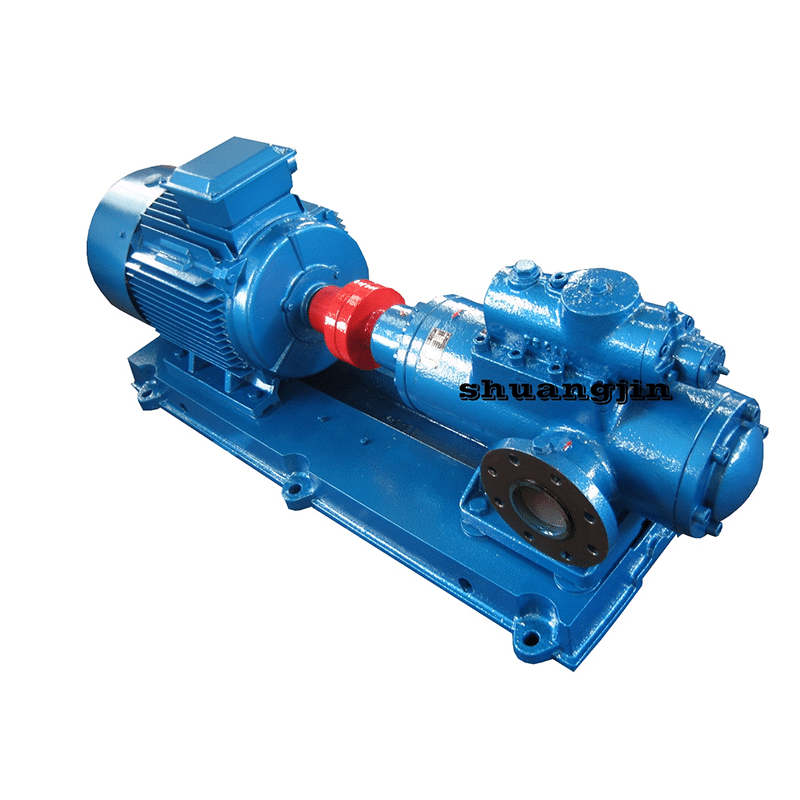

Increase Screw Pump Efficiency: Key Factors to Consider

By:Admin

In today’s fast-paced world, efficiency is key when it comes to industrial equipment. For the pump industry, efficiency not only means saving energy and reducing costs, but also improving overall performance. One company, known for their continuous innovation and dedication to excellence, is revolutionizing the pump industry with their latest breakthrough in screw pump efficiency.

With over [X] years of experience in the pump manufacturing industry, [Company Name] has become a global leader in providing high-quality pumps for a wide range of industrial applications. Their commitment to research and development has led to the creation of a new generation of screw pumps that are setting a new standard for efficiency and reliability.

The new screw pumps, developed by [Company Name], are designed to optimize the flow of liquids while minimizing energy consumption. This is achieved through a combination of cutting-edge technology and innovative engineering, resulting in a pump that not only delivers superior performance, but also reduces operating costs for their customers.

The key to the improved efficiency of these screw pumps lies in their unique design and construction. By carefully engineering the screw elements and optimizing the hydraulic profile, [Company Name] has been able to achieve higher flow rates and lower energy consumption compared to traditional screw pumps. This means that customers can expect significant savings on their energy bills while still enjoying the same level of performance and reliability that they have come to expect from [Company Name].

Moreover, [Company Name] has taken a holistic approach to their screw pump design, taking into account factors such as maintenance and longevity. By utilizing high-quality materials and advanced manufacturing processes, the new screw pumps are not only efficient, but also durable and easy to maintain. This means that customers can rely on their pump systems to operate at peak performance for years to come, with minimal downtime and maintenance costs.

In addition to their technical innovations, [Company Name] is also committed to providing excellent customer service and support. Their team of experienced engineers and technicians are dedicated to helping their customers select and install the right pump for their specific needs, ensuring that they get the most out of their investment. This personalized approach has earned [Company Name] a reputation for being a trusted and reliable partner in the pump industry.

