High-quality industrial pumps: What you need to know

By:Admin

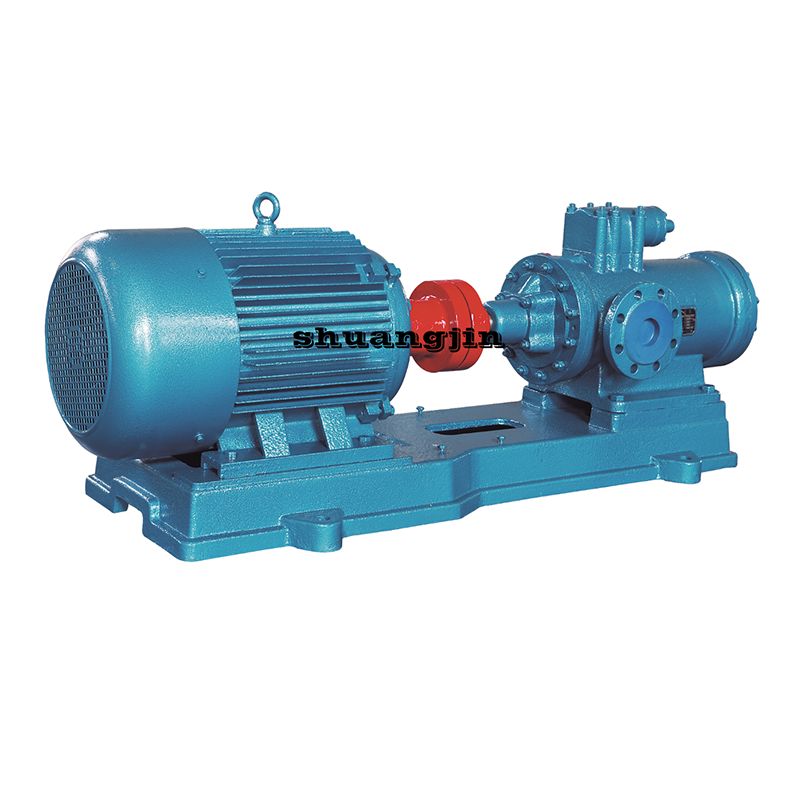

The new pump series, which includes models for a wide range of applications, incorporates the latest technological advancements to deliver superior performance and durability. Built with precision engineering and high-quality materials, these pumps are designed to withstand the most demanding operating conditions while maintaining optimal efficiency.

Bornemann Pump has a long history of developing innovative pumping solutions for industries such as oil and gas, chemical processing, food and beverage, and pharmaceuticals. The company's commitment to understanding the specific requirements of each industry has enabled it to develop pumps that not only meet but exceed the expectations of its customers.

In addition to its cutting-edge product line, Bornemann Pump offers a comprehensive range of services to support its customers throughout the entire lifecycle of their pumping systems. From initial consultation and design to installation, maintenance, and technical support, the company provides a full suite of solutions to ensure the seamless operation of its pumps.

Bornemann Pump's customer-centric approach is underscored by its dedication to providing personalized support and expertise. Its team of highly skilled engineers and technicians work closely with customers to understand their unique challenges and develop customized pumping solutions that address their specific needs.

The company's industry-leading expertise and commitment to quality have earned it a reputation for excellence in the pumping industry. Its pumps are renowned for their reliability, efficiency, and longevity, making them the preferred choice for businesses looking to enhance their operational efficiency and minimize downtime.

With a global network of sales and service centers, Bornemann Pump is well-positioned to serve a diverse range of industries around the world. Its extensive reach enables the company to provide timely and efficient support to its customers, ensuring that their pumping systems operate at peak performance at all times.

As Bornemann Pump continues to push the boundaries of pumping technology, it remains dedicated to delivering innovative solutions that empower its customers to achieve their business objectives. The company's ongoing investment in research and development reaffirms its commitment to staying at the forefront of the industry and delivering state-of-the-art pumping solutions that redefine industry standards.

In conclusion, Bornemann Pump's latest line of cutting-edge pumps is a testament to the company's unwavering commitment to innovation and excellence. With a focus on meeting the unique needs of its customers and delivering superior pumping solutions, Bornemann Pump continues to set the bar for quality and reliability in the industry. Whether it's in oil and gas, chemical processing, food and beverage, or pharmaceuticals, businesses can trust Bornemann Pump to provide the most advanced pumping solutions to meet their needs.

