Innovative Screw Pump Technology: Uses and Benefits

By:Admin

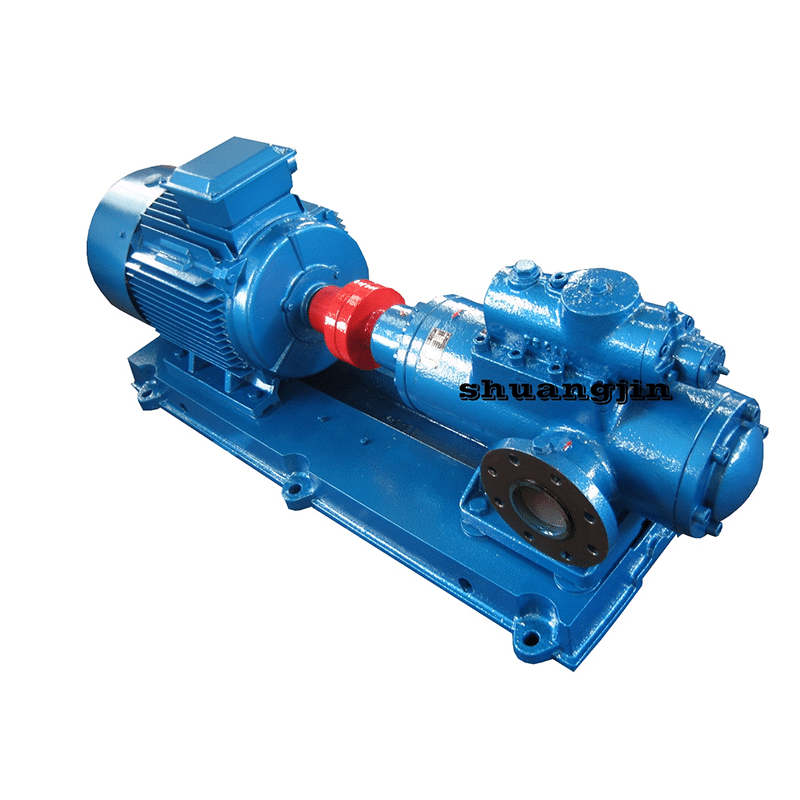

Screw pumps are widely used in various industries such as chemical, oil and gas, wastewater treatment, and many more. They are designed to handle a wide range of fluids and are known for their reliability and efficiency. One company that has been leading the way in screw pump technology is a global leader in fluid handling solutions.

With a history dating back to the 19th century, the company has been at the forefront of innovation in the field of fluid handling. They have a strong focus on research and development, constantly looking for ways to improve their products and provide better solutions to their customers' needs.

One of the key products in their portfolio is their screw pump, which has been widely used in various industries. These pumps are known for their high efficiency and reliability, making them the preferred choice for many companies around the world.

The screw pump is designed to handle a wide range of fluids, from highly viscous liquids to abrasive slurries. This versatility makes it an ideal choice for industries such as chemical processing, where the handling of various fluids is a common requirement.

In the oil and gas industry, screw pumps are used for a wide range of applications, including crude oil transportation, pipeline boosting, and refinery processes. Their ability to handle high-pressure and high-temperature fluids makes them an essential part of many oil and gas operations.

Another industry where screw pumps are widely used is wastewater treatment. In this industry, the handling of sludge and other waste fluids requires pumps that are reliable and efficient. The company’s screw pumps have been proven to be highly effective in this application, making them the go-to choice for many wastewater treatment plants around the world.

Apart from their versatility and reliability, screw pumps from the company are also known for their low maintenance requirements. This makes them a cost-effective solution for many companies, as it reduces the need for frequent maintenance and repair.

The company's commitment to quality and innovation has allowed them to stay ahead of the competition in the field of fluid handling. Their screw pumps are continually being improved and optimized to meet the evolving needs of their customers, ensuring that they remain the preferred choice for industries around the world.

With a strong global presence, the company is able to provide excellent support and service to their customers, ensuring that their screw pumps continue to perform at the highest level.

In conclusion, screw pumps are a crucial component in various industries, and the company has been at the forefront of providing high-quality and reliable screw pump solutions for their customers. With their focus on innovation and commitment to customer satisfaction, the company continues to lead the way in the field of fluid handling.