The impact of this new generation of screw pumps from [Company Name] is already being felt across various industries, from oil and gas to chemical processing and beyond. Customers are reporting significant energy savings and improved operational efficiency, thanks to the superior performance of these pumps.

In conclusion, [Company Name] continues to push the boundaries of pump technology with their latest breakthrough in screw pump efficiency. By combining innovative design, superior engineering, and a commitment to customer satisfaction, they are setting a new standard for efficiency and reliability in the pump industry. As the demand for more efficient and reliable pump solutions continues to grow, [Company Name] is well-positioned to lead the way with their cutting-edge technologies and unwavering dedication to excellence.

Company News & Blog

Top Pumps in the Oil and Gas Industry: A Comprehensive Guide

In the fast-paced and ever-evolving world of the oil and gas industry, the demand for efficient and reliable pump solutions continues to grow. As the need for increased production and operational excellence becomes more critical, companies are turning to innovative pump technologies to enhance their processes and elevate their performance. One company at the forefront of this movement is {} (company name), a leading provider of pump solutions for the oil and gas sector.With a proven track record of delivering high-quality and dependable pumps, {} (company name) has established itself as a trusted partner for companies operating in the oil and gas industry. The company's extensive range of pump products caters to various applications, including upstream exploration and production, midstream transportation, and downstream refining and distribution. From centrifugal pumps and positive displacement pumps to submersible pumps and reciprocating pumps, {} (company name) offers a comprehensive selection of equipment designed to meet the diverse needs of its customers.In addition to its broad product portfolio, {} (company name) sets itself apart with its commitment to innovation and technological advancement. The company invests heavily in research and development to continuously improve its pump designs, enhance performance, and optimize efficiency. By staying at the forefront of technological innovation, {} (company name) is able to offer cutting-edge solutions that address the evolving challenges and demands of the oil and gas industry.One of the key areas where {} (company name) excels is in providing pumps for artificial lift systems, which play a crucial role in maximizing production from oil and gas wells. By leveraging sophisticated pump technologies, such as electric submersible pumps (ESPs) and progressive cavity pumps, {} (company name) helps operators extract oil and gas from challenging reservoirs and achieve higher flow rates and improved recovery rates. These advanced pump solutions have proven to be instrumental in increasing operational efficiency and driving profitability for oil and gas companies.Moreover, {} (company name) places a strong emphasis on reliability and durability, recognizing the harsh and demanding environments in which its pumps are deployed. The company's pumps are engineered to withstand the rigors of oil and gas operations, delivering consistent performance and minimizing downtime. With a focus on quality and longevity, {} (company name) ensures that its customers can rely on its pumps to operate seamlessly and effectively, even in the most challenging conditions.As sustainability and environmental responsibility take center stage in the oil and gas industry, {} (company name) also prioritizes the development of energy-efficient pump solutions. By optimizing hydraulic designs, minimizing energy consumption, and reducing emissions, the company's pumps contribute to the industry's efforts to enhance sustainability and minimize its environmental footprint. This commitment to sustainable practices underscores {} (company name)'s dedication to being a responsible and conscientious player in the oil and gas sector.Looking ahead, {} (company name) remains steadfast in its mission to provide innovative and reliable pump solutions that empower its customers to achieve their operational objectives and drive success in the oil and gas industry. By leveraging its expertise, technological prowess, and unwavering commitment to excellence, {} (company name) is poised to continue leading the way in delivering cutting-edge pump solutions for the evolving needs of the oil and gas sector. As the industry continues to evolve, {} (company name) stands ready to support its customers with the pump technologies they need to thrive in an increasingly complex and competitive landscape.

