Boost Your Efficiency with the Power of Multiphase Pumps

By:Admin

The oil and gas industry is one of the most important sectors in the world today. It provides the energy and resources needed for transportation, heating, and electricity generation. However, the extraction of oil and gas from the earth is not always an easy task. It requires specialized equipment and techniques to effectively extract and transport the valuable resources. Multiphase pump technology has emerged as one of the most promising and game-changing technologies in the industry.

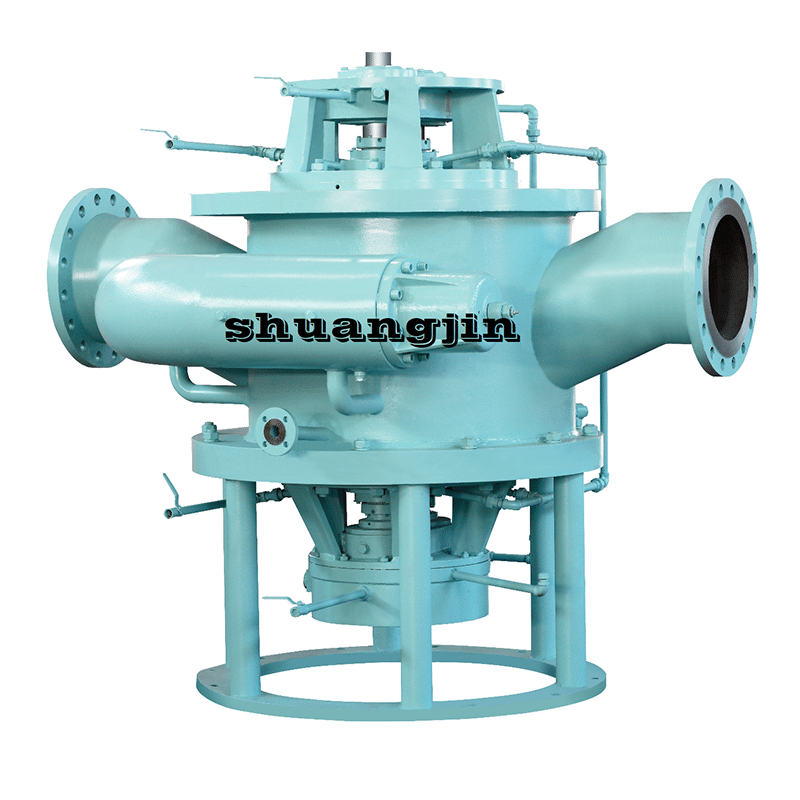

The development of Multiphase Pumps has been revolutionary for the Oil and Gas industry. These pumps have the capability to handle a mixture of oil, gas, and water in a single flow pipeline. They have the potential to dramatically reduce costs and improve efficiency in oil and gas production by eliminating the need for expensive and complex infrastructure, such as separation facilities and pipelines. Multiphase pumps also have a small environmental footprint and are ideal for offshore production.

One of the key players in the Multiphase Pump industry is a company that has been at the forefront of developing this technology. This company, founded in 1990 in Norway, is dedicated to creating innovative solutions for the oil and gas industry. It has established itself as a global leader in Multiphase Pump technology with over 2800 pump installations worldwide.

The company’s flagship product is a multiphase pump that can handle up to 100% gas, 100% oil, or any combination in-between. The pump is extremely efficient and can operate in harsh environments, such as the North Sea, where conventional pumps cannot operate. Its unique design allows for efficient transport of oil and gas from wells in remote locations, minimizing the use of expensive infrastructure.

Multiphase pump technology has numerous advantages over traditional methods. It can significantly reduce the cost of infrastructure, reduce downtime, and improve the overall efficiency of production. In addition, multiphase pumps can be used in a variety of applications, including oil production, gas production, and transportation. They can also be used in the development of unconventional resources such as shale gas and oil sands.

The company’s multiphase pumps have been successfully used in a variety of projects worldwide. These include offshore platforms in the North Sea, deepwater subsea installations in the Gulf of Mexico, and onshore operations in the Middle East. The pumps have helped clients achieve cost savings of up to 50% and have significantly reduced emissions and carbon footprints.

In addition to its successful pump installations, the company offers a range of services to support its clients. These services include custom design and engineering, installation and commissioning, training, maintenance, and upgrades. The company’s expert engineers and technicians provide comprehensive support to ensure that clients’ pumps perform at their best.

