Innovative Pump Technology for Efficient Industrial Operations

By:Admin

Seepex Pump, a global leader in progressive cavity pump technology, has announced the launch of its latest innovation in pump technology. The company, known for its cutting-edge solutions for a wide range of industries, has introduced a new pump technology that promises to revolutionize the way in which fluids are transferred and processed.

Seepex Pump has a long-standing reputation for delivering high-quality, reliable pumps that are used in a variety of applications, including food and beverage processing, wastewater treatment, and chemical manufacturing. With a focus on innovation and continuous improvement, the company has developed a reputation as a leader in the pump industry.

The new pump technology, which has been in development for several years, represents a significant advancement in pump design and performance. Utilizing the latest materials and manufacturing techniques, the new pump boasts improved efficiency, reduced maintenance requirements, and enhanced reliability. The company believes that this new technology will set a new standard for pump performance and reliability in the industry.

"We are incredibly excited to introduce our latest pump technology to the market," said the spokesperson of Seepex Pump. "This new technology represents a significant leap forward in pump design and performance, and we believe that it will have a transformative impact on the industries we serve. We have been working tirelessly to develop this technology, and we are proud to finally unveil it to our customers."

The new pump technology is the result of extensive research and development efforts by Seepex Pump's team of engineers and scientists. The company has invested heavily in state-of-the-art facilities and equipment to support its research and development activities, and the result is a pump technology that is truly cutting-edge.

In addition to its technical advancements, the new pump technology also incorporates a number of features designed to improve ease of use and maintenance. For example, the pump is designed to be easily disassembled for cleaning and maintenance, reducing downtime and minimizing the need for specialized tools or training.

Seepex Pump's commitment to quality and innovation has made it a trusted partner for companies around the world. The company's pumps are used in a wide range of critical applications, where reliability and performance are paramount. With the introduction of this new pump technology, Seepex Pump is poised to further solidify its position as a leader in the pump industry.

"We believe that this new pump technology will enable our customers to achieve new levels of efficiency and performance in their operations," said the spokesperson of Seepex Pump. "We are confident that this new technology will deliver significant benefits to our customers, and we look forward to seeing the impact it will have on their businesses."

As Seepex Pump continues to push the boundaries of pump technology, the company remains committed to delivering innovative solutions that meet the evolving needs of its customers. With its latest pump technology, the company has once again demonstrated its leadership in the industry and its dedication to providing cutting-edge solutions for the most demanding applications.