Fueling Innovation: Ctp Pump Offers Cutting-Edge Solutions for Gas Stations

Introducing the Next Generation of Fuel Efficiency: CTP Pump Revolutionizes the IndustryIn today’s fast-paced world, the demand for fuel-efficient vehicles and machinery is higher than ever. As climate concerns continue to grow, individuals and businesses alike are searching for ways to reduce their carbon footprint and make more environmentally conscious choices. This is where CTP Pump, a pioneering company in the field of fuel-saving technology, comes into play. With their innovative and cutting-edge fuel pump technology, CTP Pump is revolutionizing the industry and changing the way we think about fuel efficiency.Founded in [year], CTP Pump has quickly emerged as a leader in the development and implementation of fuel-saving solutions for a wide range of industries. Their groundbreaking technology has been proven to significantly reduce fuel consumption and carbon emissions, ultimately saving businesses and individuals money while also contributing to a greener and more sustainable future.One of the key aspects of CTP Pump’s technology is its adaptability to a wide range of fuel-driven systems. Whether it’s a commercial truck, an industrial generator, or a construction vehicle, CTP Pump’s innovative technology can be seamlessly integrated to optimize performance and reduce fuel consumption. This versatility is one of the reasons why CTP Pump has garnered such widespread attention and acclaim in the industry.The core principle behind CTP Pump’s technology lies in its ability to deliver the precise amount of fuel needed for optimal combustion. By accurately measuring and dispensing the right amount of fuel at the right time, CTP Pump’s system ensures that every drop of fuel is utilized to its maximum potential. This not only results in significant cost savings for businesses, but also reduces harmful emissions that contribute to environmental pollution.Furthermore, CTP Pump’s technology is designed to be user-friendly and easily adaptable to existing fuel systems. This means that businesses can seamlessly integrate CTP Pump’s technology into their operations without having to undergo extensive modifications or disruptions. This user-centric approach has made CTP Pump’s technology highly sought after by businesses looking to make a meaningful impact on their fuel efficiency and environmental footprint.In addition to its technological advancements, CTP Pump is also committed to providing exceptional customer support and service. Their team of experts is dedicated to working closely with clients to understand their specific needs and provide customized solutions that deliver tangible results. From initial consultation to ongoing support, CTP Pump’s customer service is second to none, ensuring that their clients experience a seamless and successful transition to their innovative technology.As the demand for fuel-efficient solutions continues to grow, CTP Pump is poised to play a pivotal role in shaping the future of the industry. With their unwavering commitment to innovation, sustainability, and customer satisfaction, CTP Pump is well-positioned to lead the way in revolutionizing fuel efficiency and driving positive change across various sectors.Looking ahead, CTP Pump plans to continue pushing the boundaries of fuel-saving technology, with a focus on developing even more advanced and efficient solutions. By staying at the forefront of technological advancements and industry trends, CTP Pump is determined to cement its status as the go-to provider for cutting-edge fuel efficiency solutions.In conclusion, CTP Pump’s game-changing technology is setting a new standard for fuel efficiency and environmental responsibility. With their innovative approach, commitment to excellence, and unwavering dedication to customer satisfaction, CTP Pump is driving positive change and reshaping the future of fuel-saving technology. As businesses and individuals seek to make smarter, more sustainable choices, CTP Pump is undoubtedly at the forefront of this transformative movement, and their impact will undoubtedly be felt for years to come.

