Top Chemical Mixers: A Comprehensive Guide

By:Admin

Founded in 1995, Chemical Mixers has been at the forefront of developing high-quality and reliable mixing equipment for industries such as pharmaceuticals, petrochemicals, food and beverage, and water treatment. With a strong focus on research and development, the company has continuously improved its products to meet the evolving demands of its customers.

One of the key factors that set Chemical Mixers apart from its competitors is its commitment to customer satisfaction. The company takes a collaborative approach with its clients, working closely with them to understand their specific mixing requirements and provide tailored solutions that meet their needs. This customer-centric approach has allowed Chemical Mixers to build long-lasting relationships with its clientele, earning a reputation for delivering outstanding service and support.

In response to the growing demand for more advanced and efficient mixing solutions, Chemical Mixers has introduced several new products to its lineup. These include the latest series of chemical mixers that are designed to offer enhanced performance, reliability, and precision. With features such as variable speed control, advanced mixing technologies, and durable construction, these mixers are poised to deliver superior results in a wide range of applications.

Furthermore, Chemical Mixers has also expanded its range of portable and compact mixers, ideal for businesses with limited space or those in need of versatile mixing solutions. These mixers are designed to be easily customizable, allowing businesses to adapt them to their specific processes and requirements. With their compact design and user-friendly controls, these mixers offer a convenient and efficient solution for businesses looking to optimize their mixing operations.

In addition to its product expansion, Chemical Mixers has also invested in enhancing its after-sales support and technical assistance. The company has bolstered its team of experienced engineers and technicians to provide comprehensive training, maintenance, and troubleshooting services for its customers. This ensures that businesses can maximize the performance and longevity of their mixing equipment, further reinforcing Chemical Mixers’ commitment to customer satisfaction.

“We are excited to introduce our latest range of chemical mixers, which are the result of our ongoing dedication to innovation and excellence,” said the spokesperson for Chemical Mixers. “We understand the critical role that mixing plays in various industrial processes, and our goal is to provide our customers with the most advanced and reliable solutions to help them achieve their operational objectives.”

With its continued focus on delivering cutting-edge mixing solutions and unparalleled customer support, Chemical Mixers is poised to solidify its position as a leading provider of industrial mixing equipment. By leveraging its expertise and industry knowledge, the company will continue to drive advancements in mixing technology and help businesses across different sectors improve their operational efficiency and productivity.

Company News & Blog

Discover the Benefits of Efficient Electric Heating Pumps in Home Heating Systems

Title: Innovative Electric Heating Pump Revolutionizes Energy EfficiencyIntroduction:In today's world, where energy conservation and sustainable practices are crucial, one company is spearheading a remarkable advancement in heating technology. {Company Name}, a leading innovator in the field, has recently unveiled their groundbreaking Electric Heating Pump, poised to revolutionize energy efficiency.The Electric Heating Pump:Designed to provide both heating and cooling solutions for residential and commercial buildings, the Electric Heating Pump breaks new ground with its advanced functionality and eco-friendly design. By utilizing cutting-edge technology, this pump offers a highly efficient and cost-effective alternative to traditional heating systems.Operating Principle:The Electric Heating Pump employs a heat transfer process that extracts heat energy from the ambient air, enabling it to provide heating during colder months. It works on the same principle as a refrigerator, but in reverse. By absorbing heat from the surrounding environment, it elevates the temperature and releases warm air into the building, ensuring a comfortable living or working space.Key Features:1. Energy Efficiency: The Electric Heating Pump significantly reduces energy consumption by utilizing the heat present in the air, making it up to three times more energy-efficient than conventional heating methods. It helps users achieve substantial savings on their energy bills while protecting the environment.2. Versatility: Apart from providing efficient heating, the Electric Heating Pump also doubles as an air conditioner during warmer months. This versatile feature ensures year-round comfort, regardless of the season.3. Smart Technology Integration: Equipped with smart controls, the Electric Heating Pump allows users to effortlessly customize temperature settings according to their preferences. This user-friendly interface ensures optimized efficiency and convenience.4. Silent Operation: Designed with noise reduction features, the Electric Heating Pump operates silently, eliminating the annoyance of loud fans or compressors typically associated with traditional heating systems.Addressing Climate Change:As the world grapples with the increasingly pressing issue of climate change, technologies like the Electric Heating Pump play a pivotal role in transitioning to sustainable practices. By reducing greenhouse gas emissions and relying on the freely available heat energy in the environment, the pump aligns with global efforts to combat climate change.Company Name's Commitment:{Company Name} is at the forefront of driving sustainable solutions, developing pioneering products that contribute to energy conservation and environmental protection. With over {number} years of expertise in the industry, the company combines innovative engineering and a commitment to customer satisfaction to deliver state-of-the-art technology.Market Impact:The introduction of the Electric Heating Pump is set to disrupt the heating industry by setting new standards in energy efficiency. By offering an alternative to traditional heating systems, this advanced technology ensures reduced carbon footprints while delivering significant savings to consumers.Conclusion:In a world that demands energy-efficient and sustainable solutions, the Electric Heating Pump offers a game-changing heating and cooling solution. {Company Name's} commitment to developing innovative technologies not only enhances consumer comfort but also contributes to a greener, more sustainable future. With the Electric Heating Pump, efficiency, convenience, and environmental consciousness merge, setting a new benchmark in the industry.