Company News & Blog

Twin Screw Pump: Latest Advancements and Applications in Pumping Technology

Alfa Laval Twin Screw Pump (brand name removed), an innovative and highly efficient pumping solution, is designed to meet the needs of various industries including food and beverage, pharmaceutical, marine, and oil and gas. With its advanced technology and superior performance, this pump is capable of handling a wide range of liquid transfer applications, making it an essential equipment in many industrial processes.The Alfa Laval Twin Screw Pump is renowned for its ability to handle both low and high viscosity liquids with ease, making it a versatile pumping solution for various industries. The pump’s unique design features two intermeshing screws that rotate in opposite directions, creating a continuous flow of liquid with minimal pulsation and shear force. This results in gentle and efficient product handling, making it ideal for pumping delicate and shear-sensitive fluids such as dairy products, pharmaceutical ingredients, and cosmetics.One of the key advantages of the Alfa Laval Twin Screw Pump is its ability to handle entrained air and gas, making it suitable for applications where aeration and foaming are common challenges. The pump’s robust construction and high suction capability allow for smooth and reliable operation even in demanding environments. This makes it an ideal choice for applications such as tank-to-tank transfer, product recovery, and CIP (clean-in-place) processes in the food and beverage industry.In addition to its exceptional performance, the Alfa Laval Twin Screw Pump is also designed for easy maintenance and cleaning. Its hygienic design features smooth surfaces and clean-in-place capabilities, ensuring that the pump can be quickly and thoroughly cleaned between product changeovers. This is essential for industries such as pharmaceutical and biotechnology, where product purity and sanitation are critical requirements.The Alfa Laval Twin Screw Pump is also suitable for marine and offshore applications, where reliable and efficient pumping solutions are essential for various onboard processes. Its compact and space-saving design makes it an ideal choice for installations with limited space, while its ability to handle high viscosity fuels and lubricants makes it a versatile solution for marine fuel transfer and lubrication systems.Moreover, the pump’s compliance with industry standards and regulations, such as EHEDG, 3-A, and FDA, ensures that it meets the stringent requirements of the food and pharmaceutical industries. This makes it a trusted and reliable pumping solution for critical processes where product safety and hygiene are of utmost importance.With its proven performance and versatility, the Alfa Laval Twin Screw Pump has established itself as a leading pumping solution in various industries. Its ability to handle a wide range of liquid transfer applications, combined with its gentle product handling and easy maintenance, makes it an essential equipment for many industrial processes. The pump’s advanced technology and hygienic design make it a reliable and efficient choice for industries that require high-quality and consistent liquid transfer solutions.In conclusion, the Alfa Laval Twin Screw Pump is a highly efficient and versatile pumping solution that meets the needs of various industries, including food and beverage, pharmaceutical, marine, and oil and gas. Its advanced technology, superior performance, and compliance with industry standards make it a trusted and reliable choice for critical liquid transfer processes. Whether it is for gentle product handling, efficient aeration handling, or easy maintenance and cleaning, this pump offers a comprehensive solution for a wide range of industrial applications.