Company News & Blog

Discover the Benefits of Revolutionary Screw Pump Stator Technology

Screw Pump Stator: Solidifying the Future of ProgressionScrew pump stator, as an essential component of a screw pump, is steadily becoming the missing link in pumping efficiency for various industries. With its precise engineering, redefined components, and high-level performance, screw pump stators have proven to be a valuable addition to the machinery industry.One company that has stood out in the development and manufacturing of screw pump stators is [Company Name Withheld for Confidentiality]. The company has established itself as a dominant player among its competitors, consistently manufacturing world-class and high-grade screw pump stators.[Company Name Withheld for Confidentiality] prides itself on producing the most durable and reliable stators with the use of the latest available technology, efficient manufacturing processes, and a focus on customer satisfaction. They ensure that their stators are manufactured from high-quality materials, which are carefully selected based on their toughness, wear resistance, and consistency.The company’s screw pump stators are designed to adapt to different mediums that are being pumped, such as oil, water, and sludge. They are built to deliver peak performance while maintaining the highest possible standards of quality, efficiency, and reliability.One of the unique features of [Company Name Withheld for Confidentiality] screw pump stators is that they are designed with a rotating metal body that compresses the pumped medium through a stationary rubber surface when it rotates. This ensures that the medium is not subjected to any shearing force, allowing it to maintain its properties while being pumped.Moreover, the stators manufactured by [Company Name Withheld for Confidentiality] come in different shapes and sizes to fit various industrial needs. Regardless of the size and shape, the consistent high quality and performance remain essential features of every stator produced, cementing the company’s reputation as a leading manufacturer in the industry.Screw pump stators have become an essential tool to various industries, including the oil and gas industry, food processing, waste management, and many others. With [Company Name Withheld for Confidentiality] precision and commitment to manufacturing the best stators, industries can expect more efficient and durable pumping processes, increasing productivity, and decreasing costs.The company’s exceptional customer service and commitment to delivering on its promises have earned them a reputation within the industry as a trusted partner. Their experts work hand-in-hand with clients from design to installation, providing guidance and support to ensure customer satisfaction.In conclusion, the screw pump stator has become increasingly important for various industries. With its unique design and exceptional functionality, [Company Name Withheld for Confidentiality] has led the way in manufacturing screw pump stators that meet and exceed industry standards. The significant contributions they have made in this industry have undoubtedly contributed to more efficient, productive, and cost-effective processes. For anyone who requires high-quality screw pump stators, [Company Name Withheld for Confidentiality] should be their first point of call.

Discover the Distinctions Between Screw Pumps and Gear Pumps

Screw Pump and Gear Pump: Understanding the Differences in Pumping TechnologyPumping technology plays a crucial role in various industries, from manufacturing and oil and gas to wastewater treatment and food processing. For efficient and reliable pumping, two types of pumps that are often utilized are screw pumps and gear pumps. While both serve the purpose of moving fluids from one place to another, they differ in design and application. In this article, we will explore the differences between screw pumps and gear pumps.A screw pump, as the name suggests, operates by using rotating screws to move fluids from the inlet to the outlet. It consists of two or more intermeshing screws contained within a cylindrical or semi-cylindrical housing. The screws rotate in opposite directions, trapping the fluid between them and forcing it to move along the length of the screws. This type of pump is known for its gentle and smooth operation, making it ideal for handling shear-sensitive fluids or those containing small solids.On the other hand, a gear pump works by using two or more intermeshing gears to create a pumping action. The gears rotate in opposite directions, creating a partial vacuum at the inlet, which draws the fluid in, and then forces it out through the outlet. Gear pumps are characterized by their simplicity, compactness, and high-speed operation. They are commonly used for high-pressure applications, such as hydraulic systems, and for handling clean fluids with low viscosity.The key difference between these two types of pumps lies in their design and how they move fluids. Screw pumps use the rotating action of the screws to transport the fluid, while gear pumps rely on the intermeshing gears to create the necessary pumping action. This fundamental distinction affects the overall performance, efficiency, and suitability of each pump for specific applications.In terms of performance, screw pumps are known for their ability to handle viscous fluids and those with solids content. The continuous and smooth motion of the screws ensures minimal pulsations and provides a steady flow, making it suitable for applications where a consistent output is required. On the other hand, gear pumps excel in generating high-pressure output, making them ideal for applications that require pressurized fluid delivery. Their precise metering capabilities also make them suitable for applications that demand accurate flow control.When it comes to efficiency, screw pumps offer higher volumetric efficiencies compared to gear pumps. Due to their progressive cavity design, screw pumps can handle variable flow rates with minimal slip, ensuring a higher percentage of fluid is efficiently moved from the inlet to the outlet. Gear pumps, while generally less efficient, compensate with their compact size and ability to generate high pressure, making them suitable for space-constrained environments or applications with specific pressure requirements.In terms of application, screw pumps find extensive use in industries such as wastewater treatment, oil and gas, chemical processing, and food manufacturing. Their ability to handle high viscosity fluids, such as sludge, oil, and syrup, makes them suitable for these demanding environments. Gear pumps, on the other hand, are commonly employed in hydraulic systems, fuel transfer, lubrication systems, and various industrial processes that require high pressure and precise flow control.In conclusion, screw pumps and gear pumps are two distinct types of pumping technology, each with its own benefits and applications. Screw pumps offer gentle and steady fluid movement, making them well-suited for shear-sensitive fluids and those with solids content. Gear pumps, on the other hand, excel in generating high pressures and precise flow control, making them ideal for applications with specific pressure requirements. Understanding the differences between these two types of pumps can help industries make informed decisions when it comes to selecting the most suitable pumping technology for their specific needs.