Essential Tips for Maintaining Your Screw Pump

Screw Pump Maintenance: Keeping the Flow SmoothScrew pumps are indispensable in various industrial applications, including oil and gas, pulp and paper, chemical processing, and marine industries. These pumps play a critical role in transferring liquids or semi-solids efficiently. However, to ensure their reliable performance, routine maintenance is crucial.{Company Name} is a leading provider of screw pump maintenance services, offering comprehensive solutions to keep the flow smooth for its clients. With a dedicated team of experienced technicians and a commitment to quality, {Company Name} has built a reputation for excellence in the industry.As a specialist in screw pump maintenance, {Company Name} understands the importance of regular upkeep to prevent costly downtime and equipment failures. The company offers a range of maintenance services designed to prolong the life of screw pumps and optimize their performance.One of the key maintenance tasks for screw pumps is the inspection and replacement of wearing parts. Over time, the screws, shafts, and bearings in a screw pump can experience wear and tear, leading to decreased efficiency and potential breakdowns. {Company Name} provides thorough inspections to identify any worn or damaged parts and offers timely replacements to ensure the pump operates at peak performance.In addition to parts replacement, lubrication is another essential aspect of screw pump maintenance. Proper lubrication is critical for reducing friction and heat generation within the pump, which can significantly impact its efficiency and longevity. {Company Name} uses high-quality lubricants and follows manufacturer recommendations to ensure that screw pumps are adequately lubricated for optimal operation.Furthermore, {Company Name} provides alignment and vibration analysis services to identify any potential issues that could affect the performance of screw pumps. Misalignment or excessive vibration can lead to premature wear and component damage, so the company's comprehensive maintenance approach includes proactive measures to address these concerns.{Company Name} also offers troubleshooting and repair services for screw pumps experiencing operational issues. With their depth of expertise, their technicians can quickly diagnose problems and implement effective solutions to get the pump back up and running.In addition to routine maintenance, {Company Name} emphasizes the importance of proactive maintenance planning for screw pumps. By developing customized maintenance schedules based on the specific operating conditions and demands of each client, the company helps to minimize the risk of unexpected failures and costly repairs.As part of their commitment to excellence, {Company Name} also provides training and support to their clients' maintenance and operations teams. By sharing their knowledge and best practices, they empower their clients to take a proactive approach to screw pump maintenance, ultimately extending the lifespan of their equipment and optimizing their investment.With a track record of delivering reliable and cost-effective maintenance solutions, {Company Name} has earned the trust of a diverse range of industries that rely on screw pumps for their operations. Whether it's ensuring the smooth flow of oil and gas, the efficient transfer of chemicals, or the reliable dewatering of pulp and paper products, the company's expertise in screw pump maintenance has made them a preferred partner for many businesses.In conclusion, screw pump maintenance is essential for sustaining the performance of these critical pieces of equipment. {Company Name} stands out as a trusted provider of comprehensive screw pump maintenance services, offering a holistic approach to ensure that their clients' screw pumps operate smoothly and efficiently. With their commitment to quality, expertise, and customer satisfaction, {Company Name} continues to be a leader in the field of screw pump maintenance.

Improving Efficiency of Screw Pumps: Key Factors to Consider

Screw pumps are an essential component in many industries, as they are used for a wide range of applications such as wastewater treatment, oil and gas production, and chemical processing. Their efficiency and reliability are critical for the smooth operation of these processes. Recently, {company name}'s innovative screw pumps have been making waves in the industry for their outstanding efficiency and performance.{Company name} is a leading manufacturer of screw pumps, with a reputation for delivering high-quality products that exceed customer expectations. With a strong emphasis on research and development, the company is constantly pushing the boundaries of pump technology to improve efficiency and performance.The latest innovation from {company name} is a new line of screw pumps that boast an impressive level of efficiency. These pumps are designed to minimize energy consumption while maximizing output, providing significant cost savings for users. The unique design of these pumps allows for smooth and stable operation, even in challenging environments.One of the key factors in the efficiency of {company name}'s screw pumps is their use of advanced materials and precision engineering. The company utilizes high-grade materials that are selected for their durability and ability to withstand the harsh conditions in which the pumps are often used. Additionally, the pumps are carefully engineered to minimize friction and resistance, leading to improved energy efficiency and reduced wear and tear.In addition to their efficiency, {company name}'s screw pumps also offer a high level of reliability. The company takes great pride in the quality and durability of their products, ensuring that they can withstand the demands of heavy-duty applications. This reliability is a crucial factor for industries such as oil and gas production, where downtime can result in significant financial losses.{Company name} is committed to providing exceptional customer support and service. They work closely with their clients to understand their specific needs and tailor their products to meet those requirements. This collaborative approach has earned them a loyal customer base, as well as a reputation for delivering outstanding products and support.The efficiency and reliability of {company name}'s screw pumps have made them a popular choice in a wide range of industries. Customers across the globe have benefited from the cost savings and improved performance offered by these innovative pumps. As industries continue to seek ways to improve efficiency and reduce their environmental impact, {company name}'s screw pumps are well-positioned to play a significant role in these efforts.In conclusion, {company name} has established itself as a leader in the manufacture of screw pumps, with a strong focus on efficiency, reliability, and customer satisfaction. Their innovative approach to pump design and engineering has resulted in a range of products that offer exceptional performance and cost savings for users. As industries continue to evolve and seek more sustainable solutions, {company name}'s screw pumps are well-equipped to meet these challenges and provide the efficiency and reliability that customers demand.