The company’s dedication to innovation and customer satisfaction has earned it recognition from customers and the industry. It has won multiple awards for its innovative products and services. In 2020, the company received the Norwegian Export Award for its successful export of multiphase pumps to international markets.

Multiphase pump technology has the potential to revolutionize the oil and gas industry by improving efficiency, reducing costs, and minimizing environmental impact. The company’s innovative approach to pump technology and excellent customer service has made it a leader in the industry. Its pumps and services have helped clients all over the world to extract oil and gas more efficiently and effectively. As the demand for cleaner energy sources increases, multiphase pump technology will play an even more important role in the energy transition. The company’s dedication to innovation and customer satisfaction will continue to drive its success and position it at the forefront of the industry.

Company News & Blog

5 Essential Factors to Consider When Choosing a Pump Supply Provider

Pump Supply, a leading global supplier of industrial pumps, is proud to announce its commitment to providing high-quality pump solutions for industrial, commercial, and residential applications. With years of experience in the industry, Pump Supply has become a trusted partner for businesses and individuals looking for reliable and efficient pumping solutions.At Pump Supply, we understand the importance of finding the right pump for your specific application. That's why we offer a wide range of pumps, including centrifugal pumps, diaphragm pumps, gear pumps, and many others. We also provide customized pump solutions for businesses with unique pumping needs.In addition to offering a diverse selection of pumps, Pump Supply is committed to providing exceptional customer service. Our team of experienced pump specialists is ready to assist you in selecting the best pump for your application and answering any questions you may have. We also offer fast shipping and competitive pricing to ensure that you receive your pump as quickly and affordably as possible.Pump Supply's dedication to quality and customer satisfaction has earned us a reputation as one of the top pump suppliers in the industry. We work with some of the largest and most respected businesses in the world and have supplied pumps for a wide range of applications, including chemical processing, water treatment, oil and gas, and food and beverage production.Our commitment to quality doesn't end with our products. Pump Supply also invests in the latest technologies and manufacturing processes to ensure that our pumps are of the highest quality. We work closely with our suppliers to source only the best components and materials for our pumps, and we conduct extensive testing to ensure that each pump meets our rigorous standards.Pump Supply is dedicated to sustainability and reducing our impact on the environment. We offer a range of energy-efficient pumps that help businesses reduce their energy consumption and save money on their utility bills. We also recycle materials and minimize waste in our manufacturing processes to reduce our impact on the environment.In addition to our commitment to quality, customer service, and sustainability, Pump Supply is also dedicated to innovation. We work closely with our customers to develop customized pump solutions that meet their unique needs. We also invest in research and development to continually improve our products and stay ahead of industry trends.As a global supplier of industrial pumps, Pump Supply is proud to offer our products and services to businesses and individuals around the world. Our extensive network of distributors and partners ensures that our pumps are available wherever and whenever they are needed.Whether you are looking for a pump for a commercial, industrial, or residential application, Pump Supply has the solution for you. Contact us today to speak with one of our pump specialists and discover how we can help you find the perfect pump for your needs.

