Screw Pump Installation and Function in Ships

By:Admin

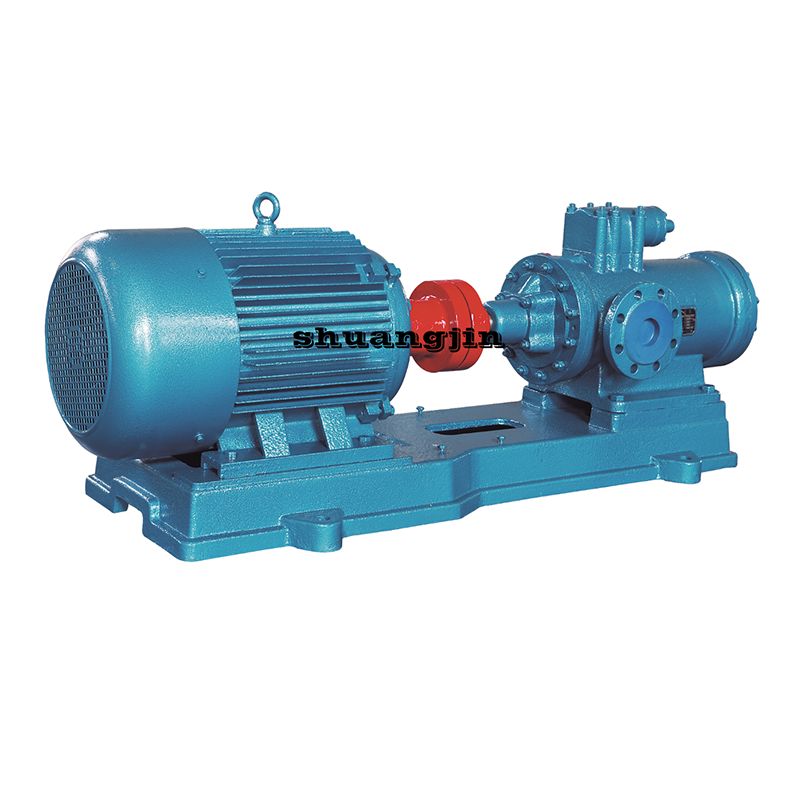

Screw pumps are a crucial component in ships, playing a vital role in the efficient operation of marine vessels. These pumps are widely used in the shipping industry for various applications, including cargo handling, fuel transfer, and ballast water management.

{Company Name} is a leading manufacturer of screw pumps for the maritime industry. With a strong focus on innovation and technology, the company has been providing high-quality and reliable screw pumps to shipbuilders and shipowners around the world. The company's screw pumps are designed to meet the specific requirements of the marine industry, offering efficient and reliable performance in demanding maritime environments.

One of the key applications of screw pumps in ships is for cargo handling. In modern cargo vessels, screw pumps are used to transfer various types of liquid cargo, such as chemicals, petroleum products, and edible oils. The precise and consistent flow characteristics of screw pumps make them an ideal choice for the safe and efficient handling of liquid cargo, ensuring that the cargo is transferred securely and without any contamination.

Screw pumps also play a critical role in fuel transfer operations on ships. With the increasing focus on environmental regulations and fuel efficiency, shipowners are looking for reliable and energy-efficient solutions for fuel transfer. {Company Name}'s screw pumps are designed to meet these requirements, offering high efficiency and low energy consumption for fuel transfer applications. These pumps help to optimize fuel transfer processes, reducing fuel consumption and emissions, and ensuring compliance with environmental regulations.

Another important application of screw pumps in ships is for ballast water management. Ballast water is used to stabilize ships at sea, but it can also transfer harmful aquatic organisms and pathogens from one ecosystem to another. To prevent the spread of invasive species through ballast water, ships are required to install ballast water management systems, including screw pumps for ballast water treatment. {Company Name}'s screw pumps are designed to meet the stringent requirements for ballast water treatment, providing reliable and effective performance for the safe and environmentally sound management of ballast water.

In addition to these applications, screw pumps are also used in various other systems on ships, including hydraulic systems, lubrication systems, and cooling systems. {Company Name} offers a wide range of screw pumps to meet the diverse needs of the maritime industry, providing customized solutions for different ship types and applications.