Understanding the Purpose and Function of Check Valves in Plumbing Systems

Check Valves: Supporting Fluid Control in Diverse Industries Check valves play an essential role in fluid control systems of various industries. A check valve, also known as a one-way valve or non-return valve, ensures the flow of fluid in a single direction. The valve automatically closes when the flow tries to reverse, preventing backflow and protecting pumps, compressors, and other system components from damage. Check valves can be found in different types, sizes, materials, and configurations to accommodate the specific requirements of different applications. They can be classified based on their design, such as swing, lift, ball, disc, piston, or diaphragm check valves. They can also be classified based on their application, such as in-line, wafer, flanged, threaded, or soldered check valves. Check valves can be made of various materials, including brass, stainless steel, PVC, titanium, and others, depending on factors such as the fluid type, temperature, pressure, and environment. Check valves find applications in many industries that handle fluids or gases, such as oil and gas, water and wastewater, chemical, pharmaceutical, food and beverage, power generation, marine, and HVAC. For example, check valves prevent backflow in pipelines that transport oil or gas, reducing the risk of contamination and avoiding the loss of valuable resources. In water and wastewater treatment systems, check valves prevent reverse flow that could damage pumps or inject chemicals into the wrong tanks. In the chemical industry, check valves ensure the proper flow of corrosive or hazardous fluids, preventing leaks or explosions. In the food and beverage industry, check valves maintain the quality and hygiene of the products by preventing cross-contamination. In power generation plants, check valves protect boilers, turbines, and heat exchangers from damage caused by steam or water backflow. In marine applications, check valves prevent seawater from entering the ship or offshore platforms, avoiding corrosion and environmental hazards. In HVAC systems, check valves ensure the proper circulation of air or water, reducing energy waste and improving comfort. One of the leading companies that offer check valves is a trusted manufacturer with a worldwide reputation for quality and innovation. The company has been in the business of fluid control products for more than a century, providing a wide range of valves, regulators, and fittings for various industries. The company's check valves are designed and manufactured to meet the highest standards of performance, safety, and reliability, and are certified by international organizations such as ISO, API, and ASME. The company's check valves incorporate advanced features that enhance their functionality and durability. Some of these features include: - Silent operation: The company's check valves use a spring-loaded disc mechanism that allows for silent operation, avoiding the slamming noise that other types of check valves can make. The check valves also have a low cracking pressure, meaning that they open with minimal pressure from the downstream fluid, ensuring that the system starts smoothly. - Easy maintenance: The company's check valves are designed for easy disassembly and cleaning, allowing for quick and hassle-free maintenance. The check valves have a threaded bonnet that can be removed without special tools, and the internals can be accessed and removed easily. - High flow capacity: The company's check valves are engineered to provide high flow capacity with low pressure drop, allowing for efficient fluid transfer and reducing energy consumption. The check valves have a streamlined flow path that minimizes turbulence and erosion, extending the valve's lifespan and reducing the risk of leakage. - Wide compatibility: The company's check valves are compatible with a wide range of fluids, including corrosive, abrasive, and high-temperature ones. The check valves can also handle different pressures, from low to high, depending on the application. The company offers check valves in various configurations, such as swing, lift, and ball check valves, and in different materials, such as bronze, stainless steel, and PVC. Some of the company's check valves are designed for specific applications, such as its double-door foot valve for well water systems, its sanitary ball check valve for food and beverage processing, and its high-pressure lift check valve for oil and gas pipelines. Customers can count on the company's technical expertise and customer support to choose the right check valve for their specific needs. The company's engineers provide customized solutions for complex fluid control challenges, and its customer service team offers prompt and efficient assistance for any inquiries, orders, or after-sales needs. In conclusion, check valves are vital components of fluid control systems in diverse industries. They provide essential protection against backflow, ensuring the safe and efficient operation of pumps, compressors, and other equipment. The company's check valves combine advanced features, high-quality materials, and expert engineering to deliver superior performance and reliability in different applications. With its global presence and customer-oriented approach, the company is a trusted partner for fluid control solutions.