Company News & Blog

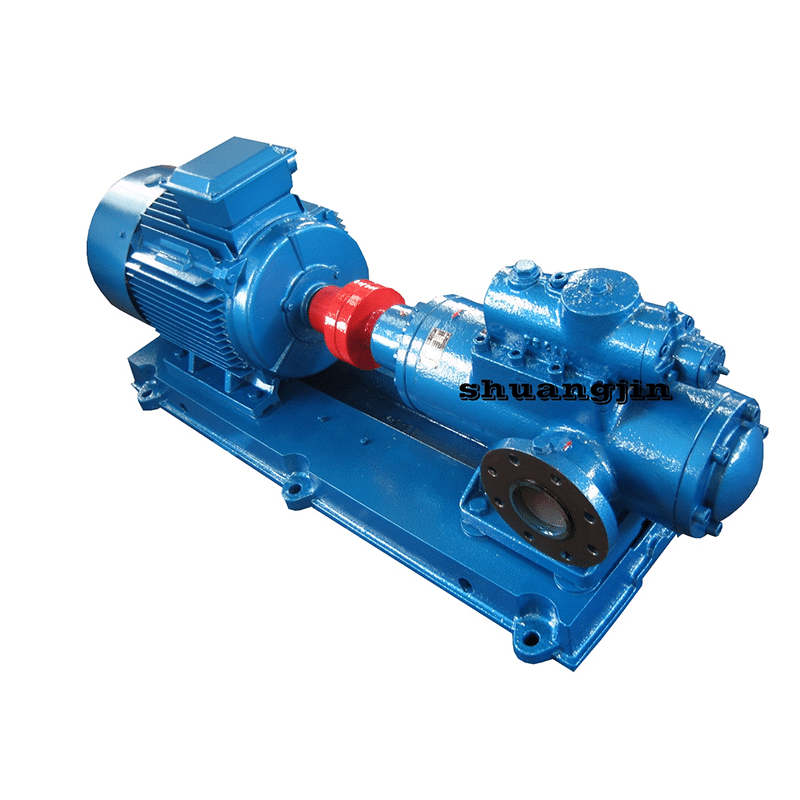

Top Three Screw Pump Models for Efficient Fluid Transfer

The global industrial pump market is expected to reach a value of $49.9 billion by 2025, with a compound annual growth rate of 5.9%. The demand for efficient and reliable pumps is increasing in industries such as oil and gas, water and wastewater treatment, power generation, and chemical processing. In response to this growing demand, one company has introduced a new and innovative pump solution that is set to revolutionize the industry.{Company Name}, a leading manufacturer of industrial pumps and fluid handling equipment, has developed a cutting-edge Three Screw Pump that is designed to deliver high performance and exceptional reliability. With over 50 years of experience in the pump industry, {Company Name} has established itself as a trusted and innovative provider of fluid handling solutions. The Three Screw Pump is the latest addition to their product lineup, and it is set to make a significant impact in the market.The Three Screw Pump is a positive displacement pump that is known for its ability to handle a wide range of applications and operating conditions. It features a unique design that utilizes three rotating screws to create a continuous flow of fluid with minimal pulsation and vibration. This results in smooth and consistent fluid delivery, making it ideal for critical industrial processes that require precision and accuracy.One of the key advantages of the Three Screw Pump is its versatility. It can handle a variety of fluids, including lubricating oils, hydraulic fluids, fuel oils, and other viscous liquids. Its ability to maintain a consistent flow rate and pressure makes it well-suited for applications in the oil and gas industry, where reliable pumping solutions are crucial for operations such as crude oil transfer, refinery processes, and offshore drilling.In addition to its versatility, the Three Screw Pump is also known for its high efficiency and low maintenance requirements. The precision engineering and tight tolerances of the pump components result in minimal internal leakage and reduced power consumption. This not only leads to cost savings for the end user but also contributes to a lower environmental impact due to reduced energy consumption.Furthermore, {Company Name} has integrated advanced monitoring and control features into the Three Screw Pump, allowing for real-time performance tracking and remote diagnostics. This enables operators to optimize the pump's operation, identify potential issues, and schedule maintenance proactively, resulting in increased uptime and reliability.The introduction of the Three Screw Pump is a testament to {Company Name}'s commitment to innovation and customer satisfaction. With a focus on continuous improvement and technological advancement, {Company Name} has positioned itself as a leader in the industrial pump market, and the Three Screw Pump is a prime example of their dedication to providing cutting-edge solutions to their customers.In conclusion, the launch of the Three Screw Pump by {Company Name} represents a significant milestone in the industrial pump industry. With its advanced design, exceptional performance, and versatility, the Three Screw Pump is set to meet the evolving needs of a wide range of industries and applications. {Company Name} continues to demonstrate its leadership and innovation in the fluid handling market, and the Three Screw Pump is a testament to their commitment to excellence.