With a strong focus on research and development, {Company Name} is continuously innovating and improving its screw pump technology to meet the evolving needs of the maritime industry. The company's state-of-the-art manufacturing facilities are equipped with the latest machinery and testing equipment, ensuring the highest quality standards for its screw pumps. Furthermore, {Company Name} has a global network of service centers and support teams, providing technical assistance and maintenance services to ensure the reliable performance of its screw pumps throughout their operational life.

As the maritime industry continues to evolve, the demand for reliable and efficient screw pumps for ships will only increase. With its commitment to innovation, quality, and customer satisfaction, {Company Name} is well-positioned to meet this demand and remain a trusted partner for the shipping industry.

In conclusion, screw pumps are a vital component for the efficient and reliable operation of ships. Whether it's for cargo handling, fuel transfer, ballast water management, or other applications, {Company Name}'s screw pumps are designed to meet the rigorous demands of the maritime industry, providing high performance, energy efficiency, and environmental compliance. With its leading position in the market and a strong commitment to technological advancement, {Company Name} continues to be a preferred choice for shipbuilders and shipowners seeking reliable and innovative screw pump solutions.

Company News & Blog

High-Quality Rotor Screw Pump for Efficient Pumping

Rotor Screw Pump, a leading manufacturer of industrial pumping solutions, has recently launched a new series of screw pumps designed to meet the growing demand for reliable and efficient pumping systems in the global market.The new series of screw pumps are the result of extensive research and development efforts, aimed at providing customers with innovative pumping solutions that deliver superior performance and durability. The company's commitment to excellence is reflected in the quality and reliability of their products, making them the preferred choice for a wide range of industrial applications.With a legacy of over 50 years in the industry, Rotor Screw Pump has earned a solid reputation for delivering high-quality pumping solutions that meet the diverse needs of their customers. The company's state-of-the-art manufacturing facilities and advanced engineering capabilities ensure that they stay ahead of the curve in terms of product innovation and performance.The new series of screw pumps feature a robust design that allows for seamless operation even in the most demanding environments. The pumps are equipped with advanced technologies that optimize efficiency and reduce energy consumption, making them an eco-friendly choice for businesses looking to minimize their environmental footprint.In addition to their superior performance, the new series of screw pumps are also designed for easy installation and maintenance, helping customers minimize downtime and maximize productivity. The pumps are built to withstand the rigors of industrial operations, delivering reliable performance day in and day out."We are excited to introduce our new series of screw pumps to the global market," said a spokesperson for Rotor Screw Pump. "These pumps represent the culmination of our decades of experience and expertise in the industry, and we are confident that they will set a new standard for performance and reliability in industrial pumping."The company's dedication to customer satisfaction is evident in their comprehensive support services, which include technical assistance, maintenance, and repair. Rotor Screw Pump's team of experts is committed to helping customers find the right pumping solutions for their specific needs, and ensuring that their equipment operates at peak efficiency at all times.With a strong focus on innovation and continuous improvement, Rotor Screw Pump is poised to remain at the forefront of the industry, providing customers with cutting-edge pumping solutions that deliver exceptional value. The company's new series of screw pumps is a testament to their ongoing commitment to excellence and their determination to meet the evolving needs of the market.As the global demand for effective pumping solutions continues to grow, Rotor Screw Pump is well positioned to capitalize on the opportunities that lie ahead. With their proven track record of delivering high-quality products and unparalleled customer support, the company is set to solidify its position as a trusted partner for businesses seeking reliable and efficient pumping solutions.The launch of the new series of screw pumps marks the beginning of an exciting new chapter for Rotor Screw Pump, as the company looks to expand its presence in key markets around the world. With their dedication to innovation and customer satisfaction, the company is well positioned to make a significant impact in the global pumping industry.