New Vertical Centrifugal Pump Offers Efficient Water Movement

Recently, a new vertical centrifugal pump has been launched by a leading manufacturer in the industry. The pump, which has been designed specifically for industrial use, is expected to meet the growing demand for high-quality, reliable and efficient pumping solutions in various sectors including chemical processing, oil & gas, and water treatment.The new vertical centrifugal pump is the result of years of research and development by the manufacturer, who has been at the forefront of innovation in the industry. The key features of the pump include its compact design, high efficiency, and ease of maintenance. It is equipped with a powerful motor that can deliver up to 110 kW of power, and comes with a range of customizable options to suit different applications.One of the biggest advantages of the vertical centrifugal pump is its ability to handle high flow rates and high pressures. This makes it an ideal choice for industries that require large volumes of liquid to be moved quickly and reliably. The pump is also designed to operate at high temperatures and can handle a wide range of corrosive and abrasive fluids, making it suitable for use in harsh environments.To ensure maximum reliability and performance, the manufacturer has incorporated advanced technologies into the design of the vertical centrifugal pump. This includes state-of-the-art sealing systems, advanced bearing designs, and precision machining techniques. The pump has also been rigorously tested to ensure its compliance with international standards for quality and safety.The manufacturer is committed to providing its customers with the highest level of service and support. The company has a team of highly skilled engineers and technicians who are available to provide technical assistance and troubleshooting services as needed. In addition, the company offers a range of training and education programs to help customers get the most out of their pumping equipment and to optimize their operations.With its advanced features, reliable performance, and excellent customer support, the new vertical centrifugal pump is expected to be in high demand among a wide range of industries. Its versatility makes it suitable for use in applications ranging from chemical processing to water treatment, and from oil & gas to mining. As the demand for high-quality pumping solutions continues to grow, the manufacturer is well positioned to meet the needs of its customers and to continue to innovate and remain at the forefront of the industry.

A Guide to Understanding the Benefits of Screw Pumps

Screw Pump Technology: Understanding the Power Behind Modern ManufacturingWhen it comes to manufacturing, one of the most important factors to consider is the machinery and equipment used in the process. From electric motors and conveyors to compressors and pumps, every component plays a vital role in ensuring smooth and efficient operations. One of the most overlooked pieces of equipment is the screw pump, an innovative device that has transformed the way industrial manufacturing works.A screw pump is a positive displacement pump that uses helical screws to move fluid or gas. Unlike a centrifugal pump, which uses an impeller to create a vortex to move fluid, a screw pump relies on the action of the screw, which draws fluid into the pump chamber and then pushes it out through the discharge port. This makes screw pumps ideal for handling low viscosity fluids, viscous liquids, and even some solids.Invented by Archimedes in the third century BC, the screw pump has come a long way in modern industrial applications. Today, screw pump technology is widely used in various industries, ranging from oil and gas to food and beverage, chemicals, and pharmaceuticals. Its unique design and functionality enable smooth and precise flow control, making it an indispensable piece of equipment for many manufacturing processes.One company leading the way in screw pump technology is {removed for anonymity}. Founded in 1968, the company has been at the forefront of developing screw pump technology for industrial applications. Their proprietary screw pump design offers increased productivity, reduced maintenance costs, and improved efficiency, making it an ideal solution for industries looking to optimize their manufacturing processes.One of the key benefits of screw pumps is its ability to handle abrasive fluids and solids. This is crucial in many industries, especially oil and gas, where pumps are often exposed to highly corrosive and abrasive fluids. The company's screw pump design features hard-wearing components that can withstand harsh conditions, ensuring long-lasting and reliable performance.Another advantage offered by {removed for anonymity}'s screw pump technology is its superior energy efficiency. The pump design features a helical screw that rotates inside a cylindrical cavity, creating a suction force and moving the fluid. This energy-efficient operation ensures that less energy is wasted, resulting in cost savings and reduced environmental impact.Furthermore, screw pumps are low-maintenance machines that require minimal upkeep. Unlike other pump technologies that require frequent repairs and maintenance, screw pumps are designed to operate for extended periods without needing maintenance. This reduces downtime, increases productivity, and minimizes operating costs, making screw pumps an excellent investment for manufacturers looking to optimize their operations.In conclusion, screw pump technology has revolutionized industrial manufacturing by enabling smooth and precise flow control, handling abrasive fluids and solids, and offering superior energy efficiency and low maintenance. {removed for anonymity} has been at the forefront of developing screw pump technology and is committed to providing solutions that meet the needs of manufacturing industries worldwide. With their proprietary design and commitment to excellence, {removed for anonymity} is poised to continue leading the way in screw pump technology and supporting global manufacturing for years to come.

