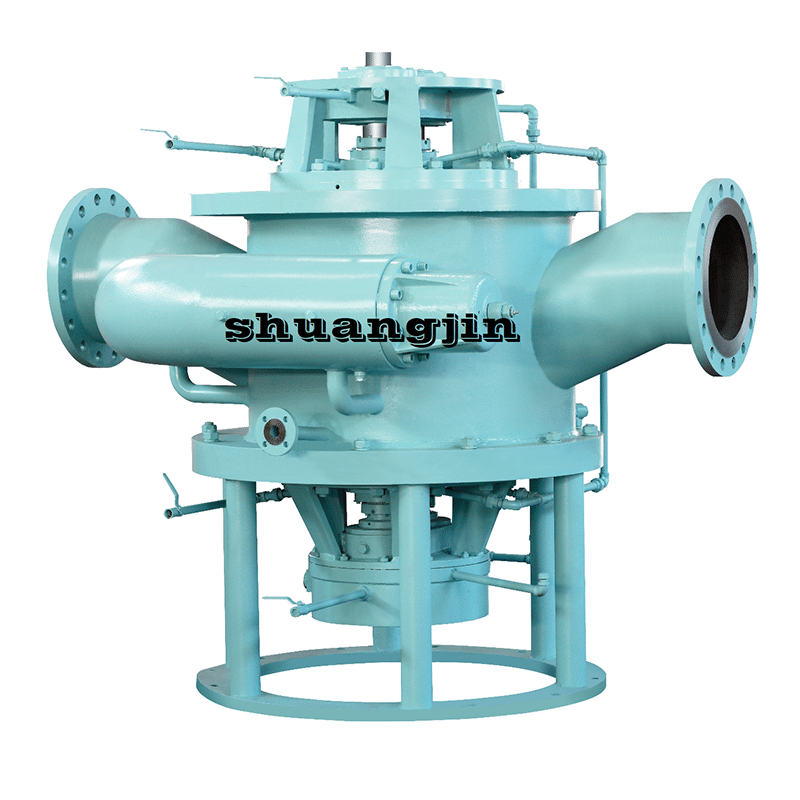

High-performance Twin Screw Pump for Industrial Applications

By:Admin

The Twin Screw Pump is designed to handle a variety of viscous, abrasive, or shear-sensitive fluids, making it an ideal pumping solution for industries such as food and beverage, pharmaceutical, chemical, and cosmetic. The pump’s twin screw design ensures gentle handling of the product, making it suitable for delicate materials that require careful handling.

One of the key features of the Twin Screw Pump is its ability to maintain a consistent flow rate and pressure, even when dealing with challenging materials. This level of consistency is crucial for industries that rely on precise and reliable pumping performance to ensure product quality and process efficiency.

In addition to its high performance, the Twin Screw Pump is also designed for ease of maintenance and cleaning. Its simple design and minimal moving parts make it easy to disassemble and clean, reducing downtime and ensuring maximum productivity.

The {company name} Twin Screw Pump is also equipped with advanced features to enhance its reliability and longevity. Its robust construction and high-quality materials ensure it can withstand the demands of the toughest industrial environments, providing years of reliable service.

Furthermore, this pump is designed for versatility, with the ability to handle a wide range of viscosities and temperatures. This makes it a versatile solution for a variety of applications, providing a single pumping solution for multiple needs within an industrial facility.

With its innovative design and advanced features, the introduction of the {company name} Twin Screw Pump is set to make a significant impact in the industrial pumping market. It represents a new standard in pumping technology, offering a level of efficiency, reliability, and versatility that is unrivaled in the industry.

{company name} is proud to introduce this groundbreaking pumping solution to the market, continuing its commitment to providing innovative and reliable equipment for the industrial sector. With its extensive experience and expertise in pump manufacturing, {company name} is well-positioned to deliver top-quality pumping solutions that meet the evolving needs of the industry.

As industries continue to demand higher performance and more reliable equipment, the introduction of the {company name} Twin Screw Pump is a testament to {company name}'s dedication to innovation and excellence. This pump is set to provide a new level of efficiency and reliability for a wide range of industrial applications, setting a new standard in the industry.