Efficiently Regulate Heat Pumps with Advanced Control Systems

Heat Pump Control: Transforming the Heating IndustryThe heating industry is transforming, and Heat Pump Control is at the forefront of this change. They are a leading manufacturer and supplier of high-quality heat pumps and controllers that are widely used in domestic, industrial, and commercial heating applications. Heat Pump Control is dedicated to producing innovative products that help homeowners and businesses improve their energy efficiency while reducing their carbon footprint.Heat Pump Control has been serving the heating industry for over a decade and has gained a reputation as a reliable and trustworthy supplier of heat pumps and controllers. Their products are designed to meet the needs of a wide range of clients, including homeowners, businesses, and industrial facilities. They also have a team of skilled technicians who are on hand to offer installation, repair, and maintenance services.One of the key features of Heat Pump Control's products is their energy efficiency. Heat pumps are known for being highly efficient, but the controllers developed by Heat Pump Control take this to the next level. Their controllers are designed to optimize the performance of their heat pumps, reducing energy consumption and enhancing overall efficiency. This means that clients can save money on their energy bills while still enjoying a comfortable living or working environment.Another important feature of Heat Pump Control's products is their versatility. They offer a range of heat pumps and controllers that cater to different applications, from small domestic installations to large industrial facilities. Their products are designed to be highly adaptable and can be customized to meet the specific needs of each client. This means that Heat Pump Control can provide solutions for a wide range of heating requirements, from single-family homes to large commercial buildings.One area where Heat Pump Control is particularly innovative is in their use of smart technology. Their controllers are designed to be fully integrated with smart home and smart building systems, allowing clients to control their heating remotely and make adjustments based on their individual preferences. This not only improves convenience but also allows for greater energy savings since clients can adjust their heating settings to suit their needs.Heat Pump Control is also committed to sustainability and reducing the carbon footprint of its products. They are constantly exploring ways to minimize the environmental impact of their products and manufacturing processes. Their heat pumps are designed to use renewable energy sources such as air and ground, which reduces the amount of non-renewable energy needed to heat homes and businesses. This approach helps clients reduce their carbon footprint and contribute to a more sustainable future.In conclusion, Heat Pump Control is a forward-thinking manufacturer and supplier of heat pumps and controllers that are transforming the heating industry. Their products are highly efficient, versatile, and adaptable, making them suitable for a wide range of applications. They also prioritize sustainability and the use of smart technology to deliver the latest innovations in the heating industry. With Heat Pump Control, clients can enjoy quality heating solutions that are designed to improve energy efficiency and reduce their carbon footprint.

Understanding the Working Principle of Single Screw Pumps

Single screw pump, also known as Archimedes screw pump, is a type of positive displacement pump that can efficiently move fluid through a system. It is a versatile and reliable pump that is widely used in various industries including oil and gas, food and beverage, wastewater treatment, and marine applications. With its simple design and high efficiency, the single screw pump is a popular choice for many pumping applications.The working principle of a single screw pump is quite simple yet effective. It consists of a single screw rotor that rotates inside a double-threaded stator. As the rotor turns, it creates cavities between the screw and the stator, which allows the fluid to be pulled into the pump. As the rotor continues to rotate, the cavities move the fluid along the length of the stator, pushing it out through the discharge port. This continuous movement of the screw rotor creates a smooth and pulsation-free flow of fluid, making the single screw pump suitable for handling shear-sensitive and viscous fluids.One company that has been at the forefront of manufacturing and supplying single screw pumps is {}. With a history tracing back to over a century, {} has established itself as a leading provider of pumping solutions for various industries. The company's single screw pumps are designed to meet the rigorous demands of modern industrial applications, offering high performance, reliability, and long service life.{}'s single screw pumps are built with precision engineering and high-quality materials to ensure optimal performance and minimal maintenance. The company offers a wide range of single screw pump models to suit different flow rates, pressures, and fluid viscosities, catering to the diverse needs of its customers. In addition, {} provides comprehensive technical support and after-sales service to ensure that its customers get the most out of their pumping systems.The application of {}'s single screw pumps spans across various industries. In the oil and gas sector, these pumps are used for transferring crude oil, drilling mud, and various other fluids in upstream, midstream, and downstream operations. In the food and beverage industry, {}'s single screw pumps are employed for handling viscous and delicate products such as chocolate, syrup, and dairy. Additionally, these pumps are widely used in wastewater treatment plants for pumping sludge, effluent, and other fluids with high solids content.The success of {}'s single screw pumps can be attributed to the company's commitment to innovation and continuous improvement. {}'s research and development team is constantly exploring new technologies and materials to enhance the performance and efficiency of its pumps. Through ongoing investment in research and technology, {} aims to stay ahead of the curve and provide cutting-edge solutions to its customers.Furthermore, {} places a strong emphasis on quality control and testing to ensure that its single screw pumps meet the highest standards of reliability and durability. The company's manufacturing facilities are equipped with state-of-the-art equipment and processes to produce pumps that are robust, efficient, and capable of withstanding harsh operating conditions.In conclusion, single screw pumps are an integral part of many industrial processes, and {} has been a key player in providing high-quality pumping solutions to a wide range of industries. With its proven track record and commitment to excellence, {} continues to be a trusted partner for businesses looking for reliable and efficient single screw pumps. As the demand for advanced pumping technology continues to grow, {} is well-positioned to lead the way with its innovative and reliable pumping solutions.