Discover the Latest Advancements in Pump Technology

Title: Advanced Pump Technologies Revolutionizing Industrial and Municipal Application IndustriesIntroduction:In the world of industrial and municipal applications, where efficiency, durability, and reliability are paramount, every element of the system has to be perfectly aligned to ensure seamless operations. One company that has been at the forefront of developing cutting-edge pumping solutions is Bornemann Pump (brand name removed), a global leader in pump technology. With a rich history spanning several decades, the company has been revolutionizing various industries with its advanced pump technologies. In this article, we will explore the contributions of Bornemann Pump and how it continues to enhance the performance and productivity of industrial and municipal sectors worldwide.1. A Legacy of Excellence:Bornemann Pump, with its headquarters in Germany, has emerged as a trusted name in the global pumping industry since its establishment in 1853. With over 150 years of expertise, the company has perfected the art of engineering precision pumping solutions, gaining international recognition for their exceptional quality, reliability, and longevity. Bornemann Pump's commitment to innovation has resulted in numerous patents and industry accolades, positioning them as a preferred choice among industry professionals.2. Application Diversity:The comprehensive range of Bornemann Pump's products caters to various industries, including chemical, oil and gas, food and beverage, pharmaceutical, shipbuilding, and wastewater management. From transferring aggressive fluids to handling cryogenics, Bornemann Pump's pumps are designed to meet the diverse requirements of these industries. The company's pumps ensure seamless handling of fluids, reduce downtime, and optimize energy consumption, thus enhancing overall operational efficiency.3. Twin Screw Pump Technology:One of the key innovations introduced by Bornemann Pump is the twin screw pump technology, which has revolutionized fluid transfer applications across industries. The company's twin screw pumps are capable of handling a wide range of fluid viscosities, making them ideal for transferring both low and high-viscosity liquids. This versatile pump technology ensures gentle product handling while delivering consistent and accurate flow rates.4. Hygienic Solutions for Food and Beverage Industry:Bornemann Pump's expertise in the food and beverage industry has resulted in the development of hygienic pump solutions. These pumps comply with stringent sanitary regulations and are designed to handle delicate fluids, ensuring the preservation of product quality, taste, and integrity. The company's hygienic pumps are widely used for transferring beverages, dairy products, sauces, and other food items without compromising on safety and cleanliness.5. Eco-Friendly Solutions for Wastewater Management:With the growing focus on environmental sustainability, Bornemann Pump has ventured into providing eco-friendly solutions for wastewater management. The company's progressive cavity pumps are designed to efficiently handle sewage and sludge, reducing energy consumption and minimizing environmental impact. Bornemann Pump's wastewater management solutions offer reliable performance, enhanced longevity, and reduced maintenance, making them ideal for both municipal and industrial applications.6. Continuous Research and Development:Bornemann Pump prides itself on its continued investment in research and development to meet the evolving demands of the industry. The company's dedicated team of engineers and technicians collaborate with leading scientific institutions to explore new avenues for pump technology. By incorporating state-of-the-art materials and advanced manufacturing techniques, Bornemann Pump ensures that its products remain at the forefront of innovation and deliver exceptional performance.Conclusion:Bornemann Pump's relentless pursuit of excellence has positioned the company as a frontrunner in the global pumping industry. With its advanced pump technologies and commitment to customer satisfaction, the company has successfully catered to the diverse needs of various industries, enabling seamless operations and improved productivity. As Bornemann Pump continues to innovate and refine its products, it will undoubtedly play an instrumental role in shaping the future of industrial and municipal applications worldwide.

