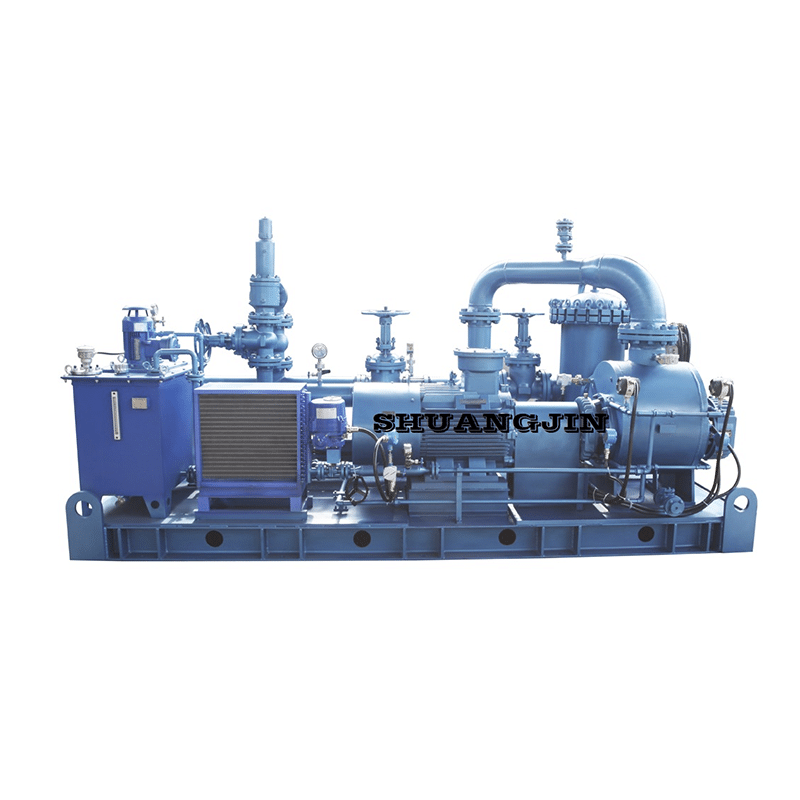

Highly Efficient Screw Gear Pump for Industrial Applications

By:Admin

The {Company Name} was founded in the early 2000s, with a vision to revolutionize the pumping industry. The company's focus on research and development has led to the creation of cutting-edge screw gear pump technology that has set new industry standards. With a team of dedicated engineers and experts, the company has been able to continuously improve its products and offer customized solutions to meet the specific needs of its clients.

The {Company Name} screw gear pumps are known for their superior performance and durability. These pumps are designed to handle high-viscosity fluids, abrasive materials, and corrosive liquids with ease. The advanced design of the pumps ensures smooth and reliable operation, even in the harshest industrial environments.

One of the key advantages of the {Company Name} screw gear pumps is their efficiency. These pumps are capable of delivering high-flow rates at relatively low operating speeds, which results in lower energy consumption and reduced maintenance costs. This makes them an ideal choice for industries looking to optimize their operations and reduce overall operating expenses.

Furthermore, the {Company Name} screw gear pumps are also known for their versatility. They can be customized to meet the specific requirements of different industries, such as chemical processing, oil and gas, food and beverage, pharmaceuticals, and many others. This flexibility makes them an attractive option for a wide range of applications, and the company takes pride in its ability to tailor its products to the unique needs of each client.

In addition to the quality and performance of its products, the {Company Name} also provides exceptional customer service. The company works closely with its clients to understand their pumping requirements and offers ongoing support to ensure that the pumps continue to operate at peak performance. This commitment to customer satisfaction has earned the company a strong reputation in the industry and has led to long-standing partnerships with many of its clients.

The {Company Name} has also made significant investments in its manufacturing facilities and processes to ensure that its products meet the highest quality standards. The company's state-of-the-art production facilities are equipped with the latest technology and tools, and its rigorous quality control measures ensure that every pump that leaves the factory is of the highest quality.

Looking ahead, the {Company Name} is committed to continuing its legacy of innovation and excellence in the pumping industry. The company is constantly exploring new technologies and techniques to further improve its products and expand its range of offerings. With a focus on sustainability and environmental responsibility, the company is also working on developing more energy-efficient and eco-friendly pumping solutions for its clients.