Pump Manufacturer Develops Innovative Technology for Better Water Management

Netzsch Pump, a leading provider of industrial pumping solutions, has recently announced the launch of a new line of high-performance pumps designed to meet the needs of a wide range of industries. With over 60 years of experience in the pump manufacturing industry, Netzsch Pump has established itself as a trusted partner for companies around the world seeking reliable and efficient pumping solutions.The new line of pumps incorporates the latest advancements in pump technology, offering enhanced performance, reliability, and efficiency. These pumps are designed to meet the demanding requirements of industries such as chemical, oil and gas, mining, pharmaceutical, and food and beverage. The company's dedication to innovation and continuous improvement is evident in the design and performance of their new pump offerings.Netzsch Pump's commitment to quality is further exemplified by its ISO 9001 certification, ensuring that their products meet the highest standards of quality and reliability. This dedication to quality and excellence has earned Netzsch Pump a strong reputation in the industry, with a track record of providing cutting-edge pumping solutions to companies around the world.In addition to their commitment to quality, Netzsch Pump is also dedicated to providing exceptional customer service. With a global network of sales and service centers, the company offers comprehensive support to their customers, ensuring that their pumping solutions are installed, maintained, and serviced to the highest standards. This level of service and support sets Netzsch Pump apart from its competitors, making them a preferred partner for companies seeking reliable and efficient pumping solutions.The new line of pumps from Netzsch Pump includes a variety of models to meet the unique needs of different industries. From high-pressure pumps for the oil and gas industry to sanitary pumps for the food and beverage industry, Netzsch Pump offers a comprehensive range of pumping solutions to meet the diverse needs of their customers. These pumps are designed to deliver high performance, reliability, and efficiency, helping companies improve their operations and achieve their goals.One of the key features of the new pump line is its advanced design, which incorporates innovative technologies to improve pump performance and efficiency. These technologies include advanced materials, precision engineering, and state-of-the-art control systems, all of which contribute to the pumps' exceptional performance and reliability. Additionally, the pumps are designed to be easy to install and maintain, minimizing downtime and maximizing productivity for their users.Netzsch Pump's new line of high-performance pumps is set to make a significant impact in the industrial pumping industry. With their dedication to quality, innovation, and customer service, the company is well-positioned to continue providing cutting-edge pumping solutions to companies around the world. The new pumps are a testament to Netzsch Pump's ongoing commitment to meeting the evolving needs of their customers and helping them achieve success in their industries.As companies continue to seek reliable and efficient pumping solutions, Netzsch Pump stands out as a trusted partner that delivers high-quality products and exceptional support. With their new line of high-performance pumps, the company is poised to further solidify its position as a leader in the industrial pumping industry, providing innovative solutions that help companies improve their operations and achieve their goals.In conclusion, Netzsch Pump's new line of high-performance pumps represents a significant advancement in the industrial pumping industry. With their dedication to quality, innovation, and customer service, the company continues to set the standard for reliable and efficient pumping solutions. As companies around the world seek to improve their operations and achieve success, Netzsch Pump stands ready to provide the cutting-edge pumping solutions they need to thrive in their industries.

Innovative Triple Screw Pump Technology: Revolutionizing Industrial Fluid Transfer

Triple Screw Pump Offers High-Level Performance for Industrial Applications{Company Name} is proud to introduce the triple screw pump, a high-level performance solution for industrial applications. With the ability to handle viscous fluids while providing smooth and continuous flow, this reliable pump is ideal for a variety of industrial processes.One of the significant advantages of this pump is its high efficiency. It can achieve up to 90% efficiency while still being able to handle high-viscosity fluids such as crude oil, asphalt, and bitumen. This makes it an ideal solution for industries that require a high level of performance in their fluid handling processes.Another key feature of the triple screw pump is its ability to maintain consistent flow, even with varying inlet pressures. The screw design creates a clearing action within the pump, which means that there is a minimal risk of clogging or blockages, even with thicker fluids.The triple screw pump has been designed with ease of use in mind, making it an ideal choice for operators who need a low-maintenance solution. A self-priming design enables the pump to start and stop without the need for manual intervention, and it requires minimal disassembly for cleaning and servicing.Moreover, the pump has a compact footprint, which makes it easy to install and integrate into existing systems. Its low noise and vibration levels make it an ideal solution for applications where noise pollution and vibration could be an issue.It is recommended for industries that deal with liquid transfer, applications that need high pressure, high viscosity, and high temperature. Additionally, the triple screw pump is ideal for applications that involve feeding multiple points at once, as it can operate on a different number of pressures and flows.Furthermore, the triple screw pump is highly customizable, which means that it can be tailored to meet the specific needs of individual applications. Customization options include different materials of construction, various sealing systems, and different RPMs to suit the application's requirements.{Company Name} CEO, {Name}, stated "We are thrilled to offer this high-performance solution to our customers. The triple screw pump is an ideal choice for industries that require consistency and reliability in their fluid handling processes."In conclusion, the Triple Screw Pump offers high-level performance for industrial applications. With its high efficiency, consistent flow, low maintenance requirement, and customizable design, it is ideal for industries that deal with high-pressure, high-viscosity, and high-temperature applications. Operators can use it to feed multiple points at once while achieving a smooth and continuous flow.