Optimize Your Home's Cooling System with a Heat Pump

Heat Pump Cooling Systems have become increasingly popular in recent years due to their energy efficiency and ability to provide both heating and cooling in one system. One company at the forefront of this technology is {company name}, a leading provider of heating, ventilation, and air conditioning (HVAC) solutions.{Company name} has been pioneering the development and implementation of heat pump cooling systems for residential and commercial applications. Their innovative designs and high-quality products have made them a trusted name in the HVAC industry.Heat pump cooling systems work by transferring heat from one location to another using a refrigerant. In the summer, the system extracts heat from inside the building and releases it outside, providing cooling. In the winter, the process is reversed, and heat is extracted from the outdoor air and brought inside to warm the building. This dual functionality makes heat pump cooling systems highly efficient and environmentally friendly.{Company name} offers a range of heat pump cooling systems designed to meet the specific needs of their customers. Whether it's a small residential unit or a large commercial installation, {company name} has the expertise and technology to deliver reliable and efficient solutions.One of the key advantages of {company name}'s heat pump cooling systems is their energy efficiency. By using the natural heat in the air or ground, these systems can provide significant cost savings compared to traditional heating and cooling systems. This not only benefits the customer's bottom line but also contributes to a reduced carbon footprint, making them a sustainable choice for environmentally conscious consumers.In addition to their energy efficiency, {company name}'s heat pump cooling systems are also known for their reliability and longevity. With a commitment to quality and performance, {company name} ensures that their products are built to last, providing peace of mind for their customers.Another important aspect of {company name}'s heat pump cooling systems is their ease of installation and maintenance. Their experienced technicians are well-equipped to handle the installation of these systems, ensuring a smooth and efficient process. Additionally, {company name} offers maintenance and support services to ensure that their customers' systems continue to operate at peak performance for years to come.{Company name} is also dedicated to innovation and continuous improvement in their heat pump cooling systems. They invest in research and development to stay ahead of the curve, incorporating the latest technological advances to enhance the performance and efficiency of their products.With a focus on customer satisfaction, {company name} is known for providing excellent service and support. Their team of knowledgeable professionals is always available to answer any questions and provide assistance, ensuring a positive experience for their customers.In conclusion, {company name} is a leading provider of heat pump cooling systems, offering reliable, energy-efficient, and cost-effective solutions for residential and commercial applications. With a commitment to quality, performance, and customer satisfaction, {company name} is a trusted name in the HVAC industry, and their heat pump cooling systems continue to set the standard for excellence in the field.