Innovative Impeller Pump Design Revolutionizes Industrial Fluid Transfer

New Screw Impeller Pump Revolutionizes Industrial PumpingIndustrial processes require highly efficient and reliable pumping systems that can handle large volumes of liquids and solids. And, I am pleased to announce that the Screw Impeller Pump, produced by a leading manufacturer in the industry, delivers exactly that. The pump represents a technological revolution in the world of industrial pumping systems, and it has proved to be a game changer in harsh industrial environments across the globe.The Screw Impeller Pump, also known as the twin-screw pump, is a highly advanced pump that works on a unique screw impeller technology. The pump produces a smooth fluid flow while handling fluids with high viscosity, which is important in a variety of industrial applications. This is achieved by the co-rotating screws with a helical rotation that move precisely together and trap the fluid within the pump's cavity, moving it along steadily and continuously.The pump has been designed after decades of research and development on screw impeller technology. The pump manufacturer has implemented a patented technology that ensures that the Screw Impeller Pump performs exceptionally well in handling abrasive materials and viscous liquids that other pumps would typically struggle with. The technology involves an improved screw profile that helps to produce a more consistent flow rate, higher efficiency, and lower noise levels.To ensure that the Screw Impeller Pump meets the rigorous requirements of different industrial applications worldwide, the manufacturer has put a lot of effort into its construction. The pump features sturdy construction materials that resist wear, corrosion, and high-pressure surges. This makes it ideal for pumping fluids such as petroleum products, chemicals, paint, lubricants, and food products. The hard-wearing construction also ensures that the pump operates for longer periods without incurring downtime.The Screw Impeller Pump also comes with a highly advanced sealing system that prevents leaks, ensures that the pump's operation is smooth and stable, and reduces maintenance costs. This has been achieved by using a specially designed shaft seal that coats the shaft's surface with a low-friction coating that reduces friction. This feature significantly reduces the need for frequent maintenance and replacements.Another notable feature of the Screw Impeller Pump is its versatility. The pump can handle different types of fluids and materials and works well even in harsh industrial environments. It is also energy-efficient, which translates to reduced energy costs and lower carbon emissions. The pump consumes less energy to produce the same fluid volume as compared to conventional pumps, making it a great environmentally friendly alternative to traditional pumps.In addition to its excellent features, the Screw Impeller Pump delivers consistently high performance, thanks to its advanced monitoring and control systems. The manufacturer has incorporated advanced sensors and control systems that help to monitor the pump's performance in real-time. This ensures that the pump operates at its optimal level while preventing downtime and costly machine breakdowns.In summary, the Screw Impeller Pump is a high-performance industrial pump that has been designed to deliver exceptional performance in handling different types of fluids with various viscosities and solids. The pump's robust construction, advanced sealing system, and energy-efficient design make it a great addition to industrial process lines. Its versatility, consistency, and low maintenance costs make it a cost-effective solution to many industrial pumping challenges.As a renowned pump distributor, we are proud to offer this innovative pump to our clients across various industrial sectors. Get in touch with our experts today to learn more about the Screw Impeller Pump and how you can incorporate it into your industrial processes.