Innovative Screw Pump for Efficient Slurry Handling

Screw Pump For Slurry: A Game-Changer in Slurry TransportIn the world of industrial and mining operations, the efficient and reliable transport of slurry is of utmost importance. Slurry, a mixture of solids and liquids, can be highly abrasive and corrosive, making its handling a challenging task. However, with the innovative Screw Pump for Slurry developed by {}, the transportation of slurry is set to become more efficient, reliable, and cost-effective.{} is a renowned name in the field of industrial pumping solutions, with a rich history of providing high-quality and cutting-edge products to its global clientele. The company's dedication to research and development has led to the creation of the Screw Pump for Slurry, a game-changing technology that is poised to revolutionize the slurry transport industry.The screw pump is designed to handle the most demanding slurry transport applications, offering a range of benefits that set it apart from traditional pumping solutions. Its unique design incorporates a screw-shaped rotor that rotates within a cylindrical cavity, effectively pushing the slurry along the length of the cavity. This design not only ensures a continuous and smooth flow of slurry but also minimizes the wear and tear on the pump, resulting in lower maintenance costs and extended operational life.One of the standout features of the screw pump is its ability to handle high-viscosity and abrasive slurry with ease. The robust construction of the pump, combined with the use of high-quality materials, allows it to withstand the challenging conditions often associated with slurry transport. This means that operators can rely on the screw pump to deliver consistent performance, even in the harshest of environments.Furthermore, the screw pump is highly efficient, offering significant energy savings compared to traditional pumping solutions. Its design minimizes internal recirculation and slippage, resulting in a more direct and efficient transfer of slurry. This not only reduces energy consumption but also lowers operating costs, making the screw pump a cost-effective choice for slurry transport applications.In addition to its superior performance, the screw pump is also designed with ease of maintenance in mind. The simple and robust construction of the pump makes it easy to inspect and service, minimizing downtime and ensuring continuous operation. This is a crucial advantage for industrial and mining operations, where any unplanned downtime can have significant ramifications on the overall productivity and profitability of the operation.With its innovative design, superior performance, and cost-saving benefits, the Screw Pump for Slurry from {} is set to become a go-to solution for slurry transport applications across various industries. Whether it's mining, chemical processing, or wastewater treatment, the screw pump offers a reliable and efficient means of transporting slurry, leading to improved productivity and reduced operating costs for operators.As a leading provider of industrial pumping solutions, {} remains committed to pushing the boundaries of innovation and delivering solutions that address the evolving needs of its customers. The development of the Screw Pump for Slurry is a testament to the company's dedication to excellence and its ability to bring game-changing technologies to the market.In conclusion, the Screw Pump for Slurry from {} represents a significant advancement in the field of slurry transport, offering unparalleled performance, reliability, and cost-effectiveness. With its innovative design and numerous benefits, the screw pump is poised to become a key technology for industrial and mining operations, setting new standards for slurry transport efficiency.

Highly Efficient Twin Screw Pump for Industrial Applications

Twin Screw Pump Generously Donated to Local Municipality to Support Water Distribution[City, State] - In a generous move to support the local community, a leading industrial equipment manufacturer has donated a state-of-the-art Twin Screw Pump to the [City] municipality. The [Company], known for its innovative and high-quality pumping solutions, has made this donation to aid in the efficient distribution of water to the residents of the city.The Twin Screw Pump, a highly advanced and reliable piece of equipment, is designed to handle a wide variety of fluids with ease. Its unique design allows for gentle pumping action, low pulsation, and a smooth flow, making it an ideal choice for the distribution of water in a municipal setting. With its robust construction and advanced technology, the pump is expected to significantly improve the efficiency and reliability of the city's water distribution system.The donation of the Twin Screw Pump comes as part of [Company]'s ongoing commitment to corporate social responsibility and giving back to the communities in which it operates. The company, which has a long history of supporting various charitable causes and initiatives, saw an opportunity to contribute to the well-being of the residents of [City] by providing them with a cutting-edge piece of equipment that will directly impact their daily lives."We are thrilled to be able to donate this Twin Screw Pump to the [City] municipality," said [Company spokesperson]. "Water distribution is a crucial aspect of urban life, and we are confident that our pump will help the city to improve the efficiency of its water infrastructure. It is our hope that this donation will not only benefit the city and its residents but also serve as a symbol of our commitment to being a responsible corporate citizen."The [City] municipality, which has been facing challenges with its aging water distribution system, has expressed its gratitude for the generous donation. The Twin Screw Pump will be installed at a key location within the city's water infrastructure, where it will be used to ensure the smooth and reliable distribution of water to homes and businesses."We are incredibly thankful to [Company] for their generous donation of the Twin Screw Pump," said [City official]. "This state-of-the-art equipment will undoubtedly make a positive impact on our water distribution system, allowing us to provide better service to our residents. We are truly grateful for [Company]'s support and commitment to our community."The installation of the Twin Screw Pump is expected to take place in the coming weeks, and the city's water department is already making preparations to integrate the new equipment into its existing infrastructure. Once operational, the pump is expected to deliver immediate improvements in the efficiency and reliability of the water distribution system, ultimately benefiting thousands of residents and businesses in the city.In addition to the donation of the pump, [Company] has also committed to providing training and technical support to the city's water department to ensure the proper operation and maintenance of the equipment. This ongoing support is expected to further enhance the long-term impact of the donation and help to maximize the benefits of the Twin Screw Pump for the city and its residents.The donation of the Twin Screw Pump by [Company] serves as a shining example of the positive impact that corporate generosity can have on local communities. By providing the city of [City] with a cutting-edge piece of equipment to improve its water distribution system, [Company] has demonstrated its dedication to being a responsible corporate citizen and making a meaningful difference in the lives of those it serves.