The Importance of Screw Pump Clearance and Maintenance for Industrial Equipment

Screw Pump Clearance: A Step Towards Efficient Industrial Operations Industrial operations often rely on the use of screw pumps to efficiently move fluids and manage production processes. The clearance of screw pumps has a direct impact on the performance and efficiency of the equipment, making it a critical element for industrial companies. Recently, (company name) has announced a clearance sale on their range of screw pumps, offering industrial clients the opportunity to upgrade their equipment at a reduced cost. This move is set to benefit a wide range of industries and businesses that rely on screw pumps for their operations.Established in (year), (company name) has been a leading provider of industrial equipment and solutions, specializing in the design, production, and distribution of a wide range of products including screw pumps. With a strong focus on innovation and quality, the company has built a strong reputation for delivering reliable and high-performance equipment to industries around the world.The clearance sale on screw pumps comes as part of (company name)'s commitment to providing cost-effective solutions to its clients. By offering discounted prices on their range of screw pumps, the company aims to support industrial businesses in upgrading their equipment without the burden of high costs. This initiative aligns with the company's mission to drive efficiency and productivity in industrial operations through the use of advanced technology and reliable equipment.Screw pumps play a crucial role in a variety of industrial applications, including chemical processing, oil and gas production, food and beverage manufacturing, and wastewater treatment, among others. The efficient movement of fluids is vital in these operations, and screw pumps are relied upon to provide continuous and reliable performance. Therefore, ensuring that screw pumps are well-maintained and up to date is essential for the smooth functioning of industrial processes.The clearance sale on screw pumps by (company name) presents an opportunity for businesses to enhance their operations by upgrading to the latest equipment. By taking advantage of the discounted prices offered, industrial clients can improve the efficiency and reliability of their fluid handling processes, ultimately leading to cost savings and enhanced productivity. Additionally, the sale provides an opportunity for businesses to stock up on spare parts or backup equipment, ensuring minimal downtime in the event of maintenance or repairs.Beyond the financial benefits, the clearance sale also reflects (company name)'s commitment to customer satisfaction and ongoing support for its clients. By offering reduced prices on their screw pumps, the company aims to strengthen its relationships with industrial partners and demonstrate its dedication to helping them succeed. (company name) understands the importance of reliable equipment in industrial settings and strives to be a trusted partner in providing the necessary solutions for sustainable and efficient operations.In conclusion, the clearance sale on screw pumps by (company name) represents a significant opportunity for industrial businesses to enhance their fluid handling processes and improve operational efficiency. With a strong focus on innovation, quality, and customer satisfaction, (company name) is dedicated to supporting industrial clients in achieving their goals and driving success. The reduced prices on screw pumps offer a chance for businesses to upgrade their equipment and invest in the reliability and performance of their operations. As industrial companies continue to seek cost-effective and reliable solutions, (company name) remains at the forefront of providing the necessary equipment and support to drive efficient industrial operations.

Discover the Top Marine Water Pump for Your Needs in 2022

Marine Water Pump Enhances Efficiency and Reliability in Marine Operations[City, Date] - As the maritime industry continues to evolve and seek innovative solutions to enhance efficiency and reliability, the Marine Water Pump has emerged as a game-changer in marine operations. Manufactured by a reputed company [], this cutting-edge technology is revolutionizing the industry's approach towards water pumping systems.With the ever-increasing demand for efficient water transportation, maintaining reliable pumping systems becomes crucial. The Marine Water Pump, crafted with precision and advanced engineering, offers an ideal solution for various marine applications. Whether it's for ballast water management, bilge pumping, or firefighting operations, this water pump offers unmatched performance and efficiency.One of the key aspects that sets the Marine Water Pump apart from traditional systems is its durability and reliability. Constructed from high-quality materials, this pump is built to withstand the harsh marine environment, ensuring longevity and minimal downtime. The corrosion-resistant body and components minimize the risk of damage and reduce maintenance costs, making it an ideal choice for marine operators seeking cost-effective solutions.Moreover, the compact design of the Marine Water Pump enables easy installation and integration into existing marine systems. Its versatility allows for seamless compatibility with different vessel types, ranging from small crafts to large commercial ships. By reducing installation time and complexity, this pump assists marine operators in streamlining their operations and maximizing productivity.Furthermore, the advanced engineering behind the Marine Water Pump ensures optimal performance and energy efficiency. With its superior pumping capabilities, this technology enables faster water transfer and drainage, saving valuable time during critical marine operations. The pump's adjustable flow and pressure settings provide operators with greater control, allowing for enhanced operational precision and flexibility.In the context of environmental sustainability, the Marine Water Pump upholds the highest standards. It incorporates advanced filtration and purification systems, ensuring compliance with strict maritime environmental regulations. By effectively managing ballast water and preventing the spread of invasive species, this pump contributes to the preservation of marine ecosystems and supports sustainable water transportation practices.In addition to its performance and reliability, the company behind the Marine Water Pump, [], brings extensive expertise and experience to the table. With a proven track record in developing innovative marine technologies, the company has earned a reputation for delivering industry-leading solutions. Its commitment to research and development ensures that the Marine Water Pump remains at the forefront of technological advancements, constantly pushing the boundaries of efficiency and reliability.To support its customers in maximizing the benefits of the Marine Water Pump, the company offers comprehensive after-sales services. With a global network of service centers and technicians, the company ensures prompt assistance and maintenance support, minimizing downtime and maximizing uptime for marine operators. This dedication to customer satisfaction has contributed to the company's strong presence in the maritime industry worldwide.As the demand for efficient water pumping systems continues to grow in the maritime sector, the Marine Water Pump stands out as a game-changer. Its durability, reliability, and efficiency make it an indispensable asset for marine operators aiming to optimize their operations and reduce costs. With the backing of its visionary manufacturer [], the Marine Water Pump is set to redefine the standards of water pumping in the maritime industry.