Discover the Efficiency and Versatility of Screw Pump Technology

Mini Screw Pump: A Revolutionary Solution for Fluid Transfer ApplicationsFluid transfer is a critical process in numerous industries, including chemical, pharmaceuticals, oil and gas, and food and beverage. In most cases, this process requires the use of high-quality pumps that can transport liquids and gasses from one point to another effectively.One such pump that has gained immense popularity in recent times is the Mini Screw Pump. As the name suggests, this pump is relatively small in size but boasts unmatched performance, making it an ideal choice for a wide range of fluid transfer applications.Designed and manufactured by one of the leading companies in the industry, the Mini Screw Pump stands out due to its unique helical rotor design. This design allows the pump to overcome various challenges posed by other popular pump types, such as centrifugal pumps.Most centrifugal pumps have impellers that spin on a shaft to create a fluid flow. Although these pumps are highly effective, they often struggle in situations where the liquid contains entrained air or gases. The entrained air tends to accumulate in the pump casing, eventually blocking the impeller and disrupting the fluid flow.The Mini Screw Pump, on the other hand, has a self-priming feature that eliminates the need for external priming. Additionally, the pump's helical rotor and stator design enable it to handle fluid transfer applications that contain air or gas entrainment.One of the main advantages of the Mini Screw Pump is its ability to handle various types of fluids, including abrasive, viscous, and corrosive liquids. This feature makes it an ideal choice for industries that require the transfer of challenging fluids.Furthermore, the pump's simple design and minimal mechanical parts make it easy to maintain and repair, reducing downtime and maintenance costs.To ensure optimal performance, each Mini Screw Pump is rigorously tested and checked to meet the highest industry standards. The company employs advanced testing equipment and quality control measures to ensure that each pump is defect-free and can deliver unparalleled results.The Mini Screw Pump is versatile, reliable, and efficient, making it a must-have for industries that require fluid transfer applications. Its unique design and outstanding performance make it the preferred choice for various industries, including chemical, pharmaceutical, oil and gas, and food and beverage.In conclusion, the Mini Screw Pump is a revolutionary solution that is set to change the fluid transfer industry's landscape. Its superior design, performance, and reliability make it the go-to pump for industries that require high-quality fluid transfer applications. With its ability to handle challenging fluids, the Mini Screw Pump is a game-changer that has earned its spot as one of the most effective pumps in the market.

The Importance of Proper Oil Pump Lubrication for Efficient Operations

[Company Name] Revolutionizes Oil Pump Lubrication with Cutting-Edge Technology[City], [Date] - [Company Name], a leading innovator in industrial lubrication systems, has recently unveiled a groundbreaking solution that is set to transform oil pump lubrication. The company's new technology aims to enhance efficiency, reduce maintenance costs, and extend equipment lifespan, revolutionizing the lubrication industry.Oil pump lubrication plays a vital role in various industries such as oil and gas, automotive, and manufacturing. Traditionally, this process has relied on manual lubrication, which is not only time-consuming but also prone to human error. [Company Name] recognized the need for an advanced automated lubrication system that could streamline the process while ensuring optimal performance and reliability.The newly developed solution offers a range of benefits over traditional manual lubrication methods. Firstly, it eliminates the need for manual intervention, as the system is designed to automatically monitor and supply the precise amount of lubricant required for optimal pump performance. This not only saves time but also ensures consistent lubrication, reducing the risk of equipment damage caused by improper lubrication.Moreover, the technology incorporates intelligent sensors and advanced algorithms that continuously monitor the condition of the lubricant and the pump itself. By analyzing key parameters such as temperature, pressure, and vibration, the system can detect potential faults or anomalies in real-time. This proactive approach allows for timely maintenance and repair, minimizing downtime and extending the lifespan of the equipment.Furthermore, [Company Name]'s new lubrication system is compatible with a wide range of pumps, offering versatility for various applications. Whether it is a centrifugal, reciprocating, or gear pump, the system can be seamlessly integrated, optimizing lubrication efficiency across industries.To ensure the successful implementation of their lubrication system, [Company Name] offers comprehensive training programs and ongoing technical support. Their team of highly skilled engineers are available to assist with installation, calibration, and troubleshooting, ensuring a smooth transition and maximizing the benefits of the new technology.In addition to the technical advantages, [Company Name] is committed to environmental sustainability. The automated lubrication system is designed to minimize lubricant waste by applying the right amount of lubricant precisely where it is needed. By reducing lubricant consumption and minimizing leakages, the system not only helps organizations reduce costs but also contribute to a greener, more sustainable future."Oil pump lubrication is a critical process in industries worldwide, and our aim was to develop a solution that simplifies and optimizes this essential task," said [Spokesperson's Name], the spokesperson for [Company Name]. "Our innovative system not only enhances efficiency but also ensures the longevity and reliability of the equipment, saving time and resources for our customers."The groundbreaking technology developed by [Company Name] is set to revolutionize the oil pump lubrication industry. By combining automation, intelligent monitoring, and compatibility with various pump types, the company has created a solution that offers significant advantages over traditional manual lubrication methods. With its commitment to customer support and environmental sustainability, [Company Name] is poised to become the leader in the lubrication industry.