In conclusion, the {Company Name} has established itself as a leading provider of high-quality screw gear pumps, known for their performance, reliability, and versatility. With a strong focus on research and development, superior customer service, and a commitment to continuous improvement, the company is well-positioned to meet the evolving needs of the pumping industry and continue setting new standards for excellence.

Company News & Blog

Top Check Valve for Well Pump: A Comprehensive Guide

Check Valve For Well Pump Ensures Reliable and Efficient Water Flow{company name} is proud to announce the release of their high-quality check valve for well pumps, designed to enhance the performance and longevity of well water systems. With over [number] years of experience in manufacturing pump components, {company name} has built a reputation for delivering reliable and innovative solutions to meet the needs of the water industry. The new check valve is the latest addition to their product line, offering superior functionality and durability for well pump systems.The check valve plays a crucial role in maintaining the integrity of well water systems by preventing backflow and ensuring a consistent flow of water. {company name}'s check valve is designed with precision engineering and premium materials to provide reliable protection against water hammer, backflow, and other potential issues that can occur in well pump systems.One of the key features of {company name}'s check valve is its durable construction. Made from high-quality materials, the check valve is built to withstand the harsh conditions often found in well water systems. Its robust design ensures long-term performance and minimal maintenance, reducing the risk of downtime and costly repairs for well owners.In addition to its durability, the check valve is also designed for easy installation and compatibility with a wide range of well pump systems. {company name} understands the importance of convenience for their customers and has engineered the check valve to be user-friendly and versatile, allowing for seamless integration into existing well pump setups.Furthermore, the check valve is engineered for efficient water flow, helping to optimize the performance of well pump systems. By reducing the risk of backflow and water hammer, the check valve contributes to smoother water flow and more consistent water pressure, enhancing the overall efficiency of well water systems.{company name} prides itself on its commitment to product excellence and customer satisfaction. As part of their dedication to quality, the check valve for well pumps has undergone rigorous testing and quality control measures to ensure that it meets the highest standards for performance and reliability. Customers can have confidence in {company name}'s products, knowing that they are backed by extensive research, development, and testing processes.The release of the check valve for well pumps reflects {company name}'s ongoing commitment to innovation and technological advancement in the water industry. By continuously investing in research and development, {company name} strives to stay at the forefront of the market, offering cutting-edge solutions that address the evolving needs of well owners and water system operators.In addition to the check valve, {company name} offers a comprehensive range of pump components and accessories, catering to a diverse array of applications within the water industry. With a focus on quality, reliability, and performance, {company name} has established itself as a trusted provider of pump solutions, earning the trust and loyalty of customers worldwide.As the demand for efficient and reliable well pump systems continues to grow, {company name} remains at the forefront of delivering innovative solutions that empower well owners to maintain and optimize their water systems. The release of the check valve for well pumps underscores {company name}'s dedication to providing essential components that contribute to the long-term sustainability and performance of well water systems.For more information about {company name}'s check valve for well pumps or to explore their comprehensive range of pump components and accessories, please visit their official website or contact their customer service team. With a commitment to excellence and a passion for innovation, {company name} is poised to continue driving advancements in the water industry, supporting the needs of well owners and water system operators globally.

