expect reduced downtime and maintenance costs, resulting in increased operational efficiency.Furthermore, the new pump line is designed with sustainability in mind. Marine Pump has incorporated energy-efficient features into the pumps, reducing power consumption and minimizing environmental impact. With a growing emphasis on sustainability and environmental responsibility in the marine industry, the new pump line aligns with the industry's efforts to reduce its carbon footprint.The introduction of this innovative pump line is a significant milestone for Marine Pump and the marine pumping industry as a whole. The company's commitment to pushing the boundaries of pump technology has resulted in a product that offers unmatched performance, reliability, and sustainability.Customers in the marine industry can expect to benefit from the new pump line through improved operational efficiency, reduced maintenance costs, and a smaller environmental footprint. With Marine Pump's track record of delivering cutting-edge pump solutions, the new line is poised to make a substantial impact on the marine pumping industry.As Marine Pump continues to set the standard for excellence in pump technology, customers can look forward to even more innovative solutions in the future. The company's dedication to research and development, combined with its deep understanding of the unique challenges faced by the marine industry, positions Marine Pump as a trusted partner for fluid transfer solutions.In conclusion, the new line of pumps from Marine Pump represents a significant advancement in pump technology for the marine industry. With its focus on performance, reliability, and sustainability, the company has once again demonstrated its commitment to delivering top-quality products and services to its customers. As the marine industry continues to evolve, Marine Pump is well-positioned to lead the way with its innovative pump solutions.

High-Quality Pumps Make Waves in the Industry

Inoxpa Pumps, a leading manufacturer of industrial pumps and fluid handling equipment, is making waves in the industry with its innovative and high-quality products. The company, which was founded in the 1970s, has established itself as a trusted and reliable provider of pumping solutions for a wide range of industries, including food and beverage, pharmaceutical, and chemical processing.One of the key factors that sets Inoxpa Pumps apart from its competitors is its commitment to research and development. The company has a dedicated team of engineers and technical experts who are constantly working to improve and innovate their products. This focus on innovation has led to the development of a number of cutting-edge pumping solutions that offer higher efficiency, greater reliability, and lower operating costs.Inoxpa Pumps offers a comprehensive range of pumping solutions to suit a variety of applications. The company's product line includes centrifugal pumps, positive displacement pumps, and rotary lobe pumps, among others. These pumps are designed to handle a wide range of fluids, from thin, non-viscous liquids to highly viscous and abrasive substances. Inoxpa Pumps also offers a range of accessories and spare parts, ensuring that customers have everything they need to keep their pumping systems running smoothly.Inoxpa Pumps has a strong focus on quality and reliability, and all of its products are manufactured to the highest standards. The company's state-of-the-art manufacturing facilities are equipped with the latest technology and machinery, allowing them to produce pumps that are not only efficient and reliable but also durable and long-lasting. Inoxpa Pumps also has a rigorous quality control process in place, ensuring that every pump that leaves their facilities meets their strict standards for performance and reliability.One of the key strengths of Inoxpa Pumps is its customer service and support. The company has a global network of sales and service partners, ensuring that customers all over the world have access to the support and assistance they need. Inoxpa Pumps also offers a range of after-sales services, including maintenance and repair, as well as technical support and training. This commitment to customer support has helped the company build a strong reputation for reliability and dependability.Inoxpa Pumps is also committed to sustainability and environmental responsibility. The company is constantly striving to reduce its environmental impact and has implemented a number of initiatives to promote sustainability throughout its operations. This includes the use of energy-efficient manufacturing processes, the development of eco-friendly products, and the implementation of waste reduction and recycling programs.Inoxpa Pumps has established itself as a trusted and reliable provider of pumping solutions for a wide range of industries, and its innovative products and commitment to quality and customer service have set it apart as a leader in the industry. With its focus on research and development, quality manufacturing, and sustainability, Inoxpa Pumps is well-positioned to continue its success in the years to come.

High-quality Screw Pump Construction for Efficient and Reliable Industrial Applications