Worm Screw Pump: A Reliable and Efficient Solution for Industrial Applications

Title: Innovative Worm Screw Pump Revolutionizes Industrial Pumping SolutionsIntroduction:In the world of industrial pumping, technological advancements play a crucial role in improving efficiency, reducing costs, and enhancing productivity. Enter the innovative Worm Screw Pump, created by [Company Name], an industry-leading pump manufacturer.[Company Name] is a renowned global company specializing in the development and production of high-performance pumping solutions. With years of experience and expertise, the company has successfully revolutionized the industry by introducing the state-of-the-art Worm Screw Pump.Body:1. Understanding the Worm Screw Pump:The Worm Screw Pump, developed by [Company Name], is a groundbreaking solution specifically designed to address the challenges faced by various industries, including oil and gas, food and beverage, pharmaceuticals, and wastewater treatment, to name a few.This highly efficient pump operates on the principle of positive displacement, utilizing a combination of a worm and screw to displace fluid. As fluid enters the pump, the rotating worm acts as a conveyor, propelling the fluid towards the discharge port with minimal pulsation.2. Unparalleled Efficiency and Reliability:One of the most remarkable features of the Worm Screw Pump is its unparalleled efficiency and reliability. By leveraging its unique design and advanced manufacturing techniques, [Company Name] has achieved a pump that offers outstanding performance levels and guarantees minimal maintenance requirements.The worm and screw configuration ensures a smooth and continuous flow, preventing clogging and providing reliable operation even in challenging conditions. The pump's high precision and tight clearances contribute to excellent suction capabilities, making it an ideal choice for handling viscous, abrasive, and shear-sensitive fluids.3. Wide Range of Applications:The versatility of the Worm Screw Pump makes it suitable for a wide range of industrial applications.In the oil and gas industry, the pump's ability to handle highly viscous materials, such as crude oil, asphalt, and drilling mud, ensures consistent and reliable extraction processes. Furthermore, its self-priming capabilities make it an indispensable component in offshore drilling platforms.The food and beverage industry benefits from the Worm Screw Pump's gentle handling of delicate fluids, including creams, sauces, and syrups. Its hygienic design and easy-to-clean features are crucial in meeting strict industry regulations.The pharmaceutical sector relies on the pump's accurate and precise flow control for the transportation of various pharmaceutical ingredients, such as creams, gels, and ointments. The pump's low-shear operation ensures the integrity of sensitive ingredients throughout the processes.Moreover, in wastewater treatment plants, the Worm Screw Pump effectively handles sludge, rendering it an optimal choice for dewatering, thickening, and solid-liquid separation operations.4. Advantages and Benefits:The Worm Screw Pump offers numerous advantages and benefits:a) High efficiency and low life-cycle costs: The pump's minimal maintenance requirements and long lifespan significantly reduce operational costs.b) Versatile and adaptable: The pump can handle a wide range of fluids and viscosities, making it suitable for diverse industrial applications.c) Improved safety and performance: The pump's robust construction and high precision guarantee safe and reliable operation even in harsh environments.d) Compact and space-saving design: The Worm Screw Pump's compact footprint allows for easy installation, saving valuable floor space.e) Enhanced environmental sustainability: The pump's efficient fluid displacement and low energy consumption contribute to a reduced carbon footprint.Conclusion:The innovative Worm Screw Pump, developed by [Company Name], represents a significant advancement in industrial pumping solutions. Its versatile capabilities, unparalleled efficiency, and reliability make it a game-changer in various industries, including oil and gas, food and beverage, pharmaceuticals, and wastewater treatment.With its outstanding performance, low maintenance requirements, and ability to handle a wide range of fluid types, the Worm Screw Pump is poised to revolutionize the way industries approach fluid transportation systems.