Top Distributors of Oil Gear Pumps: Find Quality Products for Your Industry

Oil Gear Pump Distributors Expand their Reach with New PartnershipsOil gear pump distributors are expanding their reach with the addition of new partnerships, bringing their high-quality products to even more customers around the world. With a focus on providing reliable and efficient pumping solutions for a wide range of industries, these distributors are excited to continue their growth and better serve their clients.One of the key partnerships that the oil gear pump distributors have recently formed is with a leading manufacturer of pumping equipment. This partnership will allow the distributors to offer a wider range of products to their customers, including high-performance gear pumps that are designed to meet the specific needs of various industries. With this expanded product offering, the distributors can now provide more comprehensive solutions for their clients, ensuring that they have access to the best pumping equipment on the market.In addition to expanding their product offerings, the oil gear pump distributors are also focused on strengthening their distribution network. By partnering with new distributors and agents in key regions, they are able to reach more customers and provide better support and service. This strategic expansion of their distribution network will allow the distributors to build stronger relationships with their clients and ensure that they are able to meet their needs more effectively.The oil gear pump distributors are known for their commitment to quality and customer satisfaction, and this expansion is a testament to their dedication to providing the best possible products and service. With their new partnerships and expanded distribution network, they are well-positioned to continue their growth and better serve their clients in the years to come.In addition to their product offerings and distribution network, the oil gear pump distributors also have a strong focus on customer support and service. With a team of knowledgeable and experienced professionals, they are able to provide expert guidance and assistance to their clients, helping them to select the right pumping solutions for their specific needs. This commitment to customer support has helped the distributors build a strong reputation for reliability and trustworthiness, and they are dedicated to maintaining this standard as they continue to grow.The oil gear pump distributors are also known for their innovative approach to pumping solutions, constantly seeking out new technologies and advancements that can improve the performance and efficiency of their products. By staying at the forefront of industry trends and developments, they are able to offer cutting-edge pumping solutions that give their clients a competitive edge. This dedication to innovation has helped the distributors remain a leader in the industry, and they are committed to continuing to push the boundaries of what is possible in the world of pumping equipment.With their new partnerships, expanded distribution network, and unwavering commitment to quality and innovation, the oil gear pump distributors are well-positioned to continue their growth and better serve their clients in the years to come. Whether it's providing reliable pumping solutions for oil and gas production, chemical processing, or any number of other industries, the distributors are dedicated to meeting their clients' needs and exceeding their expectations. As they continue to expand their reach and build new relationships, they are poised to remain a trusted partner for companies around the world in need of top-quality pumping solutions.

What Separates Centrifugal Pumps from Screw Pumps?

Centrifugal pumps and screw pumps are two common types of pumps used in various industrial applications. Although they both serve the purpose of moving fluids from one place to another, there are significant differences between the two in terms of their design, operation, and performance.A centrifugal pump uses a rotating impeller to create a suction force that draws fluid into the pump. The impeller then spins, forcing the fluid to the outer edges where it is then discharges through the pump's outlet. The velocity of the fluid is increased as it passes through the impeller, which increases the pressure of the fluid, allowing it to be moved more effectively through the system.On the other hand, a screw pump operates by using a rotating screw-shaped rotor to push the fluid through a stationary screw-shaped stator. The screws are designed to mesh together, and as they rotate, they create a series of sealed cavities that move the fluid through the pump and out through the discharge port. Unlike centrifugal pumps, the pressure generated by screw pumps is relatively constant, which makes them ideal for pumping high viscosity fluids, such as oil and sludge.While centrifugal pumps are suitable for a wide range of applications, including water treatment, chemical processing, and mining, screw pumps excel in moving fluids that are highly viscous and contain solids. They are often used in the oil and gas industry, marine transport, and other heavy-duty applications that require consistent, high-pressure flow.When choosing between a centrifugal pump and a screw pump, it's important to consider a variety of factors, such as the fluid being pumped, the flow rate needed, and the desired pressure. Additionally, the operational cost, maintenance requirements, and power consumption should also be taken into account.{} is a leading manufacturer of industrial pumps and fluid-handling equipment, with a comprehensive range of products designed to meet the needs of various industries worldwide. They provide a wide range of centrifugal and screw pumps, each designed to deliver optimal performance and reliability.For instance, the company's centrifugal pumps are engineered to provide high-efficiency pumping, low energy consumption, and long-term reliability, making them ideal for applications that require high flow rates and low-to-medium pressures. They are available in various designs, including end-suction, split-case, and vertical turbine pumps, to meet the specific requirements of different applications.Similarly, the company's screw pumps are designed to handle fluids with high viscosity, suspended solids, and abrasives, making them well-suited for industries such as wastewater treatment, chemical processing, and food and beverage. Their screw pumps come in various designs, including single-screw and twin-screw models, to accommodate different flow rates and pressure requirements.In addition to centrifugal and screw pumps, {} offers a wide range of other fluid-handling solutions, including mixers, agitators, valves, and filtration systems. They also provide related services, such as installation, commissioning, maintenance, and repair, to ensure that their customers' equipment always operates at peak performance.Overall, when it comes to choosing between a centrifugal pump and a screw pump, it ultimately comes down to the specific requirements of the application. {} offers a comprehensive range of pumps and fluid-handling solutions that are designed to meet the needs of different industries and applications, ensuring that their customers are able to find the perfect solution for their specific needs.