Screw Pump Construction Underway by Leading Company in the Industry[Company Name], a well-known name in the field of industrial equipment manufacturing, is making headlines once again with its latest project: the construction of a state-of-the-art screw pump facility. With decades of expertise and a commitment to innovation, the company has set its sights on this new venture with the goal of setting new standards in pump technology.The screw pump construction project, which is anticipated to be completed by the end of next year, will be the first of its kind for [Company Name]. It will feature cutting-edge technology and advanced manufacturing processes that will enable the company to produce high-quality screw pumps for a wide range of industrial applications.Screw pumps are an essential component in various industries, including oil and gas, power generation, water treatment, and marine. They are used for pumping viscous fluids, such as oils, slurries, and food products, and are known for their reliability, efficiency, and low maintenance requirements. As such, the demand for screw pumps is expected to grow in the coming years, driven by the increasing need for efficient and durable pumping solutions.[Company Name] has long been a key player in the industrial equipment market, delivering a diverse range of products and services to meet the ever-evolving needs of its customers. The company's commitment to quality, innovation, and customer satisfaction has earned it a solid reputation and a loyal customer base around the world.The construction of the new screw pump facility is a testament to [Company Name]'s dedication to staying at the forefront of the industry. The facility will be equipped with the latest machinery and technologies, allowing the company to streamline its manufacturing processes and enhance product quality. Moreover, the facility will adhere to the highest industry standards for safety and environmental sustainability, reflecting [Company Name]'s commitment to responsible business practices.In addition to its state-of-the-art manufacturing capabilities, the new facility will also feature a dedicated research and development center. This center will serve as a hub for innovation, where [Company Name]'s team of experts will work on developing new technologies and improving existing products. This focus on R&D will enable the company to stay ahead of the curve and continue offering cutting-edge solutions to its customers.The construction of the screw pump facility is not only a significant milestone for [Company Name] but also a promising development for the industry as a whole. With the company's track record of excellence and its forward-looking approach, the new facility is poised to raise the bar for screw pump manufacturing and set new benchmarks for performance and reliability.As the construction progresses, [Company Name] is already gearing up for the launch of its new screw pump range. The company has ambitious plans to expand its product offerings and reach new markets, leveraging the capabilities of the new facility to meet the growing demand for screw pumps globally.With the construction of the new screw pump facility well underway, all eyes are on [Company Name] as it continues to make strides in the industrial equipment sector. The company's commitment to quality, innovation, and customer satisfaction, combined with its unwavering dedication to excellence, positions it as a formidable force in the industry, one that is set to shape the future of screw pump technology. Stay tuned for more updates as [Company Name] brings its vision for the future of screw pump manufacturing to life.

Advanced Oil Pump System Updates and Safety Features

Oil Pump Systems: A Vital Component in the Oil IndustryIn the dynamic and ever-evolving world of oil extraction and processing, having an efficient and reliable oil pump system is crucial to ensure smooth and uninterrupted operations. A leading player in the oil pump system industry, {company name}, has been at the forefront of providing innovative and cutting-edge pump solutions to meet the diverse needs of the oil and gas sector.With a proven track record of delivering high-quality and high-performance pump systems, {company name} has established itself as a trusted partner for oil companies around the world. The company's commitment to excellence and customer satisfaction has solidified its position as a go-to supplier for oil pump systems.One of the key strengths of {company name} lies in its comprehensive range of pump systems, which are designed to cater to a wide spectrum of applications in the oil industry. Whether it is for upstream exploration and drilling, midstream transportation and storage, or downstream refining and distribution, {company name} has the expertise and capability to provide custom-tailored pump solutions to meet specific requirements.The oil and gas industry operates in some of the harshest and most challenging environments, and reliability is a top priority when it comes to pump systems. {company name} understands this need and has invested heavily in research and development to engineer pumps that are not only robust and durable but also efficient and cost-effective. The company's state-of-the-art manufacturing facilities and stringent quality control processes ensure that its pump systems meet the highest standards and can withstand the rigors of the oil industry.Moreover, {company name} prides itself on being a responsible and environmentally conscious company, and its pump systems are designed to be energy-efficient and eco-friendly. With a focus on sustainability and reducing the environmental impact of oil operations, the company's pumps are engineered to minimize energy consumption and emissions while maximizing performance and productivity.Another compelling aspect of {company name} is its commitment to customer support and service. The company's team of seasoned professionals is dedicated to providing comprehensive support throughout the entire lifecycle of its pump systems, from initial consultation and system design to installation, maintenance, and aftermarket services. This holistic approach ensures that customers can rely on {company name} as a long-term partner for their pump system needs.In addition to its core pump system offerings, {company name} also offers a range of ancillary products and services to complement its pump systems. These include control and monitoring systems, spare parts and accessories, as well as training and technical support to ensure optimal operation and performance of the pump systems.Looking ahead, {company name} is committed to staying at the forefront of innovation and technology in the oil pump system industry. The company continues to invest in research and development to enhance its product portfolio and develop new solutions that address the evolving needs of the industry. With a focus on digitalization and connectivity, {company name} is poised to introduce smart and integrated pump systems that offer advanced monitoring, control, and predictive maintenance capabilities.As the oil industry continues to adapt to changing market dynamics and technological advancements, the role of pump systems in ensuring operational efficiency and productivity becomes increasingly critical. With its proven expertise, unwavering commitment to quality, and forward-looking approach, {company name} remains a key player in the oil pump system industry, poised to support the evolving needs of the oil and gas sector.