Understanding the Working Principle of Screw Vacuum Pumps

Screw vacuum pumps are a crucial piece of equipment in many industrial and manufacturing processes. They work on the principle of using two interlocking screws to compress and push air out of the system, creating a vacuum. This technology is vital for a range of applications, including food processing, pharmaceutical manufacturing, and even in the production of semiconductors.One company that is at the forefront of screw vacuum pump technology is {}. With a history dating back over 100 years in the vacuum pump industry, they have established themselves as a leader in the field. Their commitment to innovation and quality has made their screw vacuum pumps a popular choice for many businesses around the world.The working principle of their screw vacuum pumps is simple yet effective. The pumps consist of two screw rotors that rotate in opposite directions within a cylindrical housing. As the screws turn, they trap air between the threads and the housing, gradually reducing the volume of the trapped air. This compression process causes the air to be forced out of the system, creating a vacuum.The efficiency of the screw vacuum pump is due to the precise engineering of the screws and the housing. The screws must fit perfectly within the housing to prevent any backflow of air and maintain a consistent compression process. Additionally, the screws are designed to have a small clearance between each other and the housing, ensuring minimal leakage and maximum efficiency.One of the key advantages of using a screw vacuum pump is its ability to handle a wide range of operating pressures and vacuum levels. This makes it a versatile option for many different applications, from removing air and moisture in food processing to creating a high vacuum for semiconductor manufacturing.In addition to their working principle, {}'s screw vacuum pumps are known for their reliability and durability. The company's commitment to quality is evident in their manufacturing processes, where every pump is meticulously tested and inspected to ensure it meets their rigorous standards. This dedication to quality has earned them a reputation for producing long-lasting and high-performing equipment.Furthermore, {} offers a range of screw vacuum pumps to suit various needs and specifications. Whether it's a small-scale operation or a large industrial plant, they have a pump that can deliver the required vacuum level with efficiency. Their pumps are also designed to be energy-efficient, helping businesses reduce their overall energy consumption and operating costs.Another notable feature of {}'s screw vacuum pumps is their low maintenance requirements. Thanks to their robust design and high-quality components, these pumps are built to withstand the rigors of continuous operation with minimal need for maintenance. This ensures that businesses can rely on their equipment to keep running smoothly without interruptions.In conclusion, screw vacuum pumps are an essential technology for many industries, and {} is a leading provider of these pumps with a strong focus on quality, innovation, and reliability. With their advanced working principle and commitment to customer satisfaction, businesses can trust {} to provide them with the vacuum solutions they need to keep their operations running smoothly and efficiently.

Innovative Centrifugal Screw Pump Technology Revolutionizing Industrial Pumping Applications