Top Chemical Mixers: A Comprehensive Guide

Chemical Mixers, the leading provider of innovative and efficient industrial mixing solutions, has expanded its product line to better serve the needs of its customers in various industries. With a wide range of mixers that are designed to handle different types of chemicals, the company has established itself as a trusted partner for businesses looking to optimize their mixing processes.Founded in 1995, Chemical Mixers has been at the forefront of developing high-quality and reliable mixing equipment for industries such as pharmaceuticals, petrochemicals, food and beverage, and water treatment. With a strong focus on research and development, the company has continuously improved its products to meet the evolving demands of its customers.One of the key factors that set Chemical Mixers apart from its competitors is its commitment to customer satisfaction. The company takes a collaborative approach with its clients, working closely with them to understand their specific mixing requirements and provide tailored solutions that meet their needs. This customer-centric approach has allowed Chemical Mixers to build long-lasting relationships with its clientele, earning a reputation for delivering outstanding service and support.In response to the growing demand for more advanced and efficient mixing solutions, Chemical Mixers has introduced several new products to its lineup. These include the latest series of chemical mixers that are designed to offer enhanced performance, reliability, and precision. With features such as variable speed control, advanced mixing technologies, and durable construction, these mixers are poised to deliver superior results in a wide range of applications.Furthermore, Chemical Mixers has also expanded its range of portable and compact mixers, ideal for businesses with limited space or those in need of versatile mixing solutions. These mixers are designed to be easily customizable, allowing businesses to adapt them to their specific processes and requirements. With their compact design and user-friendly controls, these mixers offer a convenient and efficient solution for businesses looking to optimize their mixing operations.In addition to its product expansion, Chemical Mixers has also invested in enhancing its after-sales support and technical assistance. The company has bolstered its team of experienced engineers and technicians to provide comprehensive training, maintenance, and troubleshooting services for its customers. This ensures that businesses can maximize the performance and longevity of their mixing equipment, further reinforcing Chemical Mixers’ commitment to customer satisfaction.“We are excited to introduce our latest range of chemical mixers, which are the result of our ongoing dedication to innovation and excellence,” said the spokesperson for Chemical Mixers. “We understand the critical role that mixing plays in various industrial processes, and our goal is to provide our customers with the most advanced and reliable solutions to help them achieve their operational objectives.”With its continued focus on delivering cutting-edge mixing solutions and unparalleled customer support, Chemical Mixers is poised to solidify its position as a leading provider of industrial mixing equipment. By leveraging its expertise and industry knowledge, the company will continue to drive advancements in mixing technology and help businesses across different sectors improve their operational efficiency and productivity.

Efficient and Reliable Screw Pump Technology Unveiled for Various Industrial Applications