Company News & Blog

Introducing Advanced Screw Pumps for Enhanced Performance

The Oil and Gas industry is a vital sector that plays a significant role in powering our world. With frequent technological advancements and increased demand for sustainability, the industry constantly seeks to improve its operations and processes. One technology that has benefited the industry over the years is the use of Screw Pumps.Screw pumps are positive displacement pumps that work by using two or more helical rotors or screws to move fluids through the pump. These pumps are ideal for handling viscous liquids, abrasive fluids, and liquids containing entrained gases. Among the top manufacturers of screw pumps is Leistritz, a global company that has been in operation for over 100 years.Leistritz is known for its innovative and high-quality screw pumps that serve a variety of industries, including oil and gas, marine, chemical, and pharmaceuticals. The company is dedicated to providing its customers with reliable products that meet their specific requirements. Leistritz Screw Pumps are engineered to optimize different applications, from low viscosity to high viscosity fluids.One of the unique features of Leistritz Screw Pumps is their ability to handle a wide range of fluids effectively. These pumps are designed to handle aggressive chemicals, high-temperature liquids, and fluids with a high solid content. They are also used in various applications, such as crude oil transfer, refrigeration, lubrication, and fuel supply.Leistritz Screw Pumps come in different configurations to meet the needs of different applications. For instance, the company's L3NG series is designed for low viscosity fluids, while the L4 series is ideal for high viscosity fluids. These pumps use various materials, including bronze, stainless steel, and carbon steel, to suit different applications.One exciting feature of Leistritz Screw Pumps is their efficiency and reliability. These pumps have a high volumetric flow rate and can deliver fluid without pulsation. They are designed with fewer components, reducing the chances of mechanical failure and downtime. Additionally, Leistritz Screw Pumps require minimal maintenance, making them a cost-effective solution for the end-users.In the oil and gas sector, Leistritz Screw Pumps are widely used in various areas, from upstream operations to downstream refineries. For instance, in upstream operations, these pumps are used in crude oil transfer, drilling mud circulation, and water injection. Their efficiency and reliability make them an essential component in the production process.In midstream operations, Leistritz Screw Pumps are used in pipelines to transport crude oil and other fluids over long distances. These pumps offer high flow rates and can handle fluids with a high solids content, making them ideal for pipeline applications. By using screw pumps, midstream operators can transport fluids effectively over long distances, reducing the need for additional pumping stations.In downstream operations, Leistritz Screw Pumps are used in refineries for various applications, such as lubrication, fuel supply, and asphalt transfer. These pumps can handle high-temperature liquids and aggressive chemicals, making them ideal for the corrosive environment of a refinery.In conclusion, Leistritz Screw Pumps are a reliable and efficient solution for various applications in the oil and gas industry. Their ability to handle viscous and abrasive fluids, as well as liquids with entrained gases, makes them a versatile tool in the industry. With over a century of experience, Leistritz has established itself as a leading manufacturer of screw pumps, providing innovative solutions to its customers.