Ultimate Guide to Industrial Marine Pumps: Uncovering the Top Solutions for Efficient Operations

[Assistant]Title: Leading Industrial Pump Manufacturer Expands Product Line to Meet Growing DemandSubtitle: Company showcases advanced solutions aimed at revolutionizing industrial marine applications [Introduction]In today’s rapidly evolving industrial landscape, the demand for efficient and reliable industrial marine pumps has reached unprecedented heights. Recognizing this, one of the industry's leading manufacturers has recently expanded its product line to cater to the needs of this niche market. This move aims to revolutionize the way industries approach marine applications, promising enhanced performance, reduced downtime, and improved sustainability.[Company Background]With decades of experience in pump manufacturing, the company has established itself as a trusted global leader in the industry. Known for its commitment to innovation and cutting-edge technology, the company has garnered a robust reputation within various sectors, including marine, oil and gas, power generation, and chemical processing.Driven by a passion for continuous improvement, the company invests heavily in research and development to ensure the highest quality products are offered to its customers. As a result, they boast an extensive portfolio of efficient, durable, and cost-effective solutions that have become synonymous with excellence.[Diverse Product Range]Expanding on their range of industrial pumps, the company has launched an array of advanced marine pumps, specifically designed to withstand the harsh operating conditions encountered in marine environments. These pumps offer a wide range of applications, including ballast water management, cargo handling, bilge pumping, cooling systems, and more. The company's commitment to meeting the unique demands of the marine industry is evident through the latest product offerings.1. Cutting-edge Ballast Water Management Systems: Recognizing the significance of environmental conservation, the company has developed highly efficient ballast water management systems that comply with international guidelines. With advanced filtration and disinfection technologies, these systems ensure the prevention of invasive species transfer without compromising vessel performance.2. Cargo and Bilge Pumps: Engineered to handle the demanding requirements of cargo handling and bilge pumping, the company's pumps deliver exceptional reliability and operational efficiency. With features like high flow rates, corrosion resistance, and low maintenance requirements, these pumps stand as a testament to the company's commitment to delivering long-lasting and highly effective solutions.3. Cooling Systems: Marine vessels mandate reliable cooling systems to maintain optimal operating temperatures. Understanding this critical need, the company offers an extensive range of cooling pumps designed to withstand the unpredictable conditions encountered at sea. Notable features include compatibility with both fresh and seawater, efficient heat transfer capabilities, and high corrosion resistance.[Innovation and Sustainability]Priding itself on being an industry pioneer, the company continuously strives to develop sustainable solutions to minimize environmental impact. The introduction of eco-friendly materials, energy-efficient systems, and technologies that reduce carbon emissions further reinforces their commitment to sustainability.To enhance operational efficiency, the company has incorporated smart monitoring technologies into their marine pumps. Real-time data monitoring and predictive maintenance capabilities ensure optimal performance, reduced downtime, and cost-effective operations.[Future Prospects]With their expanded marine pumps portfolio, the company is well-positioned to cater to the rapidly growing industrial marine sector. As the demand for efficient water management, cargo handling, and cooling systems continue to rise, the company's advanced solutions are set to play a pivotal role in transforming the industry.To further support their customers, the company has bolstered its after-sales services, ensuring timely maintenance, spare parts availability, and a dedicated support team to cater to any queries or concerns. These customer-centric initiatives reinforce the company's commitment to delivering holistic and reliable solutions to clients worldwide.In conclusion, the recent expansion of industrial marine pumps by the leading pump manufacturer demonstrates their dedication to meeting the requirements of this rapidly expanding market. With innovative technologies, sustainable practices, and a commitment to customer satisfaction, the company aims to revolutionize the industrial marine industry, setting new benchmarks for efficiency, reliability, and environmental responsibility.