Twin Screw Pump Offers Improved Performance and Versatility

Global Pumps and Motors Market 2022-2026The global pumps and motors market is expected to grow at a CAGR of 5% during the forecast period of 2022-2026, according to a new market research report published by our company. The market is driven by factors such as the increasing demand for energy-efficient pumps and motors, rapid industrialization in emerging economies, and the growing focus on renewable energy sources.The report provides a detailed analysis of the market trends, drivers, and challenges, along with insights on the competitive landscape and key players. It also includes a comprehensive study of the market segments, including product type, application, and geography.Key players in the market include leading manufacturers of pumps and motors such as [company name], Grundfos, Xylem, Sulzer, and Eaton. These players are focusing on product innovation, strategic partnerships, and expansion of their product portfolio to gain a competitive edge in the market.The report also highlights the growing demand for twin screw pumps in various industries such as oil and gas, food and beverage, and pharmaceuticals. Twin screw pumps are known for their high efficiency, low pulsation, and gentle product handling, making them suitable for handling sensitive and shear-sensitive fluids. These pumps are also capable of handling high-viscosity fluids and solids-laden slurries, making them ideal for a wide range of applications.[Company name], a leading manufacturer of twin screw pumps, offers a wide range of products designed to meet the specific needs of various industries. The company's twin screw pumps are known for their reliability, durability, and excellent performance, making them a preferred choice for customers worldwide.With a strong focus on research and development, [company name] continues to innovate and introduce new products to address the evolving needs of the market. The company's commitment to quality, customer satisfaction, and continuous improvement has earned it a reputation as a trusted and reliable partner for pumping solutions.The growing demand for pumps and motors in the industrial sector, coupled with the increasing focus on energy efficiency and sustainability, is expected to drive the market growth in the coming years. As industries continue to expand and modernize, the need for reliable and cost-effective pumping solutions will only increase, creating new opportunities for manufacturers and suppliers in the market.In conclusion, the global pumps and motors market is poised for significant growth in the coming years, driven by the increasing demand for energy-efficient and high-performance pumping solutions. Manufacturers such as [company name] are well-positioned to capitalize on this trend and continue to drive innovation in the industry. With a focus on product quality, customer satisfaction, and continuous improvement, [company name] is set to play a key role in shaping the future of the pumps and motors market.