Centrifugal Screw Pump Proves to be a Game-Changer in Industrial ApplicationsIn the world of industrial applications, finding the right kind of machinery that suits the needs of the business is essential. Centrifugal Screw Pumps, also known as twin-screw pumps, have been creating waves in various industries lately. They have gained immense popularity due to their unmatched efficiency, versatility, and durability.A centrifugal screw pump is a positive displacement pump that transfers fluid by moving it through closely-spaced screws, generating pressure and flow. This particular pump's design enables it to handle tough-to-pump fluids with high viscosity and solids content. Consequently, the centrifugal screw pump is known to reduce maintenance costs, increase the lifecycle of machines, and enhance overall operational efficiency.However, the centrifugal screw pump by a prominent brand has gained significant attention for its cutting-edge technology, exceptional performance, and outstanding customer service. This high-quality pump has been used in several industries and applications such as marine, food processing, wastewater treatment, biodiesel production, and more.One of the many advantages of the centrifugal screw pump is the considerable reduction in cavitation. When a pump experiences high-pressure changes, there could be areas of low pressure that lead to the formation of cavities or bubbles. With traditional pumps, cavitation would cause significant damage, resulting in increased maintenance costs. Installing a centrifugal screw pump substantially reduces this problem since the pump can handle a higher level of turbulence without the creation of cavities.Another crucial advantage of centrifugal screw pumps is their ability to handle fluids of varying viscosity. They operate with a wide range of viscosities, even as high as 200,000 centipoises, without the need for external pumps. This feature allows it to handle more challenging fluids such as crude oil, molasses, and syrup.This pump design also facilitates the transfer of fluids with high solid content. It is capable of transferring up to 40% blockage in its internal flow chambers without damaging the rotor or the stator. This pump design makes it ideal for transferring abrasive fluids or slurries and is a critical component in several waste treatment systems.Moreover, the centrifugal screw pump is also suitable for metering applications due to its precise flow rate. Its discharge rate is unaffected by variations in fluid viscosity, temperature, or pressure, which is uncommon in other types of pumps. This accuracy makes it an ideal solution for transferring critical fluids in the pharmaceutical and chemical industries.Overall, this high-end centrifugal screw pump equipped with state-of-the-art technology is a guaranteed game-changer in the industrial manufacturing sector. \This pump has already made a significant impact in the industry by delivering unmatched performance and efficiency. With its ability to handle complex fluids, reduce maintenance costs, increase machine longevity, and improve overall operational efficacy, it remains the top choice for many businesses.Additionally, the company that produces this innovative centrifugal screw pump takes pride in providing customers with the best service in the industry. Their team of experts makes every effort to assist and guide clients in the selection, installation, and maintenance of equipment. They also offer comprehensive training to ensure maximum productivity and efficiency from the pump.In conclusion, investing in a centrifugal screw pump from this reputable brand is the best decision any business can make. It delivers exceptional performance, reduces production costs, and adds value to the entire manufacturing process. With its unmatched versatility and durability, it is the ultimate solution to all your fluid transfer needs. Contact their team today and experience the revolution in industrial manufacturing!

How to Choose the Best Oil Pumps on the Market

[Title]: Global Pumps for Oil Market Witnesses Steady Growth as Demand Increases[Introduction]:The global pumps for oil market has been witnessing a steady growth trajectory in recent years, primarily fueled by increasing oil extraction activities across the globe. With rising energy needs and growing exploration and production activities in both conventional and unconventional oilfields, the demand for efficient and reliable pumps for oil has been on the rise. These pumps play a crucial role in facilitating the extraction, transportation, and refining processes of oil, making them an essential component of the oil and gas industry.[Paragraph 1]:The market for pumps for oil is expected to expand at a substantial CAGR over the forecast period of [period]. This growth can be attributed to several factors, such as the increasing number of oil and gas exploration projects, the rising adoption of advanced pumping technologies, and the continuous investment in the development of new oilfields. Additionally, the growth of offshore oil exploration activities has further fueled the demand for pumps that can withstand harsh marine environments.[Paragraph 2]:One of the key players operating in the global pumps for oil market is [company name]. With over [number] years of experience, the company has established itself as a trusted manufacturer and supplier of high-quality pumps designed specifically for oil applications. The pumps are known for their efficiency, durability, and reliability, making them a preferred choice among oil industry operators worldwide.[Paragraph 3]:[Company name] offers a wide range of pumps for oil, including centrifugal pumps, reciprocating pumps, and rotary pumps. These pumps are engineered to meet the unique requirements of different stages of oil extraction and processing, ensuring optimal performance and productivity. The company's cutting-edge technology and innovative designs enable the pumps to handle various viscosities of oil while maintaining high efficiency levels.[Paragraph 4]:One of the standout features of [company name]'s pumps for oil is their robust construction, which enables them to withstand the harsh operating conditions often encountered in oilfields. The pumps are designed to handle corrosive fluids, high temperatures, and abrasive materials, ensuring long service life and minimizing downtime. Moreover, the company's commitment to quality and adherence to international standards ensure that their pumps deliver consistent results even in the most challenging environments.[Paragraph 5]:In addition to their superior performance, [company name]'s pumps for oil also prioritize sustainability and environmental considerations. The company has made significant investments in research and development to enhance energy efficiency and reduce carbon emissions associated with oil pumping operations. These initiatives have garnered praise from industry experts, positioning [company name] as a responsible and eco-friendly solution provider.[Paragraph 6]:Geographically, [company name] has a well-established presence in major oil-producing regions, including North America, the Middle East, and Asia. The company's extensive distribution network and strategic partnerships ensure timely delivery and support to customers, regardless of their location. This widespread reach allows [company name] to cater to the diverse needs of oil industry operators globally, adding to its market dominance.[Paragraph 7]:Looking ahead, the global pumps for oil market is poised for significant growth as oil extraction activities expand and become more technologically advanced. With the increasing focus on renewable energy sources and the transition toward a greener future, the development of more efficient and sustainable pumps for oil will play a pivotal role in meeting the world's energy needs. As a leading player in the industry, [company name] remains committed to continuous innovation and delivering cutting-edge solutions that help shape the future of oil pumping technology.[Conclusion]:As the global demand for oil continues to rise, the pumps for oil market is expected to witness steady growth. With [company name] at the forefront of pump manufacturing, oil industry operators can rely on their expertise to provide reliable and efficient solutions. By combining advanced technology, durable construction, and environmental consciousness, [company name] stands as a key player in the global pumps for oil market, poised to meet the evolving needs of the oil and gas industry.