Screw Pumps Gain Popularity in Industrial Processes

Title: Innovative Screw Pump Revolutionizes Fluid Handling IndustryIntroduction:In an era where efficiency and sustainability are at the forefront of industrial innovations, Flowserve Corporation, a renowned provider of fluid handling solutions, has introduced its groundbreaking Screw Pump system. Revolutionizing fluid handling by exceeding industry standards, the Flowserve Screw Pump offers unparalleled performance and versatility across multiple sectors.Body:1. The Evolution of the Screw Pump:Traditionally, screw pumps have played a crucial role in fluid handling applications. Over the years, advancements in technology and engineering have led to the development of more efficient and reliable screw pump systems. The Flowserve Screw Pump is the culmination of years of research and development, addressing the industry's existing challenges.2. Enhanced Efficiency and Performance:Designed with precision engineering, the Flowserve Screw Pump outperforms its competitors in terms of efficiency, reliability, and performance. Its unique, helical screw rotor design allows for gentle fluid handling and reduces pulsation, minimizing energy loss. This innovative design also helps overcome cavitation issues and extends the pump's service life. In addition, the pump's compact size maximizes installation flexibility, making it suitable for various applications.3. Versatile Applications:The Flowserve Screw Pump can be seamlessly integrated into numerous industries and applications. Whether it be oil and gas, chemical processing, power generation, wastewater treatment, or food production, its adaptability across industries makes it a highly sought-after solution. By addressing diverse fluid handling challenges, the Screw Pump simplifies operations, reduces downtime, and improves overall productivity.4. Environmental Sustainability:As environmental concerns continue to rise, the demand for greener solutions within industrial sectors is increasing. Flowserve's Screw Pump stands out in this regard, as it promotes sustainability by reducing energy consumption and minimizing waste generation. With its optimized efficiency, the Screw Pump helps companies meet their sustainability goals, contributing to a cleaner and more environmentally friendly future.5. Intelligent Control and Monitoring:Flowserve has integrated smart technology into the Screw Pump system, enabling remote control and real-time monitoring capabilities. This advanced feature allows operators to easily monitor performance, diagnose potential issues, and make necessary adjustments from a centralized location. With improved data analytics, predictive maintenance becomes feasible, enhancing the pump's reliability and reducing unexpected downtime.6. Global Adoption and Success Stories:Since its introduction, the Flowserve Screw Pump has witnessed widespread adoption and commendable success across various industries worldwide. Leading companies have reported increased efficiency, reduced maintenance costs, and enhanced productivity through the implementation of this cutting-edge solution. Testimonials from satisfied customers serve as a testament to the superiority of the Screw Pump.7. Flowserve's commitment to Customer Service:Flowserve, a globally recognized brand in the fluid handling industry, places significant emphasis on providing excellent customer service. With a vast network of service centers and well-trained engineers, Flowserve ensures prompt assistance, spare parts availability, and technical support. This commitment to customer satisfaction enhances the overall experience of implementing the Screw Pump system.Conclusion:Flowserve's Screw Pump has emerged as a game-changer in the fluid handling industry. With its unmatched performance, versatility, and commitment to sustainability, the Screw Pump offers a comprehensive solution to diverse fluid handling challenges. As global industries realize the importance of efficient and sustainable operations, the adoption of this cutting-edge technology is expected to grow exponentially, revolutionizing the way fluids are handled in various applications.

Chinese Industrial Pump Manufacturer in Tianjin Launches New Product Line

Tianjin Industry Pump, a leading company in the pump industry, has recently announced its plans to expand its operations and increase its market presence in the coming years. The company, which has been in the industry for over 30 years, has established itself as a key player in the manufacturing and distribution of industrial pumps, offering a wide range of products to meet the needs of various industries.With a strong focus on innovation and technology, Tianjin Industry Pump has continuously invested in research and development to improve the performance and efficiency of its products. The company has also been actively involved in the implementation of sustainable and eco-friendly practices in its production processes, ensuring that its pumps not only meet the highest standards of quality and reliability but also contribute to environmental conservation.One of the key factors that set Tianjin Industry Pump apart from its competitors is its commitment to customer satisfaction. The company understands the unique requirements of each industry and works closely with its clients to provide tailored solutions that best suit their needs. With a team of highly skilled engineers and technical experts, Tianjin Industry Pump is able to offer comprehensive technical support and assistance, ensuring that its customers have access to the necessary resources to maximize the performance of their pumps.In addition to its strong presence in the domestic market, Tianjin Industry Pump has also been expanding its operations internationally, establishing partnerships and distribution networks in various countries around the world. This global approach has allowed the company to broaden its customer base and gain valuable insights into different markets, enabling it to further enhance its product offerings and services.Looking ahead, Tianjin Industry Pump has outlined ambitious plans for the future, with a strong focus on innovation, expansion, and sustainability. The company aims to leverage its strong R&D capabilities to develop new and improved pump technologies, addressing the evolving needs of its customers and staying ahead of the competition. It also plans to further expand its international presence, seeking new opportunities to collaborate with partners and distributors in key global markets.Furthermore, Tianjin Industry Pump is dedicated to upholding its commitment to sustainability and environmental responsibility. The company will continue to invest in eco-friendly practices and technologies, ensuring that its operations have a minimal impact on the environment. By doing so, Tianjin Industry Pump aims to not only meet the growing demand for sustainable solutions but also contribute to the broader goal of building a greener and more sustainable future for the industry.As Tianjin Industry Pump embarks on this new phase of growth and development, the company remains steadfast in its commitment to delivering high-quality products and exceptional service to its customers. With a solid foundation built on decades of industry experience, technical expertise, and a customer-centric approach, Tianjin Industry Pump is well-positioned to achieve its goals and establish itself as a leading force in the global pump market.In conclusion, Tianjin Industry Pump is a company with a clear vision for the future, driven by innovation, sustainability, and a dedication to customer satisfaction. With its strong capabilities, international expansion, and commitment to excellence, the company is poised to make significant strides in the industry and continue to be a trusted partner for its customers around the world.