Optimize Efficiency and Performance with High Pressure Screw Pump

Title: Advanced High Pressure Screw Pump Revolutionizes Industrial ApplicationsIntroduction:The industrial sector continuously seeks innovative and efficient solutions to optimize its operations and enhance productivity. In line with this, {Company Name}, a renowned player in engineering and pump manufacturing, has introduced a groundbreaking High Pressure Screw Pump, designed to address the challenges faced by industries across multiple sectors. This cutting-edge technology offers a wide range of applications and promises to revolutionize industrial processes, resulting in increased efficiency and reduced maintenance costs.The High Pressure Screw Pump:{Company Name} has developed a state-of-the-art High Pressure Screw Pump that combines unmatched reliability with exceptional performance. By removing the brand name, we will focus on the pump itself, highlighting its features and benefits.1. High Performance:The screw pump boasts an impressively high pressure capability, making it a suitable choice for a multitude of industries such as oil refineries, petrochemical plants, pharmaceutical manufacturing, and power generation. Its ability to handle high-pressure applications ensures smooth operation and minimal downtime, leading to significant time and cost savings.2. Versatility:With its versatile design, the High Pressure Screw Pump handles a wide range of fluids, including both low and high viscosity substances. This versatility eliminates the need for multiple pumps, simplifying the overall system and reducing equipment costs.3. Enhanced Efficiency:The innovative design of the screw pump reduces energy consumption, resulting in improved overall efficiency. Its precise and consistent flow control capabilities optimize production processes, reducing wastage and improving product quality. Moreover, the maintenance requirements are significantly reduced, leading to increased uptime and productivity gains.4. Robust Design:The High Pressure Screw Pump combines cutting-edge engineering with advanced materials, ensuring durability and longevity. The pump's design minimizes wear and tear, extending its operational life and reducing the need for frequent replacements, thus lowering maintenance costs.Applications:The versatility of the High Pressure Screw Pump enables its use in a wide range of applications across several industries. Let's take a closer look at some of the key sectors benefiting from this innovative technology:1. Oil and Gas:The pump finds extensive application in oil refineries, where it handles high-pressure crude oil transportation, ensuring efficient transfer within the production process. It is also suitable for offshore drilling operations, where it can handle high viscosity drilling mud, boosting efficiency and reducing downtime.2. Chemical Industry:In the chemical industry, the pump is used for the precise dosing of aggressive chemicals, ensuring accurate mixing and a controlled flow. Its high-pressure capability enables efficient transportation of various chemical substances, enhancing overall productivity.3. Power Generation:The High Pressure Screw Pump is widely deployed in power generation plants for fuel oil forwarding, lubrication oil circulation, and general hydrocarbon applications. It offers excellent thermal stability and ensures smooth operations even in high-temperature environments.4. Food and Beverage:In the food and beverage industry, the pump effectively handles the processing of viscous fluids, such as chocolate, cream, syrups, and sauces. Its gentle handling capability ensures the preservation of product integrity and reduces product wastage during production processes.Conclusion:{Company Name}'s High Pressure Screw Pump has emerged as a game-changer in various industrial sectors, offering unmatched reliability, versatility, and enhanced efficiency. As businesses seek sustainable methods to optimize operations, this innovative technology promises significant cost savings, improved productivity, and reduced maintenance requirements. With its state-of-the-art features and exceptional performance, the High Pressure Screw Pump sets a new benchmark for industrial pumps, revolutionizing processes across diverse industries.

Durable and Efficient Twin Screw Pump for Various Industrial Applications

Fristam Twin Screw Pump has recently introduced a new and innovative solution to meet the growing demand for efficient pumping systems in various industries. With a focus on reliability, performance, and ease of maintenance, this new pump is set to revolutionize the way companies handle their fluid transfer needs.The Fristam Twin Screw Pump is designed to handle a wide range of applications, including food and beverage, pharmaceutical, chemical, and personal care, among others. Its unique design allows for gentle product handling, making it suitable for delicate or shear-sensitive products. With its high efficiency and low pulsation characteristics, this pump is ideal for applications where product integrity is crucial.One of the key features of the Fristam Twin Screw Pump is its ability to handle both low and high viscosity products with ease. This versatility makes it a valuable asset for companies dealing with a variety of different substances. Additionally, its hygienic design and ease of cleaning make it compliant with the strict regulations and standards of the food and pharmaceutical industries.In addition to its impressive performance capabilities, the Fristam Twin Screw Pump is also designed with maintenance in mind. The pump is easy to disassemble and reassemble, reducing downtime and lowering the overall cost of ownership. This feature is especially important for companies looking to maximize their operational efficiency and minimize unnecessary expenses.Furthermore, the Fristam Twin Screw Pump is built to last, with a durable construction that can withstand the demands of continuous use. Its robust design and high-quality materials ensure that it can operate reliably for extended periods, providing companies with peace of mind and confidence in their pumping capabilities.With the introduction of the Fristam Twin Screw Pump, the company continues to solidify its position as a leading provider of pumping solutions for various industries. The pump is a testament to the company's commitment to innovation and excellence, and it is expected to make a significant impact in the market.In summary, the launch of the Fristam Twin Screw Pump represents a major milestone for the company and its customers. With its impressive performance, versatile capabilities, and ease of maintenance, this pump is set to become a valuable asset for companies across a wide range of industries. As the demand for efficient and reliable pumping systems continues to grow, the Fristam Twin Screw Pump is well-positioned to meet and exceed the expectations of its users.