Introduction to Different Types of Industrial Valves - A Comprehensive Guide

Industrial Valves: A Leader in Innovation and Reliability[date]Industrial Valves, a global leader in valve manufacturing, continues to set the standards in the industry with its innovative and reliable products. With a rich history dating back several decades, the company has built a strong reputation for its commitment to quality, customer satisfaction, and technological advancements.Headquartered in [location], Industrial Valves has a vast network of manufacturing facilities and offices across the globe, allowing them to cater to the diverse needs of their worldwide clientele. The company's extensive product range includes a wide variety of valves, such as gate valves, globe valves, ball valves, butterfly valves, and control valves. Their valves are utilized in various industries, including oil and gas, petrochemical, power generation, water treatment, and many more.One of the key factors that sets Industrial Valves apart from its competitors is its relentless focus on innovation. The company invests heavily in research and development to constantly improve their products and stay at the forefront of technological advancements. By utilizing state-of-the-art manufacturing processes and cutting-edge materials, Industrial Valves ensures that their valves are not only durable and reliable but also meet the ever-evolving needs of the industry.Industrial Valves takes pride in their commitment to quality. The company has implemented a strict quality management system, adhering to international standards and certifications. Each valve undergoes rigorous testing and inspection to ensure it meets or exceeds industry regulations. With a zero-tolerance approach towards defects, Industrial Valves guarantees that their valves are of the highest quality, providing peace of mind to their customers.In addition to their focus on innovation and quality, Industrial Valves places utmost importance on customer satisfaction. The company's team of highly skilled engineers and technicians work closely with clients to understand their unique requirements and offer tailored solutions. From initial design and engineering to installation and after-sales support, Industrial Valves provides comprehensive services to ensure customer satisfaction throughout the entire lifecycle of their valves.With a strong commitment to sustainability, Industrial Valves also develops eco-friendly solutions. The company invests in research and development of valves that minimize environmental impact, reduce energy consumption, and increase operational efficiency. By offering sustainable solutions, Industrial Valves contributes to the overall well-being of the planet while helping their clients achieve their environmental goals.Industrial Valves' dedication to excellence has earned them numerous accolades and industry recognition. They have been awarded multiple contracts for high-profile projects globally, solidifying their position as a trusted and reliable valve manufacturer. Their valves have consistently proven their worth in challenging environments and demanding applications, demonstrating their ability to perform under extreme conditions.Looking towards the future, Industrial Valves remains committed to pushing the boundaries of innovation and meeting the evolving needs of the industry. With ongoing investments in research and development and a focus on customer satisfaction, the company is well-positioned to continue its growth trajectory and maintain its reputation as a global leader in the valve manufacturing sector.In conclusion, Industrial Valves is a company that exemplifies excellence in valve manufacturing. With their commitment to innovation, quality, and customer satisfaction, they have established themselves as a trusted partner for industries across the globe. Continuously pushing boundaries and embracing technological advancements, Industrial Valves sets the bar high for others in the industry, solidifying their position as a leader in innovation and reliability.