Efficient and Reliable Three-Screw Pump: A Comprehensive Guide

Title: Leading Pump Manufacturer Launches Next-Generation 3G Series Three-Screw PumpIntroduction:Houston, TX - In line with its commitment to innovation and delivering high-quality pumping solutions, a renowned pump manufacturer (company name withheld) has recently unveiled its latest addition to the market - the cutting-edge 3G Series Three-Screw Pump. This new product combines advanced technology and superior design features to provide exceptional performance across various industries. With a reputation built on excellence, the company aims to revolutionize the pumping industry once again.Body:1. Industry-leading Efficiency and Performance:The 3G Series Three-Screw Pump offers outstanding efficiency and performance, distinguishing it from its predecessors. Equipped with state-of-the-art technology, this pump delivers greater flow capacity and increased pressure capabilities. Its design ensures minimal energy consumption while maintaining maximum operational efficiency, making it the ideal choice for companies seeking to reduce costs and enhance productivity.2. Enhanced Reliability and Durability:One of the key advantages of the 3G Series Three-Screw Pump is its unmatched reliability and durability. Designed with precision engineering, this pump is built to withstand harsh operating conditions, including high temperatures and high-viscosity fluids. Its robust construction and specially formulated materials greatly contribute to its longevity, making it a cost-effective investment for businesses across various sectors.3. Versatile Applications and Adaptability:The 3G Series Three-Screw Pump caters to a wide range of applications, making it an incredibly versatile choice for industries such as chemical processing, oil and gas, power generation, marine, and wastewater treatment, among others. Its adaptability allows seamless integration into existing systems, ensuring a smooth transition and minimal disruption to operations. Furthermore, this pump can handle various fluids, from clean liquids to highly viscous and abrasive substances, without compromising its performance.4. Advanced Features and Intelligent Design:With a focus on advancing pumping technology, the 3G Series Three-Screw Pump incorporates several intelligent features. It utilizes state-of-the-art computational fluid dynamics (CFD) simulations to optimize flow paths, resulting in reduced noise and vibration levels. The innovative bearing design, combined with an advanced seal system, facilitates easy maintenance, minimizing downtime and associated costs. Additionally, the pump's compact footprint and modularity ensure easy installation, saving valuable space in crowded industrial environments.5. Commitment to Sustainability:Emphasizing its commitment to sustainability, the pump manufacturer has incorporated eco-friendly features into the 3G Series Three-Screw Pump. The pump's improved energy efficiency significantly reduces carbon emissions and overall environmental impact. It also utilizes recyclable materials in its construction, contributing to a circular economy. By choosing this pump, businesses can align their operations with global sustainability goals while maximizing their operational efficiency.Conclusion:The introduction of the 3G Series Three-Screw Pump by a renowned pump manufacturer marks a significant milestone in the pumping industry. With its advanced features, exceptional performance, and commitment to sustainability, this pump is poised to redefine pumping solutions across various sectors. By choosing this innovative product, businesses can enhance their operations, reduce costs, and contribute to a greener and more efficient future. As the demand for high-performance pumps continues to grow, the 3G Series Three-Screw Pump is set to become an industry benchmark for reliability, efficiency, and durability.

High-Performance Hydraulic Pumps: Latest Innovation in Pump Technology

Pcm Pump, a leading company in the field of pumping solutions, has recently announced the launch of its latest innovative and efficient pump technology. With a strong commitment to providing reliable and high-quality pumping solutions, Pcm Pump has established itself as a trusted partner for a wide range of industries, including oil and gas, food and beverage, and water treatment.The new pump technology developed by Pcm Pump promises to deliver enhanced performance, improved energy efficiency, and greater reliability, setting a new standard in the industry. This breakthrough is the result of extensive research and development efforts aimed at addressing the evolving needs of the market and advancing the state-of-the-art in pumping technology.According to company spokesperson, the new pump technology represents a significant milestone in Pcm Pump's ongoing commitment to innovation and excellence. "We are thrilled to introduce this cutting-edge pump technology to our customers," said the spokesperson. "Our team has worked tirelessly to develop a solution that not only meets the current demands of the market but also anticipates the future needs of our clients. With this new technology, we are confident that we can provide our customers with the most advanced and reliable pumping solutions available."The new pump technology is designed to offer a range of benefits to customers across various industries. Its enhanced performance and energy efficiency will enable businesses to improve their operational efficiency and reduce their environmental footprint. In addition, the new technology is expected to deliver greater reliability and durability, minimizing downtime and maintenance costs for customers.Pcm Pump's commitment to innovation and excellence is further reflected in its comprehensive range of pumping solutions. The company offers a wide variety of pumps, including progressive cavity pumps, peristaltic pumps, and centrifugal pumps, all designed to meet the diverse needs of its customers. With a focus on quality, reliability, and efficiency, Pcm Pump has built a strong reputation as a preferred partner for pumping solutions.In addition to its innovative pump technology, Pcm Pump also prides itself on providing exceptional customer service and support. The company's team of experts is dedicated to assisting customers in selecting the right pumping solutions for their specific needs and ensuring that they receive the necessary technical support and assistance. Pcm Pump's commitment to customer satisfaction is evident in its long-standing relationships with a wide range of clients, who continue to rely on the company for their pumping needs.Looking forward, Pcm Pump remains committed to pushing the boundaries of pumping technology and driving innovation in the industry. The company's dedication to research and development, combined with its customer-centric approach, positions Pcm Pump as a leader in the field of pumping solutions.With the launch of its latest pump technology, Pcm Pump is poised to set a new benchmark for performance, efficiency, and reliability in the industry. As businesses continue to seek more advanced and sustainable pumping solutions, Pcm Pump is well-positioned to meet and exceed their expectations.In conclusion, Pcm Pump's latest pump technology represents a significant advancement in the field of pumping solutions, showcasing the company's commitment to innovation, excellence, and customer satisfaction. As the industry continues to evolve, Pcm Pump is poised to play a pivotal role in shaping its future through cutting-edge technology and unparalleled service.