Discover the Distinctions Between Screw Pumps and Gear Pumps

Screw Pump and Gear Pump: Understanding the Differences in Pumping TechnologyPumping technology plays a crucial role in various industries, from manufacturing and oil and gas to wastewater treatment and food processing. For efficient and reliable pumping, two types of pumps that are often utilized are screw pumps and gear pumps. While both serve the purpose of moving fluids from one place to another, they differ in design and application. In this article, we will explore the differences between screw pumps and gear pumps.A screw pump, as the name suggests, operates by using rotating screws to move fluids from the inlet to the outlet. It consists of two or more intermeshing screws contained within a cylindrical or semi-cylindrical housing. The screws rotate in opposite directions, trapping the fluid between them and forcing it to move along the length of the screws. This type of pump is known for its gentle and smooth operation, making it ideal for handling shear-sensitive fluids or those containing small solids.On the other hand, a gear pump works by using two or more intermeshing gears to create a pumping action. The gears rotate in opposite directions, creating a partial vacuum at the inlet, which draws the fluid in, and then forces it out through the outlet. Gear pumps are characterized by their simplicity, compactness, and high-speed operation. They are commonly used for high-pressure applications, such as hydraulic systems, and for handling clean fluids with low viscosity.The key difference between these two types of pumps lies in their design and how they move fluids. Screw pumps use the rotating action of the screws to transport the fluid, while gear pumps rely on the intermeshing gears to create the necessary pumping action. This fundamental distinction affects the overall performance, efficiency, and suitability of each pump for specific applications.In terms of performance, screw pumps are known for their ability to handle viscous fluids and those with solids content. The continuous and smooth motion of the screws ensures minimal pulsations and provides a steady flow, making it suitable for applications where a consistent output is required. On the other hand, gear pumps excel in generating high-pressure output, making them ideal for applications that require pressurized fluid delivery. Their precise metering capabilities also make them suitable for applications that demand accurate flow control.When it comes to efficiency, screw pumps offer higher volumetric efficiencies compared to gear pumps. Due to their progressive cavity design, screw pumps can handle variable flow rates with minimal slip, ensuring a higher percentage of fluid is efficiently moved from the inlet to the outlet. Gear pumps, while generally less efficient, compensate with their compact size and ability to generate high pressure, making them suitable for space-constrained environments or applications with specific pressure requirements.In terms of application, screw pumps find extensive use in industries such as wastewater treatment, oil and gas, chemical processing, and food manufacturing. Their ability to handle high viscosity fluids, such as sludge, oil, and syrup, makes them suitable for these demanding environments. Gear pumps, on the other hand, are commonly employed in hydraulic systems, fuel transfer, lubrication systems, and various industrial processes that require high pressure and precise flow control.In conclusion, screw pumps and gear pumps are two distinct types of pumping technology, each with its own benefits and applications. Screw pumps offer gentle and steady fluid movement, making them well-suited for shear-sensitive fluids and those with solids content. Gear pumps, on the other hand, excel in generating high pressures and precise flow control, making them ideal for applications with specific pressure requirements. Understanding the differences between these two types of pumps can help industries make informed decisions when it comes to selecting the most suitable pumping technology for their specific needs.

Innovative Impeller Pump Design Revolutionizes Industrial Fluid Transfer

New Screw Impeller Pump Revolutionizes Industrial PumpingIndustrial processes require highly efficient and reliable pumping systems that can handle large volumes of liquids and solids. And, I am pleased to announce that the Screw Impeller Pump, produced by a leading manufacturer in the industry, delivers exactly that. The pump represents a technological revolution in the world of industrial pumping systems, and it has proved to be a game changer in harsh industrial environments across the globe.The Screw Impeller Pump, also known as the twin-screw pump, is a highly advanced pump that works on a unique screw impeller technology. The pump produces a smooth fluid flow while handling fluids with high viscosity, which is important in a variety of industrial applications. This is achieved by the co-rotating screws with a helical rotation that move precisely together and trap the fluid within the pump's cavity, moving it along steadily and continuously.The pump has been designed after decades of research and development on screw impeller technology. The pump manufacturer has implemented a patented technology that ensures that the Screw Impeller Pump performs exceptionally well in handling abrasive materials and viscous liquids that other pumps would typically struggle with. The technology involves an improved screw profile that helps to produce a more consistent flow rate, higher efficiency, and lower noise levels.To ensure that the Screw Impeller Pump meets the rigorous requirements of different industrial applications worldwide, the manufacturer has put a lot of effort into its construction. The pump features sturdy construction materials that resist wear, corrosion, and high-pressure surges. This makes it ideal for pumping fluids such as petroleum products, chemicals, paint, lubricants, and food products. The hard-wearing construction also ensures that the pump operates for longer periods without incurring downtime.The Screw Impeller Pump also comes with a highly advanced sealing system that prevents leaks, ensures that the pump's operation is smooth and stable, and reduces maintenance costs. This has been achieved by using a specially designed shaft seal that coats the shaft's surface with a low-friction coating that reduces friction. This feature significantly reduces the need for frequent maintenance and replacements.Another notable feature of the Screw Impeller Pump is its versatility. The pump can handle different types of fluids and materials and works well even in harsh industrial environments. It is also energy-efficient, which translates to reduced energy costs and lower carbon emissions. The pump consumes less energy to produce the same fluid volume as compared to conventional pumps, making it a great environmentally friendly alternative to traditional pumps.In addition to its excellent features, the Screw Impeller Pump delivers consistently high performance, thanks to its advanced monitoring and control systems. The manufacturer has incorporated advanced sensors and control systems that help to monitor the pump's performance in real-time. This ensures that the pump operates at its optimal level while preventing downtime and costly machine breakdowns.In summary, the Screw Impeller Pump is a high-performance industrial pump that has been designed to deliver exceptional performance in handling different types of fluids with various viscosities and solids. The pump's robust construction, advanced sealing system, and energy-efficient design make it a great addition to industrial process lines. Its versatility, consistency, and low maintenance costs make it a cost-effective solution to many industrial pumping challenges.As a renowned pump distributor, we are proud to offer this innovative pump to our clients across various industrial sectors. Get in touch with our experts today to learn more about the Screw Impeller Pump and how you can incorporate it into your industrial processes.