Discover the Top Marine Water Pump for Your Needs in 2022

Marine Water Pump Enhances Efficiency and Reliability in Marine Operations[City, Date] - As the maritime industry continues to evolve and seek innovative solutions to enhance efficiency and reliability, the Marine Water Pump has emerged as a game-changer in marine operations. Manufactured by a reputed company [], this cutting-edge technology is revolutionizing the industry's approach towards water pumping systems.With the ever-increasing demand for efficient water transportation, maintaining reliable pumping systems becomes crucial. The Marine Water Pump, crafted with precision and advanced engineering, offers an ideal solution for various marine applications. Whether it's for ballast water management, bilge pumping, or firefighting operations, this water pump offers unmatched performance and efficiency.One of the key aspects that sets the Marine Water Pump apart from traditional systems is its durability and reliability. Constructed from high-quality materials, this pump is built to withstand the harsh marine environment, ensuring longevity and minimal downtime. The corrosion-resistant body and components minimize the risk of damage and reduce maintenance costs, making it an ideal choice for marine operators seeking cost-effective solutions.Moreover, the compact design of the Marine Water Pump enables easy installation and integration into existing marine systems. Its versatility allows for seamless compatibility with different vessel types, ranging from small crafts to large commercial ships. By reducing installation time and complexity, this pump assists marine operators in streamlining their operations and maximizing productivity.Furthermore, the advanced engineering behind the Marine Water Pump ensures optimal performance and energy efficiency. With its superior pumping capabilities, this technology enables faster water transfer and drainage, saving valuable time during critical marine operations. The pump's adjustable flow and pressure settings provide operators with greater control, allowing for enhanced operational precision and flexibility.In the context of environmental sustainability, the Marine Water Pump upholds the highest standards. It incorporates advanced filtration and purification systems, ensuring compliance with strict maritime environmental regulations. By effectively managing ballast water and preventing the spread of invasive species, this pump contributes to the preservation of marine ecosystems and supports sustainable water transportation practices.In addition to its performance and reliability, the company behind the Marine Water Pump, [], brings extensive expertise and experience to the table. With a proven track record in developing innovative marine technologies, the company has earned a reputation for delivering industry-leading solutions. Its commitment to research and development ensures that the Marine Water Pump remains at the forefront of technological advancements, constantly pushing the boundaries of efficiency and reliability.To support its customers in maximizing the benefits of the Marine Water Pump, the company offers comprehensive after-sales services. With a global network of service centers and technicians, the company ensures prompt assistance and maintenance support, minimizing downtime and maximizing uptime for marine operators. This dedication to customer satisfaction has contributed to the company's strong presence in the maritime industry worldwide.As the demand for efficient water pumping systems continues to grow in the maritime sector, the Marine Water Pump stands out as a game-changer. Its durability, reliability, and efficiency make it an indispensable asset for marine operators aiming to optimize their operations and reduce costs. With the backing of its visionary manufacturer [], the Marine Water Pump is set to redefine the standards of water pumping in the maritime industry.