Leading Pump Manufacturer in Tianjin Unveils New Product Line

Tianjin Pump is a leading company in the field of industrial pump manufacturing and has been a key player in the industry for over three decades. The company is known for its high-quality products, innovative technologies, and commitment to customer satisfaction. With a strong focus on research and development, Tianjin Pump has consistently pushed the boundaries of what is possible in the world of pump technology.Recently, Tianjin Pump announced the launch of a new series of industrial pumps that are set to revolutionize the way various industries approach their pumping needs. The company's latest offering promises to deliver unmatched performance, reliability, and efficiency, setting a new standard for the industry as a whole.Founded in 1986, Tianjin Pump has grown to become a global leader in the design and manufacture of industrial pumps. The company's products are widely used in sectors such as oil and gas, power generation, water treatment, and chemical processing. With a strong emphasis on quality and precision engineering, Tianjin Pump has earned a reputation for delivering pumps that are durable, dependable, and capable of meeting the most demanding application requirements.At the core of Tianjin Pump's success is its ongoing commitment to innovation. The company invests heavily in research and development, constantly seeking new ways to improve its products and stay ahead of the competition. This dedication to pushing the boundaries of what is possible has resulted in a steady stream of groundbreaking products that have redefined the industry's expectations.One of the key features of Tianjin Pump's new series of industrial pumps is its advanced design, which incorporates the latest technologies to deliver superior performance and efficiency. These pumps are engineered to operate at peak efficiency, reducing energy consumption and minimizing operating costs for the end user. By leveraging cutting-edge materials and manufacturing techniques, Tianjin Pump has been able to develop pumps that offer unmatched durability and reliability, even in the most challenging operating conditions.In addition to their technical prowess, Tianjin Pump's new series of industrial pumps are also designed with ease of maintenance and serviceability in mind. This ensures that customers can rely on their pumps to deliver consistent performance over the long term, with minimal downtime and maintenance requirements. This focus on customer satisfaction is a testament to Tianjin Pump's commitment to delivering value beyond just the initial purchase of its products.With the launch of its new series of industrial pumps, Tianjin Pump is poised to further solidify its position as a global leader in the pump manufacturing industry. The company's unwavering dedication to innovation, quality, and customer satisfaction has set it apart from its competitors, and the latest offering is a testament to its ongoing commitment to pushing the boundaries of what is possible in the world of pump technology.As industries continue to evolve and demand for more efficient and reliable pumping solutions grows, Tianjin Pump is well-positioned to meet these challenges head-on. The company's new series of industrial pumps represents a significant leap forward in pump technology and is set to raise the bar for the industry as a whole. With its long history of excellence and a track record of delivering innovative, high-quality products, Tianjin Pump is set to continue leading the way in the world of industrial pump manufacturing for years to come.