Discover the Efficiency and Versatility of Screw Pump Technology

Mini Screw Pump: A Revolutionary Solution for Fluid Transfer ApplicationsFluid transfer is a critical process in numerous industries, including chemical, pharmaceuticals, oil and gas, and food and beverage. In most cases, this process requires the use of high-quality pumps that can transport liquids and gasses from one point to another effectively.One such pump that has gained immense popularity in recent times is the Mini Screw Pump. As the name suggests, this pump is relatively small in size but boasts unmatched performance, making it an ideal choice for a wide range of fluid transfer applications.Designed and manufactured by one of the leading companies in the industry, the Mini Screw Pump stands out due to its unique helical rotor design. This design allows the pump to overcome various challenges posed by other popular pump types, such as centrifugal pumps.Most centrifugal pumps have impellers that spin on a shaft to create a fluid flow. Although these pumps are highly effective, they often struggle in situations where the liquid contains entrained air or gases. The entrained air tends to accumulate in the pump casing, eventually blocking the impeller and disrupting the fluid flow.The Mini Screw Pump, on the other hand, has a self-priming feature that eliminates the need for external priming. Additionally, the pump's helical rotor and stator design enable it to handle fluid transfer applications that contain air or gas entrainment.One of the main advantages of the Mini Screw Pump is its ability to handle various types of fluids, including abrasive, viscous, and corrosive liquids. This feature makes it an ideal choice for industries that require the transfer of challenging fluids.Furthermore, the pump's simple design and minimal mechanical parts make it easy to maintain and repair, reducing downtime and maintenance costs.To ensure optimal performance, each Mini Screw Pump is rigorously tested and checked to meet the highest industry standards. The company employs advanced testing equipment and quality control measures to ensure that each pump is defect-free and can deliver unparalleled results.The Mini Screw Pump is versatile, reliable, and efficient, making it a must-have for industries that require fluid transfer applications. Its unique design and outstanding performance make it the preferred choice for various industries, including chemical, pharmaceutical, oil and gas, and food and beverage.In conclusion, the Mini Screw Pump is a revolutionary solution that is set to change the fluid transfer industry's landscape. Its superior design, performance, and reliability make it the go-to pump for industries that require high-quality fluid transfer applications. With its ability to handle challenging fluids, the Mini Screw Pump is a game-changer that has earned its spot as one of the most effective pumps in the market.