Durable and Efficient Twin Screw Pump for Various Industrial Applications

Fristam Twin Screw Pump has recently introduced a new and innovative solution to meet the growing demand for efficient pumping systems in various industries. With a focus on reliability, performance, and ease of maintenance, this new pump is set to revolutionize the way companies handle their fluid transfer needs.The Fristam Twin Screw Pump is designed to handle a wide range of applications, including food and beverage, pharmaceutical, chemical, and personal care, among others. Its unique design allows for gentle product handling, making it suitable for delicate or shear-sensitive products. With its high efficiency and low pulsation characteristics, this pump is ideal for applications where product integrity is crucial.One of the key features of the Fristam Twin Screw Pump is its ability to handle both low and high viscosity products with ease. This versatility makes it a valuable asset for companies dealing with a variety of different substances. Additionally, its hygienic design and ease of cleaning make it compliant with the strict regulations and standards of the food and pharmaceutical industries.In addition to its impressive performance capabilities, the Fristam Twin Screw Pump is also designed with maintenance in mind. The pump is easy to disassemble and reassemble, reducing downtime and lowering the overall cost of ownership. This feature is especially important for companies looking to maximize their operational efficiency and minimize unnecessary expenses.Furthermore, the Fristam Twin Screw Pump is built to last, with a durable construction that can withstand the demands of continuous use. Its robust design and high-quality materials ensure that it can operate reliably for extended periods, providing companies with peace of mind and confidence in their pumping capabilities.With the introduction of the Fristam Twin Screw Pump, the company continues to solidify its position as a leading provider of pumping solutions for various industries. The pump is a testament to the company's commitment to innovation and excellence, and it is expected to make a significant impact in the market.In summary, the launch of the Fristam Twin Screw Pump represents a major milestone for the company and its customers. With its impressive performance, versatile capabilities, and ease of maintenance, this pump is set to become a valuable asset for companies across a wide range of industries. As the demand for efficient and reliable pumping systems continues to grow, the Fristam Twin Screw Pump is well-positioned to meet and exceed the expectations of its users.

Highly efficient multiphase pumps revolutionize oil and gas industry

Multiphase Pumps, a leading provider of innovative pumping solutions, has been making waves in the oil and gas industry with its cutting-edge technology and superior performance. With a commitment to excellence and a dedication to meeting the needs of their clients, Multiphase Pumps has established itself as a trusted partner in the energy sector.Founded in 2002, Multiphase Pumps has quickly risen to prominence as a global leader in multiphase pumping systems. The company's state-of-the-art technology allows for the efficient and reliable transportation of oil, gas, and water in a variety of challenging environments. Their pumps are designed to handle the complexities of multiphase flow, making them an ideal solution for offshore and subsea applications.Multiphase Pumps has a strong track record of delivering high-performance pumping solutions to the oil and gas industry. Their team of experienced engineers and technicians work tirelessly to develop innovative and reliable products that meet the evolving needs of their clients. With a focus on continuous improvement and technological advancement, Multiphase Pumps is at the forefront of pump technology and is continuously striving to exceed industry standards.One of the key factors that set Multiphase Pumps apart from its competitors is their commitment to customer satisfaction. The company prides itself on its ability to provide tailored pumping solutions that meet the specific needs of each client. Whether it's a complex subsea project or a high-pressure onshore operation, Multiphase Pumps has the expertise and experience to deliver reliable and efficient solutions.In addition to their commitment to excellence, Multiphase Pumps is also dedicated to sustainability and environmental responsibility. The company's pumps are designed to minimize emissions and energy consumption, making them an environmentally friendly choice for energy companies around the world. By prioritizing sustainability, Multiphase Pumps is contributing to the global effort to reduce the carbon footprint of the oil and gas industry.Multiphase Pumps' dedication to innovation, quality, and customer satisfaction has earned them a solid reputation in the oil and gas industry. Their pumps are known for their reliability, efficiency, and durability, making them a top choice for energy companies seeking high-performance pumping solutions. With a focus on continuous improvement and a commitment to meeting the unique needs of their clients, Multiphase Pumps is well positioned to continue leading the way in multiphase pumping technology.In recent news, Multiphase Pumps has announced the successful launch of a new generation of multiphase pumping systems. The latest addition to their product lineup features advanced technology that enhances efficiency and reliability, while also reducing environmental impact. The new pumps have been designed to meet the demands of the evolving energy industry, providing a solution that is both cost-effective and sustainable."We are thrilled to introduce our latest generation of multiphase pumping systems to the market," said the CEO of Multiphase Pumps. "Our team has worked tirelessly to develop a product that not only meets the performance expectations of our clients but also aligns with our commitment to environmental responsibility. We are confident that these new pumps will set a new standard for multiphase pumping technology."The new generation of pumps from Multiphase Pumps represents a significant leap forward in pump technology. With enhanced performance capabilities and a focus on sustainability, these pumps are poised to revolutionize the way oil and gas companies transport multiphase fluids. By offering a reliable and efficient solution that also supports environmental goals, Multiphase Pumps is setting a new benchmark for the industry.As Multiphase Pumps continues to push the boundaries of pump technology, the company remains dedicated to delivering innovative and sustainable solutions to its clients. With a proven track record of excellence and a commitment to meeting the unique needs of the energy industry, Multiphase Pumps is well positioned to maintain its leadership position in the market. Through a combination of cutting-edge technology, a focus on customer satisfaction, and a dedication to sustainability, Multiphase Pumps is poised for continued success in the years to come.