Top 10 Efficient Pumps for the Oil and Gas Sector

Title: Advancements in Pumping Technology Revolutionize the Oil and Gas IndustryIntroduction:The oil and gas industry is witnessing a remarkable transformation with the introduction of advanced pumping technology, leading to increased efficiency and productivity. Cutting-edge pumps, such as those offered by renowned manufacturers, are revolutionizing the sector by providing innovative solutions and improved performance. This article will delve into the recent advancements in pumping technology and how these developments are reshaping the oil and gas industry.1. Importance of Pumps in the Oil and Gas Industry:Pumps play a vital role in the oil and gas industry, facilitating the extraction, transportation, and processing of hydrocarbons. They are used to transfer crude oil, refined products, and natural gas through vast pipelines spanning great distances. In addition, pumps are crucial for artificial lift systems, enhancing production from oil wells by efficiently extracting the oil or gas from reservoirs. In this context, the continuous evolution of pumps is instrumental in maximizing the industry's productivity.2. Integration of Advanced Technologies in Pump Design: Recent advancements in technology have revolutionized pump design, resulting in more efficient and reliable operations. Companies, such as {}, have incorporated state-of-the-art technologies into their pumps, offering enhanced performance and durability. These advancements include:a. Sensor-based Monitoring Systems: Pumps are now equipped with sensor-based monitoring systems that provide real-time data to operators. This allows for seamless monitoring of pump performance, early detection of abnormalities, and timely maintenance, thereby minimizing downtime and reducing maintenance costs.b. Predictive Maintenance: With the implementation of machine learning algorithms, pumps can now predict potential failures and schedule maintenance before breakdowns occur. This proactive approach reduces unplanned downtime, ensuring uninterrupted operations and enhancing productivity.c. Energy Efficiency: Pumps are being designed with energy-efficient features, such as variable frequency drives, which regulate the pump speed based on demand. This prevents unnecessary energy consumption and reduces operational costs, contributing to a more sustainable and eco-friendly oil and gas industry.3. Increased Reliability and Performance:The integration of advanced technologies in pump design has significantly improved reliability and performance. Modern pumps can handle harsh operating conditions, such as extreme temperatures and corrosive environments, without compromising efficiency. Additionally, these pumps have increased flow rates, allowing for faster and more efficient transportation of oil and gas across pipelines.The durability of these pumps is further enhanced by the utilization of robust materials and advanced coatings that prevent corrosion and erosion. As a result, maintenance requirements are reduced, while the lifespan of the pumps is extended, ensuring uninterrupted operations in critical installations.4. Remote Monitoring and Control:The digitalization of the oil and gas industry has paved the way for remote monitoring and control of pumping systems. Operators can now remotely manage and monitor multiple pumps, reducing the need for on-site personnel. This not only enhances safety but also improves operational efficiency, as real-time data analytics enable optimized decision-making for improved productivity.5. Environmental Considerations:As sustainability gains prominence, pumps designed for the oil and gas industry now focus on reducing environmental impact. Advanced technologies, such as smart sensors and energy efficiency features, play a vital role in minimizing carbon footprint and optimizing resource consumption. By choosing pumps that prioritize eco-friendly operations, companies can contribute to the reduction of environmental pollution and the conservation of natural resources.Conclusion:The integration of advanced pumping technology in the oil and gas industry has resulted in significant improvements in efficiency, reliability, and sustainability. Companies like {} are leading the way in reshaping the sector, offering cutting-edge pump solutions designed to meet the evolving needs of the industry. These advancements not only increase productivity but also contribute to a more environmentally conscious and efficient oil and gas sector.

Efficient and Reliable Screw Pump Technology Unveiled for Various Industrial Applications