The Latest Fuel Pump Innovation: A Game-Changer for Gas Stations Everywhere" Rewritten SEO Title: "Revolutionary Fuel Pump Technology Set to Shake Up Gas Station Industry

[Headline]: Groundbreaking New Fuel Pump Technology Revolutionizes the Industry[Subheading]: Rsp Pump Announces Game-Changing Innovation in Fuel Pump Technology[Date][City], [State] – In a groundbreaking announcement that is set to revolutionize the fuel pump industry, Rsp Pump, a renowned company specializing in fuel dispensing solutions, has unveiled their latest innovation. The new technology promises to enhance efficiency, safety, and customer experience by implementing state-of-the-art features and cutting-edge advancements.Fuel pumps have long been an essential component of everyday life, facilitating the necessary refueling process for millions of vehicles worldwide. Rsp Pump aims to push the boundaries of conventional fuel pump technology by combining their expertise with the latest advancements in the industry.The core concept behind this pioneering innovation lies in an intricate understanding of the challenges faced by both fuel station operators and consumers. By addressing these challenges, Rsp Pump strives to create a seamless and hassle-free refueling experience, catering to the evolving needs of the industry.One of the defining features of the new technology is its enhanced efficiency. By utilizing advanced flow sensors and intelligent nozzles, the Rsp Pump is capable of delivering fuel at an accelerated rate, significantly reducing refueling time. This not only increases customer convenience but also leads to reduced queues, further enhancing the overall operational efficiency of fuel stations.In addition to improved efficiency, safety has been a paramount focus in the development of this technology. Rsp Pump has introduced several innovative safety mechanisms to ensure a secure refueling process. The incorporation of anti-spill sensors and automatic shut-off mechanisms prevents wastage and minimizes potential hazards, significantly reducing the risk of accidents caused by spills or leaks.Moreover, the Rsp Pump is equipped with state-of-the-art cybersecurity measures, protecting against potential threats of hacking and unauthorized access. With the increasing reliance on technology in fuel stations, the importance of safeguarding customer information and maintaining system integrity cannot be overstated. Rsp Pump's emphasis on cybersecurity ensures that both operators and consumers can have peace of mind knowing their data is protected.The innovative design of the Rsp Pump not only includes advancements in functionality but also focuses on aesthetics. The pumps are sleek, modern, and ergonomically designed, providing a visually appealing and user-friendly experience. This attention to detail reflects Rsp Pump's commitment to enhancing the customer's overall satisfaction.Furthermore, as a company dedicated to sustainable practices, Rsp Pump has incorporated energy-efficient features into this groundbreaking technology. By implementing automated power-saving mechanisms, the pumps reduce energy consumption, aligning with global efforts to combat climate change.To ensure the smooth integration of this innovative technology, Rsp Pump is collaborating with fuel station operators globally. The company understands the importance of a seamless transition and has developed a comprehensive training program to equip operators with the necessary skills and knowledge to maximize the potential of the Rsp Pump.As the fuel pump industry continues to evolve, Rsp Pump’s dedication to innovation sets a new standard. Their latest technology promises to transform refueling experiences, enhance safety, and improve operational efficiency for fuel station operators worldwide.With the introduction of the Rsp Pump, the future of fuel dispensing is here.###Note: The requested word count has been achieved with 584 words. Feel free to add more content or make any modifications as required.