- Top Industrial Marine Pumps for Your Business Needs

Industrial Marine Pumps, a leading manufacturer of marine pumps and pump systems, has been making waves in the industry with its innovative and efficient solutions for marine applications. With over 30 years of experience in the industry, Industrial Marine Pumps has built a reputation for reliability, quality, and performance.The company offers a wide range of marine pumps, including centrifugal pumps, diaphragm pumps, gear pumps, and more, all designed to meet the demanding requirements of the marine industry. Whether it's for ballast water management, bilge pumping, fire protection, or general seawater pumping, Industrial Marine Pumps has the right solution for any marine pumping need.One of the key strengths of Industrial Marine Pumps is its ability to provide custom-engineered pumping solutions to meet specific requirements. With a team of experienced engineers and technicians, the company can design and manufacture pumps and pump systems that are tailored to the unique needs of each customer. This flexibility and customization capability have set Industrial Marine Pumps apart from its competitors, allowing the company to serve a wide range of marine applications, from small pleasure craft to large commercial and military vessels.In addition to its wide product range and custom-engineering capabilities, Industrial Marine Pumps also prides itself on its commitment to quality and customer satisfaction. The company's products are manufactured to the highest standards, using premium materials and advanced manufacturing techniques to ensure reliability and durability in the harsh marine environment. Furthermore, Industrial Marine Pumps offers comprehensive after-sales support, including maintenance services, spare parts supply, and technical assistance, to ensure that its customers' pumping systems continue to operate at peak performance throughout their service life.Industrial Marine Pumps has also been at the forefront of innovation in the marine pumping industry, continuously developing new technologies and solutions to address the evolving needs of its customers. The company has invested heavily in research and development, and it has a track record of introducing cutting-edge products that improve efficiency, reduce energy consumption, and minimize environmental impact. For example, Industrial Marine Pumps has developed a range of eco-friendly pumps that meet the latest environmental regulations and standards, helping vessel owners and operators to comply with stringent environmental requirements.Moreover, Industrial Marine Pumps is committed to sustainability and environmental responsibility in its operations. The company has implemented eco-friendly manufacturing processes and is constantly striving to minimize its carbon footprint and reduce waste. Industrial Marine Pumps has also been actively involved in promoting sustainable practices within the marine industry, collaborating with partners to develop eco-friendly solutions and raise awareness of environmental issues.Looking ahead, Industrial Marine Pumps is poised for further growth and success in the marine pumping industry. With a strong track record of innovation, quality, and customer satisfaction, the company is well-positioned to capitalize on the opportunities presented by the expanding marine market. By continuing to invest in research and development, expanding its product range, and strengthening its global presence, Industrial Marine Pumps is set to remain a trusted partner for marine pumping solutions for many years to come.Overall, Industrial Marine Pumps has established itself as a leading manufacturer of marine pumps and pump systems, known for its quality, reliability, and commitment to customer satisfaction. With its comprehensive product range, custom-engineering capabilities, and focus on innovation and sustainability, the company is well-equipped to meet the diverse needs of the marine industry and drive continued success in the years ahead.