Fueling Innovation: Ctp Pump Offers Cutting-Edge Solutions for Gas Stations

Introducing the Next Generation of Fuel Efficiency: CTP Pump Revolutionizes the IndustryIn today’s fast-paced world, the demand for fuel-efficient vehicles and machinery is higher than ever. As climate concerns continue to grow, individuals and businesses alike are searching for ways to reduce their carbon footprint and make more environmentally conscious choices. This is where CTP Pump, a pioneering company in the field of fuel-saving technology, comes into play. With their innovative and cutting-edge fuel pump technology, CTP Pump is revolutionizing the industry and changing the way we think about fuel efficiency.Founded in [year], CTP Pump has quickly emerged as a leader in the development and implementation of fuel-saving solutions for a wide range of industries. Their groundbreaking technology has been proven to significantly reduce fuel consumption and carbon emissions, ultimately saving businesses and individuals money while also contributing to a greener and more sustainable future.One of the key aspects of CTP Pump’s technology is its adaptability to a wide range of fuel-driven systems. Whether it’s a commercial truck, an industrial generator, or a construction vehicle, CTP Pump’s innovative technology can be seamlessly integrated to optimize performance and reduce fuel consumption. This versatility is one of the reasons why CTP Pump has garnered such widespread attention and acclaim in the industry.The core principle behind CTP Pump’s technology lies in its ability to deliver the precise amount of fuel needed for optimal combustion. By accurately measuring and dispensing the right amount of fuel at the right time, CTP Pump’s system ensures that every drop of fuel is utilized to its maximum potential. This not only results in significant cost savings for businesses, but also reduces harmful emissions that contribute to environmental pollution.Furthermore, CTP Pump’s technology is designed to be user-friendly and easily adaptable to existing fuel systems. This means that businesses can seamlessly integrate CTP Pump’s technology into their operations without having to undergo extensive modifications or disruptions. This user-centric approach has made CTP Pump’s technology highly sought after by businesses looking to make a meaningful impact on their fuel efficiency and environmental footprint.In addition to its technological advancements, CTP Pump is also committed to providing exceptional customer support and service. Their team of experts is dedicated to working closely with clients to understand their specific needs and provide customized solutions that deliver tangible results. From initial consultation to ongoing support, CTP Pump’s customer service is second to none, ensuring that their clients experience a seamless and successful transition to their innovative technology.As the demand for fuel-efficient solutions continues to grow, CTP Pump is poised to play a pivotal role in shaping the future of the industry. With their unwavering commitment to innovation, sustainability, and customer satisfaction, CTP Pump is well-positioned to lead the way in revolutionizing fuel efficiency and driving positive change across various sectors.Looking ahead, CTP Pump plans to continue pushing the boundaries of fuel-saving technology, with a focus on developing even more advanced and efficient solutions. By staying at the forefront of technological advancements and industry trends, CTP Pump is determined to cement its status as the go-to provider for cutting-edge fuel efficiency solutions.In conclusion, CTP Pump’s game-changing technology is setting a new standard for fuel efficiency and environmental responsibility. With their innovative approach, commitment to excellence, and unwavering dedication to customer satisfaction, CTP Pump is driving positive change and reshaping the future of fuel-saving technology. As businesses and individuals seek to make smarter, more sustainable choices, CTP Pump is undoubtedly at the forefront of this transformative movement, and their impact will undoubtedly be felt for years to come.

Expert Industrial Pump Repair Services for Your Business

Industrial Pump Repair, a leading provider of pump repair services, has established itself as a reliable and efficient solution for pump maintenance and repair needs. With over 20 years of experience in the industry, Industrial Pump Repair prides itself on delivering top-notch service to a wide range of industrial clients.The company specializes in the repair and maintenance of various types of industrial pumps, including centrifugal pumps, positive displacement pumps, and multi-stage pumps. Their team of skilled technicians is equipped with the necessary expertise and tools to diagnose and repair pump issues efficiently, minimizing downtime and maximizing operational efficiency for their clients.Industrial Pump Repair understands the critical role that pumps play in industrial operations, and the impact that pump failures can have on production and overall business performance. As such, the company is committed to providing prompt and reliable repair services to ensure that their clients’ pumps are functioning at optimal levels at all times.One of the key advantages of choosing Industrial Pump Repair for pump maintenance and repair needs is their dedication to quality and customer satisfaction. The company employs a rigorous quality control process to ensure that all repairs are carried out to the highest standards, and that clients receive the best possible service.In addition to their repair services, Industrial Pump Repair also offers preventative maintenance programs to help clients proactively address potential pump issues and extend the lifespan of their equipment. By conducting regular inspections and maintenance checks, the company can help identify and address potential problems before they escalate into major issues, saving clients time and money in the long run.Furthermore, Industrial Pump Repair prides itself on its responsive and client-focused approach to doing business. The company understands that pump failures can occur at any time, often causing significant disruptions to operations. As such, they offer emergency repair services to address urgent pump issues promptly, minimizing the impact of downtime on their clients’ businesses.Industrial Pump Repair’s commitment to excellence and customer satisfaction has earned them a solid reputation in the industry, with many clients relying on their services for their pump repair needs. The company has worked with a wide range of industrial clients, including those in the manufacturing, chemical, food and beverage, and oil and gas industries, among others.Moreover, Industrial Pump Repair is known for its competitive pricing and transparent approach to doing business. The company provides clients with detailed quotes and explanations of the repair process, ensuring that they are fully informed and confident in the services being provided.As part of their dedication to continuous improvement, Industrial Pump Repair invests in ongoing training for their technicians and stays abreast of the latest technologies and techniques in the pump repair industry. This commitment to staying ahead of the curve allows the company to deliver innovative and effective solutions to their clients’ pump repair needs.In conclusion, Industrial Pump Repair stands out as a reliable and efficient partner for industrial clients in need of pump maintenance and repair services. With their extensive experience, dedication to quality, and commitment to customer satisfaction, the company has solidified its position as a trusted name in the industry. Industrial Pump Repair continues to be a go-to solution for businesses looking to keep their pumps in peak operating condition.