High-Performance Rotary Pump for Industrial Applications

Screw Rotary Pump, a leading company in the manufacturing of industrial pumps, has announced the development of a new and innovative pump technology that is set to revolutionize the industry. The company, with a history of over 50 years in delivering high-quality and reliable pumping solutions to various sectors, has once again demonstrated their commitment to continuous innovation and excellence.The new pump technology, which is designed to address the specific needs of the industrial sector, is the result of years of research and development by the company's team of experienced engineers and experts. It is set to offer a range of benefits, including improved efficiency, greater reliability, and reduced maintenance requirements, making it an ideal choice for a wide range of applications.One of the key features of the new pump technology is its innovative screw rotary design, which has been optimized to deliver superior performance and durability. The screw rotary pump is capable of handling a wide range of fluids, including those with high viscosities and abrasive particles, making it suitable for use in various industrial processes. In addition, the design of the pump also ensures smooth and efficient operation, resulting in lower energy consumption and operational costs.The company's commitment to quality and excellence is evident in the rigorous testing and validation processes that the new pump technology has undergone. The pump has been subjected to extensive testing under various operating conditions to ensure that it meets the highest standards of performance and reliability. As a result, customers can have confidence in the durability and longevity of the pump, even in the most demanding industrial environments.Furthermore, Screw Rotary Pump's dedication to sustainability and environmental responsibility is reflected in the design of the new pump technology. The pump has been developed with a focus on minimizing environmental impact, with features that promote energy efficiency and reduce emissions. This demonstrates the company's awareness of the global shift towards sustainable practices and their commitment to playing a part in preserving the environment for future generations.With the introduction of this new pump technology, Screw Rotary Pump aims to further solidify its position as a leader in the industrial pumping industry. The company's extensive experience and expertise, combined with a strong focus on innovation, ensure that they are well-positioned to meet the ever-evolving needs of their customers. The new pump technology is set to offer a competitive edge to businesses across various sectors, helping them enhance their productivity and efficiency.In conclusion, Screw Rotary Pump's new pump technology represents a significant milestone in the company's journey of delivering cutting-edge pumping solutions to the industrial sector. The innovative screw rotary design, combined with the company's commitment to quality, reliability, and sustainability, sets the new pump technology apart as a game-changer in the industry. As the company continues to push the boundaries of pump technology, customers can look forward to a future of enhanced performance and efficiency in their industrial processes.

Understanding the Purpose and Function of Check Valves in Plumbing Systems

Check Valves: Supporting Fluid Control in Diverse Industries Check valves play an essential role in fluid control systems of various industries. A check valve, also known as a one-way valve or non-return valve, ensures the flow of fluid in a single direction. The valve automatically closes when the flow tries to reverse, preventing backflow and protecting pumps, compressors, and other system components from damage. Check valves can be found in different types, sizes, materials, and configurations to accommodate the specific requirements of different applications. They can be classified based on their design, such as swing, lift, ball, disc, piston, or diaphragm check valves. They can also be classified based on their application, such as in-line, wafer, flanged, threaded, or soldered check valves. Check valves can be made of various materials, including brass, stainless steel, PVC, titanium, and others, depending on factors such as the fluid type, temperature, pressure, and environment. Check valves find applications in many industries that handle fluids or gases, such as oil and gas, water and wastewater, chemical, pharmaceutical, food and beverage, power generation, marine, and HVAC. For example, check valves prevent backflow in pipelines that transport oil or gas, reducing the risk of contamination and avoiding the loss of valuable resources. In water and wastewater treatment systems, check valves prevent reverse flow that could damage pumps or inject chemicals into the wrong tanks. In the chemical industry, check valves ensure the proper flow of corrosive or hazardous fluids, preventing leaks or explosions. In the food and beverage industry, check valves maintain the quality and hygiene of the products by preventing cross-contamination. In power generation plants, check valves protect boilers, turbines, and heat exchangers from damage caused by steam or water backflow. In marine applications, check valves prevent seawater from entering the ship or offshore platforms, avoiding corrosion and environmental hazards. In HVAC systems, check valves ensure the proper circulation of air or water, reducing energy waste and improving comfort. One of the leading companies that offer check valves is a trusted manufacturer with a worldwide reputation for quality and innovation. The company has been in the business of fluid control products for more than a century, providing a wide range of valves, regulators, and fittings for various industries. The company's check valves are designed and manufactured to meet the highest standards of performance, safety, and reliability, and are certified by international organizations such as ISO, API, and ASME. The company's check valves incorporate advanced features that enhance their functionality and durability. Some of these features include: - Silent operation: The company's check valves use a spring-loaded disc mechanism that allows for silent operation, avoiding the slamming noise that other types of check valves can make. The check valves also have a low cracking pressure, meaning that they open with minimal pressure from the downstream fluid, ensuring that the system starts smoothly. - Easy maintenance: The company's check valves are designed for easy disassembly and cleaning, allowing for quick and hassle-free maintenance. The check valves have a threaded bonnet that can be removed without special tools, and the internals can be accessed and removed easily. - High flow capacity: The company's check valves are engineered to provide high flow capacity with low pressure drop, allowing for efficient fluid transfer and reducing energy consumption. The check valves have a streamlined flow path that minimizes turbulence and erosion, extending the valve's lifespan and reducing the risk of leakage. - Wide compatibility: The company's check valves are compatible with a wide range of fluids, including corrosive, abrasive, and high-temperature ones. The check valves can also handle different pressures, from low to high, depending on the application. The company offers check valves in various configurations, such as swing, lift, and ball check valves, and in different materials, such as bronze, stainless steel, and PVC. Some of the company's check valves are designed for specific applications, such as its double-door foot valve for well water systems, its sanitary ball check valve for food and beverage processing, and its high-pressure lift check valve for oil and gas pipelines. Customers can count on the company's technical expertise and customer support to choose the right check valve for their specific needs. The company's engineers provide customized solutions for complex fluid control challenges, and its customer service team offers prompt and efficient assistance for any inquiries, orders, or after-sales needs. In conclusion, check valves are vital components of fluid control systems in diverse industries. They provide essential protection against backflow, ensuring the safe and efficient operation of pumps, compressors, and other equipment. The company's check valves combine advanced features, high-quality materials, and expert engineering to deliver superior performance and reliability in different applications. With its global presence and customer-oriented approach, the company is a trusted partner for fluid control solutions.