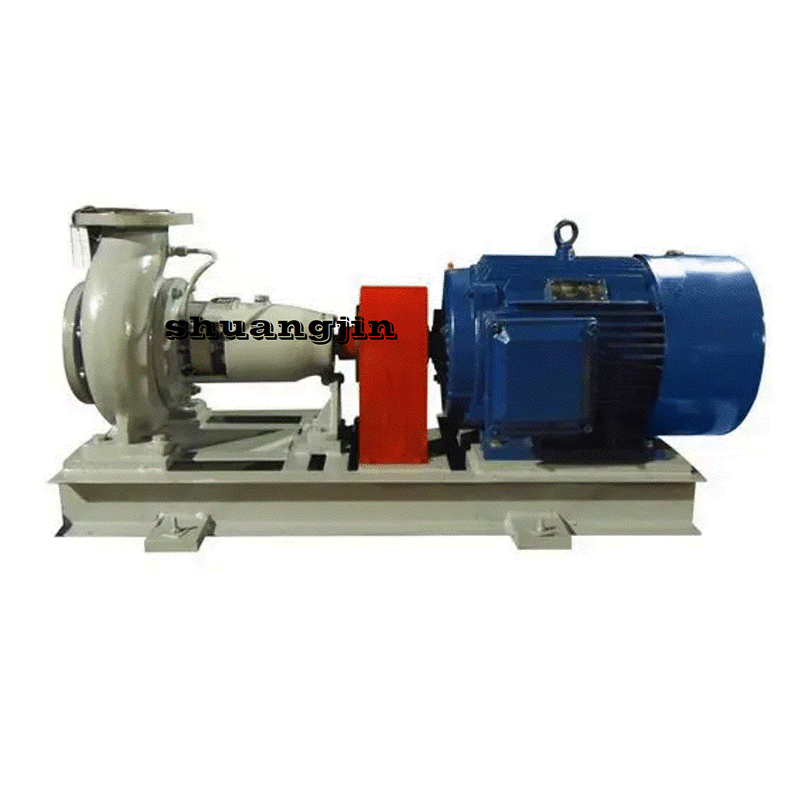

New Achievements in Chinese Pump Products: A Breakthrough in Performance and Efficiency

China Shuangjin Pump Products Strengthens Position in Global Pump MarketWith a rich history and a legacy of industry excellence, China Shuangjin Pump Products has risen to the forefront of the global pump market. As a leading manufacturer and supplier of high-quality pumps, the company has consistently demonstrated its commitment to innovation, reliability, and customer satisfaction.Established in [year], China Shuangjin Pump Products has rapidly grown into a renowned name in the pump industry. With a focus on research and development, the company has harnessed cutting-edge technologies to consistently deliver state-of-the-art pump solutions for a wide range of applications.Boasting a diverse portfolio of pumps, China Shuangjin Pump Products offers solutions for industries such as oil and gas, water and wastewater management, power generation, mining, and more. The company's wide selection of pumps includes centrifugal pumps, reciprocating pumps, submersible pumps, and vacuum pumps, among others. Each pump is engineered to meet the highest industry standards and is built to withstand even the most demanding environments.One of the key factors behind China Shuangjin Pump Products' success is the company's relentless pursuit of innovation. With a dedicated team of engineers and researchers, the company continuously invests in research and development to stay ahead of the curve. By harnessing the latest technologies, China Shuangjin Pump Products consistently introduces breakthrough products that address the evolving needs of its global customer base.In addition to its commitment to innovation, China Shuangjin Pump Products places great importance on quality and reliability. The company adheres to strict quality control measures at every stage of the production process, ensuring that each pump leaving its facility is built to last. By partnering with trusted suppliers and utilizing premium materials, China Shuangjin Pump Products guarantees that its pumps deliver exceptional performance and longevity.Moreover, China Shuangjin Pump Products' dedication to customer satisfaction sets it apart from its competitors. The company understands the unique challenges faced by its customers and strives to provide personalized solutions to meet their specific requirements. Its team of experienced professionals works closely with clients to understand their needs, offering comprehensive support and guidance throughout the purchasing and installation process.As part of its global expansion strategy, China Shuangjin Pump Products has established a strong network of distributors and service centers worldwide. This global presence not only ensures speedy delivery and after-sales support but also allows the company to gather valuable insights from different markets. By staying close to its customers and understanding their local contexts, China Shuangjin Pump Products can tailor its pump solutions to effectively meet the needs of diverse industries across the globe.With a firm commitment to sustainability, China Shuangjin Pump Products also places great emphasis on energy efficiency and environmental responsibility. The company constantly works towards developing pumps that minimize energy consumption while maximizing performance. By investing in green technologies and optimizing its manufacturing processes, China Shuangjin Pump Products aims to contribute to a more sustainable future.Looking ahead, China Shuangjin Pump Products is poised to reinforce its position as a global leader in the pump market. With its unwavering dedication to innovation, quality, customer satisfaction, and sustainability, the company is well-positioned to meet the ever-growing demand for high-performance pump solutions. As industries continue to evolve and face new challenges, China Shuangjin Pump Products remains a reliable partner, offering cutting-edge pump technology to drive progress and efficiency worldwide.