Effective Maintenance Tips for Screw Pumps

Title: Expert Tips for Screw Pump MaintenanceIntroduction:Screw pumps are vital components in a wide range of industries, including oil and gas, petrochemicals, wastewater treatment, and food processing, among others. These pumps play a crucial role in ensuring the smooth flow of liquids or semi-solid materials in various industrial processes. However, like any other mechanical equipment, regular maintenance is essential to keep screw pumps operating at optimal efficiency.In this article, we will discuss expert tips for screw pump maintenance, utilizing our industry knowledge and experience to provide valuable insights. Our aim is to help businesses maximize their operational efficiency, reduce downtime, and extend the lifespan of screw pumps, ultimately saving costs in the long run.Understanding Screw Pump Components:Before delving into maintenance procedures, it is essential to have a basic understanding of screw pump components. Screw pumps typically consist of three main parts:1. Rotors: These are the primary moving components responsible for transferring fluid. Two or more rotors with intermeshing threads create a sealed cavity that moves fluid from the pump's inlet to its outlet.2. Stator: The fixed component surrounding the rotors, the stator provides a tight seal to prevent leakage and assists in fluid movement.3. Housing: The casing that encloses the rotors and stators, ensuring a secure and stable operation.Expert Tips for Screw Pump Maintenance:1. Regular Inspection and Cleaning: - Schedule routine inspections to identify signs of wear, damage, or leakage in the pump and its parts. - Clean the pump regularly by flushing it with an appropriate cleaning agent to remove any accumulated debris or contaminants.2. Lubrication: - Ensure the rotor and stator are adequately lubricated to reduce friction, heat, and wear. - Use compatible lubricants recommended by the pump manufacturer for optimal performance.3. Shaft Alignment: - Misalignment can cause undue stress on the pump's components, leading to premature failure. - Regularly check and correct any misalignment issues to maintain smooth operation.4. Sealing System: - Inspect and replace worn or damaged seals regularly to prevent fluid leakage, ensuring efficient pump performance. - Utilize high-quality, chemical-resistant seals suitable for the specific fluid being pumped.5. Temperature and Vibration Monitoring: - Monitor the pump's operating temperature and vibrations using appropriate sensors. - Abnormal readings can indicate potential issues, such as overheating or mechanical imbalance, requiring immediate attention.6. Regular Bearing Maintenance: - Lubricate bearings as per the manufacturer's guidelines to minimize friction and prevent premature wear. - Monitor bearing condition and replace if signs of damage or deterioration are evident.7. Overload Protection: - Install overload protection devices to safeguard the pump against excessive loads, preventing potential damage.8. Spare Parts Inventory: - Maintain a stock of essential spare parts to minimize downtime in the event of failure or breakdown. - Consult with product experts to identify critical components that require immediate replacement availability.By following these expert tips, businesses can optimize the performance and longevity of their screw pumps, ensuring uninterrupted operation and maximizing efficiency.Company Introduction: {Insert company introduction here}Conclusion:Proactive maintenance of screw pumps is crucial for businesses relying on these mechanical systems to achieve smooth operations in various industries. Regular inspection, cleaning, lubrication, and addressing misalignment are just a few essential maintenance practices to keep screw pumps in optimal condition. Following these expert tips and leveraging the knowledge and experience of the company would assist businesses in reducing downtime, minimizing repairs, and extending the lifespan of their screw pumps, ultimately leading to increased operational and cost efficiencies.