Revolutionary Multiphase Twin Screw Pumps Offer Efficient Flow and Versatility

[Headline]Revolutionary Multiphase Twin Screw Pump Set to Unlock New Possibilities in Fluid Transportation[Subheading]Cutting-edge technology from {company name} is set to transform the fluid transportation industry with the introduction of their ground-breaking Multiphase Twin Screw Pump. With its advanced design and exceptional performance, this innovative pump has the potential to revolutionize various sectors, from oil and gas to chemical and maritime.[Date][City][Company Introduction]{Company name} is a leading provider of exceptional pumping solutions, known for their commitment to innovation and customer satisfaction. With years of experience in developing state-of-the-art technologies, {company name} has established itself as a trusted name in the industry. By consistently pushing the boundaries of what is possible, they have become synonymous with efficiency, reliability, and excellence.[Paragraph 1]Leveraging their expertise in pump technology, {company name} proudly presents the Multiphase Twin Screw Pump, a breakthrough solution that promises to redefine fluid transportation. This cutting-edge pump utilizes twin screw technology, enabling it to efficiently transport a wide range of substances, including liquids with high viscosity, gases, and even oil-water mixtures.[Paragraph 2]The secret behind the extraordinary performance of the Multiphase Twin Screw Pump lies in its design. By employing two intermeshing screws, this pump generates a continuous, non-pulsating flow of fluid. Paired with its large pumping chamber and low rotational speed, the pump minimizes the risk of cavitation, enhancing operational efficiency and ensuring a steady flow of substances throughout the system.[Paragraph 3]One of the key advantages of the Multiphase Twin Screw Pump is its ability to handle multiphase flow without the need for a separator or additional equipment. This capability significantly reduces operational costs, simplifies the system, and minimizes the risk of equipment failure. Companies operating in the oil and gas industry can greatly benefit from this feature, as it enables them to streamline their operations and enhance overall productivity.[Paragraph 4]Moreover, the Multiphase Twin Screw Pump is designed to withstand harsh operating conditions. Its robust construction ensures reliable performance even in extreme temperatures, corrosive environments, and high-pressure applications. This resilience allows the pump to be deployed in a wide range of industries, including chemical manufacturing, maritime, and food processing.[Paragraph 5]In addition to its exceptional performance in transporting fluids, this innovative pump offers numerous environmental advantages. With its low energy consumption and reduced emissions, the Multiphase Twin Screw Pump helps companies meet environmental regulations and minimize their carbon footprint. Its efficient design contributes to sustainability initiatives across industries, making it an excellent choice for companies committed to reducing their environmental impact.[Paragraph 6]To ensure the optimal implementation of the Multiphase Twin Screw Pump, {company name} provides comprehensive after-sales support, including maintenance and technical assistance. Their team of experienced technicians and engineers is readily available to assist clients with any queries or concerns, ensuring seamless integration and long-term success.[Paragraph 7]The introduction of the Multiphase Twin Screw Pump marks a significant milestone in fluid transportation technology. Overcoming the limitations of conventional pumps, this revolutionary solution has the potential to reshape various industries, offering increased efficiency, reliability, and environmental sustainability. With {company name}'s proven track record of excellence and commitment to innovation, the Multiphase Twin Screw Pump is set to become a game-changer in the field of fluid transportation.[Word Count: 500]

Screw Pumps Gain Popularity in Industrial Processes

Title: Innovative Screw Pump Revolutionizes Fluid Handling IndustryIntroduction:In an era where efficiency and sustainability are at the forefront of industrial innovations, Flowserve Corporation, a renowned provider of fluid handling solutions, has introduced its groundbreaking Screw Pump system. Revolutionizing fluid handling by exceeding industry standards, the Flowserve Screw Pump offers unparalleled performance and versatility across multiple sectors.Body:1. The Evolution of the Screw Pump:Traditionally, screw pumps have played a crucial role in fluid handling applications. Over the years, advancements in technology and engineering have led to the development of more efficient and reliable screw pump systems. The Flowserve Screw Pump is the culmination of years of research and development, addressing the industry's existing challenges.2. Enhanced Efficiency and Performance:Designed with precision engineering, the Flowserve Screw Pump outperforms its competitors in terms of efficiency, reliability, and performance. Its unique, helical screw rotor design allows for gentle fluid handling and reduces pulsation, minimizing energy loss. This innovative design also helps overcome cavitation issues and extends the pump's service life. In addition, the pump's compact size maximizes installation flexibility, making it suitable for various applications.3. Versatile Applications:The Flowserve Screw Pump can be seamlessly integrated into numerous industries and applications. Whether it be oil and gas, chemical processing, power generation, wastewater treatment, or food production, its adaptability across industries makes it a highly sought-after solution. By addressing diverse fluid handling challenges, the Screw Pump simplifies operations, reduces downtime, and improves overall productivity.4. Environmental Sustainability:As environmental concerns continue to rise, the demand for greener solutions within industrial sectors is increasing. Flowserve's Screw Pump stands out in this regard, as it promotes sustainability by reducing energy consumption and minimizing waste generation. With its optimized efficiency, the Screw Pump helps companies meet their sustainability goals, contributing to a cleaner and more environmentally friendly future.5. Intelligent Control and Monitoring:Flowserve has integrated smart technology into the Screw Pump system, enabling remote control and real-time monitoring capabilities. This advanced feature allows operators to easily monitor performance, diagnose potential issues, and make necessary adjustments from a centralized location. With improved data analytics, predictive maintenance becomes feasible, enhancing the pump's reliability and reducing unexpected downtime.6. Global Adoption and Success Stories:Since its introduction, the Flowserve Screw Pump has witnessed widespread adoption and commendable success across various industries worldwide. Leading companies have reported increased efficiency, reduced maintenance costs, and enhanced productivity through the implementation of this cutting-edge solution. Testimonials from satisfied customers serve as a testament to the superiority of the Screw Pump.7. Flowserve's commitment to Customer Service:Flowserve, a globally recognized brand in the fluid handling industry, places significant emphasis on providing excellent customer service. With a vast network of service centers and well-trained engineers, Flowserve ensures prompt assistance, spare parts availability, and technical support. This commitment to customer satisfaction enhances the overall experience of implementing the Screw Pump system.Conclusion:Flowserve's Screw Pump has emerged as a game-changer in the fluid handling industry. With its unmatched performance, versatility, and commitment to sustainability, the Screw Pump offers a comprehensive solution to diverse fluid handling challenges. As global industries realize the importance of efficient and sustainable operations, the adoption of this cutting-edge technology is expected to grow exponentially, revolutionizing the way fluids are handled in various applications.