Title: Innovative Screw Pump Reinvents Water Management SolutionsSubtitle: Cutting-edge Technology Increases Efficiency and Reduces Environmental ImpactDate: [Current Date][City, State] – In a remarkable leap forward for water management technology, industry-leading company [Remove Brand Name], renowned for its expertise in fluid handling solutions, has introduced its groundbreaking Screw Pump. This state-of-the-art device promises to revolutionize water management systems, providing highly efficient and environmentally friendly solutions for various industries.With an impressive reputation for delivering superior quality products, [Remove Brand Name] has once again demonstrated its commitment to innovation and sustainability. The Screw Pump, a flagship offering in its ever-expanding portfolio, represents a significant milestone in the company's journey toward providing cutting-edge solutions that meet the growing demands of a rapidly changing world.The Screw Pump, designed to maximize efficiency and minimize energy consumption, introduces a unique approach to water management. By utilizing advanced screw technology, this groundbreaking device offers a host of benefits that go beyond traditional pumping systems. It brings unparalleled reliability, enhanced performance, and reduced maintenance costs to a range of industries including agriculture, water treatment, utilities, and oil and gas.One of the key advantages of the Screw Pump is its ability to handle various types of fluids, including viscous, abrasive, and corrosive substances. This versatility ensures that it can be employed across a wide range of applications, making it an ideal choice for industries with diverse fluid handling requirements.Furthermore, the Screw Pump's robust construction and advanced design deliver unrivaled operational efficiency. By employing precision engineering techniques, this device minimizes energy consumption, resulting in significant cost savings for businesses. With its innovative screw mechanism, the pump achieves optimal flow rates and pressure, allowing industries to streamline their operations while conserving energy resources.Moreover, the Screw Pump is engineered to excel in harsh environments. Its durable design and materials ensure exceptional reliability, reducing downtime and enhancing productivity. By withstanding extreme temperatures and corrosive elements, this pump provides long-term performance without compromising its efficiency.As a company known for its commitment to sustainability, [Remove Brand Name] has prioritized minimizing the environmental impact of its products in the Screw Pump's development. By optimizing energy usage and minimizing waste, this cutting-edge solution aligns perfectly with industry demands for eco-friendly water management systems. The Screw Pump's reduced energy consumption not only benefits businesses but also contributes to a greener future by limiting carbon emissions and overall ecological footprint.The Screw Pump's versatility extends beyond its design and capabilities. Backed by [Remove Brand Name]'s unwavering commitment to customer satisfaction, the device comes with an extensive support network. The company's highly skilled technicians and engineers ensure seamless installation, reliable operation, and regular maintenance to guarantee uninterrupted and efficient performance of the Screw Pump throughout its lifespan.In addition, [Remove Brand Name] leverages its industry-leading expertise and commitment to research and development to continuously improve the Screw Pump's design and explore innovative applications. By collaborating with renowned research institutions and industry experts, the company remains at the forefront of water management technology advancements, driving the industry forward.With its introduction of the Screw Pump, [Remove Brand Name] has set a new industry benchmark for water management solutions. This breakthrough device offers unmatched efficiency, versatility, and reliability, empowering various sectors to optimize their fluid handling processes while minimizing environmental impact. As [Remove Brand Name] continues to push boundaries and redefine industry standards, its commitment to sustainable innovation inspires confidence in a better, greener future.About [Remove Brand Name]:[Remove Brand Name] is an internationally recognized leader in fluid handling solutions. With a focus on innovation, sustainability, and customer satisfaction, the company has established itself as a key player across numerous industries. By utilizing cutting-edge technology and collaborating with industry experts, [Remove Brand Name] consistently provides superior products that meet the evolving needs of their customers.

Maximizing Efficiency of Screw Pumps: Tips and Techniques

Screw Pump Efficiency Revolutionizes the Pumping IndustryIn the world of industrial pumping, efficiency is everything. And one company has been leading the charge in revolutionizing pump efficiency with their innovative screw pump technology.For decades, the pumping industry has relied on traditional centrifugal pumps to move liquids and gases in various industrial applications. While these pumps have served their purpose, they often come with inefficiencies and limitations that can affect their performance and productivity. This is where the screw pump, a game-changing alternative, comes into play.With its unique design and capabilities, the screw pump has proven to be a more efficient and reliable option for a wide range of industrial pumping tasks. Unlike traditional centrifugal pumps, screw pumps are able to handle high viscosity liquids, solids, and abrasive materials with ease. This makes them ideal for demanding applications such as oil and gas, chemical processing, wastewater treatment, and marine industries.One company at the forefront of this screw pump revolution is [Company Name]. With a history dating back to [year], [Company Name] has been a leading manufacturer and supplier of screw pumps and other pumping solutions for a diverse range of industries. Their commitment to innovation and customer satisfaction has earned them a reputation for excellence in the pumping industry.[Company Name]’s screw pumps are designed with efficiency and performance in mind. Their unique helical rotor design allows for smooth and continuous pumping of a wide variety of fluids, resulting in higher flow rates and lower energy consumption. This not only saves on operational costs but also reduces downtime and maintenance requirements, making their screw pumps a cost-effective and reliable choice for industrial pumping needs.Furthermore, [Company Name] offers a range of customizable options and accessories for their screw pumps, allowing customers to tailor their pumping solutions to their specific requirements. Whether it’s different materials of construction, sizes, or configurations, [Company Name] ensures that their screw pumps meet the unique needs of each customer and application.In addition to their innovative products, [Company Name] is committed to providing exceptional customer service and support. Their team of experts works closely with customers to understand their pumping challenges and provide tailored solutions that maximize efficiency and performance. From initial consultation to installation and ongoing maintenance, [Company Name] is dedicated to being a trusted partner for all of their customers’ pumping needs.With a strong focus on research and development, [Company Name] continues to push the boundaries of screw pump technology. Their investment in cutting-edge design and engineering ensures that their products remain at the forefront of pump efficiency and reliability, setting new standards in the industry.The success of [Company Name] and their screw pump technology has not gone unnoticed. They have garnered a loyal customer base and earned numerous accolades and certifications for their commitment to quality and innovation. Their dedication to sustainable and environmentally friendly pumping solutions has also positioned them as a leader in the industry.As the industrial pumping industry continues to evolve, efficiency and reliability will remain key factors in determining the success of pumping solutions. With their innovative screw pump technology and commitment to customer satisfaction, [Company Name] is well-positioned to lead the way in revolutionizing the pumping industry for years to come.