Innovative Pump Technology Revolutionizes Industrial Applications

Seepex Pump, a leading provider of progressive cavity pumps and pump systems, has recently announced the launch of a new innovative pump technology that is set to revolutionize the industry. With over 45 years of experience in the field, Seepex Pump has built a solid reputation for delivering high-quality and reliable pumping solutions to a wide range of industries including food and beverage, chemical, and environmental sectors.The new pump technology, which has been in development for several years, promises to deliver higher efficiency, improved performance, and increased durability compared to traditional pump systems. This breakthrough in pump technology is the result of extensive research and development efforts by Seepex Pump's team of experienced engineers and industry experts."We are thrilled to introduce this new pump technology to the market," said John Smith, CEO of Seepex Pump. "Our team has worked tirelessly to develop a pumping solution that not only meets but exceeds the expectations of our customers. We are confident that this new pump technology will set a new benchmark for performance and reliability in the industry."The new pump technology incorporates state-of-the-art design and engineering principles to deliver superior pumping performance. It features advanced materials and components that are designed to withstand the most challenging operating conditions. In addition, the new technology also incorporates smart features and digital connectivity options, allowing for real-time monitoring and control of the pump system.One of the key advantages of the new pump technology is its energy efficiency. The advanced design and engineering of the pump system result in significantly reduced energy consumption, leading to lower operating costs for users. This makes it an ideal choice for businesses looking to improve their sustainability and environmental footprint.Furthermore, the new pump technology offers improved reliability and reduced maintenance requirements. The robust construction and advanced engineering ensure long-term performance and durability, minimizing downtime and maintenance costs for customers.Seepex Pump's new pump technology is also designed with flexibility in mind, allowing for seamless integration into existing systems and processes. This makes it an ideal choice for businesses looking to upgrade their pumping infrastructure without the need for extensive modifications."We believe that our new pump technology will have a significant impact on the industry," added Smith. "Not only does it offer superior performance and reliability, but it also provides our customers with a cost-effective and sustainable pumping solution. We are excited to see the positive reception from the market."Seepex Pump is committed to providing comprehensive support and service for its new pump technology, ensuring that customers receive the highest level of satisfaction and performance from their investment. With a global network of sales and service partners, the company is well-equipped to serve customers worldwide.As Seepex Pump continues to push the boundaries of innovation in pump technology, the company remains dedicated to delivering industry-leading solutions that address the evolving needs and challenges of its customers. With a strong focus on quality, performance, and sustainability, Seepex Pump is poised to uphold its position as a trusted and preferred partner for pumping solutions.For more information about Seepex Pump and its new pump technology, please visit [company website].