Maximizing the Efficiency of Screw Pumps: Tips and Techniques

Screw Pump Efficiency: A Game-Changer in the Pump IndustryIn the world of industrial pumping, efficiency is key. The ability to move fluids and sludges at a high rate while minimizing energy consumption is a top priority for companies in a variety of industries. That's why the development of the Screw Pump has been a game-changer for many businesses, including the innovative company {}.The Screw Pump is a type of positive displacement pump that is known for its high efficiency and reliability. It consists of two main components: a screw rotor and a casing. As the screw rotor rotates, it creates a vacuum that draws in the fluid and then pushes it through the casing, resulting in a smooth and continuous flow. This design not only allows for high efficiency but also provides gentle handling of the pumped material, making it ideal for delicate or shear-sensitive fluids.{} is a leading manufacturer of Screw Pumps, with a strong focus on innovation and customer satisfaction. The company's extensive research and development efforts have led to the creation of a range of high-performance Screw Pumps that are tailored to meet the specific needs of various industries. From wastewater treatment plants to oil refineries, {} provides pumping solutions that not only improve efficiency but also reduce downtime and maintenance costs.One of the key features of {}'s Screw Pumps is their outstanding energy efficiency. By optimizing the design of the screw rotor and casing, the pumps are able to achieve high flow rates with minimal power consumption. This has not only resulted in significant cost savings for their clients but also contributed to a reduction in carbon emissions, as less energy is required to operate the pumps.Another advantage of {}'s Screw Pumps is their versatility. With the ability to handle a wide range of fluids, including viscous liquids, abrasive slurries, and even solids-laden materials, these pumps have become a go-to solution for many industries. This flexibility, combined with their robust construction and low maintenance requirements, has earned {} a reputation for delivering reliable and durable pumping solutions to their customers.In addition to their exceptional performance, {}'s Screw Pumps are backed by top-notch customer service and technical support. The company's team of experts works closely with clients to understand their specific needs and provide tailored pumping solutions that deliver the best results. From initial consultation to installation and ongoing maintenance, {} is committed to ensuring the success of their clients' operations.Looking ahead, {} is dedicated to staying at the forefront of Screw Pump technology. With a continued focus on research and development, the company is exploring new innovations to further improve the efficiency and performance of their pumps. This includes the integration of smart technologies for real-time monitoring and control, as well as advancements in materials and manufacturing processes to enhance the durability and longevity of the pumps.As industries continue to evolve and demand more sustainable and cost-effective solutions, the Screw Pump has proven to be a valuable asset. With its high efficiency, versatility, and reliability, it has become a go-to choice for companies looking to optimize their pumping operations. And with companies like {} leading the way in Screw Pump innovation, the future looks bright for efficient and effective pumping solutions.

Prolonging Lifespan of Industrial Pumps: Expert Repair and Maintenance Services

Industrial Pump Repair, a reliable provider of high-quality industrial pump services, is proud to announce their commitment to helping businesses improve the performance and reliability of their pumps. The company specializes in providing comprehensive pump repair and maintenance services to ensure that businesses can operate at peak efficiency in every aspect of their operations.With over 25 years of industry experience, Industrial Pump Repair specializes in repairing, rebuilding and maintaining all types of industrial pumps, including centrifugal, positive displacement, reciprocating, and more. The team of experienced technicians at the company are equipped with the latest tools and expertise to deliver precise and efficient pump repair services tailored to the specific needs of each customer."We understand that any downtime due to malfunctioning equipment can have a significant impact on a business's operations and profitability, which is why we prioritize our customers' needs and work tirelessly to deliver fast, reliable and cost-effective solutions," said a representative from Industrial Pump Repair.The company takes pride in their commitment to quality workmanship and customer satisfaction. They offer a variety of services to help keep industrial pumps running smoothly, including preventative maintenance programs, pump inspections, vibration analysis, laser alignment, and performance testing, to name a few.One of the key advantages of working with Industrial Pump Repair is their capability to provide on-site services. Their experienced technicians can travel to clients' facilities to diagnose and repair issues on-site, ensuring minimal disruption to their operations. They also carry a wide range of spare parts and components to minimize the time needed for repairs.In addition to their repair and maintenance services, Industrial Pump Repair offers top-of-the-line replacement pumps and parts from industry-leading manufacturers such as (need remove brand name). They provide installation and commissioning services to ensure that their clients' new pumps are installed correctly and work reliably for years.The company is committed to building long-term partnerships with their clients. They take the time to understand each client's distinct requirements and tailor their services to meet their unique needs. By providing comprehensive services that encompass every aspect of industrial pump repair and maintenance, they empower their clients to minimize their downtime, optimize their equipment's performance, and save on costs.In conclusion, Industrial Pump Repair is a trusted partner for businesses seeking to improve the reliability, performance, and efficiency of their industrial pumps. Their extensive expertise, commitment to quality workmanship, and customized services have made them a top choice among businesses in need of pump repair and maintenance services. Contact them today to experience their exceptional services and discover how they can help take your business operations to new heights.