Revolutionary Multiphase Twin Screw Pumps Offer Efficient Flow and Versatility

[Headline]Revolutionary Multiphase Twin Screw Pump Set to Unlock New Possibilities in Fluid Transportation[Subheading]Cutting-edge technology from {company name} is set to transform the fluid transportation industry with the introduction of their ground-breaking Multiphase Twin Screw Pump. With its advanced design and exceptional performance, this innovative pump has the potential to revolutionize various sectors, from oil and gas to chemical and maritime.[Date][City][Company Introduction]{Company name} is a leading provider of exceptional pumping solutions, known for their commitment to innovation and customer satisfaction. With years of experience in developing state-of-the-art technologies, {company name} has established itself as a trusted name in the industry. By consistently pushing the boundaries of what is possible, they have become synonymous with efficiency, reliability, and excellence.[Paragraph 1]Leveraging their expertise in pump technology, {company name} proudly presents the Multiphase Twin Screw Pump, a breakthrough solution that promises to redefine fluid transportation. This cutting-edge pump utilizes twin screw technology, enabling it to efficiently transport a wide range of substances, including liquids with high viscosity, gases, and even oil-water mixtures.[Paragraph 2]The secret behind the extraordinary performance of the Multiphase Twin Screw Pump lies in its design. By employing two intermeshing screws, this pump generates a continuous, non-pulsating flow of fluid. Paired with its large pumping chamber and low rotational speed, the pump minimizes the risk of cavitation, enhancing operational efficiency and ensuring a steady flow of substances throughout the system.[Paragraph 3]One of the key advantages of the Multiphase Twin Screw Pump is its ability to handle multiphase flow without the need for a separator or additional equipment. This capability significantly reduces operational costs, simplifies the system, and minimizes the risk of equipment failure. Companies operating in the oil and gas industry can greatly benefit from this feature, as it enables them to streamline their operations and enhance overall productivity.[Paragraph 4]Moreover, the Multiphase Twin Screw Pump is designed to withstand harsh operating conditions. Its robust construction ensures reliable performance even in extreme temperatures, corrosive environments, and high-pressure applications. This resilience allows the pump to be deployed in a wide range of industries, including chemical manufacturing, maritime, and food processing.[Paragraph 5]In addition to its exceptional performance in transporting fluids, this innovative pump offers numerous environmental advantages. With its low energy consumption and reduced emissions, the Multiphase Twin Screw Pump helps companies meet environmental regulations and minimize their carbon footprint. Its efficient design contributes to sustainability initiatives across industries, making it an excellent choice for companies committed to reducing their environmental impact.[Paragraph 6]To ensure the optimal implementation of the Multiphase Twin Screw Pump, {company name} provides comprehensive after-sales support, including maintenance and technical assistance. Their team of experienced technicians and engineers is readily available to assist clients with any queries or concerns, ensuring seamless integration and long-term success.[Paragraph 7]The introduction of the Multiphase Twin Screw Pump marks a significant milestone in fluid transportation technology. Overcoming the limitations of conventional pumps, this revolutionary solution has the potential to reshape various industries, offering increased efficiency, reliability, and environmental sustainability. With {company name}'s proven track record of excellence and commitment to innovation, the Multiphase Twin Screw Pump is set to become a game-changer in the field of fluid transportation.[Word Count: 500]