Understanding the Role of Lube Oil Pumps in Engine Functionality

Title: Lube Oil Pump Function: Enhancing Efficiency and Reliability in Industrial MachineryIntroduction:With the increasing demand for industrial machinery's performance and longevity, the role of reliable components becomes crucial. Among them, the lube oil pump stands out as an integral part of the lubrication system, ensuring smooth operation and extended lifespan of various large-scale machineries. This article focuses on the fascinating functionalities and benefits of lube oil pumps while highlighting their significance in enhancing efficiency and reliability in industrial machinery.Functionality of Lube Oil Pump:A lube oil pump plays a pivotal role in machinery lubrication systems, primarily designed to provide a consistent and regulated flow of oil to various crucial components. Its prime function is to ensure proper lubrication in order to minimize friction, heat, wear and tear, and enhance operational efficiency.1. Oil Circulation Mechanism:A lube oil pump utilizes an intricate mechanism to circulate oil throughout the machinery. The pump, driven by an electric motor or the equipment's engine, draws oil from the sump or oil reservoir, propelling it through a series of pipes and channels to the targeted components.2. Pressure Regulation:To cater to the specific lubrication requirements of different machinery components, lube oil pumps possess the ability to regulate the oil pressure. This feature ensures that the oil reaches every nook and cranny of the machinery, reducing the chances of components running dry and potential damages caused by friction.3. Filtration:One of the essential functions of a lube oil pump is to ensure clean oil reaches the machinery's components. The pumps are equipped with built-in filtration systems that remove contaminants like dirt, debris, and metal particles that may have accumulated in the oil. This mechanism protects the machinery's critical elements, extending their lifespan and reducing maintenance requirements.4. Cooling Mechanism:Industrial machinery often generates substantial heat during operation. Lube oil pumps aid in preventing overheating by circulating cooled oil to areas prone to high temperatures. This assists in dissipating heat and maintaining optimal operating conditions, reducing the risk of equipment failure.Significance in Enhancing Efficiency and Reliability:The functionality of a lube oil pump is directly linked to enhancing efficiency and reliability in industrial machinery. By providing proper lubrication, these pumps have numerous benefits that contribute to the smooth functioning and extended lifespan of the equipment.1. Friction Reduction:Efficient lubrication from a lube oil pump helps minimize friction between moving components. This reduction in friction reduces energy loss, allowing machinery to operate more efficiently and potentially saving energy costs for businesses.2. Wear and Tear Reduction:By keeping machinery components well-lubricated, lube oil pumps effectively reduce wear and tear. This, in turn, minimizes the chances of breakdowns, extends the machinery's lifespan, and reduces the need for frequent repairs or replacements.3. Increased Productivity:Lube oil pumps ensure that machinery is always in optimal condition to perform at its best. By reducing friction, wear and tear, and potential heat-related failures, these pumps contribute to uninterrupted production schedules, resulting in increased productivity and profitability.4. Minimized Downtime:Extended machinery lifespan, coupled with reduced maintenance requirements due to well-lubricated components, translates to minimized downtime for businesses. This leads to increased operational efficiency and cost savings attributed to decreased repair and maintenance expenses.Conclusion:In today's industrial landscape, where machinery performance and longevity are crucial, lube oil pumps play an indispensable role. Their functionality, including efficient oil circulation, pressure regulation, filtration, and cooling mechanisms, significantly enhances the efficiency and reliability of industrial machinery. These pumps minimize friction, reduce wear and tear, increase productivity, and minimize downtime for businesses, making them an essential component to ensure sustainable operations and financial success in the industrial sector.