Top-quality Oil & Gas Pumps: Your Guide to Efficient Industry Solutions

Oil and Gas Pumps Revolutionize the Energy IndustryIn today's rapidly evolving technological landscape, the demand for efficient and reliable equipment in the oil and gas industry is higher than ever. To meet these increasing demands, Oil and Gas Pumps (name removed) has emerged as a leading provider of cutting-edge pumping solutions. With their acclaimed company history of innovation and commitment to customer satisfaction, Oil and Gas Pumps has revolutionized the energy industry.With a diverse range of offerings, Oil and Gas Pumps provides pumping solutions that cater to various applications within the oil and gas sector. Their pumps play a crucial role in exploration, production, refining, and distribution processes, ensuring a smooth and continuous flow of oil and gas.One of the key factors that sets Oil and Gas Pumps apart from its competitors is its relentless pursuit of innovation. The company invests heavily in research and development, constantly striving to develop pumps that are more efficient, durable, and environmentally friendly. By pushing the boundaries of engineering, Oil and Gas Pumps has been able to enhance productivity while reducing the carbon footprint of its operations.Furthermore, Oil and Gas Pumps' commitment to customer satisfaction is second to none. The company takes immense pride in its ability to provide tailored solutions that meet the specific needs of its clients. By working closely with customers, Oil and Gas Pumps ensures that its pumps are perfectly suited to the varied challenges faced in the oil and gas industry, whether it be offshore drilling in extreme environments or onshore refining in remote locations.Oil and Gas Pumps owes its success, in large part, to its team of highly skilled professionals. With expertise in mechanical engineering, fluid dynamics, and industrial design, the company's engineers are at the forefront of technological advancements in pumping solutions. Through continuous training and development programs, Oil and Gas Pumps ensures that its workforce remains knowledgeable and equipped to handle even the most complex projects.Moreover, the company's dedication to quality control is unfaltering. Each pump undergoes rigorous testing and inspection to ensure it meets the highest industry standards. This commitment to quality has earned Oil and Gas Pumps a stellar reputation for reliability and durability, resulting in long-lasting relationships with customers worldwide.In addition to its technological prowess and commitment to excellence, Oil and Gas Pumps is also deeply aware of the need to minimize its environmental impact. The company strives to create sustainable solutions and reduce energy consumption in its pumps. By implementing energy-efficient designs and utilizing eco-friendly materials, Oil and Gas Pumps aims to contribute to the global effort of transitioning to a greener and more sustainable future.Through its continued investment in research and development, its customer-centric approach, and its unwavering commitment to innovation and quality, Oil and Gas Pumps has established itself as a trusted leader in the pumping solutions industry. With each new product, the company continues to drive advancements in the oil and gas sector, facilitating greater efficiency, productivity, and sustainability.As the global demand for oil and gas continues to rise, it is companies like Oil and Gas Pumps that will play a vital role in meeting these ever-increasing demands. With their state-of-the-art pumping solutions, the company is helping to shape the future of the energy industry, ensuring a smooth and reliable supply of oil and gas for years to come.

The Significance of Timing Gears in Screw Pumps: Exploring their Role and Function