Title: Innovative Screw Pump Reinvents Water Management SolutionsSubtitle: Cutting-edge Technology Increases Efficiency and Reduces Environmental ImpactDate: [Current Date][City, State] – In a remarkable leap forward for water management technology, industry-leading company [Remove Brand Name], renowned for its expertise in fluid handling solutions, has introduced its groundbreaking Screw Pump. This state-of-the-art device promises to revolutionize water management systems, providing highly efficient and environmentally friendly solutions for various industries.With an impressive reputation for delivering superior quality products, [Remove Brand Name] has once again demonstrated its commitment to innovation and sustainability. The Screw Pump, a flagship offering in its ever-expanding portfolio, represents a significant milestone in the company's journey toward providing cutting-edge solutions that meet the growing demands of a rapidly changing world.The Screw Pump, designed to maximize efficiency and minimize energy consumption, introduces a unique approach to water management. By utilizing advanced screw technology, this groundbreaking device offers a host of benefits that go beyond traditional pumping systems. It brings unparalleled reliability, enhanced performance, and reduced maintenance costs to a range of industries including agriculture, water treatment, utilities, and oil and gas.One of the key advantages of the Screw Pump is its ability to handle various types of fluids, including viscous, abrasive, and corrosive substances. This versatility ensures that it can be employed across a wide range of applications, making it an ideal choice for industries with diverse fluid handling requirements.Furthermore, the Screw Pump's robust construction and advanced design deliver unrivaled operational efficiency. By employing precision engineering techniques, this device minimizes energy consumption, resulting in significant cost savings for businesses. With its innovative screw mechanism, the pump achieves optimal flow rates and pressure, allowing industries to streamline their operations while conserving energy resources.Moreover, the Screw Pump is engineered to excel in harsh environments. Its durable design and materials ensure exceptional reliability, reducing downtime and enhancing productivity. By withstanding extreme temperatures and corrosive elements, this pump provides long-term performance without compromising its efficiency.As a company known for its commitment to sustainability, [Remove Brand Name] has prioritized minimizing the environmental impact of its products in the Screw Pump's development. By optimizing energy usage and minimizing waste, this cutting-edge solution aligns perfectly with industry demands for eco-friendly water management systems. The Screw Pump's reduced energy consumption not only benefits businesses but also contributes to a greener future by limiting carbon emissions and overall ecological footprint.The Screw Pump's versatility extends beyond its design and capabilities. Backed by [Remove Brand Name]'s unwavering commitment to customer satisfaction, the device comes with an extensive support network. The company's highly skilled technicians and engineers ensure seamless installation, reliable operation, and regular maintenance to guarantee uninterrupted and efficient performance of the Screw Pump throughout its lifespan.In addition, [Remove Brand Name] leverages its industry-leading expertise and commitment to research and development to continuously improve the Screw Pump's design and explore innovative applications. By collaborating with renowned research institutions and industry experts, the company remains at the forefront of water management technology advancements, driving the industry forward.With its introduction of the Screw Pump, [Remove Brand Name] has set a new industry benchmark for water management solutions. This breakthrough device offers unmatched efficiency, versatility, and reliability, empowering various sectors to optimize their fluid handling processes while minimizing environmental impact. As [Remove Brand Name] continues to push boundaries and redefine industry standards, its commitment to sustainable innovation inspires confidence in a better, greener future.About [Remove Brand Name]:[Remove Brand Name] is an internationally recognized leader in fluid handling solutions. With a focus on innovation, sustainability, and customer satisfaction, the company has established itself as a key player across numerous industries. By utilizing cutting-edge technology and collaborating with industry experts, [Remove Brand Name] consistently provides superior products that meet the evolving needs of their customers.

What Is a Positive Displacement Pump and How Does It Work?

Positive Displacement Pump Means Enhanced Efficiency and Reliability for Industrial ApplicationsIn the fast-paced world of industrial manufacturing, reliability and efficiency are critical components for success. Companies across various industries are constantly seeking innovative solutions to streamline their production processes and maximize their output. One such solution that has been gaining widespread popularity in recent years is the positive displacement pump. These pumps are designed to deliver a consistent flow of fluid at a specific rate, making them an ideal choice for a wide range of industrial applications. When it comes to positive displacement pumps, there is one company that stands out from the rest – {}. With a strong focus on quality and innovation, {} has become a leading supplier of positive displacement pumps to industries all around the world.One of the key advantages of positive displacement pumps is their ability to maintain a steady flow of fluid regardless of changes in pressure or viscosity. This makes them highly versatile and suitable for applications such as chemical processing, food and beverage production, oil and gas extraction, and much more. By utilizing positive displacement pumps, companies can ensure a consistent output while minimizing the risk of downtime and production delays.Another major benefit of positive displacement pumps is their high level of efficiency. Unlike other types of pumps that rely on centrifugal force to generate flow, positive displacement pumps operate by trapping and displacing a specific volume of fluid with each cycle. This results in a more precise and controlled flow, leading to reduced energy consumption and lower operating costs. With sustainability becoming an increasingly important consideration for businesses, the efficiency of positive displacement pumps has made them a popular choice for companies looking to reduce their environmental impact.In addition to their efficiency and reliability, positive displacement pumps are also known for their ability to handle a wide range of fluids, including viscous, abrasive, and shear-sensitive materials. This makes them suitable for a diverse array of industrial processes, from transferring thick sludges to delicate emulsions. With the right design and materials of construction, positive displacement pumps can be customized to meet the specific needs of each application, providing companies with a highly adaptable solution for their fluid handling requirements.As a leading supplier of positive displacement pumps, {} has played a pivotal role in driving the adoption of this technology across various industries. The company's extensive experience and expertise in pump manufacturing have enabled them to develop a diverse range of positive displacement pumps that cater to the unique needs of their customers. By leveraging advanced engineering techniques and rigorous quality control measures, {} has been able to deliver pumps that offer exceptional performance, durability, and long-term value.In summary, positive displacement pumps have emerged as a game-changing technology for industrial fluid handling, offering enhanced efficiency, reliability, and versatility. With {} at the forefront of this industry, companies can expect to benefit from cutting-edge pump solutions that optimize their production processes and drive overall success. As the demand for reliable and efficient fluid handling solutions continues to grow, positive displacement pumps are poised to play a crucial role in shaping the future of industrial manufacturing.