Top Industrial Valves for Your Business Needs

Industrial Valves Celebrates 50 Years of Excellence in the Manufacturing IndustryIndustrial Valves is proud to announce that it is celebrating its 50th anniversary in the manufacturing industry. The company, which was established in 1971, has spent the last five decades providing high-quality valves and other industrial products to a wide range of customers across the globe.From its humble beginnings as a small workshop, Industrial Valves has grown to become a leading manufacturer in the industry, thanks to its dedication to quality, innovation, and customer satisfaction. The company's success can be attributed to its experienced team of engineers, technicians, and support staff, who work tirelessly to ensure that every product meets the highest standards of performance and reliability.Industrial Valves specializes in the design, manufacturing, and distribution of a wide range of industrial valves, including ball valves, gate valves, globe valves, check valves, and butterfly valves. These valves are used in various industries, such as oil and gas, petrochemical, power generation, water treatment, and many others. The company also offers customized solutions to meet the specific needs of its customers, ensuring that they receive the best possible products for their applications.One of the key factors that set Industrial Valves apart from its competitors is its commitment to innovation. The company invests heavily in research and development, constantly seeking new ways to improve its products and processes. This has led to the development of cutting-edge technologies that have helped the company stay ahead of the curve in an increasingly competitive market.In addition to its dedication to quality and innovation, Industrial Valves also places a strong emphasis on customer satisfaction. The company understands the importance of building strong relationships with its clients, and it works closely with them to ensure that their needs are met in a timely and efficient manner. This approach has earned Industrial Valves a reputation for reliability and trustworthiness, making it a preferred supplier for many companies around the world.As Industrial Valves celebrates its 50th anniversary, the company is looking towards the future with optimism. It plans to continue its legacy of excellence by expanding its product range, entering new markets, and embracing the latest technologies. The company also aims to strengthen its position as a global leader in the manufacturing industry, while maintaining its core values of quality, innovation, and customer satisfaction.To commemorate this milestone, Industrial Valves is planning a series of events and initiatives throughout the year. These include special promotions, industry conferences, and charity events, all aimed at celebrating the company's achievements and expressing gratitude to its customers, employees, and partners for their continued support over the years."We are incredibly proud to reach this significant milestone in our company's history," said [company representative]. "It is a testament to the hard work and dedication of our team, as well as the trust and support of our customers. As we look to the future, we are excited about the opportunities that lie ahead and are committed to maintaining our position as a leader in the manufacturing industry."With 50 years of experience behind it, Industrial Valves is well-positioned to continue its success for many years to come. The company's dedication to quality, innovation, and customer satisfaction has set it apart in the industry, and it will undoubtedly continue to be a trusted partner for businesses around the world.