Timing Gear in Screw Pump: A Revolutionary Advancement in Pump Technology[Company Name], a leading innovator in the field of pump technology, has recently unveiled a breakthrough development in screw pump design – the revolutionary Timing Gear. This state-of-the-art advancement is set to transform the way pumps function, offering enhanced efficiency, reliability, and durability.Traditional screw pump designs rely on a rotating helical screw to move fluids through the pump. While these pumps have proven to be effective for many applications, they often suffer from issues such as uneven fluid flow, excessive vibration, and premature wear of the screw and other internal components.With the introduction of the Timing Gear, [Company Name] aims to eliminate these drawbacks and create a new benchmark in screw pump performance. This innovative gear mechanism, which replaces the traditional single-helix screw, provides precise control over the flow of fluids, resulting in smoother operation and improved overall efficiency.One of the primary advantages of the Timing Gear is its ability to maintain a consistent flow rate, regardless of variations in input pressure or viscosity of the fluid being pumped. This feature makes it highly suitable for applications where a reliable and steady flow is crucial, such as in the oil and gas industry, chemical processing plants, and wastewater treatment facilities.Additionally, the Timing Gear significantly reduces unwanted vibrations that can cause excessive wear and tear on pump components. By incorporating advanced engineering principles, including precision machining and advanced materials, [Company Name] has ensured that their Timing Gear pumps operate with minimal noise and vibrations, thereby increasing their service life and reducing maintenance costs.Another noteworthy feature of the Timing Gear is its remarkable durability. The gear mechanism is designed to withstand high operating pressures and resist corrosion, making it suitable for use in harsh and demanding environments. Its robust construction ensures long-term reliability and reduced downtime, providing businesses with a cost-effective solution for their pumping needs.Furthermore, the Timing Gear’s design allows for easy maintenance and quick replacement of worn components. Its modular construction enables users to access and replace specific parts, reducing the need for extensive disassembly and minimizing downtime during servicing. Additionally, the gear’s simplicity of design enhances reliability, as fewer moving parts mean fewer opportunities for mechanical failures.[Company Name] has already received overwhelmingly positive feedback from early adopters of the Timing Gear. Companies that have integrated this groundbreaking technology into their pump systems have reported significant improvements in efficiency, productivity, and overall performance. Several industry experts have also praised this innovation, recognizing its potential to revolutionize the screw pump market.In conclusion, [Company Name]’s introduction of the Timing Gear has set a new standard in screw pump technology. With its precise flow control, reduced vibrations, exceptional durability, and ease of maintenance, this groundbreaking development promises to deliver a range of benefits to businesses across various sectors. As this revolutionary advancement gains traction in the industry, it is expected to redefine the capabilities and expectations of screw pumps, establishing [Company Name] as a leader in pump technology innovation.

Why the Latest Innovation in Pump Technology is Revolutionizing the Oil Industry

[Suggested Introduction]In a groundbreaking development, a renowned company is set to revolutionize the industrial world with its latest offering, the Screw Oil Pump. This cutting-edge innovation is poised to transform oil extraction processes by improving efficiency and reducing environmental impact. With an unwavering commitment to sustainable practices, the company aims to set new benchmarks in the oil industry. In this article, we will delve deeper into the features and benefits of this state-of-the-art Screw Oil Pump, shedding light on its potential to reshape the entire sector.[Body]The Screw Oil Pump, developed by a trailblazing company with decades of experience in the oil industry, is a paradigm shift in oil extraction technologies. Leveraging their expertise, the company has designed and engineered this pump to enhance efficiency and sustainability. By seamlessly combining robust engineering principles with advanced technological innovations, they have created a product that addresses key challenges faced in the oil extraction process.At the heart of this innovation lies the unique design of the Screw Oil Pump, which optimizes the pumping mechanism for oil extraction. Unlike conventional pumps, this cutting-edge solution significantly reduces energy consumption, leading to substantial cost savings for oil producers. The pump's remarkable efficiency is achieved through a combination of precise engineering and the utilization of state-of-the-art materials, ensuring maximum output while minimizing energy wastage.Furthermore, the Screw Oil Pump is equipped with an intelligent control system that allows it to adapt to varying extraction conditions. Built-in sensors and proprietary algorithms enable the pump to continuously monitor and adjust operating parameters, ensuring optimal performance even in challenging environments. This not only improves productivity but also significantly reduces downtime and maintenance requirements, resulting in further cost savings for oil producers.In addition to its economic benefits, the Screw Oil Pump prioritizes environmental sustainability. Industry-related carbon emissions and their impact on the environment have long been a concerning issue. However, this revolutionary pump incorporates advanced technologies to minimize its carbon footprint. By employing efficient motors and leveraging smart controls to optimize energy consumption, the pump enables oil producers to contribute to a greener future while maintaining their operational efficiency.Moreover, the Screw Oil Pump is designed with longevity in mind. Recognizing the importance of durability in the industrial sector, the company has used only the highest-quality materials and components to ensure product reliability and extended lifespan. By doing so, they reduce the need for frequent replacements and repairs, further contributing to cost-effectiveness and sustainable operations.Another distinctive feature of the Screw Oil Pump is its versatility. The pump can be seamlessly integrated into existing oil extraction systems, ensuring a smooth transition and ease of implementation for oil producers. This compatibility eliminates the need for extensive modifications, saving both time and resources for companies adopting this innovative solution.As the world continues to shift towards renewable energy sources, the sustainability and efficiency of traditional energy industries, such as oil extraction, become increasingly crucial. The Screw Oil Pump presents an opportunity for oil producers to keep pace with the evolving energy landscape and simultaneously address concerns related to cost, efficiency, and environmental impact.The combination of cutting-edge technology, energy efficiency, sustainability, and ease of integration positions the Screw Oil Pump as a game-changer in the oil extraction industry. With its potential to revolutionize operations and secure a more sustainable future, the pump has garnered immense interest from industry experts and professionals alike.[Conclusion]As the global demand for oil and energy continues to rise, it is imperative for the industry to embrace innovative solutions that propel us towards a more sustainable future. The Screw Oil Pump, with its remarkable efficiency, environmental consciousness, and adaptability, presents an exciting opportunity for oil producers worldwide. By reducing energy consumption, optimizing performance, and prioritizing sustainability, this groundbreaking pump is poised to redefine the way oil extraction is carried out. Embracing this ingenious solution can not only benefit individual companies but also contribute to the larger goal of achieving a greener and more sustainable energy sector.