Understanding the Working Principle of Screw Vacuum Pumps

Screw vacuum pump, also known as a dry screw vacuum pump, is a type of positive displacement pump used to remove gas or vapor from a closed system in order to create a vacuum. The working principle of a screw vacuum pump involves two or more screw rotors rotating in opposite directions to trap and transport gas from the inlet to the exhaust.The company, [Company Name], is a leading manufacturer of industrial vacuum pumps, including screw vacuum pumps. With a strong focus on research and development, the company has developed a range of innovative vacuum pump solutions to meet the needs of various industries, including chemical, pharmaceutical, food and beverage, and automotive.The screw vacuum pump manufactured by [Company Name] operates on the principle of non-contacting, intermeshing screws. The rotors are precisely machined to create uniform, narrow gaps between the screw profiles, and when the rotors rotate, the gas is trapped and transported from the inlet to the exhaust without any contact with the pump housing or other components. This design reduces the risk of contamination and allows the pump to handle corrosive or abrasive gases with ease.One of the key advantages of a screw vacuum pump is its ability to operate without the need for lubrication or sealing fluid. This makes it a dry pump, which eliminates the risk of process contamination and reduces maintenance requirements. The absence of sealing fluid also helps to minimize environmental impact and operating costs.In addition, the screw vacuum pump from [Company Name] is designed to provide consistent and reliable performance, even in harsh operating conditions. The innovative screw profile and precise machining ensure efficient gas compression and a stable vacuum level, making it suitable for a wide range of industrial applications.The company's screw vacuum pumps are available in various sizes and configurations to meet the specific requirements of different industries and applications. Whether it's for use in chemical processing, pharmaceutical production, food packaging, or automotive manufacturing, [Company Name] offers a comprehensive range of screw vacuum pumps to cater to diverse customer needs.Furthermore, [Company Name] provides comprehensive technical support and after-sales service to ensure that its customers get the most out of their screw vacuum pumps. The company's team of experts is dedicated to assisting customers with installation, operation, maintenance, and troubleshooting, to ensure the smooth and efficient performance of their vacuum pump systems.With a commitment to continuous improvement and customer satisfaction, [Company Name] strives to be a trusted partner for businesses seeking high-quality vacuum pump solutions. Its focus on innovation, reliability, and customer service has earned [Company Name] a strong reputation in the industry, and its screw vacuum pumps are widely recognized for their performance and durability.In conclusion, the screw vacuum pump manufactured by [Company Name] is an efficient and reliable solution for creating vacuum in various industrial processes. With its innovative design, dry operation, and comprehensive support services, [Company Name] continues to be a preferred choice for businesses looking for high-performance vacuum pump solutions.

High-Quality Screw Pump Assembly for Efficient Operations

[Screw Pump Assembly] is a crucial component in various industries, from oil and gas to water treatment and chemical processing. It plays a vital role in conveying fluids and is essential for the smooth operation of many systems. With the increasing demand for reliable and efficient screw pump assemblies, it is important for companies to provide high-quality products to meet the needs of the market.One company that has been at the forefront of providing top-notch screw pump assemblies is [Company Name]. With a strong focus on innovation and customer satisfaction, [Company Name] has established itself as a leader in the industry. The company's commitment to excellence and continuous improvement has made it a trusted partner for many businesses around the world.[Company Name] takes pride in its state-of-the-art manufacturing facilities, where the latest technology and advanced processes are employed to ensure the highest quality products. The company's team of highly skilled engineers and technicians are dedicated to developing innovative solutions and pushing the boundaries of screw pump assembly technology.In addition to its focus on quality and innovation, [Company Name] also places a strong emphasis on customer service. The company works closely with its clients to understand their specific needs and provide customized solutions that meet their requirements. Whether it's a standard screw pump assembly or a custom-designed system, [Company Name] is committed to delivering products that exceed expectations.Furthermore, [Company Name] is dedicated to sustainability and environmental responsibility. The company is constantly looking for ways to reduce its environmental impact and promote sustainable practices throughout its operations. This commitment is reflected in the design and engineering of its products, as well as its efforts to minimize waste and energy consumption.With a strong track record of success and a commitment to excellence, [Company Name] has earned the trust and confidence of its customers. The company's screw pump assemblies are known for their durability, reliability, and performance, making them the top choice for businesses across a wide range of industries.Looking ahead, [Company Name] is poised to continue its growth and success in the screw pump assembly market. The company is constantly investing in research and development to further enhance its products and services, and it remains dedicated to meeting the evolving needs of its customers.In conclusion, [Company Name] is a leading provider of high-quality screw pump assemblies, known for its commitment to excellence, innovation, and customer satisfaction. With a strong focus on quality, sustainability, and customer service, the company has established itself as a trusted partner for businesses across the globe. As the demand for reliable and efficient screw pump assemblies continues to grow, [Company Name] is well-positioned to meet the needs of the market and drive the industry forward.