Exploring the Distinctions Between Screw Pumps and Gear Pumps – A Comprehensive Guide

Title: Decoding the Distinctions Between Screw Pumps and Gear PumpsIntroduction:In the world of fluid processing and transportation, pumps play a pivotal role in powering various industries such as oil and gas, pharmaceuticals, food processing, and many others. Screw pumps and gear pumps are two popular types of pumps used for handling different liquid mediums. Understanding the differences between these pumps is crucial in determining the most suitable choice for specific applications. This article aims to shed light on the dissimilarities between screw pumps and gear pumps, exploring their operating principles, advantages, and drawbacks.Section 1: The Operating Principles of Screw Pumps and Gear PumpsScrew pumps, also known as progressive cavity pumps, operate based on the principle of positive displacement. They consist of a rotating helical rotor that moves within a stationary double helical stator. As the rotor turns, cavities are formed and progress along the axis, pushing the liquid from the inlet to the outlet.On the other hand, gear pumps operate using the principle of positive displacement as well. They consist of two meshing gears, known as the driving gear and the driven gear, enclosed within a closely fitted housing. As the gears rotate, the liquid is trapped in the cavities between the teeth, creating a seal and forcing the liquid to move from the inlet to the outlet.Section 2: Advantages and Drawbacks of Screw Pumps and Gear Pumps2.1 Screw Pumps:Screw pumps offer several advantages, making them suitable for a wide range of applications. Firstly, they excel at handling high viscosity liquids and fluids with solid content. Thanks to their gentle pumping action, screw pumps are capable of handling shear-sensitive and abrasive fluids without compromising their integrity. Moreover, screw pumps provide a steady flow rate with minimal pulsation, ensuring smooth and consistent delivery. However, one drawback to consider is their relatively lower efficiency compared to gear pumps, resulting in higher energy consumption.2.2 Gear Pumps:Gear pumps offer their own set of advantages and drawbacks. One significant advantage of gear pumps is their ability to generate high pressures, especially in applications requiring high delivery heads. Additionally, gear pumps exhibit excellent self-priming capabilities, making them suitable for applications where a reliable suction source may be limited. However, gear pumps may struggle with handling highly viscous fluids and those containing solids. Their operation can also produce pulsations and pressure fluctuations, which can be detrimental to certain sensitive processes.Section 3: Applications and Industries3.1 Screw Pumps:Screw pumps find applications in numerous industries, such as oil and gas, wastewater treatment, and chemical processing. Their ability to handle high-viscosity fluids, combined with their gentle pumping action, makes them ideal for applications involving crude oil, sludge, and abrasive chemicals.3.2 Gear Pumps:Gear pumps find widespread use in industries such as automotive, pharmaceuticals, and food processing. The ability of gear pumps to generate high pressures and their self-priming capabilities make them suitable for applications involving lubricating oils, hydraulic fluids, and metering precise volumes of liquid.Conclusion:In conclusion, both screw pumps and gear pumps serve essential roles in fluid processing and transfer applications. Choosing the appropriate pump type depends on factors such as the viscosity of the liquid, presence of solids, required pressure, and the level of pulsation tolerance. Understanding the distinct operating principles, advantages, and drawbacks of screw pumps and gear pumps is crucial in selecting the right pump for specific industrial needs.

Understanding the Key Differences Between Centrifugal and Positive Displacement Pumps