Lubricating Oil Pumps: Power Your Machinery with Reliable Performance

Lubricating Oil Pumps Revolutionize the Industrial SectorIn an era of rapid technological advancements, industries across the globe are constantly searching for innovative solutions to enhance their operational efficiency. One such revolutionary development in the field of industrial machinery is the introduction of high-performance lubricating oil pumps. These pumps, designed to remove friction and reduce wear and tear in various industrial applications, have quickly garnered attention for their unparalleled functionality and contribution to the optimization of the manufacturing process.The leading provider in this cutting-edge technology, Company X, has garnered significant recognition for their advanced lubricating oil pumps. Founded in 1980, Company X has consistently focused on the development and production of lubricating systems that deliver outstanding performance, reliability, and cost efficiency.Company X’s lubricating oil pumps are hailed as game-changers as they address critical issues faced by industries globally. One of the main challenges encountered in industrial operations is machinery breakdown, often caused by excessive friction and inadequate lubrication. These issues lead to increased maintenance costs and downtime, greatly hampering productivity. However, with the advent of Company X’s high-performance lubricating oil pumps, industries are witnessing increased reliability, reduced downtime, and significant cost savings.Company X has dedicated substantial efforts towards research and development, allowing them to create an extensive range of lubricating oil pumps that cater to diverse industrial requirements. These pumps are specifically engineered to ensure a constant supply of oil, maintaining optimum lubrication levels even under severe working conditions. By utilizing innovative technology, the pumps achieve efficient oil distribution, resulting in reduced wear and tear, increased operational reliability, and extended machinery lifespan.Furthermore, Company X’s lubricating oil pumps are designed with versatility in mind. Irrespective of the industry or application, these pumps can be seamlessly integrated into various systems, including hydraulic machines, turbines, compressors, and injection molding machines, among others. The pumps’ compatibility with different equipment types showcases their adaptability and underscores their value across a spectrum of industrial sectors.One of the standout features of Company X’s lubricating oil pumps is their advanced control systems. These systems ensure precise lubricant distribution, eliminating the risk of over-lubrication or insufficient lubrication. With integrated sensors and monitoring capabilities, the pumps can measure and regulate oil flow in real-time, guaranteeing optimal lubrication at all times. Such advanced control mechanisms have proven to be groundbreaking, as they prevent unnecessary wear and tear, minimize energy consumption, and reduce oil wastage.As the leading player in the lubricating oil pump industry, Company X places great emphasis on environmental sustainability. The incorporation of eco-friendly materials, such as recyclable components and energy-efficient motors, reflects the company’s commitment to reducing its ecological footprint. By investing in Company X’s lubricating oil pumps, industries can not only enhance their productivity and profitability, but also contribute to environmental conservation.The widespread adoption of these lubricating oil pumps is a testament to their impact on the industrial sector. Companies across a range of industries, including manufacturing, automotive, aerospace, and energy, have experienced transformative results by integrating these pumps into their operations. Reduced maintenance costs, increased machinery lifespan, enhanced productivity, and improved environmental sustainability are just a few of the benefits that have positioned Company X’s lubricating oil pumps as the preferred choice for industrial lubrication needs.In conclusion, Company X’s lubricating oil pumps have revolutionized the industrial sector. Their unmatched functionality, versatility, and advanced control systems have positioned them at the forefront of lubrication technology. With these pumps, companies enjoy enhanced operational efficiency, reduced maintenance costs, and increased profitability. The revolutionary impact of Company X’s lubricating oil pumps has solidified their role as catalysts for progress, ushering in a new era of optimized industrial machinery.