High-quality industrial pumps: What you need to know

Bornemann Pump, a leading provider of high-quality industrial pumps, recently announced the launch of a new line of cutting-edge pumps designed to meet the unique needs of various industries. With a focus on innovation and customer satisfaction, Bornemann Pump has established itself as a trusted partner for companies seeking reliable and efficient pumping solutions.The new pump series, which includes models for a wide range of applications, incorporates the latest technological advancements to deliver superior performance and durability. Built with precision engineering and high-quality materials, these pumps are designed to withstand the most demanding operating conditions while maintaining optimal efficiency.Bornemann Pump has a long history of developing innovative pumping solutions for industries such as oil and gas, chemical processing, food and beverage, and pharmaceuticals. The company's commitment to understanding the specific requirements of each industry has enabled it to develop pumps that not only meet but exceed the expectations of its customers.In addition to its cutting-edge product line, Bornemann Pump offers a comprehensive range of services to support its customers throughout the entire lifecycle of their pumping systems. From initial consultation and design to installation, maintenance, and technical support, the company provides a full suite of solutions to ensure the seamless operation of its pumps.Bornemann Pump's customer-centric approach is underscored by its dedication to providing personalized support and expertise. Its team of highly skilled engineers and technicians work closely with customers to understand their unique challenges and develop customized pumping solutions that address their specific needs.The company's industry-leading expertise and commitment to quality have earned it a reputation for excellence in the pumping industry. Its pumps are renowned for their reliability, efficiency, and longevity, making them the preferred choice for businesses looking to enhance their operational efficiency and minimize downtime.With a global network of sales and service centers, Bornemann Pump is well-positioned to serve a diverse range of industries around the world. Its extensive reach enables the company to provide timely and efficient support to its customers, ensuring that their pumping systems operate at peak performance at all times.As Bornemann Pump continues to push the boundaries of pumping technology, it remains dedicated to delivering innovative solutions that empower its customers to achieve their business objectives. The company's ongoing investment in research and development reaffirms its commitment to staying at the forefront of the industry and delivering state-of-the-art pumping solutions that redefine industry standards.In conclusion, Bornemann Pump's latest line of cutting-edge pumps is a testament to the company's unwavering commitment to innovation and excellence. With a focus on meeting the unique needs of its customers and delivering superior pumping solutions, Bornemann Pump continues to set the bar for quality and reliability in the industry. Whether it's in oil and gas, chemical processing, food and beverage, or pharmaceuticals, businesses can trust Bornemann Pump to provide the most advanced pumping solutions to meet their needs.