[Company Introduction]{Company} is a leading manufacturer of industrial pumps, with a strong focus on providing high-quality and efficient pumping solutions to various industries. With a history of innovation and a commitment to customer satisfaction, {Company} has earned a reputation as a trusted provider of pump technology. The company's product range includes a wide variety of pumps, including centrifugal and positive displacement pumps, designed to meet the diverse needs of its customers.[News Content]Pumps are essential components in many industrial processes, and they come in various types and designs to suit specific applications. Two common types of pumps are centrifugal pumps and positive displacement pumps, each with its own set of advantages and uses.Centrifugal pumps are designed to use centrifugal force to move fluids through the pump. They work by converting the rotational energy from a motor into kinetic energy in the fluid, which is then used to increase the fluid's velocity and pressure. This type of pump is ideal for applications where a continuous flow of fluid is required, such as in chemical processing, water treatment, and HVAC systems. Centrifugal pumps are also known for their simple design, low maintenance requirements, and ability to handle high flow rates.On the other hand, positive displacement pumps work by trapping a fixed amount of fluid in a chamber and then forcing it through the pump's discharge port. These pumps are capable of generating high pressure and are commonly used in applications where precision and consistent flow rates are critical, such as in oil and gas, food and beverage, and pharmaceutical industries. Positive displacement pumps are also known for their ability to handle high viscosity fluids and for their self-priming capabilities.When it comes to selecting the right pump for a specific application, it is important to consider the differences between centrifugal and positive displacement pumps. Centrifugal pumps are typically best suited for applications requiring high flow rates and low to medium viscosity fluids, while positive displacement pumps are ideal for applications requiring precise flow control and the ability to handle high viscosity fluids.{Company} recognizes the importance of offering a diverse range of pumping solutions to meet the needs of its customers. The company's line of centrifugal pumps is designed to deliver reliable and efficient performance in various industrial applications, while its positive displacement pumps are engineered to provide precise and consistent fluid handling in demanding processes.In addition to offering a wide selection of pumps, {Company} is committed to providing comprehensive support and expertise to help customers select the right pump for their specific needs. The company's team of experts is available to offer guidance on pump selection, installation, and maintenance, ensuring that customers can achieve optimal performance and efficiency from their pumping systems.As industries continue to evolve and demand for specialized pumping solutions grows, {Company} remains dedicated to innovation and excellence in pump technology. Whether customers require centrifugal pumps for high-flow applications or positive displacement pumps for precise fluid handling, {Company} is poised to deliver reliable and efficient pumping solutions to meet their needs. With a focus on quality, performance, and customer satisfaction, {Company} is well-positioned to continue serving as a trusted partner for industrial pumping solutions.

Wholesale Check Valve Function Manufacturers: Exploring the Functionality of Check Valves in Bulk

In recent years, the demand for check valves has been steadily increasing in various industries. These valves are essential in maintaining the flow direction of fluids and preventing backflow, ensuring the smooth operation of pipelines and preventing potential damages. As a result, wholesale check valve function factories have become crucial players in meeting this growing demand.One such wholesale check valve function factory, which would like to stay anonymous for the purpose of this news article, has been making significant contributions to various industries by providing top-quality check valves. With a focus on manufacturing products that are not only reliable but also cost-effective, this factory has gained recognition for its commitment to customer satisfaction.Established several years ago, this factory has gradually expanded its manufacturing capabilities and product range to cater to diverse applications. They have a team of experienced engineers and technicians who utilize cutting-edge technology and advanced production techniques to ensure the production of high-quality check valves. These professionals have extensive knowledge and expertise in valve manufacturing, enabling them to meet the specific requirements of different industries.The check valves manufactured by this factory undergo a rigorous quality control process that adheres to international standards. They are made from durable materials that are resistant to corrosion, pressure, and temperature variations, ensuring longevity and reliability. Additionally, the valves are designed with precision to achieve maximum efficiency and minimum flow resistance, ultimately maximizing performance.One of the key features of their check valves is their versatility. Whether it's for industrial applications, water management systems, oil and gas industries, or HVAC systems, the factory can provide customized solutions to meet the unique requirements of their clients. They offer a wide range of check valves, including swing check valves, lift check valves, wafer check valves, and ball check valves, among others. This extensive selection allows customers to choose the valve that best suits their needs.Furthermore, the factory takes pride in its excellent customer service. They understand the importance of timely delivery and offer flexible shipping options to ensure that customers receive their orders on time. The factory also provides technical support and guidance to assist customers in selecting the most suitable check valve for their specific applications.As a wholesale function factory, they offer competitive prices for their check valves without compromising on quality. This has allowed them to establish long-term partnerships with clients both domestically and internationally. The factory actively seeks feedback from customers to continuously improve their products and services, striving to stay at the forefront of the valve manufacturing industry.In conclusion, wholesale check valve function factories play a crucial role in meeting the increasing demand for high-quality check valves across various industries. This anonymous factory, through its commitment to manufacturing excellence, offers a diverse range of reliable and cost-effective check valves designed to meet the specific requirements of different applications. With exceptional customer service and a dedication to continuous improvement, this factory has cemented its position as a trusted supplier in the valve industry.