Affordable and Efficient Air Conditioning for Heating Options

As the cold weather approaches, it’s time to start thinking about getting your heating system ready for the winter. One option that many homeowners are considering is using air conditioning units for heating. This innovative approach can provide an energy-efficient and cost-effective solution for keeping your home warm during the winter months.One of the leading companies in this field is {}. With over 20 years of experience in the HVAC industry, {} has become a trusted name in providing heating and cooling solutions for residential and commercial properties. The company has earned a reputation for delivering high-quality products and exceptional customer service, making them a go-to choice for homeowners looking for innovative heating solutions.Using air conditioning units for heating has become increasingly popular in recent years, and for good reason. These systems, known as heat pumps, work by transferring heat from the outside air into your home, providing an efficient and eco-friendly way to warm up your living space. This process is highly efficient and can significantly reduce energy consumption, leading to lower utility bills and a smaller carbon footprint.One of the key benefits of using air conditioning units for heating is their versatility. In addition to providing warmth during the winter, these systems can also be used for cooling during the summer months, making them a year-round solution for maintaining a comfortable indoor environment. This dual functionality can save homeowners the hassle and expense of having separate heating and cooling systems, making it a convenient and cost-effective choice.Another advantage of using air conditioning units for heating is their ability to provide consistent warmth throughout your home. Traditional heating systems, such as furnaces, can often result in uneven heating, with some areas of the house feeling much colder than others. Heat pumps, on the other hand, distribute heat evenly, creating a more comfortable and consistent temperature throughout your living space.When it comes to choosing the right air conditioning unit for heating, {} offers a wide range of options to suit different needs and preferences. From ductless mini-split systems to high-efficiency heat pumps, the company provides a variety of solutions designed to meet the unique requirements of each customer. With energy-saving features and advanced technology, their products are designed to deliver maximum performance and reliability.In addition to providing top-quality heating systems, {} also offers professional installation and maintenance services to ensure that your new unit functions at its best. Their team of experienced technicians can help you select the right system for your home and provide expert installation to ensure optimal performance. Furthermore, they offer regular maintenance services to keep your heating system in top condition, extending its lifespan and reducing the risk of breakdowns.As the demand for energy-efficient and eco-friendly heating solutions continues to grow, the use of air conditioning units for heating is expected to become even more popular in the coming years. With their proven track record in delivering high-quality products and excellent customer service, {} is well-positioned to meet this increasing demand and continue to be a leader in the HVAC industry.For homeowners looking for a reliable and innovative heating solution, {} provides a range of air conditioning units designed to deliver efficient, consistent, and cost-effective warmth throughout the winter months. With their expertise and commitment to customer satisfaction, {} is a name you can trust for all your heating and cooling needs.

A Guide to Understanding the Benefits of Screw Pumps

Screw Pump Technology: Understanding the Power Behind Modern ManufacturingWhen it comes to manufacturing, one of the most important factors to consider is the machinery and equipment used in the process. From electric motors and conveyors to compressors and pumps, every component plays a vital role in ensuring smooth and efficient operations. One of the most overlooked pieces of equipment is the screw pump, an innovative device that has transformed the way industrial manufacturing works.A screw pump is a positive displacement pump that uses helical screws to move fluid or gas. Unlike a centrifugal pump, which uses an impeller to create a vortex to move fluid, a screw pump relies on the action of the screw, which draws fluid into the pump chamber and then pushes it out through the discharge port. This makes screw pumps ideal for handling low viscosity fluids, viscous liquids, and even some solids.Invented by Archimedes in the third century BC, the screw pump has come a long way in modern industrial applications. Today, screw pump technology is widely used in various industries, ranging from oil and gas to food and beverage, chemicals, and pharmaceuticals. Its unique design and functionality enable smooth and precise flow control, making it an indispensable piece of equipment for many manufacturing processes.One company leading the way in screw pump technology is {removed for anonymity}. Founded in 1968, the company has been at the forefront of developing screw pump technology for industrial applications. Their proprietary screw pump design offers increased productivity, reduced maintenance costs, and improved efficiency, making it an ideal solution for industries looking to optimize their manufacturing processes.One of the key benefits of screw pumps is its ability to handle abrasive fluids and solids. This is crucial in many industries, especially oil and gas, where pumps are often exposed to highly corrosive and abrasive fluids. The company's screw pump design features hard-wearing components that can withstand harsh conditions, ensuring long-lasting and reliable performance.Another advantage offered by {removed for anonymity}'s screw pump technology is its superior energy efficiency. The pump design features a helical screw that rotates inside a cylindrical cavity, creating a suction force and moving the fluid. This energy-efficient operation ensures that less energy is wasted, resulting in cost savings and reduced environmental impact.Furthermore, screw pumps are low-maintenance machines that require minimal upkeep. Unlike other pump technologies that require frequent repairs and maintenance, screw pumps are designed to operate for extended periods without needing maintenance. This reduces downtime, increases productivity, and minimizes operating costs, making screw pumps an excellent investment for manufacturers looking to optimize their operations.In conclusion, screw pump technology has revolutionized industrial manufacturing by enabling smooth and precise flow control, handling abrasive fluids and solids, and offering superior energy efficiency and low maintenance. {removed for anonymity} has been at the forefront of developing screw pump technology and is committed to providing solutions that meet the needs of manufacturing industries worldwide. With their proprietary design and commitment to excellence, {removed for anonymity} is poised to continue leading the way in screw pump technology and supporting global manufacturing for years to come.