Durable and Efficient Twin Screw Pump for Various Industrial Applications

Fristam Twin Screw Pump has recently introduced a new and innovative solution to meet the growing demand for efficient pumping systems in various industries. With a focus on reliability, performance, and ease of maintenance, this new pump is set to revolutionize the way companies handle their fluid transfer needs.The Fristam Twin Screw Pump is designed to handle a wide range of applications, including food and beverage, pharmaceutical, chemical, and personal care, among others. Its unique design allows for gentle product handling, making it suitable for delicate or shear-sensitive products. With its high efficiency and low pulsation characteristics, this pump is ideal for applications where product integrity is crucial.One of the key features of the Fristam Twin Screw Pump is its ability to handle both low and high viscosity products with ease. This versatility makes it a valuable asset for companies dealing with a variety of different substances. Additionally, its hygienic design and ease of cleaning make it compliant with the strict regulations and standards of the food and pharmaceutical industries.In addition to its impressive performance capabilities, the Fristam Twin Screw Pump is also designed with maintenance in mind. The pump is easy to disassemble and reassemble, reducing downtime and lowering the overall cost of ownership. This feature is especially important for companies looking to maximize their operational efficiency and minimize unnecessary expenses.Furthermore, the Fristam Twin Screw Pump is built to last, with a durable construction that can withstand the demands of continuous use. Its robust design and high-quality materials ensure that it can operate reliably for extended periods, providing companies with peace of mind and confidence in their pumping capabilities.With the introduction of the Fristam Twin Screw Pump, the company continues to solidify its position as a leading provider of pumping solutions for various industries. The pump is a testament to the company's commitment to innovation and excellence, and it is expected to make a significant impact in the market.In summary, the launch of the Fristam Twin Screw Pump represents a major milestone for the company and its customers. With its impressive performance, versatile capabilities, and ease of maintenance, this pump is set to become a valuable asset for companies across a wide range of industries. As the demand for efficient and reliable pumping systems continues to grow, the Fristam Twin Screw Pump is well-positioned to meet and exceed the expectations of its users.

Understanding the Single Screw Pump Working Principle

Single screw pump, also known as progressive cavity pump, is a type of positive displacement pump that is widely used in various industries for transferring viscous and abrasive fluids. The working principle of a single screw pump involves a single helical rotor rotating inside a double helical stator, creating a series of sealed cavities that move the fluid through the pump.The rotor, or the single screw, is the main component of the pump. It is typically made of a hard, durable material such as stainless steel or hardened chrome, and is designed with a single helical thread that runs along the length of the rotor. The stator, on the other hand, is a double helical cavity that surrounds the rotor. As the rotor rotates inside the stator, the fluid is pushed through the cavities created between the rotor and the stator, resulting in a smooth and steady flow of the fluid.The company {}, a leading manufacturer of industrial pumps, has been at the forefront of developing and supplying high-quality single screw pumps to a wide range of industries. They have a team of experienced engineers and technicians who are dedicated to designing and producing innovative and efficient pumping solutions for their customers.The single screw pumps offered by {} are known for their reliability, durability, and high performance. They are capable of handling a wide range of fluids, including viscous and abrasive liquids, making them suitable for applications such as oil and gas, food and beverage, chemical processing, wastewater treatment, and more. The company's single screw pumps are designed to meet the specific needs and requirements of each industry, and are built to withstand the harshest operating conditions.With a focus on quality and continuous improvement, {} has invested in state-of-the-art manufacturing facilities and advanced technologies to ensure that their single screw pumps meet the highest standards of performance and reliability. Their pumps undergo stringent quality control measures and testing procedures to guarantee their performance and longevity in the field.In addition to their commitment to quality, {} also provides comprehensive technical support and after-sales services to their customers. Their team of experts is available to assist with installation, maintenance, and troubleshooting, ensuring that their customers can maximize the efficiency and lifespan of their single screw pumps.As the demand for efficient and reliable pumping solutions continues to grow in various industries, the role of single screw pumps is becoming increasingly important. With their unique working principle and the expertise and commitment of companies like {}, single screw pumps are set to play a crucial role in the movement of viscous and abrasive fluids in industrial processes.In conclusion, the working principle of single screw pumps makes them an ideal choice for transferring viscous and abrasive fluids in a wide range of industries. With their expertise, dedication to quality, and commitment to customer satisfaction, {} continues to be a leading provider of high-quality single screw pumps for industrial applications. Their pumps are designed and built to deliver exceptional performance and reliability, meeting the specific needs and requirements of their customers.