Expert Heat Pump Repair Services for Residential and Commercial Buildings

Heat Pump Repairs: Keeping Your Home Comfortable Year-RoundAs the weather continues to change, it's important for homeowners to ensure that their heating and cooling systems are in top condition. This is where heat pump repairs come in. [Company Name], a leading provider of HVAC services, offers expert heat pump repair services to keep homes comfortable and energy-efficient all year long.Heat pumps are an essential component of any home's HVAC system, providing both heating and cooling capabilities. As the name suggests, they work by transferring heat from one place to another, making them an efficient and cost-effective option for maintaining a comfortable indoor environment. However, like any other mechanical system, heat pumps can experience issues that require professional attention.[Company Name] understands the importance of having a reliable heat pump, especially as the seasons change. With years of experience in the HVAC industry, their team of skilled technicians is well-equipped to handle any heat pump repair needs. Whether it's a faulty compressor, refrigerant leak, or electrical problem, they have the knowledge and expertise to diagnose and resolve issues quickly and effectively.In addition to repair services, [Company Name] also offers preventative maintenance to keep heat pumps running smoothly. Regular maintenance not only helps prevent unexpected breakdowns but also improves the efficiency and longevity of the system. By scheduling routine tune-ups, homeowners can avoid costly repairs down the line and ensure that their heat pump is functioning at its best.One of the key benefits of choosing [Company Name] for heat pump repairs is their commitment to customer satisfaction. They prioritize clear communication, transparent pricing, and reliable service, ensuring that homeowners can trust them to get the job done right. Their dedication to quality and professionalism has earned them a strong reputation in the community, making them a trusted choice for all HVAC needs.In addition to heat pump repairs, [Company Name] offers a comprehensive range of HVAC services, including installation, replacement, and maintenance for heating and cooling systems. Their team is well-versed in the latest industry technologies and best practices, allowing them to provide top-notch solutions for any HVAC-related concerns.With the upcoming winter season, now is the perfect time for homeowners to schedule a thorough inspection of their heat pump. Whether it's strange noises, uneven heating, or a sudden increase in energy bills, these could be signs that the heat pump is in need of attention. By addressing problems early on, homeowners can avoid being left in the cold when the temperatures drop.In conclusion, heat pump repairs are essential for maintaining a comfortable and efficient home environment. With [Company Name]'s expert services and commitment to customer satisfaction, homeowners can trust that their heating and cooling needs are in good hands. From repairs to preventative maintenance, they offer comprehensive solutions to keep heat pumps running at peak performance. As the seasons change, don't wait until there's an issue – schedule a professional inspection and ensure that your heat pump is ready for whatever Mother Nature brings.