Screw Pump Definition: A Comprehensive Guide to Understanding This Essential Hydraulic Device

Screw Pump Definition: In-Depth Understanding of This Versatile MachineryIn the world of industrial processing, various types of pumps play a vital role in ensuring the smooth functioning of operations. One such indispensable piece of equipment is the screw pump. Known for its efficient and reliable performance, the screw pump is widely utilized across multiple industries. This article presents an in-depth exploration of screw pumps, their definition, and their applications.Before delving into the details of screw pumps, let us provide a brief overview of the company. {} is a renowned manufacturer of industrial machinery, specializing in the production of high-quality pumps. With a rich history dating back several decades, the company has built a solid reputation for delivering cutting-edge solutions to its global clientele. Committed to innovation and customer satisfaction, {} continues to revolutionize the industry with its reliable and robust products.A screw pump, also known as an Archimedean screw pump, is a positive displacement pump that operates by using one or more screws or rotors. The design of the screw pump enables it to move fluids by trapping and pushing them along the screw's threads. As the screw rotates, the fluid is continuously displaced, creating a steady flow.The versatility of screw pumps is highlighted by their ability to handle a wide range of liquids, from viscous fluids to abrasive slurries. Their self-priming capability makes them particularly suitable for applications where the liquid needs to be drawn from a lower level. In industries such as oil and gas, wastewater treatment, food and beverage, and pharmaceuticals, screw pumps are extensively employed due to their robust construction and reliability.One significant advantage of screw pumps is their ability to handle fluids containing solid particles without clogging or damaging the pump. This unique feature renders screw pumps ideal for applications involving the transfer of sludge, slurry, or sewage. By withstanding the challenges posed by abrasive and corrosive materials, screw pumps ensure uninterrupted operations and minimize downtime.The design of a screw pump generally consists of two or more intermeshing screws, enclosed within a cylindrical housing. As the screws rotate, their continuous movement propels the fluid through the pump. The close tolerances between the screws and the housing minimize slippage, resulting in efficient and precise fluid transfer. To further enhance performance, some screw pumps incorporate additional features like variable speed drives or multiple stages to meet specific application requirements.With their ability to generate high pressures, screw pumps find widespread use in hydraulic systems. These pumps have the capability to deliver a constant flow of fluid, making them ideal for applications requiring precise control. Screw pumps are commonly utilized in industries such as agriculture, construction, and manufacturing, where they power various equipment and provide hydraulic force for operational tasks.In conclusion, screw pumps offer a reliable and versatile solution for fluid transfer across multiple industries. Their unique design allows them to handle a wide range of fluids, including viscous, abrasive, and solid-laden substances. By ensuring continuous and efficient operation, screw pumps have become an indispensable component of industrial processes worldwide.ABOUT {}: For several decades, {} has been a leading manufacturer of industrial machinery, catering to diverse industries globally. With a customer-centric approach and a commitment to excellence, the company delivers cutting-edge solutions to meet the unique needs of their clients. Through continuous innovation and a focus on quality, {} sets industry standards and drives technological advancements. With a worldwide presence, the company continues to expand its global footprint, establishing itself as a benchmark for reliability and performance in the industrial machinery sector.