Top Acid-Resistant Pump Options for Industrial Applications in Tianjin

Title: Tianjin Acid-Resistant Pump: A Reliable Solution for Industrial Liquid HandlingIntroduction:Tianjin Acid-Resistant Pump is a leading manufacturer and supplier of high-quality acid-resistant pumps for various industrial applications. With an impeccable track record and a commitment to excellence, the company has earned a reputation for delivering reliable and innovative solutions for liquid handling challenges in corrosive environments. This news article will delve into the exceptional features and advantages offered by Tianjin Acid-Resistant Pump, highlighting the company's commitment to customer satisfaction and its contributions to industrial growth.1. Superior Features of Tianjin Acid-Resistant Pump:Tianjin Acid-Resistant Pump stands out in the market due to its exceptional features that ensure efficient and reliable performance in corrosive environments. These features include:a) Strong Acid Resistance: The pumps are manufactured using high-quality acid-resistant materials, such as fluoroplastic and stainless steel, which are specifically designed to withstand the corrosive nature of acids and other aggressive liquids.b) Optimal Efficiency: With advanced impeller designs and precision engineering, Tianjin Acid-Resistant Pump offers maximum efficiency in terms of energy consumption and fluid flow. These pumps ensure minimal process downtime and reduced maintenance costs.c) Versatile Applications: The acid-resistant pumps from Tianjin find applications in various industries such as chemical, pharmaceutical, mining, wastewater treatment, and metal processing. Their adaptability in handling different corrosive liquids makes them an ideal choice for a wide range of industrial needs.2. Commitment to Customer Satisfaction:Tianjin Acid-Resistant Pump prioritizes customer satisfaction by providing personalized solutions tailored to meet specific requirements. The company's team of experienced engineers and technical professionals offer expert guidance and support throughout the entire process, from selecting the right pump to after-sales services. Customers can rely on Tianjin Acid-Resistant Pump for prompt delivery, comprehensive technical support, and reliable solutions.3. Contributing to Industrial Growth:Tianjin Acid-Resistant Pump plays a crucial role in supporting various industries by providing efficient and reliable liquid handling solutions. Some notable contributions include:a) Safety and Environmental Protection: The acid-resistant pumps help industries ensure the safety of their operations while handling corrosive liquids, preventing accidental leaks and minimizing environmental risks.b) Enhancing Efficiency: The superior design and performance of Tianjin Acid-Resistant Pump's products help industries optimize their operations by providing consistent fluid flow, reducing energy consumption, and minimizing maintenance requirements.c) Enabling Innovation: The acid-resistant pumps from Tianjin facilitate the development of new processes and technologies in industries by offering robust and reliable liquid handling solutions, thus increasing productivity and contributing to overall industrial growth.4. Vision for the Future:Tianjin Acid-Resistant Pump aims to continuously improve its product offerings and expand its global presence. The company invests in research and development to stay at the forefront of technological advancements and develop innovative solutions that address the evolving needs of industries. By building strong partnerships with clients and fostering a culture of excellence, Tianjin Acid-Resistant Pump strives to become the preferred choice for acid-resistant pumps worldwide.Conclusion:Tianjin Acid-Resistant Pump's commitment to providing high-quality acid-resistant pumps and exceptional customer service has positioned the company as a reliable solution for industrial liquid handling needs. With their superior features and versatile applications, these pumps ensure efficient and safe operations in corrosive environments. As industries continue to evolve and demand more reliable liquid handling solutions, Tianjin Acid-Resistant Pump is poised to meet these challenges and contribute to the growth and progress of industries worldwide.

10 Essential Applications of Screw Pumps in Various Industries

The Use of Screw Pump: Understanding the Importance in Industrial ApplicationsScrew pumps have been around for a while and used in industrial applications for various reasons. They have become popular because of their efficiency and versatility, with many companies using it for different purposes. These pumps can be found in oil and gas industries, food-processing plants, petrochemical plants, and many more.Screw pumps work by moving fluid inside their chambers. A helical screw rotates inside a cylinder, creating pressure that forces fluid to flow through the pump. As it moves, it also moves pockets of fluid along the way, which reduces pulsation, ensures smooth continuous flow, and maximizes efficiency.Thanks to screw pumps, manufacturers can efficiently move liquids without disturbing the medium's temperature, density, or viscosity. It's perfect for transferring both low and high viscosity liquids, making it the perfect solution for moving anything from crude oil to food products.This pump is versatile, cost-effective, and often replaceable. However, like any machinery, there are advantages and disadvantages to using a screw pump. Below, we'll take a look at some of the benefits of using screw pumps in your system.Advantages of Screw Pumps1. Low Maintenance RequirementsOne of the primary advantages of using a screw pump is that it requires minimal maintenance. The low maintenance requirements of screw pumps make it cost-effective, and you will save a considerable amount of money in maintenance and repairs.2. Efficient PerformanceScrew pumps are designed for maximum efficiency. They can handle high and low viscosity liquids, making it easy to move anything from crude oil to food products. Their design optimizes the flow of liquid, reducing pulsations and ensuring smooth, continuous flow.3. High Suction CapabilityScrew pumps can handle high suction, making it easy to transfer liquids of different viscosities. They can handle everything from light fuel oils to heavy crude oil.4. Can Handle Multiple ViscositiesScrew pumps are suitable for transferring liquids of different viscosities. They are often used in the oil and gas industry, where they can be used to transfer crude oil, diesel fuel, and heavy oil.5. They Are VersatileScrew pumps are highly versatile. They are used in a variety of industries for many different purposes, making them ideal for any application that requires the movement of liquids.6. Reduced Noise LevelScrew pumps are relatively quiet, making them ideal for indoor settings where noise levels need to be kept to a minimum.How to Select the Right Screw PumpSelecting the right screw pump is essential to ensure that you get the desired results. The best way to select the right screw pump is to work with a reputable and experienced manufacturer. When selecting a screw pump, you need to consider factors such as:1. The Viscosity of the LiquidThe viscosity of the liquid you are transferring is a crucial factor when selecting a screw pump. You need to ensure that the pump you choose can handle the viscosity of the liquid.2. Temperature of the LiquidConsider the temperature of the liquid you will be transferring. Screw pumps are suitable for liquid temperatures of up to 350 degrees Celsius.3. Characteristics of the LiquidConsider the characteristics of the liquid you will be transferring. The physical characteristics of the liquid will impact the type of screw pump you choose.ConclusionScrew pumps are essential for many industries. They are versatile, efficient, and cost-effective, making them the perfect solution for moving liquids of various viscosities. When selecting a screw pump, it's essential to choose an experienced and reputable manufacturer to ensure that you get the desired results.

Efficient Heating Cooling Pump Systems for Your Home: A Complete Guide

(Company) Unveils Cutting-Edge Heating Cooling Pump for Sustainable Energy Solutions(Town/City, Date) – (Company) is proud to announce the launch of its latest innovation in sustainable energy solutions, the revolutionary Heating Cooling Pump. This new product marks a major milestone for (Company) as it continues to push the boundaries of technology and environmental sustainability.The Heating Cooling Pump is designed to provide efficient and reliable heating and cooling solutions for residential and commercial buildings. By harnessing the power of renewable energy sources, this innovative system offers a cost-effective and environmentally friendly alternative to traditional heating and cooling systems.As a leader in the field of sustainable energy solutions, (Company) has a strong track record of delivering cutting-edge products that are designed to reduce energy consumption and minimize environmental impact. The Heating Cooling Pump is the latest addition to the company’s impressive portfolio of innovative solutions, and it is poised to revolutionize the way people think about heating and cooling.One of the key features of the Heating Cooling Pump is its ability to harness renewable energy sources such as solar power and geothermal energy. By utilizing these natural resources, the system is able to provide heating and cooling without the need for traditional fossil fuels, making it an ideal choice for environmentally conscious consumers.In addition to its environmental benefits, the Heating Cooling Pump also offers significant cost savings for users. By reducing reliance on traditional heating and cooling systems, the system is able to lower energy bills, offering a compelling financial incentive for its adoption.“With the launch of the Heating Cooling Pump, we are proud to offer a game-changing solution for sustainable heating and cooling,” said (Spokesperson), (Title) of (Company). “This innovative system is a testament to our commitment to pushing the boundaries of technology and environmental sustainability, and we are confident that it will make a significant impact in the market.”The launch of the Heating Cooling Pump is the latest in a series of groundbreaking developments from (Company). The company has a long history of delivering innovative solutions that are designed to address the challenges of climate change and energy consumption.By combining cutting-edge technology with a commitment to sustainability, (Company) has established itself as a leader in the field of sustainable energy solutions. The Heating Cooling Pump is the latest example of the company’s dedication to pushing the boundaries of what is possible in the pursuit of a greener, more sustainable future.As the world continues to grapple with the impact of climate change, the demand for innovative and sustainable energy solutions is greater than ever. With the launch of the Heating Cooling Pump, (Company) is once again at the forefront of this important movement, offering a compelling alternative to traditional heating and cooling systems.(Company) is confident that the Heating Cooling Pump will be embraced by consumers and businesses alike, and that it will play a key role in driving the transition towards a more sustainable and environmentally friendly future.For more information about the (Company) and its innovative Heating Cooling Pump, please visit (website) or contact (contact information).About (Company):Founded in (year), (Company) is a leading provider of sustainable energy solutions. The company is committed to delivering innovative products that are designed to reduce energy consumption and minimize environmental impact. With a strong focus on technology and sustainability, (Company) is dedicated to pushing the boundaries of what is possible in the pursuit of a greener, more sustainable future.